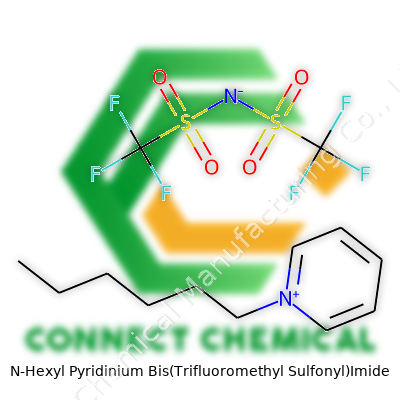

N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide: A Comprehensive Insight

Historical Development

Early work on ionic liquids started in the mid-20th century, but interest picked up heavily around the 1990s with breakthroughs in room temperature ionic liquid design. N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide came out of this surge, offering a structure that combined a long alkyl chain pyridinium cation with the large, non-coordinating bis(trifluoromethylsulfonyl)imide anion. The evolution of tasks such as green chemistry, advanced battery electrolytes, and novel phase-transfer catalysts created space for such chemicals to solve some sticky problems, building on generations of work in both organic and inorganic salt chemistry.

Product Overview

This ionic liquid stands out for its broad liquid range and impressive chemical stability. It remains fluid in a wide temperature window, showing much less volatility than conventional solvents. Its robust ionic framework lets it handle harsh conditions, such as strong bases or acids, without significant decomposition. The compound, often labeled as [HPy][NTf2], serves in a variety of technical sectors including electrochemistry, separation technology, and chemical synthesis. Packing efficiency and phase behavior in mixtures often trace back to its distinct pyridinium backbone.

Physical & Chemical Properties

N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide carries a molecular weight around 510 g/mol. Its liquid state covers a range from roughly minus 15°C to well above 200°C before any thermal breakdown shows up. The ionic character delivers high electrical conductivity, while the bis(trifluoromethylsulfonyl)imide anion limits water miscibility and increases lipophilicity compared to smaller halide salts. Viscosity trends higher than with simple salts; still, the hexyl side chain drags down melting points and boosts hydrophobic tendencies. The fair density and refractive index often place it apart from common organic solvents.

Technical Specifications & Labeling

Commercial product usually lists purity in excess of 98%, with tight controls on water and halide content. Labels carry the compound’s long systematic name, N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide, and most also include batch numbers, date of manufacture, and transportation hazard codes. Material Safety Data Sheets cover fire hazards, chemical reactivity, and recommended protection levels, drawing on GHS regulations for storage and handling.

Preparation Method

Lab-scale synthesis starts from 1-hexylpyridinium bromide or chloride, where an alkyl halide reacts with pyridine in dry acetonitrile or other polar aprotic solvents. Following the quaternization, the halide anion exchanges with bis(trifluoromethylsulfonyl)imide, which is often provided as lithium or potassium salt. Researchers favor water or dichloromethane washes to purify the ionic liquid, relying on the density difference to help separate phases. Careful drying under vacuum and moderate temperature finalizes the compound.

Chemical Reactions & Modifications

The structure tolerates functional group exchanges on both the pyridinium ring and hexyl chain. Substituting methyl for hexyl chains changes viscosity and melting behavior while keeping central ionic features. Altering the anion—swapping NTf2 for other sulfonyl or tetrafluoroborate groups—shifts solubility and polarity. These customizations tune ionic conductivity, solvent properties, and phase interaction with organics or inorganics. Reaction routes keep solvents and reagents dry to avoid hydrolysis, given the sensitivity of the imide linkage in the presence of water.

Synonyms & Product Names

Besides its systematic IUPAC label, this chemical might appear in catalogs as [HPy][NTf2] or N-Hexylpyridinium NTf2. Other names include N-Hexylpyridinium bis(trifluoromethylsulfonyl)imide and N-Hexylpyridinium triflimide. Such aliases help track publications or patents, as nomenclature varies across suppliers and chemical registries. Ensuring full clarity about synonyms matters for compliance, procurement, and research collaboration.

Safety & Operational Standards

N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide doesn’t ignite as easily as volatile solvents but still demands solid safety measures. Gloves, goggles, and chemical fume hoods help control exposure, since ionic liquids can absorb through skin or irritate eyes. Spills handled by absorbent materials require non-reactive, sealed waste disposal. National chemical agencies and manufacturers lay out personal protection guidelines, fire hazard precautions, and handling rules based on thermal stability and reactivity testing.

Application Area

Current value comes from work in electrochemistry, where stable conductivity and low volatility fit needs for safe electrolytes in batteries and capacitors. This ionic liquid also sees action in extraction technology—helping separate metal ions or organic molecules from aqueous and organic phases. In organic synthesis, its stability in both acid and base conditions opens it up as a solvent or catalyst for tough reactions. This chemical’s role in immobilizing enzymes or stabilizing nanoparticles brings it deeper into the worlds of green chemistry and nanotechnology. Industry and academic labs invest in this compound for research tools, analytical methods, and specialty materials production.

Research & Development

Academic attention stretches across investigations into ionic conductivity, phase diagrams, and structural modification. Many recent publications dig into tailoring the alkyl chain, tuning solubility for bio-based transformations, or shrinking viscosity for improved device performance. Patents include battery prototypes, new catalytic methods, and green extraction systems. Conferences often show test results for improved electrochromic devices and safe handling methods for high-performance electronics. Funding bodies target these innovation efforts, recognizing the chemistry’s potential to cut toxic emissions, save energy, and build cleaner processes.

Toxicity Research

Scientists continue probing the environmental fate and biological impact of N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide. Tests on aquatic species and cell cultures suggest moderate chronic toxicity, which ranks higher than classical organic solvents but below many halogenated organics. Biodegradation in soil or water systems proceeds slowly, cautioning against unrestricted disposal. National and international standards demand rigorous ecological study, including testing for endocrine disruption and accumulation. Ongoing work tries to balance performance with new safety standards, searching for biocompatible alternatives or reliable risk reduction methods.

Future Prospects

N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide may see increasing use as new energy storage devices emerge, especially as demand grows for stable, non-flammable electrolytes in batteries and supercapacitors. Interest also grows around “designer” ionic liquids—altering structure to move toxic behavior down while keeping critical properties in place. Expansion into pharmaceuticals, carbon capture, and greener catalysis could help replace some entrenched, high-risk chemicals. Regulatory frameworks and consumer awareness pressure suppliers to improve labeling, tracing, and end-of-life management. Researchers keep testing not just chemical performance but also life cycle analysis, waste management, and options for reclaiming or biodegrading spent ionic liquids, showing that chemical innovation links directly with sustainability and public health needs.

Not Just Another Exotic Chemical

Chemistry, despite seeming distant, shapes parts of everyday life that most of us don’t even recognize. N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide—often shortened to N-Hexyl Pyridinium NTf2—might look like a tongue-twister at first glance, but it earns its keep in labs and industries in real ways. With a structure designed for stability and unique properties, this ionic liquid has become a quiet force in new technologies. My own encounters with chemicals like this taught me that practical applications always drive demand and innovation, not the other way around.

Batteries and Energy Storage

Anyone following battery research will notice the hunger for higher safety, better cycles, and greener solutions. N-Hexyl Pyridinium NTf2 steps up as a non-volatile, thermally stable electrolyte. Lithium-ion batteries, which power phones and electric cars, suffer most when standard solvents evaporate or ignite. Here’s where ionic liquids can’t be beat. They resist burning and won’t evaporate under stress. In electrochemical tests, researchers saw longer cycling and less risk of accidental fires. Companies exploring next-gen batteries now look at these ionic liquids as routes to make energy storage safer and give batteries longer lives.

Green Chemistry and Solvent Replacement

During a stint in a university lab, I watched researchers scramble for solvents that didn’t bring headaches or environmental hazards. N-Hexyl Pyridinium NTf2 became a real option. Its chemical stability and low vapor pressure make it an ace up the sleeve for chemists swapping out older, toxic solvents. Organic synthesis often needs solvents to push reactions along, but many traditional choices end up polluting air and water. Research points to ionic liquids like this one as replacements in processes that make medicines, plastics, or specialty chemicals, cutting down on volatile organic compound emissions.

Electroplating and Metal Processing

A less flashy but no less important sector: metal finishing and electroplating. N-Hexyl Pyridinium NTf2 helps keep metal ions dissolved and outdoors the door for plating nickel, silver, or rare metals. Regular options corrode or boil away under the extreme conditions found in plating tanks, and not all ionic liquids can handle strong reducing agents. This particular compound stands out for lasting under heat and stress. Factories that coat machine parts or electronics pick up on such features fast—anything that means less waste and fewer shutdowns.

Sensors and Analytical Equipment

Precision matters in medical and environmental testing. Sensors rely on ionic liquids to manage charge flow and selectivity. N-Hexyl Pyridinium NTf2 finds a role as the medium inside ion-selective electrodes and gas sensors. Its ability to resist both heat and chemical contamination delivers more reliable readings, which translates to trust in water quality monitoring or lab diagnostics. I’ve seen firsthand that reliable sensors often decide the success or failure of a project.

Toward Safer and Smarter Chemistry

Concerns naturally arise about how expensive or rare these chemicals might be. Production costs shrink as demand rises, which happens as researchers grab onto real-world benefits. To cut risks, manufacturers stick with closed systems and recycling protocols. More training for lab techs and engineers helps, too. Pushing regulations for responsible disposal ensures that this impressive compound won’t trade one environmental headache for another.

Chemicals like N-Hexyl Pyridinium NTf2 bridge creativity and safety, often moving out of niche journals and into mainstream industries. Balanced policy, sharp research, and practical know-how let these compounds deliver safer, cleaner results—and that affects more corners of life than most people realize.

Understanding Stability Takes Experience

Chemical stability can sound complicated, but it really comes down to whether a product holds up or falls apart over time. Some drugs, foods, and industrial materials will react with air, moisture, light, or even with themselves. A lesson I learned early on—if you’ve ever cranked open an old bottle of hydrogen peroxide at home and watched it fizz out, you’ve seen instability firsthand. The stuff just doesn’t last unless you treat it right.

Real-World Examples: From Medicines to Household Goods

Pharmaceuticals are sticklers for stable conditions. Take aspirin. Store it somewhere damp and you get a bottle full of vinegar-smelling mess. The science is simple: acetylsalicylic acid cracks apart in the presence of water. Vitamin C fares even worse, losing its punch every time you leave the lid loose. Similar trouble shows up in foods—cooking oils go rancid if they sit in sunlight, flour grows moldy in a humid pantry.

The cost isn’t just wasted products. If someone takes a medicine that’s degraded—say, an antibiotic kept above room temperature for weeks—the medicine probably won’t work as intended, and that’s a public health problem. Trust in a product begins to erode if companies or clinics ignore storage requirements.

Storing Products the Right Way

Manufacturers do their part, but everything boils down to three factors: temperature, moisture, and light. Temperature swings are bad news for a lot of products. Insulin, for example, breaks down fast if left warm. Most chemical goods do best at 20 to 25°C, but plenty ask for the fridge or even the freezer. As someone who’s botched a batch of yeast by leaving it near the stove, I know the risks upfront.

Moisture turns sensitive powders into unusable bricks. Most labs and medical storerooms have dehumidifiers running around the clock. Even on a household level, silica gel packets in shoe boxes or electronics provide a layer of defense, so you don’t find a moldy mess.

Sunlight sneaks up as a hidden culprit. Some chemicals, from paints to vitamins, won’t survive direct sun. Brown bottles serve a real purpose—in pharmacies, in labs, they shield delicate ingredients from breaking down. Heat, humidity, and light together spell trouble.

Backed by Data, Not Just Caution

Decisions about storage don’t come from thin air or wishful thinking. Researchers and quality-control experts spend months running “stability studies”—they crank up the heat, pump up the humidity, shine the lights, and run tests across time. Results tell them exactly how long a product stays good, and what triggers a breakdown. If the label insists on storing between 2 and 8°C or keeping the container tightly closed, there’s real science backing it up.

How to Do Better: Practical Steps

Solid solutions start simple. Stick to labeled storage instructions—use fridges or freezers with reliable thermometers. Avoid bathrooms or kitchens for anything sensitive, since both spots have wild swings in temperature and dampness. Rotate stock, date containers, and respect expiration dates.

People working in supply chains or healthcare should push for routine internal checks: record storage temperatures, train new staff on what breaks down and why, and push suppliers for certificates of analysis that prove their product hasn’t sat in the sun on a loading dock.

The Stakes: Beyond Spoilage

At its core, protecting chemical stability means keeping products safe, effective, and trustworthy. It’s not just about fussy handling—it’s about making sure the work done in factories, farms, and pharmacies reaches people as intended. Having seen the impact firsthand, proper storage counts for far more than shelf life. It safeguards health and trust.

Digging Deeper into the Risks

N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide doesn’t show up in mainstream headlines, yet it finds its way into labs focused on ionic liquids and specialty chemical research. Its structure features a pyridinium ion matched with a powerful sulfonyl imide anion, drawing the attention of chemists looking for stable, low-volatility solvents and electrolytes. Even though its industrial applications get the spotlight, the risks tucked away in this chemical shouldn’t slip through the cracks.

Experience Handling Specialty Chemicals

In the lab, handling new chemicals goes beyond simply understanding a formula. Experience teaches that gloves and goggles become more than an accessory—they act as the last line of defense after spills, accidental inhalation, or skin exposure. During my time in a university research group, we tested countless new ionic liquids. Safety data sheets sometimes list information so plainly that the danger doesn’t feel immediate, yet skin irritation, eye burns, and odd headaches after handling pyridinium salts spoke louder than any warning label.

N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide often gets grouped with similar salts, yet each variation carries surprises. Some show moderate toxicity for aquatic life. This trait is a red flag, especially as interest in ionic liquids climbs and larger batch production becomes more common. Environmental persistence becomes an unwelcome guest, making wastewater disposal a tricky subject. Without clear protocols, improper disposal could threaten water sources and organisms.

Facts Speak Louder Than Claims

Research by K. Seddon and other ionic liquid pioneers highlights how seemingly “benign” chemicals can trigger unexpected toxicity in fish and simple test organisms. Data points show N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide can irritate skin, eyes, and, if inhaled, mucus membranes. Digesting raw safety data means facing potential reproductive impacts or DNA damage in repeated exposure scenarios. For workers in close contact, the lack of detailed long-term studies leaves a blind spot.

Chemicals with fluoroalkyl groups, like bis(trifluoromethyl sulfonyl)imide, display stubborn stability that won’t break down easily in soil or water. Over time, contamination can build up quietly before springing ecological damage or entering food chains. Even small leaks or poor handling in a single plant have ripple effects for years. The chemistry community already debates the future of “forever chemicals”—N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide shares enough features to warrant careful scrutiny.

Chasing Safer Practices and Solutions

Using proper ventilation, personal protective equipment, and full-label reading cuts risk sharply. Routine monitoring in the workplace offers a heavier shield than piecemeal checks. Research teams, for their part, need to share new findings with regulators to prevent outdated safety standards from sticking around. Testing for bioaccumulation and chronic toxicity helps plug real-world knowledge gaps faster than waiting for years of unreported cases.

Industry can take the long view by investing in greener alternatives or closed-loop recycling setups. Labeling every step of the process and encouraging transparent communication from labs helps ensure no one steps into the line of fire unprepared. Even as curiosity fuels discovery, putting people and ecosystems first writes a better story than taking shortcuts with chemical hazards.

Looking Past the Label

Consumers often check the price first. What they may miss are the small print details about purity and product specification. These two factors, not always visible in the marketing, shape trust, quality, and results. In my own experience, the disappointment of buying a supplement or ingredient that underperforms starts with vague numbers or missing information on the label. For people who rely on products for industrial, medical, or nutritional use, knowing the purity is not just good to know—it’s everything.

Understanding Purity: More Than Just a Number

Purity means the percentage of the main substance in a product compared to everything else inside the package. Let’s say you buy ascorbic acid for a lab or personal use. If the label says 99% pure, then out of every 100 grams, 99 grams are the actual compound. The rest? Possibly trace minerals, moisture, or other leftovers from the production process. Higher purity often lines up with strict applications—think pharmaceuticals or research work—where even a small impurity can interfere with reactions or outcomes.

Back when I worked in a small food production facility, we often faced issues when suppliers could not clearly specify the purity of their additives. That missing information caused production inconsistencies and left us with unpredictable results. On the other hand, a simple certificate showing assay values, heavy metals, and moisture content put our minds at ease.

Specification: The Full Picture

Specification refers to a product’s measurable characteristics. These include physical appearance, melting point, solubility, pH, ash content, and presence of contaminants. These numbers let users know what to expect. For a chemical used in electronics, things like particle size and conductivity might matter most. In a vitamin, the main concern could be purity and absence of heavy metals.

Traceability sets reputable suppliers apart. Companies who lay out details such as batch number, date of manufacture, and origin show confidence in their process. Laboratory reports from independent facilities also help, so buyers can verify claims instead of just taking the seller’s word for it. When a packaging slip matches these test results, buyers build confidence and reliability builds over time.

Risks of Unclear Standards

Without proper purity and specification, end users face risks that stretch from poor performance to downright danger. Imagine a hospital pharmacist preparing a drug from a compound of uncertain quality. Even outside health, low-grade chemicals used in food processing could add contaminants or spoil flavors. My own run-in with off-spec ingredients led to rejected product batches and high costs.

Solutions: Building Trust Through Better Information

Suppliers should display their purity and product specs clearly—preferably online for easy access. Labs and quality teams can verify that what arrives in the container matches what’s on the paperwork. Customers gain peace of mind by choosing suppliers who invest in proper testing and publish third-party certificates. On a larger scale, industry standards and government regulations force companies to keep up, and watchdog groups remain on alert for fraud or misleading claims.

Whether you’re buying vitamins, laboratory reagents, or food additives, digging into purity and specification information protects both your investment and safety. Experience shows that the few minutes spent checking quality data pay off in finished results you can count on.

Anyone who’s ever worked in a lab understands the butterflies you feel when handling a chemical you haven’t met before. N-Hexyl Pyridinium Bis(Trifluoromethyl Sulfonyl)Imide—folks in ionic liquid research often call it by its initials, HPyNTf2—brings an impressive array of properties but forces some real-world caution. Safety teams, researchers, and workers all face the same challenge: juggling discovery without endangering health or the environment.

Personal Protective Gear: No Shortcuts

Let’s start with the basics: gloves, splash goggles, and well-ventilated benches. Nitrile gloves last longer than latex against organic solvents. I’ve learned from colleagues who cut corners that skin irritation can develop faster than you think. A face shield and long-sleeved lab coat, not just a T-shirt, keep accidental splashes and stubborn residues away from skin and eyes. Strong extraction ventilation—ideally a dedicated chemical fume hood—locks down vapors. HPyNTf2 can break down at high temperatures, and though it doesn’t vaporize like diethyl ether, treating it as harmless invites trouble.

Spill Response: Think Fast, Act Faster

I’ve witnessed a few chemical spills in my day. In one case, someone hesitated and grabbed paper towels, making things worse. Spills of HPyNTf2 should not linger on a workbench or, worse, leak into a drain. Specialized absorbent pads, such as silica or polypropylene, grab liquid quickly—plain paper won’t do. Bag waste in chemically resistant containers, not regular trash. Keep a spill kit within arm’s reach. After collecting the bulk, wipe surfaces with isopropanol or ethanol to break down residues thoroughly, then rinse again with water. These steps take minutes, and save hours of paperwork and risk.

Safe Storage: Out of Sight, Out of Harm

HPyNTf2, like most ionic liquids, needs a place out of sunlight and away from heat. I always recommend locking materials in leak-proof bottles within corrosion-resistant cabinets. Well-labeled containers protect everyone. Store it apart from strong oxidizers, acids, and bases. Fumes from strong acids degrade its structure, and the last thing you want is an unexpected reaction brewing over a weekend. If your department schedules regular chemical audits, treat them as opportunities—a quick glance can spot container cracks or forgotten samples long before they pose real danger.

Disposal: Responsibility Comes Full Circle

Once the experiment ends, the leftovers pose another set of questions. Never pour HPyNTf2 down the sink or throw it in general trash. Ionic liquids may resist breakdown in municipal treatment plants and could wind up in waterways. Most responsible labs tag such chemicals for incineration at licensed facilities. Collect waste in sealed, labeled bottles, and use secondary containment to stop leaks. Keep a log of when and how much waste accumulates; tracking waste avoids mystery bottles lurking in the back of the shelf and informs staff about disposal needs.

Since persistent fluorinated molecules cause trouble for wildlife, take disposal seriously—not just to avoid fines but because it’s the right thing for the environment and local community. I’ve seen research groups work with environmental health officers to overhaul outdated protocols, making sure every hand that touches HPyNTf2 knows the risks and how to lower them. These lessons stick with you long after you leave the lab.

Raising the Bar Through Training and Support

Critically, building a culture of caution beats written rules alone. Regular, hands-on safety training helps everyone remember not just procedures, but the reasons behind them. Some of my best safety habits started as tips from scientists who shared real mishaps, not rulebooks. Encouraging open communication and reporting of near-misses prevents accidents before they start, and reminds everyone that safety is a shared investment—not a shutdown of curiosity, but its safeguard.