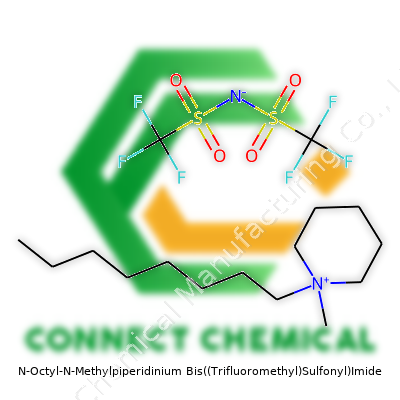

N-Octyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide: Looking Closer at a Modern Electrolyte

Historical Development

Curiosity about ionic liquids started gaining momentum in the late twentieth century, especially as researchers chased breakthroughs in green chemistry and high-performance batteries. The search for reliable, thermally stable alternatives to traditional organic solvents carried scientists down a crowded path of imidazolium and pyrrolidinium salts. Over the years, piperidinium derivatives such as N-Octyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide (often abbreviated as C8MPip-TFSI) have earned attention. Synthetic chemists tried stretching the alkyl chain lengths, trying different ring substitutions, and pairing with the versatile TFSI anion, which pushed this compound into prominent research for safe and robust electrolytes in rechargeable batteries.

Product Overview

This compound doesn’t show up on supermarket shelves or kitchen cabinets. It’s a specialty ionic liquid mainly found in laboratories and pilot plants. Chemical suppliers usually offer C8MPip-TFSI as a high-purity liquid with a deep clear color, bottled under inert atmospheres. Research teams from Japan, China, Europe, and the US treat it as a benchmark solvent for battery and supercapacitor studies. It’s expensive, reflecting its critical role and the complexity of its preparation.

Physical & Chemical Properties

N-Octyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide presents as a clear to faintly yellowish viscous liquid at room temperature. With a melting point well below freezing, it stays liquid even in cold storage, which is a huge attraction for low-temperature battery work. Its density settles around 1.2-1.4 g/cm³. The compound doesn’t explode at the sniff of a spark and resists thermal breakdown up past 300°C, outlasting many classic solvents. The large TFSI anion ensures high ionic conductivity under typical cell conditions and practically zero vapor pressure, making the compound very resistant to evaporation and flammability.

Technical Specifications & Labeling

Vendors provide C8MPip-TFSI with explicit labeling on purity, water content, and residual halide ion. Specialist uses call for water levels below 50 ppm, often achieved only by storing under dry nitrogen or argon. Batch certificates list NMR spectra, mass spectrometry verification, and, for battery applications, precise transfer into electrochemical cells in glove boxes. The molecule’s CAS number and systematic IUPAC name, along with handling precautions specific to perfluorinated anions, appear prominently. Shipping remains tightly regulated to avoid contamination or moisture pickup.

Preparation Method

The journey from raw chemicals to a bottle of C8MPip-TFSI involves plenty of careful steps. Starting with N-Methylpiperidine, alkylation with octyl bromide gives the quaternary ammonium cation. After purification, this cation exchanges halide with lithium bis((trifluoromethyl)sulfonyl)imide in water or acetonitrile, forming the hydrophobic ionic liquid through phase separation. Technicians dry it using vacuum and heating, then run purity checks using NMR and Karl Fischer titration. This method allows high reproducibility and adaptability to small or moderate scale batches, but the stringent requirements for dryness and purity push up the production costs.

Chemical Reactions & Modifications

C8MPip-TFSI’s backbone resists hydrolysis, oxidation, and typical organic side reactions. Modifiers sometimes attach different alkyl groups or switch out the TFSI for anions like FSI or PF6 to tweak ionic mobility. Researchers blend this ionic liquid with lithium salts to form hybrid electrolytes, aiming to optimize conductivity and electrochemical stability. Its piperidinium ring doesn’t open easily, which explains its durability in hostile battery environments, unlike some imidazolium cousins.

Synonyms & Product Names

The chemical literature refers to this compound with different shorthand: C8MPip-TFSI, N-Octyl-N-methylpiperidinium TFSI, or simply piperidinium-based ionic liquid. Manufacturers might list it as 1-Methyl-1-Octylpiperidinium Bis(trifluoromethylsulfonyl)imide, sticking close to the IUPAC convention for global clarity. Abbreviations such as [C8MPip][TFSI] pop up in battery and supercapacitor research, where space is tight and researchers use shorthand with abandon.

Safety & Operational Standards

Researchers handle C8MPip-TFSI with care, even though it’s a big step up from classic flammable and toxic organic solvents. Its low vapor pressure cuts inhalation risks, but gloves and goggles still stay on because accidental contact can irritate skin and eyes, and lab people don’t like chemical surprises. MSDS sheets warn against decomposing this compound over open flames or mixing with strong Lewis acids. It travels in sealed bottles, sometimes double-bagged with desiccants. Disposal follows protocols for organofluorine compounds, since the TFSI anion resists breakdown and needs proper incineration.

Application Area

Battery researchers value C8MPip-TFSI as a safer substitute for volatile carbonates in lithium-ion and sodium-ion electrolytes. Its wide voltage stability window (reaching four to five volts against lithium) sets it apart from most classic organic solvents, allowing chemists to build safer, high-energy batteries with tougher cathodes. Engineering teams test it in supercapacitors, dye-sensitized solar cells, and as an antistatic coating. The IT and automotive sectors keep an eye on this class of ionic liquids as solid-state electrolyte components, seeking operational safety alongside decent cycle life. It also appears in laboratory-scale electroplating baths and can support unusual transition-metal reactions by suppressing water activity and boosting ionic mobility.

Research & Development

Several research programs look to expand the utility of piperidinium-based ionic liquids. Journals regularly track tweaks to the alkyl chain, the cation ring size, or the nature of the anion. The focus lands mostly on meeting battery industry benchmarks: matching or beating carbonate solvent conductivity, matching cycle life under stress, and cutting flammability risks. Teams in Asia and Europe build full battery cells using C8MPip-TFSI, measuring how well the electrolyte stands up to cycling, abuse testing, and extreme climates. Materials scientists also test it for use in printable electronics, owing to its stability and ability to dissolve key conducting polymers.

Toxicity Research

Long-term toxicity research lags behind industrial enthusiasm, as with many modern ionic liquids. Recent work shows low acute toxicity toward common mammalian cell lines, but the environmental persistence of the TFSI anion keeps some regulators up at night. Biodegradability remains modest, and chronic exposure studies have only begun to map out the eco-toxicological profile. Most reports mark the compound as having low vapor emissions, which helps reduce inhalation hazards in workplace settings. That said, safety officers push for closed systems, good ventilation, and limited direct handling to prevent unknown risks. Academic groups call for more robust studies, particularly as larger-scale applications become possible.

Future Prospects

C8MPip-TFSI sits in the front row of advances in battery electrolytes and safe, high-performance energy storage solutions. The move toward electric vehicles, grid-scale batteries, and electronic consumer goods drives exploration of alternatives to organic carbonate solvents, with ionic liquids like this one often leading discussions for next-generation systems. If suppliers and researchers can keep finding ways to drive down costs, boost conductivity, and answer lingering questions about environmental and chronic health impacts, the odds of this class of chemicals rising from laboratory shelves to real-world technology look strong. Tackling energy storage challenges always means wrestling with cost, safety, and performance at the same time. It’s the companies and researchers who keep tuning the chemistry, measuring real-world performance, and keeping a close eye on safety who will shape where this ionic liquid, and others like it, go next.

Where Innovation Meets Ionic Liquids

Long names tend to put people off. Still, N-Octyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide—let’s call it OMPI-TFSI—commands real attention inside labs where new batteries and advanced electronics get built. The roots of its importance start with its identity as an ionic liquid. Unlike regular salts, not everyone can picture a salt that behaves like a syrupy liquid at room temperature. Yet, this property opens up a field of uses in electronics, energy storage, and industrial processing.

Batteries and Energy Storage: Building Better Cells

The push for greener and more reliable energy brings OMPI-TFSI to center stage in battery research. Conventional lithium-ion batteries rely on solvents that can catch fire or degrade over time. OMPI-TFSI, with its wide electrochemical window and stability, offers a safer path. The liquid doesn’t evaporate or burn under usual conditions. That means battery packs using OMPI-TFSI last longer and operate safely, even when pressed hard for performance. In practice, research has shown ionic liquids like this one keep lithium running smoothly between electrodes, which matters for folks who want to drive farther or store solar power longer.

Electronics: Keeping Devices Cool and Reliable

Anyone who has worked with electronics knows heat causes trouble. Microchips pack more transistors than ever, and circuit designers chase materials that handle heat and electrical loads without breaking down. OMPI-TFSI steps in because it resists degradation and supports high voltages. When used in supercapacitors or as part of advanced dielectric fluids, it helps manage heat and enhances device lifespan. Engineers run careful tests, stressing ionic liquids like this one so devices can work in tough environments, be it climate-controlled server rooms or electric cars out on the highway.

Industrial Applications: Cleaning Up and Separating Compounds

Manufacturers look beyond batteries. They use OMPI-TFSI in processes needing resilient solvents that don’t mix with water or mess up chemical reactions. It shines in extracting metals for electronics or recycling rare materials from used gadgets. Since it hardly evaporates and resists breaking down, it keeps unwanted compounds away. In my time watching chemical engineers at work, the move toward these ionic liquids lowers risks and decreases waste, barely producing fumes compared to older solvents.

Risks and Solutions: Safety in the Lab and Beyond

No compound comes without questions. Some ionic liquids can stick around in the environment, so regulatory bodies and research groups run tests to catch any problems early. OMPI-TFSI isn’t as toxic as some other substances used in electronics, yet teams at universities and manufacturers keep looking for tweaks to make it break down faster in nature. Adopting robust waste collection and disposal routines helps contain spills and stop long-term buildup. This approach doesn’t just tick boxes—it actually protects workers and neighbors, making sure labs and plants leave behind as little trace as possible.

Charting the Path Forward

OMPI-TFSI keeps showing up in patents and research papers. Better batteries, safer manufacturing, and electronics that last longer draw directly from its strengths. As more companies search for options that carry less risk and more promise, OMPI-TFSI and other ionic liquids invite continued curiosity and innovation. Staying informed helps bridge the gap between breakthrough science and technologies that touch everyday lives.

Recognizing the Realities of Shelf Life

Every lab worker knows the story: a reagent bottle covered in dust, label faded, contents uncertain. Hoping that it's still good feels a little like rolling dice. With chemicals, shelf life is no minor detail. Take ascorbic acid, as an example. Exposed to air or heat, it degrades into forms that do little you want, whether you’re mixing up food additives or prepping vitamin supplements. Storing it cool and dry serves as the difference between an effective experiment and wasted ingredients.

The Facts Behind Decomposition

No one wants to reach for a material and find a substitute for the actual thing. Instability creeps in through water vapor, light, and heat. Some chemicals, such as magnesium ribbon, lose their spirit by pulling moisture straight from the air, forming a mushy crust. Others, like sodium metal, risk bursting into flames in damp conditions. In research, any unexpected reaction means lost time, unreliable data, and safety hazards. Ask anyone handling peroxides—stored too long, they become ticking time bombs, all thanks to neglected expiration dates and bad seals.

Storage Solutions—from Fridge to Fume Hood

The label on a bottle can’t do all the work. I keep flammables in a yellow-painted cabinet, acid bottles separated, not just for show but to keep life and insurance premiums intact. Temperature swings mess with chemical bonds, so sticking to stable room temps, or going colder in a sealed fridge, keeps things in line. Colored glass plays its part for light-sensitive compounds, while desiccants help with substances quick to grab moisture. My own rule: if seeing crusty caps or weird smells, it's time to toss.

Learning from Real-World Incidents

It doesn’t take a big disaster to know small slips cause harm. I remember a case at a local university, where a storage room housed decades-old jars—some even forgotten by the faculty. After a batch of old ether bottles turned out to be loaded with unstable peroxides, a cleanup team spent weeks managing dangerous waste. That panic could have been dodged by minding purchase dates and making a habit of regular checks.

The Value of Simple Good Habits

Writing notes on every label, keeping a tidy log of purchase and opening dates, and separating reactive pairs: none of these steps sound fancy. Small tasks pay off by keeping everyone safe and research on track. A locked, labelled, well-organized storage space beats a cluttered shelf in preventing problems.

Solutions Built on Common Sense

Teaching basic handling skills early helps more than dense procedural manuals. Training that includes real examples—why you never store acids and bases together, or why plastic sometimes beats glass—sticks with people. Labs investing in temperature and humidity monitoring find out fast when their storage starts slipping. Automatic reminders for expiry dates can save hundreds in wasted material, and a bit of teamwork cleaning out the stockroom every few months sets a good standard.

Final Thoughts

Looking after chemical stability means more than following the rules—it’s about building habits that keep research honest and workers protected. Lost batches, spoiled experiments, or worse, accidents, all trace back to sloppy storage. Respect for the details keeps things running and avoids stories you’d rather not be a part of.

Understanding the Hazards

Chemistry labs often call for focus, patience, and a steady respect for what each bottle actually holds. N-Octyl-N-methylpiperidinium bis((trifluoromethyl)sulfonyl)imide, a mouthful of a compound, stands as a good example. It sits on the shelf with some ionic liquids, often found in batteries, electrochemistry research, and advanced separation processes. Looks might fool you. It doesn’t smoke or give off fumes the way older industrial chemicals do. But it’s not a simple salt you can rub off with soap and water.

This compound brings together organic cations and a highly fluorinated anion. Fluorinated parts in chemicals show stubborn resistance to breaking down. That means once this stuff leaks, it stays in the soil or water. The scientific literature points to possible environmental buildup, especially around research and manufacturing sites. Contact with skin or eyes can cause irritation, like many organic chemicals, but the real concern grows with chronic or repeated exposure. Some studies connect similar fluorinated chemicals with liver effects and damage to aquatic life.

The Day-to-Day Risks

During my own graduate work, I handled a lot of unusual salts and solvents like this compound. Sometimes, the safety data sheet (SDS) tells the whole truth. Sometimes, its story is incomplete until enough research piles up. In the case of these ionic liquids, much of the world still figures out the long-term health and ecological impacts. The lack of strong smell or vapor might lull folks into skipping gloves for a quick measurement. I learned that lesson the hard way with a nasty rash.

Calls to poison control lean on the precautionary principle: just because a chemical’s harm hasn't shown up loud and clear yet, doesn’t mean the coast is clear. Workers or students have the right to ask for chemical-resistant gloves, splash goggles, and lab coats whenever this compound gets opened. Fume hoods deserve regular checks. Spills can't be left to evaporate. Tossing waste in ordinary trash isn’t just lazy—it endangers local water and landfill safety.

Responsibility and Forward-Thinking

Any lab that works with this salt—or any of its ionic liquid cousins—should not treat disposal as a side thought. Waste solvents and contaminated wipes need to end up in hazardous waste bins. Storage should keep everything labeled, sealed, and clear of heat or flames. Think of disaster drills, but for the bench: do you know where the eyewash is? Do you know the procedure for skin contact, inhalation, or accidental ingestion?

More companies and universities have started tracking their ionic liquid inventories. They demand clear documentation of use and waste. That approach doesn’t just meet regulations, it reflects a culture of real respect for colleagues and the planet. It’s not overkill to talk with environmental health and safety officers before bringing new chemicals into a building. With so much yet to learn about these next-generation materials, responsibility often means acting out of caution, not waiting for regulations to catch up. Teach new researchers with real examples of how small lapses led to close calls—stories stick, and influence habits better than any SDS alone.

In the end, safety won’t come from an official checklist alone. It springs up in lab meetings, training sessions, and in a culture where everyone looks out for one another. Respect for complex chemicals means protection for yourself, your coworkers, and the environment. That’s never overreaction—it’s just smart science.

Understanding Typical Purity Levels

Most industries working with chemicals and raw materials care about purity. In pharmaceuticals, labs usually talk about purity in percentages—99% and above for many compounds. Food-grade materials often need over 95%. Lower grades, like technical or industrial chemicals, sometimes range from 90% to 97%. I’ve seen facilities that won’t accept anything less than 99.5% for drug ingredients because a single percent of impurity can ruin a batch and risk safety.

With metals, high-grade copper for electrical wiring runs above 99.9%. In semiconductors, silicon purity climbs so high, anything below 99.9999% won’t cut it. Even tiny specks of impurities can short-circuit devices or make medicines less effective. That level of stringency doesn’t come cheaply, and it often means more checks, more investment in purification, and plenty of discarded material.

How Quality Gets Checked

Companies rely on three main pillars: choosing good suppliers, testing goods rigorously, and tracing every batch back to its source. Auditors visit suppliers, demanding proof that they follow strict standards. Sometimes a supplier’s history gives peace of mind—decades of good product count as much as a piece of paper.

Many labs use analytical tools like chromatography, spectroscopy, and titration to measure what’s inside a material. I remember a time in the quality lab when a batch set off alarms for being “off-spec.” The report pointed to a trace impurity. It turned out a technician rushed the cleaning process, and a bit of the last batch crept in. The whole run landed in quarantine and got destroyed. Everyone learned that even small slip-ups ripple through the system.

Quality assurance teams examine not only what’s delivered, but also the processes behind it. They watch for cross-contamination, check equipment maintenance logs, and sample random bags or bottles. Some places even keep “retention samples”—small stashes of each batch—for years, so if someone questions quality, labs can retest the original product.

Why Purity and Quality Assurance Make a Difference

Most folks overlook why purity matters—until a recall hits the news. Impure raw materials can cause allergy outbreaks, unexpected reactions in patients, or failing electronics. The famous heparin scare in 2008, traced to contaminated ingredients, showed what happens when purity slips. The cost isn’t just measured in dollars, but in health risks and lost trust.

Assuring purity takes vigilance. Cutting corners—maybe skipping tests to save costs—rarely pays off. A single tainted shipment, once it mixes with good product, forces everyone to dig through records and start fresh. Prices go up, customers look elsewhere, and reputations take damage.

Possible Steps Forward

Automating quality tests speeds things up and catches mistakes early, but it won’t replace experienced eyes. Training workers and giving them the tools to spot mistakes matter just as much. Closer partnerships with trusted suppliers build a stronger safety net. More transparency across the supply chain also helps, as customers want to know exactly what they’re getting.

From my experience, teams who treat purity like a top priority avoid most disasters—they keep records, double-check sources, and won’t settle for “almost good enough.” It’s work that often goes unnoticed until something goes wrong, but in manufacturing, that’s the nature of doing things right.

Why Solubility Dictates Everyday Success in the Lab

People spend hours in labs looking for ways to get compounds to dissolve or to play nicely with other materials. Everyone from pharma techs to chemical engineers faces this problem. Without solid data or life experience, choosing the right solvent feels like guessing. Water won’t always do the job. Organic solvents like ethanol or acetone often get results, but only with the right substance. If you’ve ever watched a powder stubbornly float on the surface of a liquid, you know how frustrating poor solubility gets.

Understanding the Compound’s Chemistry

Personal experience taught me that diving into a compound’s structure is step one. Polar compounds don’t like non-polar solvents—oil and vinegar don’t mix for a reason. Ionic materials, like many salts, love water. They break apart and drift through like it’s home. Non-polar molecules, such as certain hydrocarbons, prefer solvents like hexane. Solvents with a similar polarity offer better results. You avoid clumps, cloudy solutions, and wasted time.

Testing Solvents: Where Facts Outshine Guesses

Solubility tables help, but nothing beats putting a tiny sample through its paces across a range of solvents. For example, caffeine slips into water and ethanol, but ask it to dissolve in oils and you get nowhere. Different temperatures and pH ranges also affect results—sometimes even a mild increase in heat helps, so I always keep an eye on temperature limits to prevent decomposition.

Compatibility: More Than Just Blending

Compatibility doesn’t stop at dissolving. If the end product needs a polymer, other additives, or storage in special containers, these choices matter. I’ve watched polymers clump and separate when exposed to the wrong plasticizer or solvent. Polypropylene and polyethylene usually resist polar solvents, while glass handles almost anything. Stainless steel suits acidic mixes but fails with strong bases or halides. Material safety data sheets help spot potential disasters before they happen.

Real-World Hurdles and Progress

Industry stories highlight the risk of cross-contamination, precipitation, and reactivity. Solvents sometimes start reactions that form unexpected by-products. Research journals report dozens of incidents each year that end in supply chain delays or even recalls. Everyone wants reproducible results—switching a solvent can mean tweaking everything from mixing speeds to storage times.

Drawing on Recommendations and Published Data

The U.S. Pharmacopeia, Sigma-Aldrich catalogs, or PubChem collections give tested solubility data. Relying on peer-reviewed journals and expert guidelines supports responsible decisions. There is real risk moving from small bench batches to industrial scale. Lab-scale trials don’t guarantee big-vat success. Staff who understand both underlying chemistry and the quirks of their own facility spot trouble early. I stand by regular team communication and detailed documentation for troubleshooting.

Solutions Learned from the Field

Protocols that include stepwise solvent addition, slow temperature change, and testing per batch save money and avoid reruns. Using small batches and mixing orders from published literature brings peace of mind. With enough practical trial, most teams find the right match—or at least know the risks up front.

Fact-based decisions build trust, reduce waste, and cut downtime. Guesswork in the realm of solubility and compatibility opens the door to expensive mistakes.