N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide: Looking Beyond the Formula

Historical Development

Few years ago, hardly anyone outside research labs talked much about ionic liquids like N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide. Before chemists began tinkering with these salt-like liquids, most folks thought solvents meant water, alcohol, or maybe acetone. Early forms of these room-temperature molten salts showed up in the 1990s, partly because the world started worrying about hazardous waste. Labs watched traditional solvents damage lungs, rivers, and ozone layers. The story began changing as researchers discovered how imide-based anions helped ionic liquids stay stable, non-volatile, and much less flammable. With each year, this class of chemicals picked up a few new advocates, thanks to evolving knowledge about their structure and unexpected performance in batteries, catalysis, and separation procedures.

Product Overview

N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide differs sharply from both classic organic solvents and other ionic liquids. What makes this product stand apart comes down to its long alkyl chain (the octyl group) attached to a pyrrolidinium ring, paired with a bulky, highly delocalized imide anion. This blend lets it act as a hydrophobic, room-temperature liquid able to dissolve oddball chemicals, separate out tough-to-disentangle electrolytes, and hold up under punishing electrical conditions. The presence of the trifluoromethyl sulfonyl group turns the whole formula into an almost non-coordinating anion, keeping reactions clean and ions moving freely. Unlike older solvents, this liquid doesn’t fume up the place or catch fire with a stray spark, and its greasy consistency brings an unusual stability to devices that have to keep running for thousands of cycles.

Physical & Chemical Properties

Pick up a bottle of this ionic liquid and it flows like a light oil, clear and almost viscous. It carries no odor—unlike ammonia or ethanol, you’ll only smell the plastic of the container. Its melting point usually sits far below room temperature, so it stays liquid on a workbench without need for special heating. Its density falls above water but beneath most mineral oils, making it easy to handle without worries about accidental puddles running all over the lab. The vapor pressure level means forget about breathing toxic fumes or watching it evaporate after a weekend left uncovered. As for electrical conductivity, the long alkyl chain lowers it compared to simpler pyrrolidinium compounds, but not by enough to matter in most battery applications. Solubility in water drops close to zero—a huge benefit when separating organics from aqueous waste.

Technical Specifications & Labeling

Every container shipped out from a reputable supplier brings a detailed label: chemical structure, purity (often 99% or higher), water content measured in parts per million, and storage guidance (away from light, keep tightly sealed, no refrigeration needed). Chemical suppliers tag this material with its CAS number, molecular formula, and advise users on trace impurity levels, which can impact sensitive catalytic processes more than anyone likes to admit. Labels usually include handling advice about nitrile gloves, goggles, and nitrile lab coats, even though spills rarely pose the risk of traditional solvents. The labeling doesn’t just warn about the substance—it sets a bar for consistency and customer trust.

Preparation Method

Getting the pure salt into a bottle starts with making the N-Octyl-N-Methylpyrrolidinium cation, usually through standard quaternization: mix N-methylpyrrolidine with 1-bromooctane, stir it in an inert solvent, coax the ions together, purify, and wash away unwanted bromide byproducts. Toss in lithium Bis((Trifluoromethyl)Sulfonyl)Imide in a controlled solvent exchange—the lithium salt swaps out its metal for the organic cation, and the desired ionic liquid forms as a new phase. Later purification with activated carbon and vacuum drying strips out trace minerals and water, stepping up the purity past the point where impurities would affect electrochemical experiments.

Chemical Reactions & Modifications

While the backbone of this ionic liquid resists attack from acids, bases, and radical initiators, skilled chemists sometimes tweak its structure to target specific uses. The octyl chain length can get adjusted for better hydrophobicity or viscosity, and cation swaps with methyl, ethyl, or benzyl groups help designers fit a precise electrochemical window. The anion rarely changes, thanks to its valuable non-coordinating character; those trifluoromethyl sulfonyl groups keep ionic mobility strong and avoid interrupting electrode reactions. Standard modifications might target higher thermal stability or reduced viscosity for special battery or catalysis needs, but the original formula keeps showing strong performance across multiple fields.

Synonyms & Product Names

Depending on which catalog you open, this product may pop up under names like C8MPyrr-TFSI, N-Octyl-N-Methylpyrrolidinium NTf2, or just “Imide-based ionic liquid with long-chain pyrrolidinium cation.” Some suppliers shorten it to [OMPy][TFSI] or combine branding and code numbers. Whatever the name, savvy researchers check the anion and cation before buying—mixing up similar-sounding names can trash a whole batch of experiments.

Safety & Operational Standards

Every technician knows not to let their guard down. Even with low volatility and reduced acute hazards, this liquid still belongs in the hands of trained users in a chemical fume hood. Direct skin contact doesn’t burn or blister but can draw out lipids from your hands and leave long-term irritation. Splashes in the eyes could stick around because of the oiliness, so goggles remain a must. If spilled on benches, the clean-up takes patience—mop up with absorbent pads and dump them in hazardous waste, since regulations haven’t caught up to the subtleties of ionic liquid disposal. MSDS sheets line out every possibility, including long-term aquatic toxicity from fluorinated byproducts if poured down drains. Facilities set up with spill kits, training drills, and regular label reading tend to avoid costly accidents.

Application Area

Engineers working with advanced lithium and sodium batteries reach for this ionic liquid to keep devices running in cycling tests that last months. It shows up in high-voltage capacitors, hydrophobic extraction columns, organic light-emitting diodes, and even as a fixative in biomolecule separations. Its heat stability lets power electronics operate above boiling water temperatures, with no smoke or chemical charring. Researchers trying to separate stubborn chemicals or destroy persistent organic pollutants sometimes pick it, trusting in its ability to dissolve weird molecules and shrug off breakdown under ultraviolet light. Even outside electronics, teams developing new lubricants or drug delivery systems toss a vial into the mix to see if its stability lends new tricks to their blends.

Research & Development

University labs keep turning out papers on how changing the pyrrolidinium ring or swapping out the alkyl chain length alters evaporation rates, ionic mobility, or thermal endurance. Some teams hunt for ways to recycle spent liquids from batteries instead of shipping barrels for incineration. Biochemists poke at possible enzyme compatibility, since traditional solvents kill protein activity almost instantly, but ionic liquids open windows for gentle separation steps. Next-generation battery researchers dunk new electrodes in it and watch the cycling performance edge higher—especially as safer chemistries become a market demand. My own experience with these liquids taught me that small tweaks in lab technique make or break a whole afternoon’s experiment, particularly when scaling from bench to pilot runs, and when collaborating with partners watching their own bottom-line costs.

Toxicity Research

Lab tests break down toxicity at three levels: acute exposure, chronic buildup, and environmental endpoints. Short-term exposure in rats and mice show almost no immediate harm, with median lethal dose values far exceeding those for standard lab solvents. That said, any substance built from long-chain organics and fluorinated anions raises questions about persistence. Studies in aquatic systems warn about accumulation possibilities, particularly for breakdown products like perfluorinated sulfonates, which resist normal wastewater treatment. Research partners dig into ways to capture and destroy these before they escape into streams. Regulatory agencies in Europe and Asia keep updating threshold exposure levels as new animal and cell culture data filter in, and most professional workplaces err on the side of caution by treating every drop as potentially hazardous till shown otherwise.

Future Prospects

Markets keep chasing better battery performance, safer electronics, and greener processing; this ionic liquid has a shot at doing all three. Research teams across continents pour time into lowering production costs, finding faster routes to make the compound from cheaper starting materials, and improving environmental controls over fluorinated waste. Software modelers and physicists try to predict which tweaks in structure yield greater longevity in storage devices. Eco-focused companies search for replacements or modifications allowing easier post-use recycling. For all the promise, success will depend on commitment to field testing, responsible waste management, and honest communication about safety and durability—goals everyone in research, manufacturing, and environmental health benefits from sharing.

Understanding the Importance of Ionic Liquids

A lot of the biggest changes in energy storage and high-tech manufacturing come out of unlikely places. Years ago, chemists realized a class of chemicals—ionic liquids—could change how we work with electricity and solvents. N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide belongs to that club. People call it by shorter names like OMPTFSI or just trim it down to the main parts, but no matter what name, this stuff earns its reputation.

Powering Better Batteries

My own first introduction to this ionic liquid came during a university project on safer lithium batteries. We kept running into problems with volatile, flammable solvents. The professors pointed us toward ionic liquids like OMPTFSI. Lithium batteries see real improvements when they swap out their usual electrolytes for something like this. Research from the Journal of Power Sources points out how OMPTFSI doesn’t burn easily, and it won’t freeze up at low temperatures. This pushes lithium-ion cells to last longer, run cooler, and stay safer—a huge deal after seeing some close calls with battery fires in labs.

Car makers and consumer electronics companies pay attention to these improvements. The combination of octyl and methyl units let this ionic liquid stay stable and allow lithium ions to slip through easily. This means higher conductivity without giving up safety. I know colleagues who won research grants to move this from academic projects into commercial prototypes. The excitement isn’t hype; the results speak for themselves.

Electronics Manufacturing Steps It Up

On the factory floor, clean processes make all the difference. In semiconductor work, you need solvents that don’t evaporate or leave residue. OMPTFSI handles that, providing a non-volatile option for processes such as etching microchips and cleaning delicate electronic surfaces. The trifluoromethylsulfonyl part repels water and keeps out impurities. Production lines run smoother, with fewer breakdowns and less environmental fallout.

I saw this firsthand while consulting for a start-up designing flexible solar panels. The engineers wanted a solvent that would not react with exotic metals but still maintain electrical performance. Ionic liquids like OMPTFSI replaced older, toxic chemicals on their line. Waste streams shrank, and both output and employee safety improved.

Shifting How Green Chemistry Works

The world faces tough questions about chemical waste and pollution. Every step toward greener chemistry counts—true for big companies and small labs alike. OMPTFSI often acts as a catalyst and solvent for reactions where water or traditional solvents create problems. By swapping in this ionic liquid, teams cut down hazardous waste and make recycling of reaction products easier. Publications like Green Chemistry highlight these advantages; in some cases, studies document over 50% reduction in solvent waste.

Challenges and the Road Ahead

Of course, nothing comes without trade-offs. OMPTFSI’s complex synthesis and rare starting materials put it out of reach for basic applications. Costs stay higher than for typical solvents or battery chemicals. Scientists look for ways to scale up production and lower expense; more efficient supply chains and recycling programs may help. Regulators also watch for long-term environmental effects. Still, as demand for safer, high-performance materials ramps up, the unique capabilities of OMPTFSI inspire real-world progress in energy, electronics, and sustainability.

Working With Chemicals: Real Life Hazards

Accidents with chemicals leave an impression you don’t forget. It’s not always the result of ignoring rules—sometimes the threat hides in plain sight. I remember working in a college lab where a bottle of nitric acid looked like water. No label, no warning, just a glass bottle next to the sink. A student washed her hands, looked confused, and only after a sting did she realize something was off. Luckily, she avoided serious harm. Not everyone is that fortunate.

Label Everything and Know Your Enemy

Identifying what you’re working with matters more than all the fancy tools in your kit. Unmarked bottles, faded stickers, vague names—these open the door to mistakes. The Material Safety Data Sheet (MSDS) covers everything you should know at a glance, from the chemical’s dangers to what happens if you spill it. No one expects to memorize the whole thing, but everyone working with chemicals ought to read it once. Knowing just one or two crucial facts, like what burns skin or creates dangerous fumes, can make all the difference.

Simple Gear Saves Lives

Lab coats, gloves, and goggles feel like overkill for mixing dye—or so it seems—until something splashes or a container leaks. Proper gloves make for more than clean hands; they protect against nasty burns and reactions. Every time I skipped my goggles, worrying about fog or comfort, I’d hear about someone ending up in the emergency room with a chemical splash to the eye. It doesn’t take much.

Respirators, fume hoods, and double-sealed bottles have saved more than a few lungs and lives in chemistry labs and factories. Ammonia, bleach, strong acids—these don’t ask for permission before filling a room with dangerous vapors. Keeping things well-ventilated is as basic as safety comes.

Clean Workspaces and Quick Response

Leftover residue, puddles, and splattered powder attract trouble. I’ve seen someone stack bottles on a sticky benchtop, only for the labels to peel and create confusion. Spills need cleaning right away—not at the end of the shift. Safety showers, eyewash stations, and fire extinguishers belong right where everyone can reach them, not stuck behind locked doors or hidden in storage.

Emergency drills help, too. In high school, a girl mixed products in the janitor closet and ended up coughing on chlorine gas. No one stood around wondering; they dragged her to fresh air and called for help right away because we’d practiced what to do.

Training and Experience Beat Complacency

Familiarity often feeds overconfidence, not safety. Seasoned workers sometimes handle substances with less care than a first-year student, just because “nothing’s happened yet.” This kind of thinking catches up quickly.

New staff need solid training—not a quick walk-through, but a hands-on session that covers what happens when things go wrong. Every manager should encourage workers to speak up about unsafe conditions. In several labs where I’ve worked, open-door safety talks kept incidents low and trust high.

Continuous Improvement

Lab and plant safety isn't just about checklists; it’s about a culture of looking out for everyone, including yourself. Simple habits—like always glancing at labels, wearing the right gear, cleaning up promptly, and keeping a lookout for subtle hazards—save time, money, and sometimes lives. Staying humble, prepared, and informed proves worth it, every single shift.

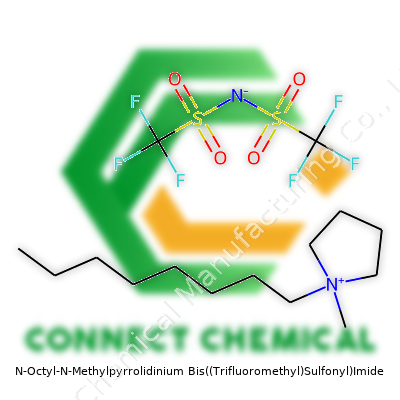

Chemical Structure

N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide, often shortened in laboratory circles to OMPTFSI, fuses two distinctive chemical components into one structure. On the one side sits the N-Octyl-N-Methylpyrrolidinium cation, a nitrogen-containing five-membered ring, with a methyl group and a straight-chain octyl group jutting off it. This cation creates a spacious, fairly hydrophobic structure, which helps push out water from any solution it occupies. On the anion side, TFSI^- boasts two powerful trifluoromethyl groups attached to sulfur and nitrogen centers. These sulfonyl structures deliver impressive stability and charge delocalization, making TFSI^- one of the most trusted anions in ionic liquid science.

Here’s the breakdown at the atomic level: the pyrrolidinium portion holds a nitrogen atom in the middle of a five-membered ring, an octyl group (eight carbons pumping out a hydrocarbon tail), one methyl group, and the rest of the ring’s saturated carbon backbone. The TFSI anion drops a bomb of electronegative power—trifluoromethyl (-CF3) groups each giving off a strong electron-withdrawing effect, tied through sulfur to a nitrogen, then out to another sulfur with the same -CF3 setup. These two parts—cation and anion—lock together by electrostatic attraction. The whole combination resists crystallization and has low volatility, which is part of its appeal for folks in battery and solvent work.

Molecular Weight

The exact molecular weight of OMPTFSI adds up all those atoms: carbon, hydrogen, nitrogen, oxygen, sulfur, and fluorine. The N-Octyl-N-Methylpyrrolidinium cation weighs in at about 198.4 g/mol. Factoring in the TFSI anion, which weighs 280.2 g/mol, the final count lands at roughly 478.6 g/mol for the whole salt. This high molecular weight, and the bulkiness of each ion, changes the behavior of the liquid—a factor anyone in battery testing or ionic transport research quickly comes to respect. Most newly engineered ionic liquids trim down on volatility and toxicity by using similar recipes, but OMPTFSI’s purposeful weight leans into stability rather than speed.

Why Structure and Weight Matter

Some colleagues in the energy storage lab talk about these chemicals like they’re roadmaps. The path of a molecule—whether it’s short and squat or long and winding—affects the way it moves electricity, the rate it takes up or releases ions, and whether it starts to break down under load. OMPTFSI’s structure fits the modern need for robust, non-volatile electrolytes. Researchers look for large ions so charge moves efficiently but the components themselves hang tight and don’t evaporate or decompose under heat. Ionic conductivity and viscosity both depend on this physical footprint. A smaller ion zips through solution but may not withstand aggressive cycling inside a battery, while a molecule like OMPTFSI brings longevity and safety into the mix, even if it sometimes slows the charge.

Implications and Practical Solutions

OMPTFSI and its kin have shaped rechargeable battery design. Their resilience under voltage makes them valuable for new generations of lithium metal and lithium-ion technologies that demand more out of a salt than simple conductivity. Labs tune the hydrocarbon tail and methyl size, or swap out TFSI for something even more chemically clever, to adjust everything from melting point to electrochemical window. Environmental groups have concerns about fluorinated compounds building up in water streams, so chemists also scope out greener anion swaps. Ongoing research seeks the same balance: hold strength and safety, tweak speed and reactivity, and try to leave a lighter environmental mark along the way.

Science Moves Forward with Strong Chemistry

Anyone who’s worked on a battery cell or mixed up ionic liquid cocktails in the lab can see why the structure and weight of molecules like OMPTFSI matter. You learn quickly that molecular details drive the big changes, whether that’s a battery that lives longer or a process that finally moves past flammability worries. Chemistry has always been the battleground of tiny choices and stubborn realities, and OMPTFSI captures that push for stability you can count on.

Everyday Concerns Around Ionic Liquids

Ionic liquids keep showing up in the headlines. Every lab talk and seminar in the field of chemistry or materials science gets around to the same question: is this stuff going to last on the bench, or will it degrade before we even get results? New researchers ask it most, but even those with years of experience have stories about wasted time and strange, unexpected reactions. Ionic liquids offer all sorts of benefits—non-flammability, low volatility, tunability for specific tasks—but stability under normal storage and usage conditions should come first.

Water: The Silent Saboteur

One detail often ignored in general presentations is how sensitive many ionic liquids are to water in the environment. Once you open the bottle, moisture in the air starts working its way into your sample. For instance, imidazolium-based ionic liquids with BF4- or PF6- anions can break down or hydrolyze over time even if the bench looks dry. This can lead to formation of HF or other toxic byproducts, turning what was a routine task into a health risk. I learned this the hard way as a graduate student after a batch of ionic liquid I had stored for a week lost its expected properties. That smell wasn’t just a nuisance—it warned of bigger problems.

Lab Air and Light: Hidden Influences

Air isn’t just a problem because of water. Oxygen can play its part, especially with ionic liquids containing sensitive organic cations or anions prone to oxidation. Light exposure throws another wrench into the works; some ionic liquids change color or degrade if left out in a brightly lit room. Plastic or glass storage helps a bit, but only if combined with careful planning around storage time and exposure. The color fade of certain salts I left near the window in my first year taught me that lesson.

Purity and Impurities: More Than Just a Number

Commercial suppliers may offer high-purity ionic liquids, yet contamination with halides, metals, or decomposition products often slips through. I found some lots arriving with trace yellow or brown colors, or with viscosity nowhere near specification. At best, this muddies analytical measurements. At worst, it can alter whole reaction pathways. Rigorous quality control at the supplier and in the lab helps, but so does skepticism: always check online forums and published audits of suppliers before purchase. Recognizing a failed bottle before committing a week to failed experiments saves headaches.

Packing and Storage: The Basics Still Matter

Many problems start with simple storage mistakes. Using old or cracked containers introduces leaks. Loose caps let in ambient air faster than you realize. Even cheap lab tape sometimes lets through enough air over a month to do damage. Refrigeration and inert gas blankets extend lifetime for the more sensitive ones. My best results came from splitting working quantities into small ampoules, keeping the rest sealed, and only ever opening what I needed.

Moving Toward Practical Solutions

Short-term, robust documentation helps the most. Many labs post labels stating date of opening and major handling notes. This seems basic, but when several students share a bottle, it makes tracking changes much easier. Standardizing checks, like periodic viscosity or conductivity testing, helps spot early changes and catches instability before it ruins experiments. For the future, further research could focus on developing hydrophobic or more robust anions and cations. While no single fix solves every issue, chemical innovation paired with practical lab habits lays the groundwork for safer, more reliable work with these versatile liquids.

Why Proper Storage Means More Than Safety

Anyone working with chemicals like N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide knows that safety and shelf life hang on good storage habits. This compound pops up in batteries, solvents, and often in labs searching for reliable ionic liquids. A quick mistake in handling or storage can blow through thousands in wasted material, damaged equipment, or, worse, risk to health. I’ve seen labs grind to a halt after a bottle turned gummy or leaky because someone overlooked the basics. Simple routines make all the difference in keeping both people and budgets intact.

Stability: What This Chemical Likes

N-Octyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide — or OMPYR-TFSI for short — comes with a few quirks. It's hygroscopic, so it sucks up moisture if left open. Exposure to air for even a couple of hours lets in enough humidity to foul a sample. Over time that extra water can change both its physical properties and even some chemical reactions involving the liquid. I keep it in an airtight, amber glass bottle, always sealed tight, and only open it in a dry box or glove bag filled with argon, especially in the summer.

Storage Conditions Everyone Should Follow

Temperature matters for OMPYR-TFSI. Leaving this chemical at room temperature, out of sunlight, delivers the best long-term stability. Direct heat speeds up any breakdown, and UV rays can nudge decomposition forward. Refrigerators don’t always help, since temperature swings with frequent door openings can drag unwanted moisture straight into the bottle. Consistent, moderate temperatures about 20-25°C do the trick. I put the bottle in a low-traffic chemical cabinet with good ventilation and dedicated desiccants. Silica gel packets, changed out every couple of months, soak up stray moisture like a charm.

Label Everything, Track Everything

One practice sharpens chemical stewardship faster than anything: labeling and record-keeping. I use waterproof labels with the full name, date received, and my initials. Tracking expiration dates and condition checks keeps surprises away. Electronic logs, snapshots at each opening, and a running tally on how much sits in inventory keep everyone honest and careful, especially in busy teams sharing stock. Reordering falls into place, fewer compounds get lost, and nothing gets used past its prime.

Hazard Management and Spill Control

No one should handle OMPYR-TFSI without eye protection and gloves, even just transferring it between bottles. Spills on bench tops lead to slippery messes and could find a way into drains — not good for health or the environment. I keep spill kits nearby with absorbent pads, not just paper towels or old rags, and treat cleanup like it matters. In cases of fire, standard CO2 or dry chemical extinguishers do the job — water can make ionic liquids like this foam or splatter.

Tighter Rules, Fewer Surprises

No single fix guarantees perfect storage, but a bit of respect for OMPYR-TFSI pays off. Desiccants protect quality. Labeled bottles keep mistakes away. Clear logs build trust across teams. Training new staff not just to follow rules but to understand why those steps matter creates a culture where both the science and the scientists thrive. That’s progress worth fighting for, bottle by bottle.