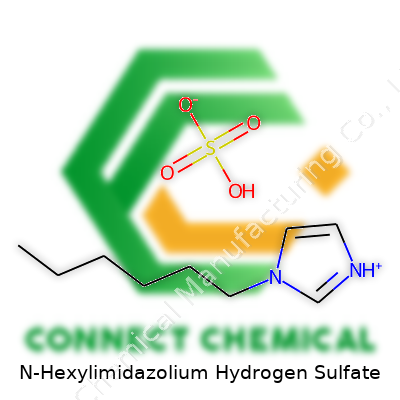

N-Hexylimidazolium Hydrogen Sulfate: More Than Just Another Ionic Liquid

Historical Development: The Road to Discovery

Looking back, ionic liquids started fascinating chemists in the late twentieth century. N-Hexylimidazolium Hydrogen Sulfate came onto the radar as researchers hunted for salts that stayed liquid at room temperature, hoping to escape the environmental headaches of volatile organic solvents. Its development didn’t happen overnight. Synthesizing imidazolium-based ionic liquids required persistence, often iterating molecular tweaks to improve thermal stabilities, maintain broad liquid ranges, and reduce corrosivity. The hexyl chain won favor for its melody of hydrophobic and cationic characteristics, while hydrogen sulfate’s strong acidity drew curious minds. Out of countless contenders, this combination carved a place for itself, especially when the focus shifted to cleaner synthesis routes and recycling solvents in greenshaded laboratories.

Product Overview: Practical Utility and What Sets It Apart

N-Hexylimidazolium Hydrogen Sulfate doesn’t just fill a bottle on a dusty shelf; it offers a direct path away from problematic solvents. Chemists, process engineers, and lab managers often bump into obstacles with flammable or highly volatile liquids. This ionic liquid rarely evaporates under normal conditions, holds up under moderate heat, and cleans up surprisingly well—at least compared to legacy solvents. Its unique cation-anion pair ensures high ionic conductivity and broad electrochemical stability, both craved among those working with catalysis and separation technology. Unlike traditional acids or chlorinated solvents, N-Hexylimidazolium Hydrogen Sulfate settles into the job quietly, allowing focus to go toward optimizing reaction conditions or improving separation efficiency, not hazard management.

Physical & Chemical Properties: Traits That Matter in the Lab

Touch it and the viscous, slippery feel stands out. N-Hexylimidazolium Hydrogen Sulfate pours as a colorless to pale yellow oily liquid at room temperature, explaining its role as an ionic liquid. It doesn’t catch fire easily—flash point rests much higher than common lab solvents. Sporting impressive thermal stability, this liquid often gets tested past 150°C before breaking down, and it barely greets the air with a scent, which colleagues appreciate in cramped labs. Soluble in water and polar organics, it resists stubborn organic solids. Its density and viscosity depend on how much water sneaks into the flask, so storage and handling affect reproducibility more than most realize. Being hygroscopic, it attracts moisture from any humid corner—critical to remember, since water content tweaks everything from electrical conductivity to reactivity.

Technical Specifications & Labeling

Quality-minded suppliers usually spell out purity up to 99%, which can look good at quick glance but missed impurities like halides or low-level organics throw off sensitive applications. Technical datasheets spell out molecular weight, standardized tests for water content (Karl Fischer titration pops up more than once), and suggested storage temperatures—usually below 25°C, away from sunlight. Each shipment needs clear label warnings—corrosive, handle with gloves, keep away from open wounds. From experience, strict compliance with labeling standards saves time and worry during inspections or if containers get moved around different storage rooms.

Preparation Method: How It’s Made

This compound often forms by a straightforward quaternization route: start with 1-hexylimidazole, add equimolar sulfuric acid while maintaining a steady, cooled stir, and allow a controlled neutralization to take place. The acid’s strength means the process gives off heat; so proper cooling, controlled addition rates, and well-chosen material selection for reactors become main concerns. Washing the crude liquid with ether strips away organic byproducts, and drying over vacuum or under inert gas tightens up specifications. Those tackling larger batches tend to automate pH readings, temperature, and rate additions—scaling up introduces problems, but the preparation follows the same logic in both bench and pilot production. Every time, moisture and contaminant control during the synthesis matters, since impurities stick around even if you can’t see them.

Chemical Reactions & Modifications

N-Hexylimidazolium Hydrogen Sulfate steps in as a solvent, catalyst, or even a starting point for other ionic liquids. Because of its acidity, it often gets selected for acid-catalyzed reactions, like esterifications or transesterifications that would fizzle or run too slow under basic ionic liquids. Chemists push the hexyl chain further, swapping it for other alkyls or mixing the hydrogen sulfate anion with different cations, customizing the solvent for specific reactivity, solubility, or temperature conditions. Lab trials keep exposing new pairings, but the hexylimidazolium backbone provides a robust starting point for modifications, letting researchers graft on functional groups or linkers for use in biphasic systems or substance extractions.

Synonyms & Product Names

Searching for this compound sometimes feels like navigating a maze of alternate spellings and commercial names: 1-Hexyl-3-imidazolium hydrogen sulfate, Hex-im-HSO4, N-Hexylimidazolium bisulfate. Vendors might pad the label with their own suffixes, but anyone trained for chromatography or process optimization recognizes the core: imidazolium cation, hexyl chain, and hydrogen sulfate anion.

Safety & Operational Standards

Even though the liquid sports several green credentials, safety in day-to-day work can’t fall behind. Prolonged skin contact leaves irritation, and accidental eye splashes sting more than diluted acid—always a good reason for face shields and splash-proof goggles. Unlike many organic solvents, this liquid doesn’t usually blow up in fume hoods, but it does corrode some metals and reacts unpredictably around oxidizers. SOPs for spills include neutralization, careful wiping, and disposal, since pouring into open drains isn’t an option, and local waste disposal guidelines frown on casual dumping. Teams I’ve worked with build regular exposure monitoring and annual training into their SOPs, underscoring the importance of handling even ‘green’ solvents with proper respect.

Application Area: Where It Works Best

Process chemists dealing with esterifications, alkylations, or acid-catalyzed transformations reach for N-Hexylimidazolium Hydrogen Sulfate often enough that it’s become a lab staple in some fields. It also shows value in extractive metallurgy, pulling specific metals out of complex mixtures more effectively than older solvent systems could manage. Electrochemists plug it into advanced battery prototypes and electroplating solutions, because it transports ions neatly and keeps cell voltages stable. Pharmaceutical labs turn to it to cut back on chlorinated solvent use, allowing them to clean up manufacturing routes and minimize regulatory headaches. Polymer scientists experiment with it in tough-to-dissolve macromolecule work, searching for cleaner, less damaging solvent systems. All these areas keep pushing the demand for carefully characterized, high-purity stocks, since trace contamination instantly shows up in high-performance applications.

Research & Development: New Paths and Unknowns

There’s always another round of tweaks happening in R&D teams. Academic labs and industry alike check the impact of structural changes, whether swapping out the hexyl chain for longer or branched options, or sliding a methyl or functional group onto the imidazolium ring to tune compatibility, acidity, or solubility. Researchers aren’t only chasing improved performance—they want greener syntheses, lower energy input, and easier recovery and recycling schemes to further reduce environmental impacts. New analytical tools, like advanced NMR, titration automation, and computational modeling, now make it much faster to connect subtle structural changes with system performance, helping scientists rack up data and move promising combinations toward pilot-scale trials.

Toxicity Research: What the Data Say

Despite the eco-friendly image that ionic liquids sometimes carry, N-Hexylimidazolium Hydrogen Sulfate isn’t without drawbacks. Early toxicity testing pointed toward moderate aquatic toxicity, mostly from the hydrogen sulfate component disrupting sensitive freshwater environments. Acute oral, dermal, and inhalation toxicity in animal models stays modest when compared to industrial solvents like toluene or acetonitrile, but chronic effects and environmental build-up still leave question marks, especially given the stubborn nature of ionic liquids in water and soil. Some research groups now focus on metabolite screening, hoping to identify exact breakdown products and assess longer-term hazards. With regulations on chemicals tightening worldwide, open data and transparent testing remain the best hedge against unpleasant regulatory surprises for companies hoping to scale up production.

Future Prospects: Advancing Beyond Today’s Use

Looking forward, N-Hexylimidazolium Hydrogen Sulfate sits at a key moment. Newer applications in renewable energy storage, biomass conversion, and closed-loop manufacturing scale up the demand for more robust, easily recyclable solvents. Industry often searches for ionic liquids with lighter environmental footprints, lower toxicity, and lower synthesis costs. Recyclability and recovery, combined with demand for renewably sourced starting materials, keep pressuring R&D to innovate. Tech innovators and chemists continue eyeing this liquid and its relatives for greener industrial chemistry, safer workplace standards, and scalable new materials, keeping this field not only relevant but essential for industries chasing lower emissions and improved process sustainability.

Digging Into What This Chemical Actually Does

N-Hexylimidazolium hydrogen sulfate isn’t something you’ll find under your kitchen sink. Tucked in labs and factories, it shows up where people want to solve tough industrial problems. I’ve followed what specialists do with this chemical, and its main claim to fame comes from working as an ionic liquid. That means it flows like water at room temperature—rare behavior for a salt—and does some serious heavy lifting where regular solvents or acids hit a wall.

Real Use Cases: Not Just a Science Fair Project

Refineries and specialty chemical plants see big upside in the environmental benefits. Old-school solvents tend to evaporate quickly and spill chemicals into air and water. Switching to N-hexylimidazolium hydrogen sulfate cuts these risks since it doesn’t fly off at low temperatures. I know companies pushing for cleaner production—recycling catalysts without breathing in fumes is a big win. Less pollution doesn’t just help the planet, it can make life better for the folks working on the floor.

This salt handles jobs that require separating tough mixtures. It proves handy when companies try to extract metals or separate dyes in textiles. Some wastewater management teams have picked up on this, using it to yank out pollutants from industrial wastewater. They cut costs on additives that would otherwise be tossed, and recover more usable materials at the same time. That’s part of why researchers see it as a cornerstone for green chemistry, especially as regulations keep nudging industries toward better habits.

Backed by Evidence, Not Hype

The benefits of these ionic liquids have been clear for some years now. For example, studies published in Green Chemistry journal show that processes using N-hexylimidazolium hydrogen sulfate generate much less hazardous waste than traditional methods. The recovery rate for metal ions like copper or zinc in electrochemical industries reaches above 90% with this compound, compared to 70% with older chemicals. Facts like these explain why more companies adopt ionic liquids in pilot plants and move beyond test tubes.

Kinks in the System and Real Solutions

It’s not perfect. Sourcing and creating ionic liquids takes skill and, honestly, money. Right now, production costs run higher than basic acids—a factor keeping it out of tiny start-ups and most small-scale operations. Some researchers are searching for cheaper ways to synthesize these salts, including using plant-based feedstock or recycling by-products from other chemical steps. If the industry can lower these costs, wider adoption is practically guaranteed.

On the regulatory side, authorities keep watch. Just because a chemical doesn’t evaporate easily doesn’t mean you can dump it down the drain. A European Chemicals Agency report advises close monitoring to make sure ionic liquids, including N-hexylimidazolium hydrogen sulfate, break down safely and don’t build up in water supplies. Enforcement matters here. It’s up to companies and labs to treat their waste streams properly and share what works as part of open data efforts.

Looking Ahead

The push for green chemistry is real. As more manufacturing steps shift toward using less toxic substances while keeping performance high, N-hexylimidazolium hydrogen sulfate stands out as one of the tools that actually makes a difference. Scientists are already testing how to recover these salts for repeat use, aiming for a full-circle system. This is how progress happens—not by headline claims, but by real-world performance stack up in the trenches.

Getting to Know N-Hexylimidazolium Hydrogen Sulfate

N-Hexylimidazolium hydrogen sulfate draws attention in the lab thanks to its unique ionic liquid properties. Chemists use it for its remarkable ability to dissolve tough substances, catalyze reactions, and offer an alternative to traditional solvents. Anyone working in synthesis, materials chemistry, and green technology might cross paths with it sooner or later.

What the Facts Say About Handling

N-Hexylimidazolium hydrogen sulfate does not carry the same reputation as some infamous hazardous chemicals, but this does not make it risk-free. Ionic liquids often get praise for being less volatile than organic solvents, but users sometimes misinterpret this as a green light for barehanded handling. That’s never a good move. Lower volatility means it will not explode into a room full of fumes, yet its ionic nature can still irritate skin and eyes. Research articles and safety data sheets point toward possible health hazards if you contact it directly or breathe in accidental aerosols.

There’s a wider concern in the chemistry community about the long-term effects of new ionic liquids, including N-Hexylimidazolium hydrogen sulfate. Not all of these substances have had the same decades-long scrutiny as legacy solvents. Some early studies hint that their breakdown products might be tricky to manage environmentally. Rats exposed to similar imidazolium compounds showed signs of toxicity at higher concentrations, especially in the liver and kidneys. Many chemists use nitrile gloves and splash goggles anyway, so standard PPE works, but I always check the glove compatibility tables—some types of gloves degrade faster than others.

Personal Take: Risks Are Real, Complacency Is Not an Option

I have worked with ionic liquids like N-Hexylimidazolium hydrogen sulfate in graduate school projects. Colleagues sometimes joked about their “benign” status compared to volatile organics. Still, accidents reminded me that the unknowns should not tempt anyone to skip precautions. I saw firsthand how a single spill on unprotected skin led to redness and stinging for hours. That made the lab enforce a stricter tool-and-tray policy. A well-organized workspace goes a long way in limiting exposure, especially with new or under-researched chemicals.

Disposal can present its own difficulties. Current regulations push researchers to treat such ionic liquids with the same caution as any other synthetic reagent. I remember a former safety officer urging us to treat waste as if it were just as unforgiving as more notorious substances—no shortcuts, no pouring down the sink. I learned that segregating this waste and labeling it properly prevents headaches down the line, especially if the environmental or health risks shift in light of new research.

Building a Safer Environment

Better labeling, in-depth safety briefings, and easy access to updated Safety Data Sheets improve safety culture. If labs invest in spill kits and regular emergency drills, everybody gets a little more peace of mind. I also favor regular conversations about what’s new in chemical safety—sometimes the youngest workers bring in the freshest data or spot risks that experienced chemists overlook. Training sessions that include real stories of close calls drive the point home much faster than abstract manuals.

Anyone handling N-Hexylimidazolium hydrogen sulfate benefits from treating it as a substance that could surprise you. Even though ionic liquids sound like a safer frontier, nature keeps finding ways to challenge assumptions. The safest hands are the ones that never let their guard down.

Why Purity Means More Than Just a Number

Working with chemicals like N-Hexylimidazolium Hydrogen Sulfate, it’s easy to get hung up on purity percentages. In research labs and chemical companies, you’ll frequently hear people ask about purity as if it’s the only thing that counts. A 98% or 99% label on a bottle seems straightforward, but the number only tells part of the story. Hidden inside that 1% or 2% are impurities that can quietly shift results or cause bigger headaches.

I’ve handled plenty of specialty salts and ionic liquids in my work, and I remember clearly how trace contamination once turned a simple synthesis project into weeks of troubleshooting. That’s why I look at purity not just as a label but as the backbone of any experiment or application involving N-Hexylimidazolium Hydrogen Sulfate.

Industry Expectations and Assay Values

Suppliers usually offer N-Hexylimidazolium Hydrogen Sulfate with purity levels ranging from 97% to 99%. An assay value tells you how much of the bottle’s content actually matches the compound you paid for. Trusted vendors use methods like HPLC (High-Performance Liquid Chromatography) or NMR (Nuclear Magnetic Resonance) to back up these values. They stake their reputation on these certificate numbers.

It’s tempting to buy cheaper batches or skip the extra certification, especially if your budget is tight. Still, lower purity introduces the risk of side-flavors in the chemistry: things like extra water, leftover solvents, or byproducts that don’t show up until your reactions start behaving oddly. That 1-2% margin holds the power to wreck selectivity in catalysis, throw off measurements, or introduce safety risks if the hidden contaminants are reactive.

Risks from Common Impurities

During manufacturing, N-Hexylimidazolium Hydrogen Sulfate can pick up unreacted precursors, metal ions, or even slight oxidation products. I’ve seen teams struggle for weeks over small deviations, only to track the issue back to an old stock bottle where the apparent high purity masked problematic impurities. In electrochemistry or pharmaceutical testing, even trace contaminants can reroute an entire outcome.

The hydrogen sulfate part of this compound means moisture matters, too. Even if a supplier says “dry,” it’s smart to check for residual water content using Karl Fischer titration to get a clear picture.

Testing and Verifying Purity Yourself

Don’t just take the purity figure on faith. Anyone running critical experiments or quality control processes should take time to double-check. Reputable labs use their own HPLC or NMR analysis, particularly if the result affects scale-up or regulatory issues. Just last year, I had an order claimed as 99% pure fail our own tests. One call to the supplier revealed an off-batch. Not fun, but mistakes like this highlight why independent checks are a must.

Building Trust and Solutions

The reality is: the more you rely on high-purity N-Hexylimidazolium Hydrogen Sulfate, the more you benefit from vendor transparency and your own experience. Working closely with suppliers, asking for full breakdowns beyond just the purity number, and running your own checks can save a ton of frustration and wasted time. In settings where strict purity is key—catalysis, pharmaceutical intermediates, or sensitive analytical work—upfront diligence beats troubleshooting later.

Solid communication between supplier and buyer, a willingness to pay for validated lots, and a habit of running your own spot-checks all translate directly to better outcomes and fewer surprises. That’s how reliable purity transforms from a sticker on a bottle into real confidence at the lab bench or factory floor.

Looking Closer at the Chemical

N-Hexylimidazolium hydrogen sulfate serves many niche uses in labs and industry, but storing it safely often gets overlooked compared to more familiar chemicals. Years of working around both students and experienced chemists showed me that even compounds with less toxic reputations demand enough respect. Accidents happen when daily safety becomes routine and workers let their guard down. Years back, I saw a bottle of ionic liquid—very similar to this sulfate—turn into a sticky mess after some moisture got inside; a rookie mistake, but the clean-up lesson stuck with everyone.

Moisture: An Unseen Foe

This salt wants to grab water straight from the air. Once a cap gets left off, or a desiccator stands open too long, the compound pulls moisture and ends up clumpy or even dissolves on the spot. That’s more than an inconvenience. If you rely on accurate measurements for synthesis, that extra water ruins consistency. Always keep the bottle closed tight. A dry, well-ventilated cupboard or a sealed desiccator with fresh silica gel stops the air from spoiling your chemical stock.

Temperature Means More Than Comfort

Many ionic liquids—this one included—handle room temperature well, but wide swings in heat or cold make a difference. I worked with a group once who stored bulk jars near a sunny window just because it was close to their hood. Over weeks, you could see the labeling fade and feel condensation inside the containers each morning. Even though N-Hexylimidazolium hydrogen sulfate won’t burn away or explode, stable temperatures preserve both purity and labeling. Store bottles away from direct sunlight, heat sources, and uninsulated outer walls. A climate-controlled stockroom works best, but even a thick-walled cabinet in the main lab keeps it away from daily temperature swings.

Splash Risks and Spills

It may not be as hazardous as corrosive acids, but this hydrogen sulfate still deserves gloves and goggles during handling. Over time, I’ve watched colleagues dismiss the importance of PPE for “benign” salts, only to struggle with skin irritation or minor burns after a mishap. A spill can travel quickly across smooth lab benches. If your workspace has children or pets nearby—think home-based researchers or smaller setups—add extra care. Store chemicals up high, out of reach, with spill containment trays underneath just in case.

Labeling and Accountability

Clear, durable labels prevent confusion when you work late or share lab space. I met a grad student years ago who reached for what he thought was a bottle of table salt, only to discover a sticky, slightly acidic liquid from a hasty decant. He learned to double-check every bottle, every time. Print and laminate labels with both the full chemical name and the common abbreviation. Include a hazard symbol if possible, and always note the preparation or purchase date. Out-of-date chemicals make results unreliable and create unpredictable risks.

Potential Solutions and Improvements

Chemical safety often comes down to habits. Training new staff or students, use real examples. Show what can go wrong—like the ruined batch or the impossible clean-up—so the lesson sticks. Schedule monthly audits, rotating who checks the cupboards for leaks, condensation, or degraded labels. Push for management to invest in good storage cabinets, temperature control, and fresh desiccants. At home, store chemicals away from food, with emergency info visible, and ensure you can reach the nearest eye wash or tap during a worst-case spill. These steps build a safer culture, long before anything actually goes wrong.

The Role of N-Hexylimidazolium Hydrogen Sulfate

N-Hexylimidazolium hydrogen sulfate turns up in those corners of industry where handling tough chemical processes demands more than old-fashioned solvents. This ionic liquid brings its own set of tricks for chemists and engineers. By swapping out volatile organic solvents for this stable and tuneable compound, manufacturers put themselves in a position to sidestep air quality and safety headaches. Many workers in the chemical sector have dealt with fumes from strong acids and solvents; using ionic liquids can actually make the air around the job less hazardous. I’ve worked in lab environments where solvent exposure made daily tasks a battle with headaches, so seeing this shift is a relief.

Catalysis and Synthesis

One key use of N-Hexylimidazolium hydrogen sulfate is as a catalyst. In the production of esters, especially, this ionic liquid steps in and often takes away the need for harsh mineral acids that corrode equipment and raise operating costs. Its ability to speed up reactions while staying stable even at high temperatures earns it a solid spot on plant floors. Companies lean on this property to drive down downtime and boost throughput, without cutting corners on safety or reliability. In real-world terms, simpler clean-up and lower risk of corrosion mean more uptime for the machinery and fewer headaches for maintenance staff.

Solvent in Extraction Processes

Industries using N-Hexylimidazolium hydrogen sulfate for extraction stand to make gains in both yield and safety. Traditional extractions often count on volatile or flammable solvents; this is where ionic liquids like this one stand out. Thanks to their low vapor pressure, they nearly eliminate the risk of workplace fires tied to evaporation and accidental ignition. This has already made a difference in companies I've followed, especially in the pharmaceutical world, where safety and purity both matter. Cleaner processes mean better products with fewer surprises in the final tests, which builds trust with customers and regulators alike.

Green Chemistry and Reduced Environmental Impact

There’s no way around it: industry leaves a footprint, and part of pushing back means adopting cleaner technologies. N-Hexylimidazolium hydrogen sulfate can be reused multiple times without losing edge. This stands in stark contrast to one-off acids or solvents that wind up as hazardous waste. Eco-friendly operations now count on ionic liquids to help meet stricter emission and disposal rules. I've seen leadership in companies breathe easier knowing they’re stacking up fewer barrels for hazardous waste disposal. They save money and demonstrate commitment to greener business, which gets noticed by everyone from investors to new hires.

Potential in Energy Storage and Electrochemistry

Research into lithium batteries and fuel cells keeps pointing at ionic liquids like this one for new ideas. Their stability in strong electrical fields lets engineers use them as both electrolytes and conductive materials. In industries working to step away from fossil fuels, the quirks of these liquids let researchers fine-tune battery performance and safety. Staying updated on real-world trials, I’ve noticed teams replacing traditional solvents with ionic liquids to avoid thermal runaway events. With energy security taking center stage, these safer materials offer a route to more dependable batteries without the risk of runaway reactions.

Challenges and Solutions Ahead

Cost and recycling remain as real-world challenges. The up-front price of ionic liquids can turn off companies with tighter budgets, which I’ve seen firsthand in smaller operations. Startups and established players can both tackle this by pooling research or by pushing for commercial-scale recycling systems. Partnerships with universities and government grants have chipped away at these hurdles, making ionic liquid adoption practical for more than just Fortune 500s. For industries wrestling with chemical waste and efficiency, these collaborations offer a productive path forward.

References:- Smith, E.L., Abbott, A.P., Ryder, K.S. “Deep Eutectic Solvents (DESs) and Their Applications.” Chem. Rev. 2014, 114, 21, 11060−11082.

- Hough, W.L., Smiglak, M., Rodríguez, H. et al. “The third evolution of ionic liquids: active pharmaceutical ingredients.” New J. Chem., 2007, 31, 1429–1436.

- Bica, K., Gaertner, P., Rogers, R.D. “Ionic liquids and fragrances – direct isolation of orange essential oil.” Green Chem., 2011, 13, 1997-1999.