N-Hexyl Pyridinium Hexafluorophosphate: An In-Depth Commentary

Historical Development

Chemists always look for new possibilities, and ionic liquids like N-Hexyl Pyridinium Hexafluorophosphate have sparked excitement since the late 20th century. Early work surrounding pyridinium-based ionic liquids drew attention during the solvent revolution that picked up speed in the 1990s, when environmental worries drove labs away from classical volatile organic solvents. The shift toward hexafluorophosphate anions came as researchers targeted compounds offering non-flammability and low vapor pressure without giving up solubility and structural control. Over the years, tweaking alkyl chain lengths and cation-anion combinations proved key to unlocking distinct performance traits, and the hexyl pyridinium pair turned into a serious contender for electrochemistry and clean synthetic processes. My own dives into archival chemical literature show plenty of trial and error until the pyridinium core rang the bell in scalable, less wasteful electrochemical systems.

Product Overview

N-Hexyl Pyridinium Hexafluorophosphate doesn’t shout its presence in a lab, but its story runs deep. The compound forms through pairing a six-carbon straight-chain alkyl group on pyridinium with the reliable hexafluorophosphate counterion, creating a salt that usually appears as a white to off-white powder or as a viscous liquid, depending on exact hydration and processing steps. Chemists value the compound for standing up to both heat and chemical stress, making it a solid choice for advanced analytical techniques and benchscale reactions. The market recognizes it under names like 1-Hexylpyridinium hexafluorophosphate or HPyPF6. The blend of positive and negative ion creates a balanced, high purity substance that skirts the problems of many older, more hazardous chemicals once used for similar roles.

Physical & Chemical Properties

Every time I work with this salt, its true worth shows up in the lab. Its melting point sits low for an ionic compound, often dropping under 100°C, and the density ranges from 1.2 to 1.3 g/cm³. Thermal stability checks out up to 200°C, where many traditional molecular solvents can’t compete. N-Hexyl Pyridinium Hexafluorophosphate rarely evaporates, which makes open handling less risky, and water solubility remains limited—though it dissolves well in acetonitrile, DMSO, and acetone. The low volatility, paired with an impressive electrochemical window of 4 to 5 volts, feels invaluable for researchers running sensitive battery and electroplating experiments. Chemical resistance to both acid and mild base completes the final reason this compound keeps showing up on my order forms.

Technical Specifications & Labeling

Manufacturers provide this salt in sealed glass bottles or high-density polyethylene containers to guard against moisture and contamination. Purity runs 98% or better, with water content typically below 1%. Labels carry detailed batch numbers, expiration dates, and clear hazard pictograms. Many supply chains, especially those in North America and the EU, follow REACH or TSCA guidelines to ensure traceability and safety info stays on hand. Professional labs expect documentation outlining synthesis method, residual solvent profiles, and storage temp recommendations. This attention to recordkeeping stems from decades of chemical stewardship mistakes, so clear information on every bottle makes a huge difference when troubleshooting odd reaction outcomes or scaling up from milligrams to kilograms.

Preparation Method

Making N-Hexyl Pyridinium Hexafluorophosphate usually means following a two-step process. First, chemists perform nucleophilic alkylation—mixing pyridine with 1-bromohexane or 1-chlorohexane under reflux to produce N-hexylpyridinium halide. Then, metathesis swaps the halide for hexafluorophosphate, often by stirring the crude alkylpyridinium salt into an aqueous solution of potassium hexafluorophosphate. The salt crashes out, ready for filtration and recrystallization from ether or acetone. Careful control over temperature and thorough washing matter, since trapped halide or water raises conductivity and throws off downstream applications. Small process changes—a different solvent, a shift in stirring speed—sometimes mean the difference between a chunky, impure mess and clean, free-flowing powder.

Chemical Reactions & Modifications

In my years spent helping grad students troubleshoot project setbacks, the multi-purpose chemistry of this salt always impressed me. The pyridinium ring stands ready for all sorts of functionalization: N-alkylation, C-H activation, or further ion-exchange to tailor solubility and ionic character. The hexafluorophosphate anion doesn’t budge under most mild conditions, bringing lasting stability in ionic liquid synthesis or as an inert supporting electrolyte. This kind of versatility bridges organometallic catalysis, coordination chemistry, and the world of green solvents, giving labs options to steer selectivity or swap in a new cation for comparison. Unlike traditional alkali metal salts or volatile organics, working with this ionic pair tends to reduce side reactions, simplify product purification, and support more reproducible results.

Synonyms & Product Names

Shoppers trying to avoid confusion should know N-Hexyl Pyridinium Hexafluorophosphate wears many hats: 1-Hexyl Pyridinium Hexafluorophosphate, 1-Hexylpyridinium hexafluorophosphate, or HPyPF6. Careful attention to the exact descriptors and supplier part numbers goes a long way in avoiding mix-ups with similar compounds such as methyl, butyl, or octyl chain analogs. Despite the shifting trade names or labels, the critical identifiers—like the CAS number—let you check certificates of analysis, purity records, and even international shipping restrictions without much trouble.

Safety & Operational Standards

Looking at the lab bench, safety never gets old. N-Hexyl Pyridinium Hexafluorophosphate demands respect for eye and skin protection, along with fume hood handling in case of dust or accidental spills. Safety datasheets flag its potential for mild irritation, and some sources note slow hydrolysis can release traces of HF in wet conditions. Training matters: my experience shows that well-written protocols and easy-to-find PPE keep near misses at zero, even for new hires who never handled ionic liquids before. Waste collection bins must remain labeled for halogenated and PF6 wastes, which call for specialized treatment under country-specific hazardous waste guidelines. Awareness around water reactivity and the unlikely but serious risk of PF6 breakdown means everyone needs quick access to spill kits, emergency eyewash stations, and first aid information.

Application Area

Electrochemists, battery researchers, and green chemistry specialists count on N-Hexyl Pyridinium Hexafluorophosphate for good reason. The ion pair barely conducts water and boosts ionic mobility inside devices like dye-sensitized solar cells, double-layer capacitors, and lithium-ion batteries. Analytical labs lean on its staid physical nature for sample prep, liquid chromatography, and as a medium in supercapacitor and fuel cell test beds. My own team turned to it repeatedly for improving reproducibility in organic electrosynthesis, since the wide electrochemical window cuts interference and helps bump up yield. Its odd blend of thermal and solvent resistance opens doors for emerging techniques—like catalysis in ionic media or designing separation systems that dodge volatile organic emissions.

Research & Development

Big breakthroughs often arrive at the intersection of practicality and pure curiosity, and this compound has played a quiet but steady role in modern chemical R&D. Startups tackling green energy rely on ionic liquids like HPyPF6 for designing reliable batteries with better charge–discharge cycles. Academics working on biomolecule extraction and functional material synthesis find the salt useful for fine-tuning solvent systems. Patent filings covering custom ionic liquids for biomass processing, separation science, and low-temperature catalysis sometimes list N-Hexyl Pyridinium Hexafluorophosphate as a co-solvent or template, thanks to its balance between size, charge distribution, and low volatility. Labs keep optimizing synthesis routes to cut costs and lower waste, since any improvement trickles down into scale-up for real-life manufacturing.

Toxicity Research

I keep an eye on emerging safety studies, since the full toxicological picture keeps evolving as new data appears. In vitro tests and aquatic toxicity screens point toward moderate hazards: the compound doesn’t readily bioaccumulate, but its breakdown in the environment can create persistent fluorinated byproducts. Oral LD50 tests in rodents sit higher than acutely toxic salts, but care must be given to skin or eye exposures, which can cause irritation on contact. Regulators in Europe and the US have prompted clear hazard labeling, and lab trainers stress best practices for minimizing exposure and spill risk. While N-Hexyl Pyridinium Hexafluorophosphate doesn’t carry the same stigma as early quaternary ammonium salts, responsible researchers study disposal procedures and alternatives with lower long-term ecological effects.

Future Prospects

Fresh uses keep popping up across science and industry as demands on stability, selectivity, and safety rise year by year. Scientists continue pushing the envelope with ionic liquids in solid-state electrolytes for next-generation power storage and in low-emission separation techniques. Demand for non-volatile, tunable solvents puts N-Hexyl Pyridinium Hexafluorophosphate on lists for battery start-ups, analytical chemistry expansions, and green chemistry initiatives. Emerging synthetic biology and pharmaceutical research call for custom ionic liquids to dissolve awkward biomolecules fast, and HPyPF6’s low toxicity and easy customization make it a contender. At the same time, growing focus on sustainability sparks work on greener versions, biodegradable analogs, or new salts with similar performance but lower fluorine impact. The chase continues as regulatory frameworks set higher bars, encouraging both incremental tweaks and bold new discoveries.

This chemical in research and real life

Chemistry labs often seem like treasure troves for tongue-twister compounds. N-Hexyl Pyridinium Hexafluorophosphate stands out as one with real-world applications beyond its dense name. Some scientists and researchers see this ionic liquid not as a curiosity, but as a flexible toolkit component that unlocks all sorts of possibilities.

Its power in green chemistry

I’ve seen many older chemical processes that rely on toxic solvents. They’re not kind to either the researcher or the environment. N-Hexyl Pyridinium Hexafluorophosphate steps in where old-school approaches leave off. Because of its ionic liquid form, it brings low volatility, thermal stability, and good solubility for a lot of organic and inorganic compounds. I remember working on an extraction process and noting how this class of liquids pulled certain metal ions from water much more efficiently than classic solvents. This sort of property means industries can handle tough separations with less pollution and lower fire risk.

New frontiers in batteries and electronics

Lab tours for high schoolers usually spark questions about how batteries keep getting better. The answer lies in the chemistry behind the scenes. N-Hexyl Pyridinium Hexafluorophosphate helps designers push the limits for supercapacitors, lithium-ion batteries, and next-gen fuel cells. Its ionic nature creates a highly conductive medium, a big deal for energy storage. Over the past decade, published papers have shown how ionic liquids like this one support faster ion transport and longer cycle life, especially since they don’t evaporate or break down as quickly as traditional organic solvents.

Cleaner reactions, less waste

Factories that synthesize fine chemicals need efficiency without sacrifices to safety. N-Hexyl Pyridinium Hexafluorophosphate finds its place here as both a solvent and a catalyst. Reports in journals like Green Chemistry highlight a trend: swapping out volatile organics for ionic liquids means cleaner product and smaller hazardous waste streams. This trend comes up a lot in pharmaceutical and specialty chemical manufacturing. I’ve talked to chemists who’ve trimmed their waste disposal bills and reported fewer headaches from toxic vapors after switching over.

Risks and trade-offs

No one compound solves every problem. Ionic liquids show promise, but disposal raises questions. Some hexafluorophosphate salts can generate toxic byproducts in incinerators. I’ve seen researchers juggling benefits and drawbacks, careful not to trade one risk for another. Ongoing studies look for ways to recover and reuse these liquids, either by recycling or by tweaking the chemistry to make them more biodegradable. Responsible sourcing and handling remain a priority, especially as use grows outside academic labs.

A future shaped by smarter choices

The reason N-Hexyl Pyridinium Hexafluorophosphate gets attention isn’t just about numbers in a flask. It’s about replacing the worst habits of old chemistry with safer, cleaner, and more efficient methods. Companies can explore closed-loop processing, creative recycling, and strict oversight to stretch the benefits while shrinking the drawbacks. As with most new chemical tools, its value depends on the thoughtfulness of those who use it. Science marches forward, one molecule at a time, toward a better balance between progress and responsibility.

The Building Blocks of N-Hexyl Pyridinium Hexafluorophosphate

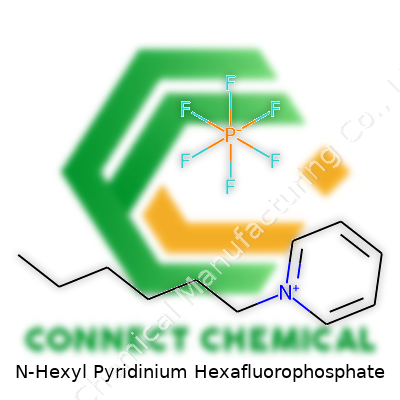

N-Hexyl pyridinium hexafluorophosphate brings together two distinct components. On one end, you find the N-hexyl pyridinium cation, derived from pyridine, a nitrogen-containing aromatic ring. If you stack six carbons in a straight chain and connect that tail to the nitrogen atom, you have the "hexyl" part attached to the pyridinium ring. The structure, at its core, is a pyridinium ion modified by a long, unbranched alkyl chain.

On the other side, hexafluorophosphate (PF6-) forms the counterion. Six fluorine atoms surround a central phosphorus atom, locked in a near-perfect octahedral geometry. This ion stands out not just for its symmetry and size, but also its remarkable chemical stability, which matters a lot in practical laboratory settings and industrial processes.

Why Structure Matters Here

Every part of this compound—cation, anion, chain length—changes performance and safety. I’ve worked with ionic liquids, including N-alkyl pyridinium salts like this one, in solvents and as electrolytes. The hexyl chain adds bulk and hydrophobicity, nudging the compound away from water solubility. This influences how it mixes or separates with other chemicals. You won’t find this kind of compound mixing well with water, but try combining it with an organic solvent or other ionic liquids, and you start to see what sets it apart.

The hexafluorophosphate anion does more than provide charge balance. It resists hydrolysis, unlike other anions such as chloride or tetrafluoroborate. Labs value this stability. The PF6- component also pulls down the melting point due to its size and geometry, which often pushes N-hexyl pyridinium hexafluorophosphate into the liquid state at room temperature. That helps researchers in the field of green chemistry keep operations less reliant on hazardous, highly volatile organic solvents.

Broader Impact and Hazards

The utility of this compound shines in electrochemistry, phase-transfer catalysis, and even advanced battery work. If you work in a battery research lab, you’ll see the appeal: high ionic conductivity without relying on solvent systems that catch fire. But the very features that boost performance call for respect. Hexafluorophosphate salts, if mishandled or exposed to moisture, can break down to form hydrofluoric acid—corrosive and toxic, causing severe chemical burns. In my own work, any procedure involving PF6- starts with lab gloves and eye protection, because mishaps with this family of chemicals can be unforgiving.

Chemists today try to balance performance with safety. Some teams focus on alternatives that keep ionic conductivity strong but use less hazardous anions. I’ve seen movement toward other salts such as bis(trifluoromethylsulfonyl)imide (TFSI). It’s not always a straight swap—sometimes the advantages of PF6- matter too much to avoid—but the pressure to shift away from potentially hazardous ingredients stays strong in regulatory and research circles.

Advancements and Responsible Use

Using N-hexyl pyridinium hexafluorophosphate responsibly means knowing what each atom brings. Researchers design containment and handling protocols rooted in the realities of this structure. Factoring in the octahedral PF6- anion’s stability, plus the hydrophobic and bulky hexyl-substituted pyridinium ring, affects not just a lab’s layout but downstream environmental decisions. Waste disposal systems get tailored accordingly, limiting the risk of environmental release.

Staying updated about the latest findings on the reactivity and degradation products of hexafluorophosphate boosts both safety and innovation. Training new chemists means not just repeating textbook structures, but instilling respect for every subtle twist that comes from structure—because nothing in a chemical formula is just for show.

Chemical Curiosity and Caution

N-Hexyl Pyridinium Hexafluorophosphate, often spotted in research labs, serves as an ionic liquid with a growing roster of technical uses. Chemists have gravitated toward ionic liquids since they offer things like low volatility and the ability to dissolve a wide range of materials. Anyone who’s spent time around these chemicals soon hears one key question: what kind of hazards or toxic risks follow in their wake?

Peeling Back Layers on Safety

Digging into published data, you’ll find descriptions pointing out that pyridinium-based ionic liquids may not be as friendly as their “green chemistry” reputation suggests. N-Hexyl Pyridinium Hexafluorophosphate can irritate skin, eyes, and the respiratory tract. If you’ve ever splashed something like this on your gloves in the lab, you learn quickly that direct contact feels unpleasant. Lab reports spell out dangers that reach past short-term irritation. Given enough exposure, it can hurt aquatic life. Just as telling, tests on related pyridinium salts have revealed toxic effects that reach cell membranes and enzyme systems.

Most people in my line of work rely on the data sheets and hazard statements issued for chemicals. For this ionic liquid, the literature commonly flags risks like organ damage with repeated or long exposures, and warns against releasing the material into waterways. The hexafluorophosphate group adds its own punch. Compounds containing it sometimes break down under certain conditions, letting out hydrofluoric acid. Chemists treat hydrofluoric acid with the highest respect—many have vivid memories from training, hearing about hospitalizations that resulted from even minor contact.

Lack of Universal Clarity

Authorities have not yet handed down set guidelines or clear-cut limits on workplace exposure to N-Hexyl Pyridinium Hexafluorophosphate, so caution remains the norm. In absence of hard numbers from regulatory agencies, most professionals treat this chemical much like other hazardous materials—double-checking ventilation, using splash goggles, donning chemical-resistant gloves.

On the toxicity score, comparisons with other pyridinium and hexafluorophosphate compounds can fill some gaps. Acute oral toxicity studies in lab animals put similar chemicals into ranges considered "moderate" to "severe" risk. More worrisome, some research points to lasting effects on the nervous system or organ function from long-term low-level exposure. Both workplace safety experts and academic researchers recommend using closed systems or effective fume extraction when handling or transferring the material.

Toward Practical Solutions

To reduce hazards, storing and labeling containers with chemical-resistant coating goes far. Staff need training, not just in written protocol, but through drills using neutralizing agents and spill kits. Local exhaust ventilation cuts down on inhalation risks. Waste collection points should funnel material into safe disposal routes. Even small spills count, since hexafluorophosphate breakdown could linger and affect air quality or local groundwater.

Risk speaks louder than reputation. Ionic liquids like N-Hexyl Pyridinium Hexafluorophosphate can anchor safer, more sustainable chemistry, but hazards demand respect. I’ve seen researchers shift away from this class of chemicals toward greener alternatives or tweak protocols to minimize contact. Staying alert, using physical barriers, and keeping an eye on new findings help everyone keep safety a living priority.

Understanding the Chemical and Its Real-Life Impact

N-Hexyl Pyridinium Hexafluorophosphate isn’t the kind of chemical you stumble on outside research labs, battery facilities, or electrochemical development spaces. This ionic compound shows up in the world of specialized batteries and advanced materials science. If you’ve handled fine powders or hygroscopic salts before, you’ll know how quickly a careless moment can ruin a whole batch. Keeping this compound stable isn’t simply a matter of shelf space; the real trick is respecting what moisture and heat do to it.

Why Moisture and Heat Pose a Real Threat

I’ve spent plenty of time in university labs, watching small mistakes unravel expensive experiments. N-Hexyl Pyridinium Hexafluorophosphate draws water. If someone leaves a vial untightened, air sneaks in, humidity gets to work, and the salt can clump or break down. These changes hit its purity and reliability. Once a chemical picks up enough water, it could fail to deliver those tight electrochemical results. That’s the difference between a working prototype and hours of lost effort.

Choosing the Right Storage Conditions

Forget leaving open bottles on a bench or a cluttered shelf. This compound belongs in a cool, dry spot. I always use a desiccator whenever a salt has this kind of affinity for moisture. There’s nothing fancy about a desiccator, but it makes a world of difference. You toss in a few fresh desiccant packs, maybe some silica gel, and you’ve set up a protective barrier. For some labs, dry boxes with nitrogen atmospheres work even better—the goal is keep water vapor out and keep temperature stable.

Labeling, Containers, and Common Sense

Glass containers with tight-sealing caps win over everything else for small samples. Clear labeling helps everyone avoid mistakes. The worst messes in a shared lab come from hurriedly grabbing the wrong reagent. Add warning labels for sensitive or hazardous chemicals; people notice what might spell trouble.

In my early days, I once saw someone pour a fresh batch of ionic salt into an old Tupperware container, thinking it was “just for a few hours.” Two days later, the stuff looked chunky, and the material had lost its punch. Skip plastic; only use glass or high-quality fluoropolymer bottles for chemicals that don’t forgive mistakes.

Minimizing Accidents and Waste

Sometimes bottles break, or a researcher drops a cap—stuff happens. Spills feel more likely if the material sits close to an edge, or if the container feels slippery from condensation. Place chemicals in a secure, designated spot, away from heat or direct sun. Routine checks show if labels have faded, caps turned brittle, or moisture crept inside.

The Bigger Picture: Responsibility in Shared Spaces

Some labs run on thin budgets, with students cycling through projects, so clear guidelines and habits matter more than fancy systems. Each person needs to know why those rules exist. Unsafe storage means ruined material and a high risk of health problems if someone breathes dust or mishandles the compound. Consistency lowers risks and protects both research and people. Stocking up on proper glassware, clear labels, and tested procedures saves trouble down the line. That’s the real safeguard for the next experiment and everyone working beside you.

Looking Past the Label: Purity That Actually Matters

N-Hexyl Pyridinium Hexafluorophosphate often finds its way into research labs, battery prototypes, and specialty chemical applications. Chemists in the real world, like myself, know how often just “95% pure” on a bottle doesn't tell the full story. Most suppliers offer this compound at 98% or higher, with top-tier outfits providing 99% purity backed by a solid chromatography report. That difference shows up in the details. A 1% impurity—especially with ionic liquids—can introduce water or organic byproducts that mess with conductivity, solubility, or even the color of the solution.

Spectroscopy, like NMR or FTIR, offers proof beyond a spec sheet. Anyone counting on reliable data or reaction outcomes needs to see those spectra. It's not just academic—one summer, I worked with a batch that claimed high purity, but the subtle off-color and odd melting point told the real story. Running a quick NMR revealed residual hexyl halide, which we had to remove with extra purification steps. Time wasted. Many others in R&D have similar stories.

Water Content: The Silent Disruptor

Electrolyte developers talk about water ppm more than anyone outside the field suspects. Small amounts—under 500 ppm—of water inclusion can still disrupt carefully controlled reactions. Most trusted suppliers offer Karl Fischer titration results. I've seen a few sneakily skip that, selling what looks fine until a project falls apart. Companies paying for quality should ask for water content results before purchase, not after.

Metal Ions and Other Subtle Stowaways

Even as organic chemists, we keep an eagle eye on trace metals. For N-Hexyl Pyridinium Hexafluorophosphate, iron, sodium, or copper can cause headaches in electrochemistry. ICP-MS or atomic absorption data can give a more complete picture. Once a supplier got lazy, and we found iron levels high enough to muddy cyclic voltammetry data—no supplier’s guarantee on purity means much without those numbers to back it up.

Physical Appearance Isn't Just Cosmetic

Most expect a white to off-white powder or, sometimes, slightly creamy needles for the pure compound. Any grayish tinge or clumping signals trouble. It’s not just about looking pretty—physical changes often follow storage issues, contamination, or improper halide removal. Researchers looking for long shelf life keep their material cool and tightly capped, usually under a dry nitrogen blanket. Old habits from grad school stick: check your sample under good light, don’t trust the packaging sight-unseen.

How Reputable Suppliers Try to Stand Out

The best vendors provide batch-level certificates of analysis. Those COAs list NMR, HPLC, water content, melting range, and metal traces—all on one sheet. Good suppliers ship in double-sealed bottles with desiccant. They don’t hide behind vague “high purity” claims and will answer requests for analytical data without delay.

Reliable sourcing keeps projects on track. I’ve worked with teams that switched to small specialty firms after too many failures using bulk chemical houses. Paying more for transparency in specs saved months of repeated experiments. It’s not about following regulations—it’s about avoiding the cost of rework, missed milestones, or long troubleshooting sessions.

Making Informed Choices

Those who need N-Hexyl Pyridinium Hexafluorophosphate should put pressure on sellers for detailed specs. Specifications matter most when the work depends on trusted inputs—cutting corners only leads to bigger problems downstream. As practitioners demand better information, suppliers with detailed, honest reporting rise above those pushing generic purity claims. That shift keeps science on steady ground and prevents small mistakes from snowballing into big ones.