N-Hexylimidazolium Dihydrogen Phosphate: Insight and Application

Historical Development

Looking back, ionic liquids like N-Hexylimidazolium Dihydrogen Phosphate didn’t capture much attention until the late 1990s. Chemists often focused on tried-and-true organic solvents, finding comfort in the familiar until the harmful impact on health and the environment pushed researchers out of that comfort zone. Now, a compound like N-Hexylimidazolium Dihydrogen Phosphate stands among the few that managed to break into mainstream research. Years ago, scientists hunting for alternatives to volatile organic compounds started tuning imidazolium structures, and soon realized alkyl substitutions such as the hexyl group influenced both the substance’s properties and the way it interacted with other chemicals. As a result, what started as a small offshoot in the field of green chemistry gave birth to a whole new class of designer solvents, each with a unique fingerprint.

Product Overview

N-Hexylimidazolium Dihydrogen Phosphate comes from the marriage of organic and inorganic chemistry. This ionic liquid features an imidazolium ring decorated with a six-carbon chain and counterbalanced by a phosphate anion. Chemists prize it for its room-temperature liquidity, minimal evaporation, and resistance to catching fire, making it especially useful for jobs where safety matters. Whether used on the lab bench or in industrial equipment, its ease of handling stands out against traditional alternatives like acetonitrile or chloroform. The large cationic head and the smaller inorganic anion create a set of characteristics that allow for unexpected uses well beyond simple solvent replacement.

Physical & Chemical Properties

At a glance, N-Hexylimidazolium Dihydrogen Phosphate appears almost unremarkable—a viscous, often clear or slightly yellowish liquid that barely carries a scent. Digging deeper, you find its boiling point sits above 300°C, far beyond most common organic compounds. It also resists freezing until below −60°C. Low vapor pressure translates to practically zero evaporation at room temperature, helping labs cut down on air contamination. Its imidazolium backbone adds thermal stability, while the hexyl group increases hydrophobicity enough to offer possibilities in phase-transfer tasks. With a density usually around 1.05–1.15 g/cm³ and a conductivity that holds up compared to other ionic liquids, it bridges the divide between easy mixing and selective solubility. Handling reveals another benefit: it stands up to most acids and bases under normal conditions, with phosphoric acid derivatives providing an extra layer of buffering when exposed to shifts in pH.

Technical Specifications & Labeling

Manufacturers provide this compound with purity above 98%. Each bottle comes clearly labeled with batch numbers, manufacture dates, and storage requirements. Labels also note the material’s water content because even small amounts of moisture can change its properties. Viscosity values, ionic conductivity, and decomposition temperatures are essential metrics attached to technical data sheets. Hazard statements draw attention to possible skin and eye irritation, and bottles include guidance to keep the contents tightly sealed, away from direct sunlight or high temperatures. By following exacting standards for quality and traceability, suppliers meet the demands of research-intensive environments.

Preparation Method

Production usually begins with the alkylation of an imidazole core. A controlled reaction introduces the hexyl group, forming N-hexylimidazole. To create the ionic liquid, chemists react this precursor with phosphoric acid or a dihydrogen phosphate salt through a straightforward ion exchange. The resulting mixture undergoes purification, including multiple washing steps and vacuum drying, to strip away unreacted materials and by-products. Skilled process control ensures a consistent final product, free from halide residues or excess acid—two impurities that disrupt sensitive experiments. The hands-on work, from monitoring temperatures to adjusting solvent choices, reflects the fine line between lab-scale syntheses and commercial batches.

Chemical Reactions & Modifications

Once obtained, the compound serves both as a reaction medium and as a reactant. N-Hexylimidazolium Dihydrogen Phosphate works as a catalyst in esterification and transesterification, offering mild conditions and high selectivity for certain transformations. Its imidazolium cation can be tailored with different alkyl chains to shift its solubility and interaction with organic or inorganic species. Researchers explore anion exchange to form novel ionic liquids with customized properties, each suited to a specific set of challenges in extraction, catalysis, or biotransformation. In some cases, the compound even acts as an active participant in hydrogen-bonding networks, driving unexpected chemistry not possible with conventional solvents.

Synonyms & Product Names

This compound travels under several names, depending on who is handling it. N-hexylimidazolium dihydrogen phosphate stands as its IUPAC name, but some people call it 1-hexyl-3-methylimidazolium dihydrogen phosphate or simply [HexIm][H₂PO₄]. Trade names often compress these formal terms to abbreviations or blend ‘imidazolium phosphate’ with the hexyl chain’s length. This naming flexibility stems from the broad diversity common among ionic liquids.

Safety & Operational Standards

Work with N-Hexylimidazolium Dihydrogen Phosphate demands respect for both chemical and personal safety. Direct skin or eye contact brings irritation, so proper gloves, goggles, and lab coats count as essentials instead of extras. Splash hazards rise during transfer, particularly as viscosity encourages lingering drops on glassware and gloves. Local regulators set exposure limits, and standard operating procedures insist on use inside fume hoods to avoid accidental inhalation or vapor buildup. Disposal routes treat it as a specialty chemical, often requiring incineration or expert neutralization so that environmental impact stays minimal. With the right habits, this compound supports ongoing research without putting teams or surroundings at risk.

Application Area

Over the past decade, N-Hexylimidazolium Dihydrogen Phosphate attracted interest in areas ranging from green chemistry to materials processing. Industrial catalysis benefits from its low volatility and thermal stability, making it useful for reactions that run hot or require long times. Analytical scientists use it in sample preparation and extraction, exploiting its tunable solubility to pull contaminants or target compounds out of complex mixtures. In electrochemistry, it serves as a non-volatile supporting electrolyte suited for specialized batteries and capacitors. Water treatment and biomass conversion represent two arenas where its green credentials give it a distinct edge, providing new ways to break down stubborn feedstocks or recover precious resources. The variety of uses shows a compound’s real-world value depends as much on creativity as on textbook chemistry.

Research & Development

Universities and industry labs continue to test the boundaries of what this ionic liquid can do. Research groups investigate its ecological profile, biocompatibility, and ability to serve as a solvent for enzymes or pharmaceuticals. Studies look at how the imidazolium group’s structure controls both the chemical environment and the reactivity inside catalytic cycles. Development teams search for ways to recycle and recover the liquid from process streams, aiming to reduce costs and waste. Cross-disciplinary projects tie it to sensor design, nanomaterials, and even next-generation lubricants. The relentless push for safer, smarter materials keeps N-Hexylimidazolium Dihydrogen Phosphate in the spotlight.

Toxicity Research

Health and environmental safety cannot be separated from technological progress. Early toxicity reports suggest N-Hexylimidazolium Dihydrogen Phosphate is less hazardous than many classic industrial solvents, but not entirely risk-free. Some studies indicate low acute toxicity to mammals, while aquatic tests show certain concentrations affect microbe or algae growth. Bioaccumulation appears limited, but breakdown products of the imidazolium structure require more investigation to fully understand their fate and persistence. Ongoing research — often driven by tighter regulations — checks for chronic effects, reproductive hazards, and subtle influences on ecosystems. As evidence grows, companies and labs improve their handling practices and search for benign alternatives if risks come into focus.

Future Prospects

Looking ahead, new ideas stand ready to reshape the uses and reputation of N-Hexylimidazolium Dihydrogen Phosphate. Advances in computational chemistry let researchers predict how minor structural changes drive big performance jumps. Demand for greener solutions continues to drive adoption in clean energy, sustainable manufacturing, and pollution control. The search for solvents that do more with less waste aligns with regulatory and ethical demands for cleaner technologies. Limitations in cost, toxicity, and recyclability remain, but nothing motivates innovation like real-world needs. Future generations of this compound might boast improved biodegradability or even specialized roles in medicine or electronic devices. Its journey mirrors the wider shift in chemistry toward responsible invention and thoughtful application, proof that even the most technical materials find meaning in real problems and honest solutions.

Digging Into the Real-World Side of an Unusual Compound

N-Hexylimidazolium dihydrogen phosphate doesn’t usually show up in the headlines. If you’ve never heard of it, you’re not alone. I ran into its name in graduate school during a project on ionic liquids—those odd “designer” salts that stay liquid even at room temperature. This compound finds a purpose because it brings together two useful building blocks. The imidazolium part helps things dissolve, and the phosphate is great at shuttling protons and stabilizing certain tricky reactions.

Researchers first gravitated toward N-Hexylimidazolium dihydrogen phosphate for green chemistry applications. Industrial giants want alternatives to old-school solvents that pollute air and water. Chemists get excited about ionic liquids like this one because they don’t evaporate much, which means way fewer toxic fumes in the factory or lab. Facts from multiple green chemistry research groups show that these liquids cut air emissions in half or more, especially in processes like cellulose processing or certain sliding-scale organic syntheses.

Unlocking Value in Biorefinery and Biomass Processing

One bright spot for this compound involves biorefineries—those places working hard to turn tough plants into renewable fuels or bioplastics. Breaking down biomass isn’t easy. The cell walls of things like straw and wood resist most solvents, but ionic liquids loosen the tough structure. N-Hexylimidazolium dihydrogen phosphate gets chosen because it chews through stubborn lignocellulosic matter better than many other options. In published studies, it achieved close to 90 percent yield for converting plant sugars, while reducing the risk of dangerous byproducts. Fewer emissions and better yields catch the attention of companies chasing both profit and environmental targets.

From what I’ve seen, labs like using this particular compound for enzyme stabilization, too. Certain enzymes lose shape outside their comfort zone. This ionic liquid can be a gentle partner, raising enzyme stability by nearly triple in some biotransformations. Researchers have shown that it helps enzymes run tougher reactions, which matters for greener manufacturing and drug development.

Challenges: Not All Green Solutions Are Ready for Prime Time

Still, wide adoption runs into trouble. Many ionic liquids, including N-Hexylimidazolium dihydrogen phosphate, carry a hefty price tag and sometimes toxic breakdown products if the chemistry isn’t locked down. My former team ran cost comparisons—it turns out bioethanol made using these solvents can carry a 20 percent markup over traditional processes, mainly because separating and recycling the liquid isn’t trivial. The phosphate part can lead to unwanted build-up in water systems if waste isn’t managed properly.

Paths Forward: Safer, Smarter, Cheaper?

With a few targeted changes, the benefits could spread further. Researchers at government labs are working on cheaper routes to make and recycle N-Hexylimidazolium dihydrogen phosphate. Focusing on safer “closed-loop” systems could trap solvent and reduce waste. For water treatment or biorefinery startups, joining forces with engineers can help scale these solutions without letting run-off slip through the cracks.

Knowing what’s at stake, I see N-Hexylimidazolium dihydrogen phosphate as both a promising tool and a challenge. Every new compound that promises cleaner processes ought to come with a full life cycle check, not just an emissions snapshot. Scientists, business leaders, and regulators need old-fashioned teamwork as much as cutting-edge chemistry to turn these discoveries into a win for people and the planet.

Why Chemical Storage Isn’t Just a Science Thing

Properly storing chemicals isn’t just about following lab manuals. It keeps people safe and saves money. N-Hexylimidazolium Dihydrogen Phosphate acts as an ionic liquid and has a unique chemical makeup, so if you don’t respect its quirks, you risk ruined experiments or equipment—or even health problems you didn’t bargain for. In my lab days, I learned not every chemical wants the same type of home, and lessons often came after spilled bottles or those surprise headaches you regret ignoring.

Temperature, Light, and Air: The Big Three

Right out of the gate, keep N-Hexylimidazolium Dihydrogen Phosphate away from heat. Room temperature cuts it for daily storage, but direct sunlight, heaters, and hot spots by the window chip away at its stability. Set your storage up in a cool part of your workspace, far from temperature swings.

Light breaks things down. Since this compound doesn’t get along with strong light, use amber bottles or stick it in a shaded cabinet. This keeps chemical bonds from loosening and sidesteps unwanted reactions you’ll end up cleaning.

This chemical also likes to cling to water in the air—hygroscopic is the word—so moisture sneaks in if you leave the cap loose or decant out in humid conditions. That’s a headache I dealt with after a summer thunderstorm in a poorly ventilated lab. Tightly close bottles after each use, and pick containers with good seals. Running a dehumidifier or using silica gel nearby helps, especially if your building sweats through the warmer months.

Containers Matter More Than You Think

This isn’t the stuff you pour into a random recycled jar. Glass stands up best to a lot of chemicals, including ionic liquids. Some plastics react. I once used a plastic container for a similar compound, and after a month, the bottom was sticky. Glass or high-quality plastic with chemical resistance saves time and keeps unknown contaminants away. Always label containers clearly, to dodge confusion or mistakes.

Keep It Dry, Keep It Separate

No one likes chemical surprises on the shelf. Store N-Hexylimidazolium Dihydrogen Phosphate away from acids, bases, and strong oxidizers. Even if you think it’s safe, all it takes is a leaky bottle next door to cause a mess—or worse. I saw lab mates stack bottles for space, but a splash got into an incompatible chemical’s container. That misstep led to a day’s worth of cleanup and an awkward safety meeting.

Moisture control is about more than just tight lids. You can add desiccant packs inside cabinets or even in the outer packaging. Look for moisture indicators to give an easy check daily, instead of waiting for trouble.

Monitoring and Training Take Top Billing

Just sticking a bottle on a shelf and calling it a day gets you trouble. Someone must keep track of inventory and regularly inspect containers for leaks, clogs, or contamination. New staff—especially students—don’t always know the quirks of each chemical. Monthly reviews and refresher training can save labs from accidents or wasted material.

Safe storage takes effort, but a little bit of upfront work keeps your workplace running smoothly and everybody healthy.

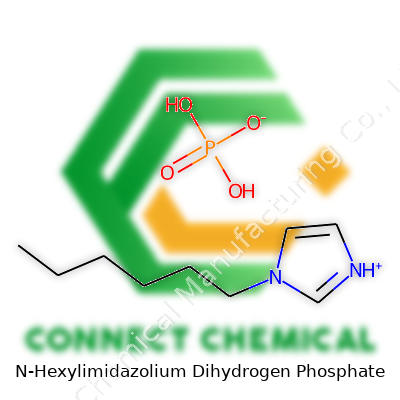

Breaking Down the Chemical Structure

N-Hexylimidazolium dihydrogen phosphate sounds like a mouthful, but it’s easier to grasp once you picture its key parts. Picture an imidazolium ring—a five-membered ring with two nitrogen atoms sitting next to each other. Attach a straight-chain hexyl group (six carbons in a row) to one of the nitrogens, and that’s the first half sorted. The other piece, dihydrogen phosphate, comes from phosphoric acid, HOPO3H2, with a negative charge hanging onto two hydrogens. Combine both, you’ve got a salt: an organic cation teamed up with an inorganic anion.

The N-hexylimidazolium cation gives this compound a unique profile. The long hexyl chain adds flexibility and hydrophobicity, which affects how this salt behaves in solvents and at interfaces. With the imidazolium core, you see strong interactions with a variety of molecules. This structure has made imidazolium salts, especially ionic liquids, stand out for their thermal stability and low volatility.

Why Structure Matters in Real Life

With chemistry, structure changes everything. N-Hexylimidazolium dihydrogen phosphate proves this in fields from green chemistry to electrochemistry. Ionic liquids like this steer away from traditional organic solvents—avoiding toxic vapors and flammability. Researchers and engineers working in laboratories often talk about the difference a longer alkyl chain (such as hexyl) can make. Suddenly, the viscosity drops or the solubility improves. An electrolyte’s ability to hold and transport charges gets a boost. In some labs I’ve visited, folks swap out smaller-chain imidazoliums for hexyl or even longer, hunting for precisely this effect.

There’s also the phosphate side. Dihydrogen phosphate anion brings hydrogen bonding and buffering capacity. It’s more than just a counterion; it shapes how the whole salt interacts with water and acids, as well as with hydrogen bond donors and acceptors. This combination has led to their role in catalysis—phosphates can nudge reactions in specific directions. People looking for environmentally gentle ways to drive chemical reactions often lean heavily on these salts.

Concerns and Possible Ways Forward

Ionic liquids aren’t without headaches. Their chemical stability eases concerns about fire or evaporation but builds questions about what happens after use. N-Hexylimidazolium dihydrogen phosphate does not break down quickly once released into the environment. Disposal and life-cycle impact still need more investigation. As I’ve learned watching waste management projects, some compounds used as green alternatives wind up creating fresh disposal puzzles. Biodegradation studies, as well as policy around chemical disposal, have not caught up with the pace of ionic liquid research.

Manufacturers can start looking at designing ionic liquids that break down more easily or can be recycled after use. One smart approach comes from tweaking the alkyl chain—using branches or introducing functional groups that encourage microbial processing after disposal. Creating a closed-loop system for ionic liquid recovery makes a difference, too. Labs working with these chemicals can pick up solvent recycling units that process and recover used salts for another round, limiting environmental exposure.

Takeaway from the N-Hexylimidazolium Dihydrogen Phosphate Story

A deeper look at the structure of N-Hexylimidazolium dihydrogen phosphate shows real innovation paired with real-world challenges. Every atom matters, from the ring to the chain to the phosphate. The right chemical design brings improvements in performance and sustainability, but it asks for the same care after the reaction as before it. Chemists, engineers, and policymakers need to work side-by-side, making the promise of ionic liquids as green tools into a sustainable reality.

What Is N-Hexylimidazolium Dihydrogen Phosphate?

N-Hexylimidazolium dihydrogen phosphate looks like one of those long and fancy names cooked up in chemistry labs. This substance belongs to the family of ionic liquids, which have earned a reputation for dissolving just about anything and sticking around longer than most other solvents. Some researchers swear by these liquids for their unusual ability to do a scientist's dirty work—extracting precious metals, breaking down plant matter, or running cleaner chemical reactions.

Is It Hazardous or Toxic?

A lot of the so-called “green” chemicals get a free pass because they don’t catch fire, don’t go boom, and don’t stink up the place. This doesn’t mean they’re harmless. The conversation about N-Hexylimidazolium dihydrogen phosphate and safety isn’t just for folks in lab coats. I remember seeing chemists use “green” ionic liquids for years, only later realizing some of these liquids gave everyone headaches and dry skin. Sometimes, nobody bothered to ask about long-term effects because the chemicals didn’t look or smell dangerous.

Research groups have tested imidazolium-based ionic liquids, and early signs aren’t all that reassuring. Many of these liquids can irritate skin and eyes. Some mess with the environment by hanging around in water or soil, and they don’t break down as easily as advertised. Toxicology screens have shown that a lot of these ionic liquids harm water fleas and fish at low concentrations. Lab studies published in Green Chemistry and Environmental Science & Technology show that these chemicals disrupt cell walls, kill helpful bacteria, and may change the way smaller animals breathe or develop. N-Hexylimidazolium dihydrogen phosphate shares a similar structure. It likely carries many of the same risks.

Environmental Risks and Long-Term Impact

Down the drain or into the dumpster is the usual fate for many lab chemicals. Some ionic liquids end up in wastewater. At that point, your local water treatment plant is dealing with something it wasn’t built to break down. Plants and aquatic life face higher toxicity than we’d expect from regular household chemicals. Even in moderate doses, ionic liquids can linger, accumulating over time. We could wind up solving one pollution problem by creating another quiet, invisible one—one researchers and locals complain about only once things start to look odd in rivers and lakes.

Personal Protection and Industry Practices

From personal experience working near compounds like this, gloves and goggles are your best friends. Some people brush this off. After all, a chemical without a warning symbol doesn’t always ring alarm bells. Skin irritation and headaches suggest caution, and nobody wants to be the person who ignored early warning signs. Chemical suppliers and factories can step up by opening their books. Ingredients, exposure limits, and disposal rules shouldn’t be trade secrets. Workers who use these chemicals need detailed handling guides—not blanket statements.

Pushing for Safer Choices

Safer alternatives exist, but only if enough folks raise these questions. Academic research should be paired with honest talk from lab veterans. Products get pushed as green, but it never hurts to ask for more proof. Demand toxicity data. Share findings openly. Tighter safety ratings and direct education keep scientists, workers, and communities in the loop.

N-Hexylimidazolium dihydrogen phosphate isn’t a household chemical, but its risks deserve real attention before someone else learns the hard way.

Getting Down to What’s Actually in the Bottle

Stepping into any laboratory supply catalog, there’s always a silent question hanging in the air: “How pure is this chemical, really?” N-Hexylimidazolium dihydrogen phosphate—one of those room-temperature ionic liquids with a growing list of uses—draws the same look. Chemists check the certificates and think through the implications. Purity matters, especially with specialty chemicals.

Standard Purity Levels and What They Mean

Commercial suppliers usually put out N-hexylimidazolium dihydrogen phosphate with purities labeled between 95% and 99%. On paper, this percentage gives a comforting sense of reliability. Demands for higher-grade samples generally drive the cost up, as is true for most ionic liquids and organic salts. Not every experiment or industrial process gets away with “close enough.” Small impurities sometimes act as silencers, boosters, quenchers, or outright saboteurs in chemical systems.

The Reality: What Purity Means in Practice

Numbers on a spec sheet don't always tell the full story. Most reputable manufacturers provide access to an analysis certificate for each batch, showing levels of water (moisture), inorganic ions, and muffled traces of unreacted imidazole or hexyl precursors. From my own time in the lab, I've seen two different bottles—both stamped “≥97% purity”—behave very differently in catalytic tests, which brought up unexpected variables. A single digit in purity kicks off its own domino effect, whether you’re talking about a fuel cell prototype or a new phase-transfer system for organic synthesis.

Why the Source Matters

The reliability of these purity claims leans heavily on the supplier. Trusted chemical companies run proper NMR, GC-MS, and Karl Fischer titrations and aren’t shy about sharing trace impurity profiles. Lab-scale syntheses done in-house tend to come up short; they can sneak in byproducts or salt residues, which often show up only after running an experiment and seeing things go sideways. Academic and industrial settings both benefit from keeping suppliers transparent with their testing protocols.

Impacts on Research and Industry Work

A chemist working with N-hexylimidazolium dihydrogen phosphate in a drug discovery project won’t want leftover solvents fouling up receptor-binding studies. In scale-up scenarios, batch-to-batch inconsistency exposes process steps to unnecessary risk. Regulatory filings—even for “non-toxic” ionic liquids—get messier with vague purity data. At the bench level, trace moisture sometimes slips past the certificates and hinders air- and moisture-sensitive applications.

Solutions for the Purity Puzzle

Tighter communication with suppliers helps catch problems before they derail a year-long project. Verification shouldn’t stop with the supplier’s word; in-lab testing—NMR for organics, ionic chromatography for traces, or even TGA for residual solvents—gives confidence. Paying attention to storage makes a difference as well. Ionic liquids tend to absorb water from the air; even high purity at shipping can sink quickly if left open on a shelf inside a humid lab. Documentation, transparency, and a willingness to run a sanity check go further than wishful thinking. Quality in, quality out—that still rings true.