N-Octylimidazolium Tetrafluoroborate: A Modern Chemical Story

Historical Development

N-Octylimidazolium tetrafluoroborate did not arrive overnight. Chemists began experimenting with imidazolium-based ionic liquids in the late 20th century, looking for options beyond traditional volatile solvents. The urge to find safer, greener alternatives pushed researchers to imidazolium salts with various alkyl chains. The addition of the octyl group opened new doors, as extended alkyl chains offered both improved hydrophobicity and notable thermal stability. Over decades, publications started tracking the performance of these ionic liquids in real experiments, such as catalysis and electrochemistry. Experience has shown that innovation in this field grew from persistent trial-and-error, often in crowded research labs that could easily have gone unnoticed but contributed quietly to a wave of safer chemical progress.

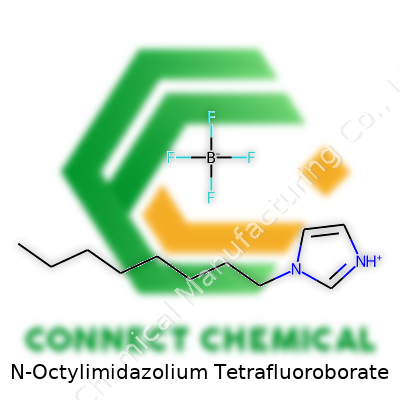

Product Overview

In its most recognizable form, N-Octylimidazolium tetrafluoroborate features an imidazole ring holding an octyl chain wrapped around a tetrafluoroborate anion. This combination delivers a substance that flows easily at room temperature and couples oil-loving and water-loving properties. Scientists appreciate the way it dissolves stubborn organic molecules as well as some salts. Those who have worked with these salts remember the feeling of handling something with both real substance and surprising versatility—neither like thin water nor dense oil.

Physical & Chemical Properties

The addition of a long octyl group to the imidazole core fundamentally shifts the salt’s behavior. Clear to pale yellow in appearance, this ionic liquid avoids strong odors and offers a viscosity that resists spills but pours steadily. Its melting point tends to stay below 30°C, which means normal laboratory environments can keep the salt liquid without special heating. Tetrafluoroborate imparts chemical stability, resisting breakdown even at higher temperatures and in the presence of many reactive compounds. Water solubility drops off dramatically, a fact noticed every time someone tries to clean out a reaction flask—the hydrophobic tail clings stubbornly to surfaces. Conductivity, key for electrochemical uses, remains steady but not the best in its class; still, it stands out against organic solvents in both ionic movement and lifespan.

Technical Specifications & Labeling

Manufacturers and suppliers list N-Octylimidazolium tetrafluoroborate with clear technical benchmarks. Purity often exceeds 98%, with minor impurities sometimes flagged on detailed safety data sheets. Shelf life runs several years when kept away from moisture. Packaged in amber glass to block light, labels display batch number, full molecular structure, storage temperature suggestions, and relevant hazard pictograms. I have seen institutions demand certificates of analysis for every new batch—no one wants to risk a sensitive experiment to a contaminated bottle.

Preparation Method

Researchers build N-Octylimidazolium tetrafluoroborate using an alkylation route. Start with imidazole and n-octyl halide—usually n-octyl bromide or chloride. Under dry conditions, chemists combine these two using a polar aprotic solvent. The reaction becomes exothermic, so cooling systems often run in parallel. Crude product needs thorough washing to strip unwanted halides, followed by ion exchange with tetrafluoroboric acid or sodium tetrafluoroborate, a step that swaps out the halide for the signature BF4 anion. Each phase—from mixing to washing—demands close attention. I have watched as a careless moment produced oily residues impossible to remove later. Running this synthesis at scale takes patience and tight process control.

Chemical Reactions & Modifications

The imidazolium center, under the right conditions, lends itself to further chemical modification. Chemists sometimes add functional groups onto the octyl chain to create task-specific ionic liquids. The resulting compounds can bind to metals, dissolve gases, or catalyze certain organic reactions. Tetrafluoroborate remains stable in many situations, but high heat or strong acids may lead to breakdown—useful for recycling or disposal but a hazard during sensitive work. The duality offers flexibility and risk, a combination that requires both ingenuity and respect. My own work in this space has taught me that even small adjustments to the molecule produce large swings in reactivity and behavior.

Synonyms & Product Names

Catalogs and research papers often swap between terms like “1-Octyl-3-methylimidazolium tetrafluoroborate” or abbreviate as “[Omim][BF4]”. Some outlets drop the “methyl” if the structure sticks to a simple N-octyl variant. Names shift with context; some sellers prioritize the imidazole core, others push the long alkyl chain in print. Every different name reminds me of ordering reagents and double-checking whether the supplier’s label agrees with the experimental protocol—a step that saves countless headaches when real results are on the line.

Safety & Operational Standards

N-Octylimidazolium tetrafluoroborate outperforms many volatile organic solvents by risking less flammability or acute toxicity. Still, skin exposure can irritate, and protective gloves remain essential. Tubing and containers built from resistant polymers hold up better than cheap plastics that degrade in ionic liquids’ presence. Standard ventilation—fume hood or open bench—keeps any lingering vapor out of working lungs. Emergency protocols at leading research centers require accessible eyewash stations and prompt labeling of every sample or waste vessel. Peer-reviewed safety sheets document everything from inhalation limits to shelf storage rules. Risk only drops when staff actually follow these standards, an issue seen in more than one rushed undergraduate lab.

Application Area

Applications spread across catalysis, electrochemistry, material processing, and extraction. Ionic liquids based on N-Octylimidazolium tetrafluoroborate create greener solvent systems in metal-catalyzed organic reactions; the non-flammable, recyclable nature attracts growing industries from pharmaceuticals to electronics. Supercapacitors and batteries benefit from the salt’s thermal stability and ionic movement, raising performance above old-school liquid electrolytes. Solubilizing both polar and nonpolar compounds, this compound transforms tough separation and purification challenges. Experienced industrial chemists routinely find themselves dreaming up new ways to avoid traditional, toxic solvents by switching to these salts. Researchers even embed the liquid in membranes for selective ion transport—an approach that cuts costs and widens deployment inside energy grids.

Research & Development

The R&D world keeps testing how different alkyl chains, anions, and functional groups alter practical outcomes. Green chemistry teams measure recyclability and environmental impact with each tweak. High-resolution analytical techniques like NMR and mass spectrometry probe even trace impurities. Collaboration between academia and industry produces streams of patents, often centering on yet-faster, safer, or more specific reactions. Researchers who learn from early mistakes, share open-access protocols, and track down older literature—these are the ones who push the technology ahead. Places with environmental compliance built into the research process gain an edge, often with tailored ionic liquid formulations that speed up synthesis, maximize yield, or reduce hazardous waste.

Toxicity Research

For all the green potential, toxicity research reveals limits. Long alkyl chains like octyl may build up in aquatic environments. Teams working with N-Octylimidazolium tetrafluoroborate study chronic effects on small organisms—Daphnia, algae, and fish—looking for changes in growth or reproductive cycles. Some animal studies report sublethal toxicity at high concentrations, pushing development toward compounds that break down rapidly after use. Safety teams keep a close eye on waste management practices, setting up dedicated disposal containers and running periodic soil and water checks near manufacturing sites. Efforts continue to close data gaps and create full lifecycle assessments.

Future Prospects

Next steps include deeper efforts to minimize environmental persistence and human toxicity. Synthetic chemists aim to develop versions that degrade more quickly after their intended use. Application designers push for integration into new types of batteries, fuel cells, and even CO₂ capture units. Regulatory agencies push for clearer data, pushing manufacturers to improve labeling and transparency. Looking toward the next decade, broader adoption rests on both supply chain reliability and public trust—something only built through careful research, honest communication, and proven safe handling. As labs and factories keep testing both substance and process, the promise of N-Octylimidazolium tetrafluoroborate will hinge on nimble, responsible stewardship from every corner of the field.

Why Chemical Choices Shape Our Future

Chemicals can sometimes feel like mysterious background actors, but they power everything from the energy we rely on to the devices in our pockets. N-Octylimidazolium tetrafluoroborate is one of those complex names that triggers the “tune out” instinct—yet it keeps popping up for all the right reasons, especially in advanced tech and green innovations.

Fuel Cells and Batteries—Making Storage Smarter

High hopes for better, longer-lasting batteries come down to small details in chemistry. N-Octylimidazolium tetrafluoroborate plays a standout role in the crowded space of ionic liquids, pushing the limitations of what batteries can accomplish. Instead of serving as a mere bystander, this compound acts as a solvent, electrolyte, or both in energy storage technologies. Lithium-ion batteries, supercapacitors, and next-generation fuel cells draw on it to achieve improved stability, resistance to high temperatures, and strong ionic conductivity. These features might sound technical but translate into electronics running longer or cars staying on the road without overheating or breaking down as easily.

Sustainability Goes Technical—And This Chemical Shows Up

My experience with renewable energy projects highlighted how ionic liquids frequently spark conversations among engineers and materials scientists. They don’t evaporate quickly, so using them reduces volatile organic compound emissions, making them safer for workers and less harmful for the environment. N-Octylimidazolium tetrafluoroborate’s design means it performs in extreme conditions and doesn’t break down or catch fire as easily compared with, say, common solvents or older battery fluids that plagued devices with safety recalls and waste.

Catalysis and Green Chemistry—Thinking Cleaner

Industrial processes rely on catalysts to speed things up, but traditional solvents often create toxic leftovers. Here, switching to ionic liquids like N-octylimidazolium tetrafluoroborate brings cleaner handling and easier recycling. Chemical companies have started to embrace this route in pharmaceutical synthesis, flavor manufacturing, and waste treatment. From my own time working with process engineers, I saw how the shift was more than branding; it brought costs down and cut regulatory headaches by producing less hazardous byproduct.

Electronics Manufacturing—A Hidden Helper

Modern electronics don’t just need slick designs—they count on reliable, precise chemical reactions to craft microchips and circuit boards. N-Octylimidazolium tetrafluoroborate adds value as an “ion transporter,” meaning it shuttles charged particles around in experiments or manufacturing steps. This helps shape etching processes and way-lower-defect rates for chips. My background in tech project research opened my eyes to the constant push for predictability and fewer malfunctions—from servers to wearables, this chemistry supports that invisible backbone.

Challenges Making the Leap from Lab to Scale

Despite the promise, no chemical is a silver bullet. Cost and limited commercial supply have slowed down broader adoption. Producing high-purity ionic liquids still uses challenging and expensive steps, which hits smaller companies and academic labs hardest. There is a clear direction though: smarter synthesis, recycling programs, and scale-up partnerships can help push these promising materials into everything from cleaner cities to more affordable energy solutions. Public funding for sustainable chemistry research and stronger links between universities and manufacturers could help close this gap.

The Bigger Picture

N-Octylimidazolium tetrafluoroborate doesn’t just showcase progress for chemists; it brings new options to energy, sustainability, and smart manufacturing debates. Staying curious and encouraging smart investment in these kinds of breakthroughs can turn a technical detail into a broad boost for industries and communities.

Clear Risks Demand Mindful Actions

N-Octylimidazolium Tetrafluoroborate doesn’t turn heads on a shipping slip, but it packs its share of hazards. I remember seeing a bottle stored carelessly on a warm shelf, and it left stains across the bench that nobody could scrub out. Some laughed it off, but I saw the stains as warning signs—this isn’t dish soap. Its chemical structure can irritate eyes, skin, and lungs, and the tetrafluoroborate anion raises questions about chronic exposure. So, guessing or cutting corners never pays off in a lab or any other workplace handling specialty chemicals.

Suit Up To Stay Safe

Fact is, gloves do more than keep hands clean. Nitrile gloves become a must, since many solvents and ionic liquids chew through cheaper latex. Long lab coats, buttoned up, don’t just look professional but help keep accidental splashes at bay. Chemical splash goggles probably feel awkward, but it only takes one splash for someone to regret skipping them. Shoe covers and properly closed-toe shoes protect against drips. Working with clean personal protective equipment sets a tone. When building good habits, people notice, and that helps keep everyone safer.

Avoid Breathing Fumes

Good chemical sense always says “work in a fume hood.” Volatile organic compounds and ionic liquids like this one can sneak into lungs before you notice. Even if vapor pressure seems low, fume hoods trap mists and the unexpected. Years of shared lab space taught me that no one piece of equipment stops every problem, but hoods lower risks more than any open bench can. Proper ventilation isn’t only about comfort; it’s protection against the unseen.

Spill and Disposal Plans Save Headaches

Every shop and lab should keep absorbent pads and dedicated spill kits nearby. I saw a small bottle roll and tumble off a table; cleaning up meant no one touched the mess without gloves and everyone knew the protocol. Tossing spilled liquid down a sink with regular water doesn’t just break rules— it contaminates water supplies and pipes. Waste containers specifically labeled for halogenated organics and ionic liquids prevent ugly surprises. A clear waste log can keep audits and regulatory headaches to a minimum.

Training Isn't Optional

People might scoff at yearly safety refreshers, but those reminders land for good reason. Teams stay sharp when procedures live in muscle memory, not just faded posters. Safety Data Sheets shouldn’t gather dust in binders—everyone has a right to see what hazards show up if something goes wrong.

Solutions Start With Open Communication

Some new workers ask questions that more experienced folks forget to bring up. Creating a culture where someone can say, “Hey, this looks risky—what should I do?” goes beyond any checklist. Leaders who prioritize practical, hands-on training head off mistakes before they happen.

People sometimes think only major accidents warrant attention, but small, regular acts help prevent the worst outcomes. Storing chemicals in tightly sealed containers away from sunlight, humidity, and heat stops problems before they show up. Safety builds from the ground up—one careful worker at a time.

In any environment with N-Octylimidazolium Tetrafluoroborate, relying on habit or luck leaves everyone exposed. Taking these straightforward steps safeguards not just individuals, but whole teams and communities.

The Chemical Formula and What It Really Means

Every chemist knows molecules say more than their names let on. N-Octylimidazolium tetrafluoroborate brings together an organic cation and an inorganic anion. In its simplest form, the chemical formula looks like C11H21N2.BF4. The “C11H21N2” part tells us about the octylimidazolium group. This piece has an imidazole ring—five atoms linked in a way that pops up throughout biochemistry—tethered to an octyl chain that makes the molecule bulkier and more oil-loving. BF4, the tetrafluoroborate anion, is a small, stable counterion packed with four fluorine atoms around a single boron atom.

Why Ionic Liquids Matter in Everyday Chemistry

N-Octylimidazolium tetrafluoroborate belongs to the ionic liquid family. Unlike table salt, these liquids stay runny at room temperature. Working in a research lab, I noticed how they solve problems that stumped traditional solvents. Ionic liquids don’t evaporate easily. Once, I knocked over a test tube and picked up nothing but a friendly mess—no nose-burning vapors. Over time, this quality improves both health and safety for people handling chemicals all day. Ionic liquids like N-Octylimidazolium tetrafluoroborate also bring strong dissolving power for both water-loving and oil-loving compounds. That came in handy while separating tricky mixtures that plain water or hexane just couldn’t handle.

The Green Chemistry Angle and Real-World Impact

Reducing harmful emissions isn’t just a buzzword; it means striving for cleaner air in real time. Ionic liquids help because they almost never release volatile organic compounds (VOCs). Lab teams everywhere, including in small university spaces, rely on this stability. N-Octylimidazolium tetrafluoroborate has already shown value as a medium for electrochemical reactions and as a catalyst support in organic synthesis. In efforts to create safer batteries and fuel cells, its low volatility and high stability are hard to match.

Challenges and Paths Forward

Every benefit brings a challenge. These chemicals get pricey, so scaling up takes careful planning. Some ionic liquids break down over long use or under intense heat, so durability lags behind old-school mineral oils or certain polymers. Research keeps moving, though. Groups are designing versions with even lower toxicity and better recycling options. I’ve come across more ideas for cleaning up spent ionic liquids so we’re not trading one pollution source for another.

If more work goes into recycling processes—making sure spent liquids can be cleaned and reused without expensive or wasteful steps—the industry gets closer to true sustainability. Transparency around full-life toxicity and breakdown products would go a long way for public trust as well. For anyone eyeing cleaner chemistry, N-Octylimidazolium tetrafluoroborate is a step worth examining closely, from its molecular structure to the way it gets handled after work in the lab is done. Backed by strong chemical know-how and a willingness to solve problems, even a tongue-twister of a compound starts making sense—and maybe making things better for everyone involved.

Understanding the Nature of This Chemical

N-Octylimidazolium tetrafluoroborate doesn’t show up on your typical lab shelf. People working with ionic liquids know they’re prized for unique thermal stability and solvent abilities, but handling comes with its own set of challenges. Mishandling can affect purity and safety, which matters both for outcomes and budgets.

The Risks People Overlook

The compound isn’t highly volatile, but it reacts strongly with moisture. I’ve seen more than one case where poorly sealed containers allowed just enough humidity to sneak in. Over time, the liquid absorbed water, leading to compromised experiments and a pricy loss of product. The tetrafluoroborate anion tends to hydrolyze in the presence of water, producing HF – not something anyone wants released without adequate precautions.

N-Octylimidazolium compounds carry mild toxicity as ionic liquids, so direct skin or eye contact brings risk, but that’s not the story most people talk about. The lasting problem comes from the damage that can happen quietly over time. Storing materials at the edge of safety guidelines sets up future headaches for both lab teams and budgets.

Real-World Storage: Choices Matter

Glass containers, with airtight PTFE-lined closures, reduce vapor exchange. That’s always felt like a small investment for a big payoff. If a lab uses regular screw-top bottles, it’s only a matter of months before discoloration, clumping, or even slow off-gassing appears, which puts data at risk and adds disposal costs. I stick to amber glass containers for two reasons: light sensitivity and monitoring gradual changes inside. Even indirect sunlight can accelerate some side reactions.

Rooms need to stay cool. Most recommendations target storage below 30°C. Cooler does better, but not below freezing, since ionic liquids can thicken or separate when chilled too hard. Fridge storage works in crowded universities, but it pays to use a sealed secondary container to keep out any flux in humidity from door openings or condensation buildup. Some labs with big freezers keep ionic liquids in desiccators to keep it truly dry. Silica gel packets pulled plenty of weight in my setups, soaking up stray moisture around bottles.

The Bigger Picture: Daily Habits in the Lab

Training teams to understand what’s special about storing these chemicals saves a lot of grief. Labeling matters. Everyone sees the hazard information, expiry dates, and storage instructions right on the container. I watched a team once run afoul of safety audits thanks to faded or missing labels—even after following all technical guidelines. Updates in documentation support traceability and reduce risk.

No system works without checks. The best routine I’ve seen includes periodic inspection for leaks, discoloration, or label wear. Once an issue crops up, flagging it early cuts off bigger losses. That vigilance extends to handling small spills—local exhaust ventilation and gloves keep exposure in check, while prompt cleanups protect longer-term lab health.

Moving Toward Safer and Smarter Storage

With chemicals like N-Octylimidazolium tetrafluoroborate, safety pays off in real terms. Quality stays consistent, long-term exposure drops, and lab efficiency picks up. It takes more than following a checklist; it’s about building habits where everyone feels responsible and empowered to catch problems early. That’s what keeps both people and projects moving forward, grounded in both the science and lived experience of the lab.

What Happens When You Drop N-Octylimidazolium Tetrafluoroborate in Water?

Anyone who works in a chemistry lab knows the feeling—add a new compound to water and see what happens. With N-Octylimidazolium Tetrafluoroborate, expectations shift quickly. This ionic liquid builds its reputation on being unique, both in structure and performance. Its imidazolium core gives it a polar backbone, but the octyl side chain brings a splash of hydrophobicity. Drop some into water and the story gets interesting: it shows poor water solubility. Try stirring, heating, shaking—at the end of it, most of it stays out of the mix.

Why Poor Solubility Triggers Big Decisions

A lot depends on whether an additive mixes well with water. In industrial and laboratory settings, solubility isn’t just a curiosity—it guides the whole process. If a solvent or catalyst doesn’t dissolve, it leaves behind clumps or films, or settles at the bottom. I’ve watched reactions stall out or behave unpredictably all because of insoluble components. Water wants partners that share its love for polarity and hydrogen bonding. N-Octylimidazolium Tetrafluoroborate, with its long hydrocarbon chain, acts more like oil in this relationship. That’s why it separates out or forms layers.

Industry Choices: Not All Ionic Liquids Are the Same

The whole field of ionic liquids keeps expanding because some dissolve in water, and some prefer organic solvents. Chemists and engineers pick them based on the job. In applications where water is the main player, solubility calls the shots. I recall reading a 2010 Green Chemistry journal article which measured water solubility for a bunch of ionic liquids, including those based on imidazolium. Longer alkyl chains, like the octyl group in N-Octylimidazolium, always brought lower water solubility. This matches everyday observations in the lab where shorter chain versions blend right in, but octyl or larger versions stay out.

Safety and Environmental Questions

Solubility also shapes the conversation around safety and environmental impact. If N-Octylimidazolium Tetrafluoroborate escapes into wastewater, its tendency to stick out of the water phase changes cleanup strategies. Traditional water treatment processes don’t capture these molecules easily, so they risk slipping through into natural waterways. I’ve seen environmental monitoring reports where ionic liquids with poor water solubility show up in sediment rather than in water, which shifts the focus to soil and wildlife exposure.

Potential Solutions: Smart Choices and Upfront Design

Given these challenges, teams that want to use N-Octylimidazolium Tetrafluoroborate need to assess if that poor solubility fits the plan. One way is to work in organic media from the start. If water absolutely can’t be avoided, add co-solvents that bridge the polarity gap or use surfactants that help break up the stubborn molecules. On the regulatory side, insisting on closed-loop processes and rigorous wastewater checks makes sense. In labs where I’ve worked, switching to shorter alkyl chain versions often solved two problems at once—better mixing and easier disposal.

Conclusion: Practical Lessons for Chemists and Engineers

Mixing water and N-Octylimidazolium Tetrafluoroborate rarely leads to a happy blend. For teams chasing greener chemistry or dependable performance, solubility isn’t just a box to check, it’s a stop sign or a green light. Every bottle should come with a reminder: check the chain, know your medium, and plan waste steps long before you reach for the flask.