N-Octyl-N-Methylpyrrolidinium Bromide: A Deep Dive

Historical Development

Scientists first synthesized N-Octyl-N-Methylpyrrolidinium Bromide during a period of explosive growth in ionic liquid chemistry. About two decades ago, chemists recognized pyrrolidinium cations as promising building blocks thanks to their stability. As industries hunted for new solvents and electrolytes less toxic than traditional salts, this specific compound stood out. Its quaternary ammonium structure attracted researchers interested in both thermal and chemical robustness. From the earliest patents to modern lab protocols, this salt’s journey mirrors the increasing demand for adaptable and environmentally aware chemical ingredients. Academic literature started tracking practical uses, from catalysis to advanced energy storage, opening a field that blends curiosity with market pressure.

Product Overview

N-Octyl-N-Methylpyrrolidinium Bromide steps up in both research and commercial sectors as a specialty ionic compound. Chemists see value in the unique pairing of the octyl and methyl groups with the pyrrolidinium ring. The resulting cation, paired with bromide, becomes useful in organic synthesis, phase-transfer catalysis, and even as a test electrolyte for new battery chemistries. Bulk suppliers and niche distributors list it in their catalogs, sometimes under slight variations in naming. Seeing how it gets priced, the market signals a compound still moving from lab curiosity to a stable ingredient for advanced formulations. Researchers often mention the substance for its combination of moderate hydrophobicity and charge stability.

Physical and Chemical Properties

Engineers take note: these salts hold up under high temperatures without breaking down easily. The long alkyl chain—octyl—adds to its oil affinity, making it less prone to water or acid decomposition. Many report its melting point climbs well above room temperature, bringing a waxy solid with a faint odor. Solubility plays a major role. N-Octyl-N-Methylpyrrolidinium Bromide dissolves in dimethyl sulfoxide, acetonitrile, and other polar solvents, but resists simple mixing with straight water. Chemists studying ion mobility pay close attention to its viscosity and ionic conductivity, which sits in the mid-range compared to shorter or longer tail analogs. Ions from the sample act predictably in electrochemical setups, showing both chemical and electrostatic consistency.

Technical Specifications & Labeling

Quality-minded labs look for precise technical data: high assay (often above 98%), limited moisture, and specification sheets citing heavy metal content below acceptable thresholds. The packaging typically states such details, along with CAS numbers and batch information. Reliable suppliers give spectral data, titration results, and storage guidance. In regulatory contexts, European and international shipping laws require strict labeling for transportation. Product codes and standard unit sizes—typically from grams to kilograms—address projects ranging from benchtop studies to small-scale production campaigns. Any deviation in specs can lead to unexpected outcome, especially when designing sensitive analytical or synthesis work.

Preparation Method

Most chemists start with pyrrolidine and perform alkylation using octyl and methyl halides in a controlled, stepwise fashion. Good ventilation and proper PPE go hand-in-hand with each shake, stir, and reflux, because alkyl halides don’t play nice with careless handling. Early steps call for precise temperature and time control to avoid side reaction. Following this, extraction and washing—often with polar and non-polar solvents—remove byproducts before vacuum drying. Purification often turns to recrystallization, guided by thin-layer chromatography or NMR monitoring. Yields can fluctuate based on reagent grade, purity of the starting materials, and small tweaks in work-up conditions. Those details mean the difference between a usable crop of product or an afternoon of extra troubleshooting.

Chemical Reactions and Modifications

This salt doesn’t just sit on a shelf. Chemists crank up the possibilities by swapping the bromide for other anions, creating analogues for different conductivity or solubility requirements. The alkyl chain can also serve as an anchor for further functionalization, such as attaching dye ligands or cross-linking groups for materials science. Catalysis studies point to this salt helping shuttle ions across phase boundaries, while adding molecules that adjust electronic or structural properties. Some labs even build on its backbone for advanced supramolecular chemistry, tailoring architecture at the nanoscale. These routes open not just academic curiosity but also industrial relevance where tailored performance improves bottom line.

Synonyms and Product Names

You’ll find this compound with a few names, depending on distributor tradition, regional standards, or the context of a research report. N-Octyl-N-Methylpyrrolidinium Bromide may appear as 1-Methyl-1-Octylpyrrolidinium Bromide, OMPrBr, or similar trade names in catalogues. Detailed technical documents often include both International Union of Pure and Applied Chemistry (IUPAC) names and shortened versions. Distributors may add their batch IDs or variant codes, and some suppliers use brand-protected tags for specialized markets. In my experience flipping through catalogs, it pays to double-check synonyms before placing an order or running a literature search—one letter swapped or skipped can throw off a critical experiment or procurement process.

Safety and Operational Standards

Material safety data points to skin and eye irritation risk, especially when handling neat powder or concentrated solutions. Manufacturers warn about potential ingestion or inhalation hazards, and recommend gloves, goggles, and fume hood use. Disposal ties back to local and national regulations for quaternary ammonium salts and halogenated waste. Proper labeling during storage and shipping matches international hazard pictograms and United Nations recommendations. Labs keep detailed logs of inventory and incidents, not just for compliance, but to keep staff confident and operations smooth. Regular safety training and up-to-date chemical hygiene plans make a difference here; nobody wants to deal with an emergency caused by lax safety culture.

Application Area

Researchers use N-Octyl-N-Methylpyrrolidinium Bromide in many directions. Electrolyte research taps into its ionic conductivity in experimental batteries and capacitors. Phase-transfer catalysis takes advantage of its amphiphilic nature, shuttling reactants across boundaries that would otherwise stall a reaction. Some medical and pharmaceutical teams eye this salt for potential drug delivery methods, while membrane scientists see its use in customizing nanofiltration systems. In synthesis labs, its unique properties promote reactions that struggle under more traditional conditions. Analytical chemists rely on the clear, repeatable ionic behavior for calibration standards and reference points. Its growing profile in the materials science world hints at applications in advanced coatings and composite fabrication.

Research and Development

The race to improve ionic liquids and designer salts fuels ongoing exploration. Universities and industrial labs alike run tests looking at performance tweaks—pushing toward more efficient electrolytes or safer, more selective catalysts. Green chemistry initiatives focus on reducing environmental impact during production and use, seeking routes that skip toxic reagents or minimize waste. Startups and established chemical giants both back research to lower manufacturing costs and unlock new sectors, such as sustainable plastics or digital electronics. For every reported publication, there’s usually a handful of follow-ups aiming to tweak the recipe, modify a chain, or extend shelf life. Feedback between industry and academia keeps the pipeline stocked with ideas and real-world problems to solve.

Toxicity Research

Toxicology profiles don’t stay static. Ongoing tests look at acute and chronic exposure in both lab animals and environmental microcosms. Early data suggests similar quaternary ammonium compounds can have moderate aquatic toxicity and bioaccumulation risks. Regulatory bodies track new studies and update lists of controlled substances based on fresh findings—what looked benign in small-scale evaluation sometimes looks different as larger environments come into view. Labs routinely review published work, both to protect their teams and ensure downstream impacts don’t surprise customers, regulators, or the public. Safer alternatives or improved formulations emerge in part from scrutinizing every signal in these toxicity screens.

Future Prospects

Forward-looking companies and labs dig in to answer industry demand for greener, smarter chemicals. Sustainable sourcing and improved synthesis stand front and center; techno-economic analysis asks not just about performance but lifecycle cost and impact. Energy and electronics manufacturers see a path to better batteries, supercapacitors, and even flexible devices drawing on this salt’s unique ionic balance. Drug developers latch on to controlled-release potential, and water treatment innovators see promise in customizable filter properties. Each development takes cues from real-world feedback and regulatory shifts. The cycle of improvement, validation, and application branches outward as more eyes land on this compound’s robust chemical profile matched with adaptable applications.

The Real-World Uses of a Complex Compound

N-Octyl-N-Methylpyrrolidinium Bromide doesn’t roll off the tongue, but every part of its name hints at the roles it plays in science and industry. You won’t find it on grocery shelves or hear about it on morning news, yet it shapes the world of chemistry in small but measurable ways. My first experience with this compound involved research on ionic liquids in an academic lab. The professor warned us: handle it with gloves, measure it with care, and always label your beaker. At the time, nobody outside of specialty labs talked about it, but now it pops up in research articles and patent filings across the globe.

Unlocking New Possibilities in Chemistry

Researchers prize N-Octyl-N-Methylpyrrolidinium Bromide for its ability to dissolve, solubilize, and separate. Its ionic structure nudges it into a category called “ionic liquids.” These chemicals remain liquid at low temperatures and show impressive thermal stability. Scientists often look for alternative solvents that cut down hazardous waste. Here, this compound stands out. In my experience, switching from volatile organic solvents to ionic liquids reduces evaporation, lets processes run longer, and exposes workers to fewer fumes. A colleague once shared how swapping in ionic liquids slashed both waste and energy needs in her pharmaceutical process.

In the world of organic synthesis, this compound works as a solvent or a catalyst, supporting key chemical reactions and making selectivity easier to achieve. Pharmaceutical labs want reactions to go smoothly, with fewer byproducts and higher yields. Repeated trials show that N-Octyl-N-Methylpyrrolidinium Bromide often improves reaction performance. Scientists in analytical labs use it to help separate tough mixtures, such as chiral drugs or proteins. Its ability to “tune” chemical environments lets experts fine-tune processes that must meet tight regulations.

Emerging Roles in Clean Technology

The push toward sustainable industries has brought new attention to this compound. People working on electrochemical devices, like batteries, see value in its stable, conductive properties. This ionic liquid supports energy storage in “supercapacitors,” which charge fast and last through thousands of cycles. In my own study group, using this compound in prototype batteries cut down heat buildup and increased storage capacity. Researchers aim to stretch these gains into larger, grid-scale storage. If that succeeds, it could change how we store solar or wind energy.

Water treatment labs also look to N-Octyl-N-Methylpyrrolidinium Bromide. Its surfactant qualities help it grab and trap heavy metals or organic contaminants from water supplies. Imagine a remote village with polluted groundwater: scientists can deploy technologies built on compounds like this to filter out poisons more efficiently than older methods allow.

Responsible Use and Safety

With new chemicals come safety questions. Safe handling, waste management, and full disclosure remain critical. The chemical industry increasingly calls for green credentials and transparent supply chains. My experience tells me: transparency reduces accidents, cuts down poisonous byproducts, and gives local communities a say in what enters their environment.

N-Octyl-N-Methylpyrrolidinium Bromide highlights the spirit of discovery in chemistry. It isn’t a miracle fix, but its presence in so many forward-looking projects shows that even lesser-known compounds deserve attention. Real progress depends on safely unlocking the hidden value of every tool—no matter how hard its name is to pronounce.

Diving Into the Molecular Blueprint

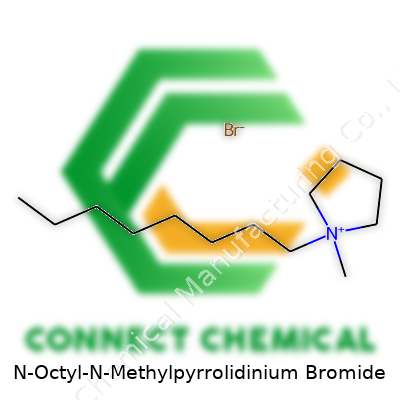

N-Octyl-N-methylpyrrolidinium bromide takes shape from the pyrrolidine ring, that classic five-membered loop with a nitrogen at its core. This foundation is hardly unique in chemistry, but subtle tweaks transform it into something with its own set of uses and quirks. Once a methyl group locks onto the nitrogen, the structure picks up a compact, positively charged face. Extend that reach by adding an octyl group — eight carbons in a row — and the molecule grabs hold of a new personality, balancing between water-loving and oil-loving environments. The formula, C14H30BrN, distills this design in numbers: carbon chains built for flexible chemistry plus the heavy-hitter, bromide, acting as the counterion.

Everyday Chemistry: Beyond Textbook Drawings

Anyone who spends time in a lab or flips through journals recognizes the importance of a structure that brings opposites together. The long octyl tail sets up hydrophobic interactions, working well in systems that need to wedge grease and water together — or break them apart. That slick trick turns out key for applications like surfactants and even the formation of ionic liquids. The real-world value grows from this combination, not just because it sounds good on paper, but because separating or mixing materials faster means saving resources or improving outcomes. The positive charge from the methylpyrrolidinium helps stick the molecule to surfaces, shift solubility, and open up a toolbox of chemical modifications.

A Legacy of Research Tied to Function

Chemists already look to similar ionic liquids to handle tasks big industry throws at them, from solvent replacements to catalysts in green chemistry projects. N-Octyl-N-methylpyrrolidinium bromide fits that trend, providing a backbone for safe, stable and versatile solutions. Research published in the Journal of Physical Chemistry and in panels at the ACS highlights how tweaking the alkyl chain grows or shrinks the molecule’s binding power and environmental footprint. Its bromide ion, beyond balancing charge, helps modulate conductivity—especially in batteries or as an electrolyte in advanced capacitors. These features do not simply read as specs; they forge ahead in labs trying to ditch volatile organic compounds or improve separation efficiency in pharmaceuticals.

Safety and Environmental Concerns Deserve Attention

Even the most promising chemistry can pose challenges. Bromide salts and long-chain ammonium compounds prompt questions about toxicity, persistence, and safe disposal. The trick comes in recognizing both the benefit and the burden. Real safety starts with responsible use. Labs need solid data on biodegradability and pathways for breakdown. Incorporating closed-loop systems and recycling or neutralizing the compound after use goes a long way toward protecting water sources and minimizing risk to both people and ecosystems. This approach is not just smart; it is essential for sustainable chemistry.

What's Next? Smarter Molecules, Smarter Use

Keep an eye on regulators, as more data about their environmental impact enters the conversation. Funding robust studies and transparent reporting of outcomes can drive best practices and give everyone more confidence in these advanced materials. More chemistry isn’t always better, but better chemistry, with thoughtful molecular design and real respect for downstream effects, pushes progress where it matters.

Why Storage Details Matter for Chemical Safety

N-Octyl-N-Methylpyrrolidinium Bromide doesn’t show up as a household name. Labs and manufacturers handling specialty chemicals know it's not about the name—it's about the risks, responsibility, and what can go wrong if corners get cut. I’ve worked with similar ionic liquids and strange salts; unplanned reactions, spills, and exposure incidents have kept people up at night. A clear-headed approach with a focus on proven practices gives everyone a safer workplace.

Keep Moisture and Contaminants at Bay

No one wants to lose purity in the storeroom. Water absorbs fast, and over time, N-Octyl-N-Methylpyrrolidinium Bromide turns sticky, lumpy, or even clumpy if humidity seeps in. It pays to use airtight containers—preferably glass or high-quality plastic with secure lids. Silica gel packs or desiccators in storage areas help keep the moisture low. It’s a straightforward habit: store away from sinks, open windows, or areas where water vapor lingers.

Temperature and Light Concerns

Heat can change things quickly. Most ionic liquids keep their cool at room temperature, but sudden swings—especially in non-climate-controlled areas—can cause slow decomposition or alter physical properties. Cool, stable storage out of direct light preserves the shelf life. Aluminum foil or opaque containers can limit light exposure, and I’ve watched bottles degrade sitting on sunny shelves, wasting expensive materials. Keeping inventory off radiators or south-facing windows protects both product and people.

Separate from Incompatible Chemicals

Careless stacking of chemicals sets up unwanted reactions. Bromide salts like this one may react with strong acids, oxidizers, or other reactive groups. Organizing storage by known compatibility charts—often found posted by safety officers or seen in well-run labs—prevents cross-contamination and reduces the odds of an emergency. Labeling every container and group together similar risk profiles. I’ve seen near-misses come from innocent mistakes, like mixing incompatible waste streams or failing to segregate reagents properly.

Personal Safety—It’s Not Just Paperwork

Handling brings people right up against the hazards. Gloves and eye protection aren’t just for show. The need for proper lab coats, safety goggles, and gloves shows up in every chemical hygiene plan for a reason. Skin exposure to N-Octyl-N-Methylpyrrolidinium Bromide can cause irritation or allergic reactions, and inhalation of dust or fumes is another risk. Fume hoods and ventilated enclosures keep the workspace safe. Any practice that limits skin and breathing contact makes sense. Spills should get cleaned with disposable towels or spill kits, not bare hands or rags that go back in the laundry.

Training and Emergency Preparation

Experience doesn't guarantee memory during a crisis. Refresher sessions on spill response, fire hazards, and chemical first aid keep teams sharp. Even seasoned professionals need reminders: Know where the eyewash, showers, and exits stand. SDS (safety data sheets) stuck on the inside of cabinets or uploaded where everyone can find them solve confusion in the middle of an accident. Simple facts—like proper response to ingestion, inhalation, or splash—save time and prevent panic.

Responsible Disposal

Unused or spent N-Octyl-N-Methylpyrrolidinium Bromide won’t leave the lab with normal trash. Waste codes, local rules, and company policies all play into safe, legal disposal. I’ve seen firms fined heavily not for the use, but for treating chemical waste like regular garbage. Chemical waste programs and regular audits reduce both liability and environmental impact.

Practical Takeaways

Taking shortcuts on storage and handling leads to damaged goods and puts lives at risk. Following practical, field-tested guidelines—dry, cool, well-organized storage; real protective equipment; and sharp emergency prep—pays off every time. These habits aren’t just rules, they’re the foundation of a responsible workplace, backed by everyday experience and broader safety data.

What Is N-Octyl-N-Methylpyrrolidinium Bromide?

N-Octyl-N-Methylpyrrolidinium Bromide pops up in labs and certain manufacturing settings. Its name alone signals that this isn't something you stumble into at a grocery store. Workplaces lean on specialty chemicals like this for tasks involving solvents and electrolytes or for research focused on ionic liquids.

Health and Safety Questions

There’s always curiosity, sometimes anxiety, about safety and toxicity. Chemical safety should never be an afterthought. People expect clean air and a safe environment. If a compound lands on your desk, you want to know what it might do if inhaled, swallowed, or touched. You can’t always tell by a smell or a quick glance at the beaker.

This specific compound does not have a vast library of public toxicity studies. That raises uncertainty. Similar ionic liquids have raised eyebrows for their ability to irritate skin or eyes, and some can stress the liver if exposure lasts too long. I remember working with chemical stocks in college, pulling out gloves, eye protection, and lab coats every time a bottle had words longer than a short sentence. It wasn’t paranoia. Accidents can make you learn the hard way.

Facts from Research

My searches show that N-Octyl-N-Methylpyrrolidinium Bromide brings risks if swallowed or handled without care. The European Chemicals Agency lists it as causing skin, eye, and respiratory irritation. Rats exposed to related pyrrolidinium salts had some organ toxicity at high doses, especially with long exposure. There’s also evidence from similar compounds showing threats to aquatic life if drained away carelessly.

Acute poisoning cases don’t hit headlines, but chronic risks matter. People who mix, store, or ship these types of chemicals carry responsibility beyond themselves—no one wants pollution trickling into sewer systems or someone facing hospital visits because a label was skipped.

Best Practices from Experience

Relying only on the safety sheet feels like wishing on a coin. My advice is to wear gloves, goggles, and lab coats without hesitation. Always check local rules on chemical disposal. Fume hoods aren’t just for show, and it’s wise not to eat or drink near workspaces containing exotic chemicals. Even in well-run labs, spills happen fast. Quick action, like having spill kits and eye wash stations, limits harm.

Manufacturers rarely enjoy publicity from careless spills. Everybody remembers the headlines when rivers or lakes suffer from chemical leaks. Companies that promote strong training and push for regular safety audits lower injury rates, and investors appreciate fewer workplace accidents.

Safer Alternatives or Improvements

Science keeps looking for less hazardous substitutes in both labs and industries. Ionic liquids themselves emerged as “greener” options to replace volatile organic solvents, but not all achieved that promise. Some trade low evaporation for risk of persistence in nature. Good rule: always look for a safer or biodegradable option if it does the job.

Clear communication about risks—through labels, data sheets, and training—gives everyone better odds. Knowing what you’re working with changes decisions from guesswork to health protection. Personal responsibility matters: nobody wants to bring home hidden toxins on work boots or sleeves. If supervisors foster respect for protective gear, not just compliance, workplaces feel a lot safer.

Looking Beyond the Label

Many labs and manufacturers rely on N-Octyl-N-Methylpyrrolidinium Bromide for ionic liquid research and battery electrolyte development. The bottle’s purity grade often tells part of the story, but people overlook how purity touches product performance and safety. The difference between “technical grade” and “analytical grade” means more than a marketing tweak; it sets the baseline for what’s possible in real-world applications. Analytical grade usually promises 98% or higher purity, with precise impurity profiles—something that matters when every percent influences experimental outcomes. Technical grade products might only guarantee around 95%, sometimes less, often with less disclosure around contaminant identities.

Why Purity Sets the Rules

N-Octyl-N-Methylpyrrolidinium Bromide has become a staple in advanced materials, from electrochemical cells to extraction processes. Any hint of contamination throws results off-track. One batch from an overseas supplier hit my benchtop with “99%” claimed, but mass spectrometry showed bromide content barely making 97%. Lab staff lost hours tracking unexplained anomalies. Purity isn’t about chasing a laboratory ideal; it’s about minimizing downtime, rerun costs, and making sure your results stand up to scrutiny. Nobody wants to rerun a week-long test because a trace solvent or metal ion ruined the outcome.

Grades in the Market: What You Really Get

Suppliers usually sort N-Octyl-N-Methylpyrrolidinium Bromide into categories like technical, laboratory, and analytical grade. The most reputable vendors provide certificates with detailed impurity breakdowns. Suppliers open to third-party verifications move to the top of my list. Analytical grade, at 98% or above, remains the gold standard for sensitive research. For some industrial routes, 95% suits bulk processes where a touch of impurity won’t sink product specs, but that rarely flies in battery research or chromatography.

Quality Control: What Labs Should Demand

Labs that skip verification make life harder down the line. Running regular NMR or HPLC screens beats relying on a printed number. The stories about supplies changing from batch to batch carry weight. Purity isn’t static. Suppliers sometimes tweak routes or source precursors from different vendors. Consistent sourcing and open lines with your chemical supplier, in my experience, lower risks and help ensure your projects run smoother.

Pathways to Better Standards

Lab managers who expect more transparency push the market towards higher standards. I look for suppliers who issue a new certificate with every batch, not just a generic product sheet, and who welcome customer feedback. Some labs—especially those working on scale-up—pool resources for group testing. Shared data gives negotiating power and sharpens detection of recurring problems. Open conversations between chemists and suppliers help the industry catch contamination sources early, and standardized certification builds trust in the supply chain.

Final Thoughts on Grade and Purity

People don’t buy N-Octyl-N-Methylpyrrolidinium Bromide for its name—they buy it for consistent, reliable performance in demanding settings. That’s impossible without real purity, documented every time, backed by traceable, open-source data. Setting higher expectations and running a quick confirmation test on new batches keeps labs a step ahead and makes every experiment, and every product, a bit more reliable.