N-Methylimidazolium Trifluoromethanesulfonate: From Discovery to Modern Applications

Historical Development

N-Methylimidazolium Trifluoromethanesulfonate emerged from the burst of work in ionic liquids during the late 20th century. Scientists in academic and industrial labs across Europe and Asia hunted for alternatives to volatile organic solvents, seeing potential in salts that melt below 100°C. As ionic liquids started to capture the imagination of chemists looking for greener solutions, the imidazolium family, especially those with the trifluoromethanesulfonate anion, gained attention. Their history isn't just a lineage in a patent database; it's a trail of trial and error in the lab, where stubborn lab coats split imidazole rings and worked through columns brimming with fluorinated anions. Much of this pursuit built on fundamental studies of imidazole itself, a workhorse heterocycle with a place in biochemistry and industrial chemistry alike. Once researchers noticed the stability and unique properties that these ionic liquids brought, N-Methylimidazolium Trifluoromethanesulfonate found its way from academic curiosity to industrial pipelines.

Product Overview

You don’t have to search through old chemistry journals to see why this compound stands out. It’s a clear-liquid or white-solid ionic liquid that offers chemists a functional tool as both a solvent and a reactant. N-Methylimidazolium Trifluoromethanesulfonate often gets selected for its chemical resilience, paired with the ability to dissolve a swath of polar and nonpolar compounds. This flexibility gives it a seat at the table in synthetic chemistry, electrochemistry, and catalysis. It’s not a commodity by any stretch—sourcing quality product with clean spectral data and reliable handling profiles matters. Researchers and manufacturers who work with it notice how it plugs gaps in process design, sometimes letting you cut out multiple steps or avoid the pitfalls of highly volatile solvents.

Physical & Chemical Properties

Hold a bottle of N-Methylimidazolium Trifluoromethanesulfonate and it's hard not to notice its high boiling point and negligible vapor pressure. These features give it a major operational benefit in labs that dread dealing with noxious fumes or strict ventilation protocols. Its glass transition temperature sits much lower than traditional salts and it stays stable against air and moisture under typical conditions. Chemically, the methyl-imidazolium cation interacts strongly with the triflate anion, offering not only stability but broad solvating ability. It resists thermal decomposition beyond 200°C and avoids hydrolysis under standard pH ranges, which spans its workings from dryboxes to glovebox-free environments. The density sits around 1.4 g/mL, noticeably heavier than water, and its ionic conductivity positions it perfectly for electrochemical devices. Some of the earliest work I did in ionic liquids relied on these exact traits, and I’ve seen first-hand how a stable, low-volatility substance speeds up benchtop operations.

Technical Specifications & Labeling

Suppliers list N-Methylimidazolium Trifluoromethanesulfonate under CAS 133920-49-5 with purity over 98%. Common bottles come with clear warnings for laboratory use only, and they’re labeled with batch-specific NMR, IR, and elemental analyses. Sometimes producers flag trace water content and halide impurities, a detail that anyone in catalysis cares about. I’ve worked with companies that run additional Karl Fischer titrations before shipping, understanding that moisture kills many sensitive reactions or skews electrolyte performance. Regulatory labels notice its non-flammability but stress skin and eye irritation risks—so gloves and goggles become standard. Tracking shelf life, guidance suggests sealed storage in dry, cool spaces, as persistent exposure to air or sunlight degrades product quality over months.

Preparation Method

Modern labs don’t need a PhD to make N-Methylimidazolium Trifluoromethanesulfonate, but experience with dry solvents, nitrogen lines, and clean glassware really helps. Synthesis typically starts with methylating imidazole under basic conditions, making N-methylimidazole. This gets mixed with trifluoromethanesulfonic acid, keeping stoichiometry tight to control byproducts. Usually, slow addition under cooling prevents charring or loss of volatile methyl groups. Labs neutralize, wash, and dry the mixture before vacuum distillation or recrystallization. Anyone trying this without access to high-quality starting materials quickly finds themselves stuck with brown residues or persistent odor. Several years ago, I spent an afternoon troubleshooting yields and can vouch for the frustration of scale-up when each small impurity torpedoes downstream applications, especially in analytical chemistry.

Chemical Reactions & Modifications

N-Methylimidazolium Trifluoromethanesulfonate stands as more than a bystander. Its cation structure lets it coordinate Lewis acids and transition metals, boosting reaction rates in cross-coupling, metathesis, and cycloaddition. The stable, non-coordinating triflate anion resists nucleophilic attack, ensuring the ionic liquid doesn’t participate in side reactions. Labs use it as a green solvent in alkylation or Diels-Alder chemistry. At the same time, the imidazolium backbone can get tuned—add a longer alkyl group or swap TFMS for other anions to adjust solubility or reactivity. The chemistry textbooks often gloss over how much time goes into tweaking side chains and anions for optimized catalysis; every slight change impacts separation, selectivity, and operational cost downstream.

Synonyms & Product Names

You might see this compound under several names—N-Methylimidazolium triflate, 1-Methylimidazolium triflate, or methyl-imidazolium trifluoromethanesulfonate. In catalogs, it appears as [Mmim][OTf] or [Meim][TfO]. Science papers often abbreviate ruthlessly, showing just [Mmim][TfO]. While synonyms can feel like a headache, especially sorting through decades of literature, they remind us of the organic, sometimes chaotic, way chemical knowledge spreads between research groups and through language barriers.

Safety & Operational Standards

Working with N-Methylimidazolium Trifluoromethanesulfonate, the safety data sheet spells out precautions unmistakably. Contact with the skin or eyes leads to irritation, sometimes with delayed symptoms, and ingestion must be avoided. Labs require nitrile gloves—latex sometimes swells—and goggles every time. Spills wipe up easily because it's nonvolatile, but anything absorbed in paper or cloth heads straight to hazardous chemical disposal, never a regular trash bin. Ventilated hoods make sense when weighing or transferring, and even though no one reports acute toxicity at low doses, chronic exposure goes untested at industrial scales. I learned early to double-check for cross-contamination, especially in shared glassware; otherwise, reactions with sensitive anhydrides failed or electrochemical cells gave nonsense results. In production sites, air monitoring focuses more on possible acidic vapors or dust rather than solvent toxicity—showing how these operational standards evolve with how the material actually behaves in real settings.

Application Area

N-Methylimidazolium Trifluoromethanesulfonate bridges academic curiosity and industrial utility. It powers research in homogeneous catalysis, replacing air-sensitive or foul-smelling solvents in transition metal-catalyzed couplings. Electrochemists turn to it when traditional media break down at high voltages or where ionic conductivity matters—think high-efficiency capacitors or green batteries. Organic synthesis groups like it for mild conditions during alkylations and cyclizations, swooping in for reactions that benefit from high polarity but can’t risk reactive halide ions. Many pharmaceutical labs now screen this liquid for process development, seeing if they can replace more dangerous solvents as regulatory pressure mounts. In biomaterials, it lets scientists process cellulose or chitin without harsh acids. My own experience as a researcher trying to scale hydrogenation found that a small tweak—substituting this ionic liquid for a traditional polar solvent—meant lower waste, easier separation, and less corrosion on steel reactors.

Research & Development

The science community treats N-Methylimidazolium Trifluoromethanesulfonate as a jumping-off point. Year on year, conferences teem with new ways to blend, modify, and deploy this compound. Electrochemical engineers tweak the cation structure, aiming for higher stability inside supercapacitors. Synthetic groups play with the anion, swapping in alternatives that offer greater selectivity or environmental friendliness. One fruitful path focuses on pairing this ionic liquid with enzymes for green biocatalytic transformations—speeding up reactions without the harsh conditions of old-school organic solvents. Universities and big companies alike fund projects that search for new partnerships, whether with renewable substrates or as combined reaction-separation media. During my own time attending research symposia, discussions about this ionic liquid always draw a crowd: process chemists, physical chemists, and even chemical engineers see opportunities to cut costs or open the door to novel products.

Toxicity Research

Chemists can’t ignore toxicity, especially as regulators ask more about the fate of each process ingredient in waste streams. N-Methylimidazolium Trifluoromethanesulfonate shows low acute toxicity in standard fish and mammalian studies, but questions around chronic effects and bioaccumulation haven’t vanished yet. It doesn’t quickly degrade in the environment, so industrial users set up closed-loop systems to keep discharges to a bare minimum. Animal tests show that skin or oral exposure at moderate doses doesn’t provoke systemic toxicity, though irritation still happens at local contact sites. You’ll rarely see risk assessments as static checklists—each year, more labs commit to tracking the compound under varied operational scenarios, isolating intermediates, and prying open environmental fate. It takes cooperation between chemical, health, and environmental specialists, drawing on real data rather than assumptions. I still remember being part of a roundtable at an industry conference, hammering home how baseline testing drives not just compliance, but smarter, safer process design.

Future Prospects

N-Methylimidazolium Trifluoromethanesulfonate sits poised to grab a larger slice of the chemical innovation pie. With battery manufacturers seeking ways to stretch device life and cut fire risk, ionic liquids already draw heavy R&D attention, and this specific compound’s conductivity and thermal stability make it a top candidate. Interest in cleaner, solvent-free organic synthesis leads to more labs adopting this liquid as both a process fluid and recyclable support. Green chemistry rules inspire further modifications—scientists replace or tweak the cation and anion in search of biodegradable versions without losing performance. As scale-up becomes cost-competitive, downstream markets like drug manufacture and renewable material processing show up on the horizon. I’m reminded of the early 2000s, watching old-school chemists frown at the "fad" of ionic liquids; now, many of those same hands turn to these materials as reliable workhorses for both research and production, illustrating how innovation rarely travels a straight line but often circles back, stronger and cleaner than before.

Understanding What’s Special About This Chemical

N-Methylimidazolium trifluoromethanesulfonate isn’t a household name, but in certain labs, it makes a real difference. This chemical combines a positively charged imidazole ring with a trifluoromethanesulfonate counterion. That formula gives it a set of characteristics that push boundaries in research and industry, especially for those working with ionic liquids and advanced electrochemistry.

Solvent Use: More Than Just a Cleaner

Most basic solvents dissolve simple stuff, but this one handles more complex tasks. In electrochemistry and synthetic chemistry, picking the right solvent can shift an entire reaction. N-Methylimidazolium trifluoromethanesulfonate stands out for its high polarity and stability. That means tricky reactions, ones that need salts or strong acids, often run smoother in its presence. Researchers who need a medium for handling tough compounds turn to it for just that reason.

Conductivity and Battery Research

Conventional batteries rely on familiar liquids inside, but chemists keep searching for new formulas that extend battery life or handle more charge cycles. That’s where ionic liquids come in. The low volatility and wide electrochemical window of N-methylimidazolium triflate put it in the running for safer and more robust batteries. I’ve seen journals packed with reports on its ability to support high ionic conductivity without catching fire, which keeps it in the loop for green technology development.

Making Organic Synthesis More Efficient

Anyone who’s tried a complicated chemical synthesis knows the frustration of side reactions and wasted yield. N-Methylimidazolium trifluoromethanesulfonate works as a reaction promoter, especially in transition metal catalysis. The ionic nature of this compound can stabilize catalytic intermediates, leading to higher product yields after purification. That doesn’t just save money—it also means fewer potentially toxic byproducts handle needs for stricter environmental regulations.

Catalyst and Enzyme Support

In enzyme chemistry, water doesn’t always do the trick. Certain reactions need a medium that won’t denature proteins yet still allows for changes to happen efficiently. Scientists mix this ionic liquid with biocatalysts, finding it sometimes boosts enzyme activity while reducing side effects like aggregation. This can open up whole new processes in the pharmaceutical industry and green chemistry, moving away from harsh solvents.

Environmental Advantages Over Old Practices

Hazardous chemicals have left a stain on many fields, both literally and in reputation. N-Methylimidazolium trifluoromethanesulfonate brings lower flammability and less evaporation than volatile organic solvents, which means safer labs. It also doesn’t clog the air with toxic fumes. That’s something every chemist, and anyone working nearby, can appreciate, especially with the focus on reducing environmental impact. The compound’s recyclability adds to the appeal: it often survives reactions unchanged, so users can reclaim and use it again.

Balancing Promise With Caution

Every novel chemical comes with hope and hype, but also questions. While N-methylimidazolium triflate cuts down on some hazards, concerns remain about toxicity if not managed properly. Safety data sheets call for careful handling and disposal to avoid skin contact or ingestion. Researchers must follow evolving best practices—good ventilation, gloves, waste protocols—if they want the upsides without new risks.

Looking to the Future

Chemists continue to put this compound to work in fields like battery technology, green synthesis, and catalysis. As demand for cleaner and safer chemicals grows, uses for N-Methylimidazolium trifluoromethanesulfonate will likely keep expanding. Its unique combination of safety and performance pushes researchers and industry leaders to look beyond traditional solvents, and many are watching closely to see just how far it can go in reshaping the landscape of modern chemistry.

Getting to the Heart of Ionic Liquids

Anyone who has spent time in a chemistry lab probably remembers that moment of awe when a simple tweak to a molecule’s makeup can change everything—its color, its smell, and most important, its potential for something new. N-Methylimidazolium trifluoromethanesulfonate falls squarely into this category of compounds where the practical and the innovative blend. This molecule holds court in the family known as ionic liquids, those curious salts that remain liquid at room temperature.

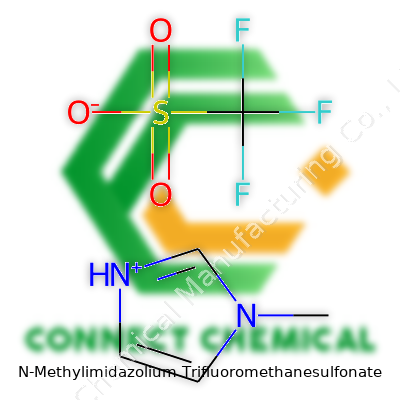

The Shape and Significance of Structure

Let’s break it down. N-Methylimidazolium carries a positively charged core. The imidazolium ring itself features two nitrogens spaced at positions 1 and 3 on a five-membered aromatic ring. Slap a methyl group onto one of those nitrogens—specifically, the one at the “N-1” site—and you’ve got yourself the N-methylimidazolium cation. The charge on the molecule means it worries less about volatility and more about interactions.

Paired with this, trifluoromethanesulfonate comes along as the negatively charged companion. Known in labs as triflate, this anion consists of a sulfonate group, three strongly electron-withdrawing fluorine atoms attached to a single carbon, and a direct connection to sulfur through an oxygen atom. Its chemical shorthand, CF3SO3-, doesn’t do justice to the stability it delivers.

Why Structure Changes the Game

Ionic liquids like this one caused a stir in green chemistry circles. I remember early days trying to coax stubborn organic compounds into dissolving without kicking up a noxious cloud of solvent. N-Methylimidazolium triflate didn’t evaporate the way regular solvents did. That lack of vapor pressure, thanks to those charged bodies, cuts down on fumes and reduces the risk of chemical exposure in the air.

Its structure—the robust imidazolium ring, methyl tweak, and the massive, inert triflate anion—wraps up to create a liquid that can handle extreme chemical environments. The electrons on the triflate anion don’t get distracted easily, so they rarely join in on side reactions. That’s a benefit for anyone running sensitive catalytic processes. You want your precious reagents going where they should, not burning away energy on pointless tangents.

Real-World Impact and Solutions

From direct experience, finding solvents that support both sustainability goals and tough reaction conditions often means making trade-offs. This compound started to pop up in research aiming to replace harsh, volatile solvents in pharmaceutical and electronic applications. Eliminating volatile organic compounds from a process helps prevent workplace accidents and slashes cleanup costs.

There’s always a catch. High cost limits its use outside specialized industries. Producing these ionic liquids at scale could bring costs down. Upcycling waste streams from the chemical industry might offer precursors for their manufacture. Investing more in circular chemistry—taking spent molecules and refreshing them instead of dumping or burning—should help broaden access and keep things on a greener path.

Looking Ahead

As more labs use N-methylimidazolium triflate, lessons learned from pilot plant to factory floor can guide how to design safer, more affordable ionic liquids. Keeping an eye on toxicity, degradability, and recovery methods for both the cation and anion parts will decide whether these chemicals stay as niche solutions or grow into mainstream tools for tomorrow’s clean chemistry.

Why Moisture and Air Sensitivity Still Matter in the Lab

Chemistry brings with it a fair share of routine: weighing powders, opening bottles, sealing argon lines. Now, for anyone working with ionic liquids such as N-Methylimidazolium Trifluoromethanesulfonate, one question comes up often—does it suck up moisture from the air or fall apart just by sitting out? The answer shapes how people handle the stuff, and how results hold up.

Let’s talk moisture. Some chemists almost feel haunted by the memory of hygroscopic reagents. Drying agents, glove boxes, cautious storage—these become habits after enough ruined syntheses. Ionic liquids have a reputation for being tricky with water. With N-Methylimidazolium Trifluoromethanesulfonate, reports and hands-on experience point squarely to real hygroscopic behavior. Leave a sample out, and it draws in water like a magnet. The small ions, especially the trifluoromethanesulfonate part, let water sneak in and mess with purity. Not really surprising, since lots of ionic liquids do just that.

Fact-Check: Is Air a Problem Too?

So, does the air beyond moisture pose a risk? Air sensitivity usually means a chemical changes or gets damaged by oxygen or carbon dioxide floating around. That seems less of a worry here. I’ve never seen this ionic liquid degrade just because of air exposure—what bites is always the humidity. Analytical papers back me up; N-Methylimidazolium Trifluoromethanesulfonate’s structure stays intact in dry air. The issue always circles back to water sneaking in.

Impact: Why Chemists Should Care

Storing a highly hygroscopic material takes some forethought. Any water that slips in changes physical properties. Density shifts. Viscosity drifts. Spectra come back weird. Reproducibility takes a real hit. If you ever run an experiment, record results, then wonder why someone else can’t match them, water levels might be the culprit. It’s a simple step—keep the bottle closed, reseal with dry gas, consider those desiccators your friend.

In an academic setting, first-year graduate students might learn the hard way—an ionic liquid that soaked up moisture over a weekend delivers wacky yields. In an industrial lab, unnoticed water changes process reliability. Small mistakes snowball, costs grow, and confidence in scale-up drops.

Solutions and Safer Practice

High-purity work deserves careful storage. Using a glovebox keeps water away entirely. If that’s not practical, dry boxes or strong desiccators pull their weight. Squeeze as much air from bottles as you can before resealing. Personal tip: don’t trust the cap alone—use parafilm or tape for extra insurance. Consider aliquoting smaller amounts, so you don’t keep opening the main container.

Labeling makes a difference too—date each container, jot down if it got exposed, and aim to use up opened samples fast. Good notes solve mysteries when odd results turn up months later.

N-Methylimidazolium Trifluoromethanesulfonate keeps reminding us that chemistry remains grounded in the basic stuff: keep your hands clean, protect your reagents, trust direct observation. The water is invisible, but the impact sure isn’t.

Why Storage Details Matter More Than Labels Suggest

N-Methylimidazolium Trifluoromethanesulfonate has found work in electrochemistry labs, research setups, and various synthesis procedures because of its distinct physical and chemical traits. Nobody wants dangerous surprises when opening a chemical cabinet, and everyone values an uncluttered process that prevents unnecessary headaches. Storage steps often get glossed over, but just a few mistakes can change a smooth lab day into a cleanup nightmare.

The Real Risks

Chemicals like N-Methylimidazolium Trifluoromethanesulfonate often behave predictably, but the moment moisture or heat gets involved, all bets are off. Ionic liquids grab hold of water out of the air with surprising ease. Over time, letting moisture slide means ruined samples and, in some cases, altered reactivity. The trifluoromethanesulfonate piece of the molecule deserves respect because strong acids or bases can push it to react unexpectedly, throwing off both purity and safety. Peregrine storage makes cleanup harder, and anyone who has needed to re-order rare reagents knows the frustration of waste compounded with new risks.

Lessons from the Bench

Early in my research days, I skipped over basic storage steps and paid for it with ruined product, wasted time, and a lesson that stuck with me. A messy bottle—sticky, partly decomposed—reminded me that air-exposed ionic liquids turn unreliable fast. Crystal-clear labels, routine storage checks, and vigilance matter much more than fancy containers.

Getting the Storage Right

Cool, dry, and dark locations help chemicals like this one last. Room-temperature shelves right beside windows invite sunlight and humidity, so aim for cabinets away from direct light, where airflow doesn’t drag in extra moisture. Airtight containers—glass with a snug screw cap beats plastic every time—keep water vapor out and stop contamination from the start. I’ve learned the hard way that desiccators cost very little compared to the price of ruined reagents, and silica packs tossed inside storage spaces add an extra layer of protection.

If the lab shares space or runs busy hours, secure labeling is simple but valuable. Clear hazard pictograms signal risk to every user, and date-of-opening notes save arguments about how old an unlabeled bottle may be. Chemical refrigerators help if summer heat turns your workspace into a sauna. Avoid repeated thawing and warming cycles; constant temperature keeps chemistry predictable.

What Else to Watch

Never stack incompatible chemicals together, especially where strong bases and acids cluster. Spills happen, so access to spill control materials sits on the front line of safe practice. Regular inspections—checking containers for cloudiness, leaks, or unexpected solid buildup—make a difference. Rushed researchers often skip these habits and regret it later, as I’ve seen too often in shared graduate labs.

A Shared Responsibility

Beyond just sticking to a material safety data sheet, responsible scientists work together to preserve not only their own samples, but everyone’s safety. Reliable habits—proper shelving, regular monitoring, and a culture of open communication—turn routine storage into a backbone of good science. When people respect the quirks and limits of a substance like N-Methylimidazolium Trifluoromethanesulfonate, future syntheses and discoveries run smoother and safer for everyone.

Understanding the Risks

Anyone who steps foot in a lab with N-Methylimidazolium Trifluoromethanesulfonate, often called an “ionic liquid” by chemists, picks up on one thing quickly: this isn’t your everyday salt. Some chemists chase its thermal stability and nifty solvent qualities, but mishandling can land you in a world of trouble. Working with chemicals like this, I’ve had to learn what can go wrong the hard way—skin irritation, trouble breathing, even fires from unlikely sources if you drop your guard. The key is never betting your health on luck or shortcuts.

Practical Measures in the Lab

It sounds basic, but gear matters. Grab goggles that seal well. Regular safety glasses aren’t built for splashes. I’ve seen a minor spill splash upward faster than you’d think, lucky to miss someone’s eyes. Use chemical-resistant gloves, not those light-duty latex ones. Nitrile or even neoprene fits better for jobs where liquids with aggressive ions are in play. A lab coat is your friend—buttoned up, sleeves down. Long pants are a must; shorts and sandals only belong at the pool, not here.

Good ventilation saves headaches, literally and figuratively. Fume hoods aren’t decorations. Before opening the bottle, switch on the hood fan and check the sash height. Sudden whiffs of unknown vapors can bring dizziness and coughing. An open beaker lets molecules sneak into your breathing space. Once, a colleague let vapors build up working out in the open. He lost a whole afternoon recovering.

Handling and Storage Tips

Keep the container tightly closed, away from heat or sparks. This chemical may not ignite as easily as most solvents, but it’s got a mind of its own when mixed with incompatible substances. Never underestimate the surprise of accidental reactions. Store it in a cool, dry place—think chemical storage cabinets with secondary containment in case of leaks.

Label every container, even temporary ones. I’ve caught myself reaching for what looked like a water bottle, only to double-check and see an unmarked flask nearby. It doesn’t take much for a mix-up to get ugly. Write the date received, and keep a log if possible. Unattended bottles can slowly degrade or absorb moisture, and you don’t want to deal with mysterious changes overnight.

Disposal: Don’t Improvise

Pouring leftover N-Methylimidazolium Trifluoromethanesulfonate down the drain is reckless and illegal in most places. Chemical waste collection isn’t glamorous, but playing hero by “making it disappear” builds risk for everyone. Mark the waste bottle clearly and keep it away from any organic solvents unless your waste service says mixing is allowed. Waiting for pickup can be a hassle, yet environmental fines and health risks stack up much faster.

Responding to Accidents

No matter how careful you stay, spills occur. Know where the spill kits sit, and walk through the emergency plan with your team. A little prep on cleanup—absorbent pads, neutralizers, and how to use them—makes the difference between contained mess and a full lab evacuation.

Training isn’t just a box to check. It stops panic when seconds count. Keep a cheat sheet of emergency contacts and a list of first-aid procedures taped in plain sight. Quick action protects your eyes, your lungs, and your coworkers’ health too.

Final Thoughts on Responsibility

Taking N-Methylimidazolium Trifluoromethanesulfonate for granted leads to the kind of close calls that stick with you. Building safe habits protects your health and keeps science moving forward. Standard protocols work because people before us learned from accidents. Leverage that experience, hold yourself—and your team—accountable, and keep every experiment as safe as possible.