N-Octylimidazolium Hydrogen Sulfate: Commentary on Development, Application, and Future

Historical Development

Chemists started searching for better solvents decades ago when classic organic solvents kept posing fire, toxicity, and environmental risks. In that search, the family of ionic liquids, which includes N-Octylimidazolium hydrogen sulfate, caught the attention of academic groups and industry labs. By the late 1990s, researchers realized that tuning the structure of the imidazolium cation could change physical properties in ways that open up new applications, from green synthesis to catalysis. As pioneers tinkered with substituting side chains and changed the acids attached to the imidazolium ring, the octyl chain and hydrogen sulfate combo stood out for its mix of hydrophobicity and ionic character. Practical uses started growing in the early 2000s, and the number of papers jumped each year. This shows that new ionic liquids, like the octylimidazolium group, don't just appear overnight: they emerge from relentless adjustment and patience in the lab, always driven by actual needs in cleaner reactions, safer solvents, and new separations.

Product Overview

N-Octylimidazolium hydrogen sulfate appears as a viscous, colorless or light-yellow liquid at room temperature. It brings low volatility to the workbench and features a high ionic content. Chemists working with this molecule soon notice how it dissolves both organic and inorganic substances, handling everything from metal ions to tricky organic molecules. The long octyl side chain tweaks its balance between water-loving and water-hating tendencies, letting it take on tasks stymied by either water or classic organic systems. This balance opens the door for new kinds of reactivity, as well as stabilization in new formulations that need robust, adaptable media.

Physical & Chemical Properties

With a melting point below room temperature, N-Octylimidazolium hydrogen sulfate stays liquid under most ambient conditions. Its low vapor pressure discourages loss to evaporation, a big advantage for safety and environmental goals. The octyl group gives it enough hydrophobicity to craft two-phase systems with water, and the hydrogen sulfate counterion offers notable acid strength. Electrical conductivity remains decent thanks to its fully ionic nature, making it useful in applications like batteries or electrochemical synthesis. The viscosity can be high compared to water but sits in a manageable range for stirring and pumping in industry or lab work. Water solubility, while moderate, enables enough miscibility for extraction or catalysis without runaway mixing. Its density sits well above water—experienced workers quickly spot the difference during separations or extractions.

Technical Specifications & Labeling

Industrial suppliers usually provide N-Octylimidazolium hydrogen sulfate at purities above 98%. Trace metals and halide contaminants sit below strict thresholds, usually under 200 ppm, since these can interfere with catalysts or cause unwanted decomposition. Color must remain within visual limits, often judged by APHA or Hazen color standards. Acidity titrations confirm the strength and quality of the hydrogen sulfate function, with manufacturers usually providing detailed batch analysis sheets. Labels must carry UN identification for safety transport, and both Globally Harmonized System (GHS) and local hazard warning symbols mark the proper use cases. Storage on operation floors should follow robust secondary containment, as spills can create slippery surfaces and pose minor acid hazard. Shelf life depends on container integrity and exposure to air or light—often, manufacturers set typical recommendations not out of strict decomposition risk, but to ensure optimum performance in sensitive processes.

Preparation Method

The classic route begins by mixing 1-octylimidazole with the proper strong acid, typically sulfuric acid, under controlled cooling. The reaction needs attention to exotherms as acid meets organics and starts salt formation. Slow acid addition, often over an hour, avoids hot spots or runaway local pH drops. The ionic liquid separates after the reaction, often forming a distinct heavy layer, which can be washed with organic solvents like diethyl ether to remove impurities. Afterwards, vacuum drying ensures removal of traces of unreacted acid or water. In larger plants, this process moves into stirred reactors with built-in temperature and pressure monitoring, sometimes under inert atmospheres to prevent unwanted oxidation.

Chemical Reactions & Modifications

N-Octylimidazolium hydrogen sulfate plays dual roles, serving as a reaction medium and contributing acid for various catalytic cycles. The imidazolium component holds up well against most nucleophiles and electrophiles under standard conditions, allowing for one-pot syntheses where conventional solvents might fail due to toxicity or volatility. Modifications arise primarily on the alkyl group or the counterion. Swapping to longer chains increases hydrophobicity, affecting partition behavior. Shifting to other acidic counterions like methanesulfonate creates systems with tuned acidity or oxidation power. In reactions, it supports catalysis in esterifications, oxidations, and polymerizations due to its robust ionic structure and the persistent acidity of the hydrogen sulfate anion. The molecule can also anchor phase-transfer catalysts or stabilize reactive intermediates when classic organic solvents might quench the desired transformations.

Synonyms & Product Names

In catalogs and research papers, this compound appears as 1-octyl-3-methylimidazolium hydrogen sulfate, 1-octylimidazolium hydrogen sulfate, or sometimes abbreviated as [OiMIM][HSO4]. Synonyms often reflect systematic nomenclature, sometimes swapping “imidazolium” for “imidazolinium,” though the chemistry stays the same. Trade labels occasionally include company-specific identifiers or product codes. Awareness of synonyms matters when sifting through older research or foreign-language papers—familiarity with the multiple names prevents missed insights.

Safety & Operational Standards

Anyone working with N-Octylimidazolium hydrogen sulfate should maintain chemical goggles, gloves, and splash shields due to its moderate acidity and potential to irritate skin and eyes. Spills require neutralization and careful cleanup, as the liquid can create very slippery conditions, especially around metal and tile. Waste protocols recommend collection and specialist incineration, avoiding direct release into wastewater streams due to both acidity and aquatic toxicity. OSHA and EU REACH both require clear labeling and traceability from production to disposal. Training all staff working near storage or transfer points cuts risk—many minor incidents come down to simple mistakes like open containers or forgotten gloves. Proper ventilation, even for low-volatility liquids, helps control fumes in case of accidental acid evolution.

Application Area

This ionic liquid serves in multiple technical fields. In organic synthesis, its acidity and stability permit esterifications, alkylations, and polymerizations with improved yields and cleaner processes. In separation science, its unique solubility supports rare-earth extraction by creating two-phase systems where metals selectively partition into the ionic liquid phase. In battery R&D, the ionic nature and low vapor pressure lend themselves to electrolytes in advanced electrochemical devices. The ability to dissolve both polar and non-polar organic compounds attracts labs developing new catalyst systems for clean manufacturing, optoelectronic materials, and smart polymers. Waste gas scrubbing, including SOx and NOx removal, can benefit from its high thermal and chemical stability. In each of these areas, the balance struck between hydrophobicity and ionic acidity makes it a strong alternative to both volatile solvents and corrosive mineral acids.

Research & Development

R&D teams remain active in modifying the imidazolium cation and the hydrogen sulfate counterion to further tune properties like conductivity, solubility, and catalytic activity. Analytical labs work to map how trace contaminants in production batches impact reaction selectivity or device performance. Teams in green chemistry labs publish new protocols calling for reductions in toxic byproducts and better recyclability. Electronic engineers look for tweaks that would allow safer, longer-lived batteries and capacitors based on these ionic media. Collaborative efforts between academia and industry keep the pipeline robust, aiming for cost reductions and scale-up routes that retain purity and performance. Ongoing conferences always include fresh data on structure-function relationships, real-world deployments, and lessons from early adopters. This active conversation ensures the field doesn't stagnate—real progress in ionic liquids flows from honest comparison, open troubleshooting, and steady feedback from the end users.

Toxicity Research

Toxicology studies to date show moderate acute toxicity for most imidazolium-based ionic liquids in aquatic systems. The longer alkyl side chains, such as the octyl group, can increase bioaccumulation risk compared to their shorter cousins. Testing in cell cultures and small animal models points to local irritation and, at higher doses, systemic effects—mostly linked to surfactant properties and acid strength. Discharge into aquatic environments must be avoided, as sublethal concentrations can impact fish and invertebrate enzyme systems. Occupational exposures have triggered rare cases of skin reaction in those with preexisting sensitivities. Studies ongoing in environmental chemistry teams focus on breakdown products in wastewater and possible remediation routes. Regular monitoring of workplace air, surface, and water contamination help spot and address lapses before health issues arise.

Future Prospects

The drive to replace hazardous solvents and inefficient reaction media ensures ongoing growth for molecules like N-Octylimidazolium hydrogen sulfate. Advances in ionic liquid recycling, including back-extraction and electrochemical regeneration, raise hopes that future applications will balance cost, safety, and environmental impact. AI-driven modeling now helps predict which structural tweaks lead to gains in specific performance metrics, so next-generation variants may arrive faster than their predecessors. Researchers in the field continue tradeoffs between chain length, counterion selection, and manufacturing cost—deeper understanding of how subtle differences play out in real applications will open doors for wider commercial roll-out. Toxicity mitigation, both through structure design and better end-of-life strategies, remains essential for long-term success. This compound and its cousins suggest that the era of “one-size-fits-all” solvents may be fading—flexible, smart solvents built for purpose keep moving from niche to norm in labs and factories worldwide.

Understanding Its Place in Modern Chemistry

N-Octylimidazolium hydrogen sulfate isn’t the sort of name that pops up at the dinner table, but this ionic liquid has started grabbing attention in laboratories and manufacturing plants. Over years spent watching trends in green chemistry, I’ve noticed how these liquids push industries toward less toxic processes. Chemists value N-Octylimidazolium hydrogen sulfate because it brings unique properties—high thermal stability, low vapor pressure, and the ability to dissolve both organic and inorganic substances. In practical terms, this means industries can use it in ways that cut down on volatile organic compounds, which often escape into the air and cause environmental headaches.

Helping Along Cleaner Reactions

Ionic liquids like N-Octylimidazolium hydrogen sulfate show up most in the search for better catalysts. Labs rely on its ability to speed up reactions without needing extra heat or pressure, slashing energy demand. Some years back, I watched a pilot project swapping out conventional acids in biodiesel production for this very compound. Not only did the process run cleaner, but it also produced less waste. The result: a boost for both efficiency and the environment.

Catalysis isn’t its only job. Separation and extraction processes, especially for metals and rare earth elements, often turn harsh and dirty. Traditional solvents introduce a real mess of pollution and complicated disposal. Here, N-Octylimidazolium hydrogen sulfate steps in as an alternative. Its chemical makeup lets it latch onto various ions and carry them out of waste streams or ores, trimming back the need for harsh chemicals. This shift supports better handling of resources and cleaner downstream products.

Environment and Workplace Safety Take a Front Seat

Ionic liquids drew me in while working on a waste treatment project in graduate school. We hoped to find substitutes for solvents that threatened worker health or leached into waterways. N-Octylimidazolium hydrogen sulfate, with its low evaporation rate, helped build a process where fumes became a memory, not a hazard. Since then, industry data has backed up these lab results, showing meaningful drops in toxic emissions.

Regulatory trends suggest that companies picking up on these safer solvents can get out ahead of tightening rules. That edge doesn’t just cut risk; it often saves money through fewer compliance headaches and friendlier public relations. Modern supply chains look for partners who care about safety and sustainability, which means chemicals like this stand to grow in use.

What Comes Next?

While applications keep growing, practical challenges remain. Cost sits near the top—ionic liquids often come heavier on the wallet than traditional acids or solvents. Scaling up production could drive down prices, opening more doors beyond specialty industries. Chemists and process engineers across the country keep experimenting, aiming to recycle ionic liquids like N-Octylimidazolium hydrogen sulfate instead of treating them as single-use. That kind of change would solve both environmental and economic challenges, letting more people benefit from these advances.

From my own experience sitting through endless trial runs and safety meetings, I’ve learned innovation rarely lands overnight. Still, every industry reaching for cleaner, safer methods finds itself returning to the toolkit provided by compounds like N-Octylimidazolium hydrogen sulfate. Its story gets told in every lab swapping toxic solvents for something better.

Understanding N-Octylimidazolium Hydrogen Sulfate

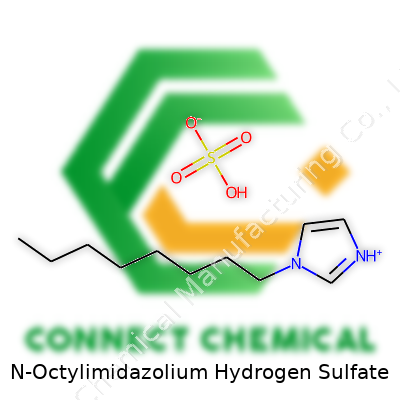

In laboratories and chemical industries, N-Octylimidazolium Hydrogen Sulfate pops up as an ionic liquid worth a second look. Its formula is C11H21N2+·HSO4-. The compound features the N-octyl side chain extending from the imidazole ring, partnered with a hydrogen sulfate ion. Scientists see more than just letters and numbers here—this molecular structure pushes boundaries in green chemistry.

Why the Formula Matters

Anyone who has worked in synthesis finds that ionic liquids like N-Octylimidazolium Hydrogen Sulfate are changing the playbook. Traditional solvents often come with fire hazards, nasty odors, and troubles in waste disposal. Ionic liquids such as this one step up with low volatility and thermal stability, nudging lab work towards safer ground. It’s not only about the numbers in C11H21N2+·HSO4-; their performance genuinely shapes reaction outcomes.

I remember running organic extractions with volatile solvents under the fume hood, covering my bases and hoping accidents stayed far away. The moment ionic liquids entered the scene, especially those based on imidazolium, that stress dialed down. Less odor, fewer risky vapors, reduced environmental load. The formula points to a structure that can stand up to heat without breaking a sweat. That means less energy wasted maintaining careful temperature control and more reliable scale-ups from lab bench to pilot plant.

Applications Shaped by Structure

This specific combination, N-Octylimidazolium cation with hydrogen sulfate anion, offers more than a safer solvent. The long alkyl chain in the cation tunes the liquid’s viscosity and dissolving power. For researchers, this means a route to dissolve reactants that laugh at other solvent choices. Catalysis, separation processes, or extraction of bioactive compounds all benefit. Hydrogen sulfate as the counter anion also brings mild acidity to the mix. That touch of acid can speed up certain organic reactions, like esterification or alkylation, taking the pressure off additional acid catalysts—less chemical waste, fewer complications.

A report from the Royal Society of Chemistry highlights how these ionic liquids can cut energy use by as much as a third compared to traditional solvents. That type of efficiency can shave real money from industrial bills and leaves a lighter carbon footprint in its wake. With environmental policy tightening around the globe, every chemical process that reduces hazardous byproducts gets a warmer welcome.

What Could Improve?

Despite all the promise, ionic liquids like N-Octylimidazolium Hydrogen Sulfate face hurdles. Cost sticks out. Synthesis for these tailored molecules can get pricey. Widespread commercial adoption means researchers and manufacturers need to focus on routes that cut costs without draining resources. Toxicity gets flagged too—just because a liquid doesn’t volatilize easily doesn’t mean it belongs in the ecosystem. There’s ongoing work looking at long-term environmental effects, aiming for ionic liquids that remain benign throughout their life cycle.

Smart Moves Forward

Lab workers, engineers, and manufacturers eye ionic liquids for more than their shiny safety record. Every process needs scrutiny: balancing lab results, environmental health, and production costs. N-Octylimidazolium Hydrogen Sulfate brings promising chemistry, yet its place in industry depends on careful hands, more research, and a nudge toward greener synthesis.

Understanding the Stuff on the Shelf

N-Octylimidazolium hydrogen sulfate isn’t just any lab reagent. It belongs to the group of ionic liquids, which are catching more attention because of their versatility in green chemistry and industrial processes. These chemicals can help with tasks from catalysis to extraction and can also make certain reactions run smoother. But anyone who’s ever worked in a lab — where time is short and spills are memorable — knows that proper storage keeps work safe and projects moving.

Basic Storage: Not Just Common Sense

Experience in shared labs taught me that even the smartest people forget basic storage rules. N-Octylimidazolium hydrogen sulfate doesn’t demand high-tech storage, but it responds poorly to careless handling. This compound absorbs water easily, so humidity creates headaches quickly: think clumpy solids, unpredictable concentrations, or loss of purity. High humidity can trigger degradation, which defeats the purpose of using a pure reagent in the first place. That’s why it does best in tightly sealed containers, using glass or plastic that resists chemical attack.

A dry shelf, away from direct sunlight and drafts, usually works well. Desiccators add an extra layer of security—cheap insurance against moisture. Exposure to water doesn’t just shorten shelf life; it can also alter how the substance reacts or increase the chance of a messy accident during an experiment.

Temperature: More Than Just Room Temperature

Most recommendations point to “cool, dry place,” but it pays to know what that looks like. I’ve lost batches to heat waves in buildings without proper air conditioning. This liquid is stable at room temperature, but warmer environments can speed up unwanted changes or cause containers to break down. Refrigeration isn’t a must for every lab, but keeping it out of hot closets or window sills goes a long way.

Labeling and Safety Go Hand in Hand

Mislabeling or grabbing the wrong bottle happens more often than many admit. A clear label with the full name, date of arrival, and hazard information saves hassle later. N-Octylimidazolium hydrogen sulfate isn’t especially toxic, but splashes on skin or in eyes sting. That means gloves and goggles should stay within reach, along with spill kits and eyewash stations. Good storage always connects with good habits – knowing where danger sits and preparing for it keeps people and projects safe.

Keeping It Out of the Wrong Hands

In shared facilities, chemicals walk off or mix up more often than outsiders think. Designated storage spaces with access logs or basic inventory checks prevent confusion and loss. It’s not about fancy surveillance, just being aware of inventory and teaching respect for the chemicals on the shelf.

Solutions That Work in Real Labs

The reality is that no single storage setup covers every possible scenario. In my work, we set up humidity monitors and simple logbooks. Silica gel packets tucked inside supply cabinets proved to be an easy fix for moisture, since labs often run hot or damp. Shared wisdom, not expensive tech, solves most problems.

Guidelines matter, but commitment from everyone in the lab shapes how well they work. Consistent labeling, regular checks for leaks or crusted lids, and a culture of asking questions all keep storage reliable. Rather than letting new chemicals stack up on any spare shelf, a bit of attention keeps future projects trouble-free and safe.

Bringing Lesser-Known Chemicals Into Focus

People often talk about common chemicals and their dangers—like bleach in the laundry or ammonia under the sink. Most folks don’t hear much about ionic liquids, including N-Octylimidazolium Hydrogen Sulfate. Scientists have used these ionic liquids for advances in batteries, clean energy, and chemical engineering. Safe packaging and handling get a lot of attention in labs, but real-life spills and accidents never feel distant enough for anyone who’s actually worked with them.

Looking Beyond the Label

N-Octylimidazolium Hydrogen Sulfate gets praise for being less volatile, less flammable, and often more “eco-friendly” than older solvents. But less volatility does not always mean fewer health risks. For example, hugging close to the beaker and sniffing this stuff won’t fill your nose with strong fumes like ammonia, but that doesn’t mean it can’t slip past gloves or hang around on a benchtop. The point is, less odor and less sting in the air make it easier to forget that skin contact and long exposure still bring risk.

Known Toxicity: Limited Data Means Real Caution

Toxicity studies on N-Octylimidazolium Hydrogen Sulfate remain thin. Structure-wise, these imidazolium-based salts may show some toxicity similar to other ionic liquids, with research hinting at cell membrane disruption and aquatic toxicity. One study from 2014 flagged that certain imidazolium salts become harmful to aquatic life even at low concentrations. Another research group suggested that long alkyl chains (like octyl) raise the risk of bioaccumulation—meaning the stuff could stick around in living tissue longer than anyone wants.

Most manufacturers provide a safety data sheet (SDS), and reading these always reminds me how little we know about new chemicals until demand forces long-term studies. The SDS for N-Octylimidazolium Hydrogen Sulfate lists standard precautions: wear gloves, goggles, launder exposed clothes, and avoid pouring down the drain. The lack of in-depth toxicology testing means the “not known to cause cancer” stamp shouldn’t make anyone careless. Over the years, I’ve seen new chemicals get fast-tracked for use before researchers discover chronic effects—sometimes years down the road.

Practical Steps for Safer Handling

Anyone handling N-Octylimidazolium Hydrogen Sulfate should always use proper personal protective equipment. Nitrile gloves work better than latex because the compound’s oily texture slides past thin latex more easily. Full goggles, sleeves, and working with a fume hood make sense—especially if transferring larger quantities or mixing with other reactive materials.

Waste should go into hazardous containers meant for ionic liquids, not the general trash or sink. Perfect practice means labeling bottles with names and hazard warnings, storing them out of reach from heat strands or sunlight, and keeping a spill kit on hand. Education wins out over shortcuts. Trainers and supervisors should review incident reports, even for near-misses, so teams learn before accidents hurt anyone.

Transparency, Not Fear

Nobody expects researchers or technicians to ban every new solvent or ionic liquid. Instead, choosing careful storage, protective gear, and getting the word out about proper disposal helps reduce risk to people and the environment. Pushing for new studies, especially independent toxicity research, will tell us more than any safety sheet written before field experience builds up. We need a shift toward keeping our labs and workplaces honest, informed, and quick to adapt—because the unknowns with these “green” chemicals deserve just as much respect as the old ones stacked in dusty cabinets.

Breaking Down Its Physical Appearance

N-Octylimidazolium hydrogen sulfate stands out even at first glance. It's a liquid at room temperature, not a powder or a solid block. Whenever I see the word “imidazolium,” I picture something that’s likely part of the ionic liquid family, and this one fits that profile. The clear to pale amber color makes it easy to distinguish from darker industrial chemicals. Since it doesn’t solidify at room temperature, keeping it stored or transferred through pipes becomes a lot less troublesome.

Texture and Handling

N-Octylimidazolium hydrogen sulfate carries a bit of heft. Its viscosity feels much closer to syrup than water. Try pouring it, and it flows slower, with some resistance. That thicker texture arises from the long octyl chain attached to the imidazolium ring. Anyone handling the liquid will also notice there’s not much smell at all, making time in the lab a bit more comfortable compared to acidic or solvent-heavy substances.

Spills don’t splash everywhere, either. This thicker consistency helps make cleaning up easier than with low-viscosity liquids that can run wild on a bench top.

Melting and Boiling Points

High melting and boiling points allow this compound to remain stable across a wide range of temperatures. Most ionic liquids like N-Octylimidazolium hydrogen sulfate melt far below 100°C, often hovering around 20-40°C, and boil much higher than water—sometimes staying liquid long after other solvents have already vaporized or decomposed. A colleague once said, “You know it’s special when you can autoclave it and it just keeps calm.”

Working with compounds that don’t evaporate or break down when you crank up the heat can save a lot of grief in synthesis or extraction processes. It cuts down on waste and repeated runs.

Solubility and Compatibility

I’ve always appreciated how adaptable ionic liquids can be, and this compound is no different. It dissolves nicely in water due to its ionic nature but doesn’t mind the company of some organic solvents, either. That balance gives chemists a wider playground. Instead of being forced to use harsh or toxic solvents, you can rely on N-Octylimidazolium hydrogen sulfate for gentler extractions or catalysis.

The ability to switch between phases or blend with certain organics means less hazard and more efficiency. Dealing with fewer chemical incompatibilities opens up space for greener approaches in chemical processes.

Thermal and Chemical Stability

One reason I find this compound particularly valuable: it stays put even under tough conditions. It's resistant to light and oxygen exposure, so you don't see it breaking down or yellowing on the shelf over time. That stability means a longer shelf life, which saves money and headaches from constant reordering and replacement.

Factories and labs with busy schedules need materials they can rely on, and I've seen situations where switching to more robust ionic liquids led to fewer production stops. Chemical stability also supports the push for greener chemistry, as less frequent disposal translates into less pollution.

Potential Solutions for Safer and Smarter Use

With any chemical, no matter how stable, safe handling remains top priority. Proper labeling, sealed storage, and training for all handlers help prevent misuse. Adopting industry best practices enhances lab and factory safety, especially with newer materials that some team members might not know well yet. Reliable supply chains and robust quality checks also support consistent performance. Industry-wide collaboration can achieve safer, cleaner methods by tapping into the impressive stability and versatility of compounds like N-Octylimidazolium hydrogen sulfate.