N-Octylimidazolium Tosylate: Exploring History, Properties, and Future Impact

Historical Development

Speaking about N-Octylimidazolium Tosylate brings to mind a big shift in how chemists approach ionic liquids. For years, the field seemed stuck with simple room-temperature salts, crowded by imidazolium and pyridinium bases. The late 1990s brought new faces, including longer alkyl chains tied to imidazole rings. My first experience with ionic liquids came during some stubborn synthesis experiments, and I remember how the jump from butyl to octyl chains led to lower volatility and an entirely new set of properties. That leap made imidazolium salts favorites beyond their beginnings in electrochemistry. Digging through patent archives and chemistry journals, N-Octylimidazolium Tosylate stands out in the timeline as a critical building block, especially after researchers noticed that substituting the anion could sharpen the liquid’s stability for real-world processes.

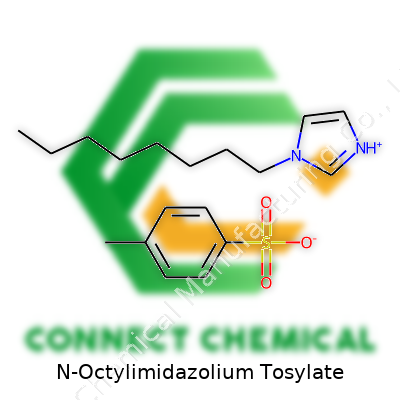

Product Overview

N-Octylimidazolium Tosylate belongs to a family of organic salts recognized for their ionic nature, but this one combines an eight-carbon octyl group with an imidazole core, finished off by a tosylate (para-toluenesulfonate) counterion. In the lab, it often appears as a pale, viscous liquid, tougher to spill and friendlier to handle than the more toxic halide versions. Consistent shelf stability marks out this compound, and its ionic structure creates low vapor pressure—something you notice if you’ve ever cleaned up after a reaction gone astray. You won’t find the acrid smell of ammonia here. Suppliers sometimes market it as 1-Octyl-3-methylimidazolium Tosylate or just OMIM Tosylate, avoiding confusion with shorter-chain cousins.

Physical & Chemical Properties

Take N-Octylimidazolium Tosylate in hand, and you find a substance that resists evaporation even under moderate heat. Its melting point often falls below typical room temperature, making it a stable liquid for months on end. You see the golden hue most clearly when perched in a glass vial, though pure samples show faint color. Its notable density and high viscosity mean that pouring takes patience, but those same qualities prevent accidental spills from spreading. Solubility sits high in polar organic solvents like acetonitrile or methanol, yet it also shows enough affinity for water that you can separate contaminants with ease. Thermal stability tops many organic liquids, and decomposition only starts at temperatures higher than most standard lab ovens. What caught my attention is its wide electrochemical window: you can push voltage far further during experiments without the liquid breaking down, an advantage that expands its reach in research.

Technical Specifications & Labeling

Manufacturers list the molecular formula as C16H26N2O3S, with a molecular weight closing in on 342.46 g/mol. Label details demand purity upwards of 98% because any stray salt or moisture changes its performance in sensitive applications. Packagers rely on amber glass to shield the product from light, a tip I picked up after more than one clear vial led to slight degradation during open-air storage. Safety data sheets flag reasonable care, pointing out that its low volatility limits inhalation but doesn’t remove the chance of skin or eye irritation. Shipping standards in most countries don’t mark it as hazardous, though regulatory data sheets still suggest keeping it sealed and dry like other fine chemicals.

Preparation Method

Synthesizing N-Octylimidazolium Tosylate looks simple on paper but benefits from experience. The route starts by quaternizing 1-methylimidazole with 1-bromooctane under stirring and mild heat, usually in a polar solvent. Once the reaction mix turns viscous and yields the bromide salt, a metathesis swap with sodium tosylate in water converts the bromide to tosylate by simple phase separation. Extract, dry with magnesium sulfate, and filter—what remains behind captures the heart of the ionic liquid. Any traces of starting material vanish after repeated washings and gentle vacuum drying. Chemists who practice this process share a nod about cleaning glassware afterward, since the stickiness lingers.

Chemical Reactions & Modifications

What makes N-Octylimidazolium Tosylate a playground for chemists is how the octyl group adds bulk and hydrophobicity, compared to its smaller siblings. The imidazolium core doesn’t get in the way of functionalization, allowing tweaks to the cation for specific applications—ranging from introducing substituents to change solubility or modifying the tail to anchor it in polymeric systems. The tosylate ion, for its part, stays inert during most reactions, holding the charge balance. That simplicity boosts its reliability when building catalyst supports or media for selective solvation. Organic chemists also appreciate how this salt dissolves both polar and non-polar substrates, creating a custom solvent for trickier syntheses or extraction steps.

Synonyms & Product Names

Lab catalogs don’t always spell things the same way, which caused confusion in my early days. Common synonyms include 1-Octyl-3-methylimidazolium Tosylate, OMIM Tosylate, or simply Octylimidazolium Tosylate. Suppliers sometimes use product numbers tied to purity or packaging size, but the core identity of the compound doesn’t waver. Double-checking the chemical structure—octyl on the N1 position, methyl on N3, and tosylate as the anion—guarantees the right bottle lands on your bench.

Safety & Operational Standards

Safe handling of N-Octylimidazolium Tosylate doesn't bring the same anxiety as older solvents, but sensible habits still matter. Gloves and safety glasses earn their keep, especially if you’re pouring from stock bottles or cleaning spills. Though the liquid stays put and rarely splashes, skin contact leads to moderate irritation, and ingestion or inhalation of fine spray—rare, but possible in aggressive mixing—calls for medical review. Disposal routes should follow organic waste protocols, avoiding drains since breakdown in water treatment may stay incomplete. Lab audits review logbooks on usage, reinforcing accountability for any quantities bought or used. Secure storage in a cool, dry space away from acids or bases avoids unexpected reactions and keeps the shelf life long.

Application Area

Real demand for N-Octylimidazolium Tosylate takes off in research and manufacturing, grounded in its stability and strong dissolving power. In the world of catalysis, it acts as a green solvent in coupling reactions or as a medium for transition metals to work their magic without leaching into product streams. Electrochemists value the salt’s broad window for voltage, so supercapacitor labs and battery researchers use it to investigate high-energy materials. Pharmaceutical teams use its solvent properties to boost the yield of active ingredients or to extract natural products without using chlorinated waste. I’ve seen colleagues draw on it for gas absorption studies, trying to fine-tune how a solvent captures sulfur dioxide or carbon dioxide from flue gas. The compound works quietly in the background of coatings, sensors, and extraction units, with less hype but more reliability compared to traditional organics.

Research & Development

Innovation in N-Octylimidazolium Tosylate circles around greener production methods, improved purity, and expanded functional variations. Teams across Europe and Asia dig into ways to make the synthesis less dependent on high-purity halides, aiming to cut down on waste streams and lower costs. The search for tailored imidazolium salts pushes boundaries in incorporating chiral centers or ionic functionalities, creating room for custom solvents that go beyond what’s on today’s market. Partnerships with academic labs encourage open data-sharing, giving industry more tools to track performance in battery electrolytes, pharmaceuticals, and high-value recycling. Private companies fund toxicity and fate studies to convince skeptics about environmental persistence, moving past anecdotes to hard evidence. Technical bulletins from leading suppliers include real-time updates about performance benchmarks and new safety standards, a level of transparency that builds trust.

Toxicity Research

Any new solvent brings questions about toxicity—a lesson I learned talking with environmental chemists concerned about bioaccumulation. Early studies flagged imidazolium salts for moderate aquatic toxicity, especially for shorter chains. Octyl substitutions move the compound up the chain, so studies now look at chronic effects, degradation rates, and the metabolite release after disposal. Test results from zebrafish and daphnia report higher tolerance than with halide analogs, but scientists haven’t closed the door on long-term risks. Labs track breakdown products using chromatography or mass spectrometry, and if any compound raises questions, researchers dig in to trace its journey. Responsible labs follow up with soil and water tests before recommending the product for open-environment use.

Future Prospects

Looking ahead, N-Octylimidazolium Tosylate has a real shot at shaping the next wave of clean chemical processes. Its unique blend of low volatility, high stability, and chemical flexibility ticks many of the boxes for green chemistry. Ongoing projects aim to broaden its reach in carbon capture, electrochemical cells, and fine chemical synthesis. One area that catches my eye points to integrating this compound in next-generation batteries, as it offers durability that water-based and traditional organic solvents can’t touch. Researchers eye tweaks to both cation and anion sides, hoping for even safer, more versatile variants. Ongoing collaborations between academia and industry mean the data keeps getting richer, allowing science to ground decisions in solid evidence without losing sight of safety and environmental responsibility.

Not Just Another Chemical in the Toolkit

A name like N-Octylimidazolium Tosylate doesn’t roll off the tongue, but try talking to a chemist about ionic liquids and you’ll see their eyes light up. My own dive into green chemistry a few years back put me face-to-face with this compound. Its main draw comes from its role as an ionic liquid, which basically means it acts like salt that stays liquid at room temperature. Exotic as it sounds, this stuff gets pulled into some pioneering research and industrial applications.

What Sets It Apart?

Solvents often evoke thoughts of harsh smells and environmental headaches, but ionic liquids like N-Octylimidazolium Tosylate bring something different. Compared to classic organic solvents, it resists evaporation, so you don’t have a headache from fumes, and it’s got a knack for dissolving materials that won’t budge for anything else. Researchers lean on these strengths for tasks ranging from biomass processing to electrochemistry. My own experience in a renewable energy lab taught me that ionic liquids can break down tough plant matter, setting the stage for biofuels. It’s a puzzle piece for chemists who want better results without raising the risk to worker health or the environment.

Growing Uses in Clean Tech and Beyond

One of the breakthroughs I saw involved energy storage. Battery researchers look for ways to improve power and life span without making batteries more volatile. N-Octylimidazolium Tosylate, thanks to its stable ionic structure, steps in as an electrolyte in supercapacitors or lithium batteries. Early experiments pointed toward safer, more efficient systems. Looking at patents and commercial white papers, you’ll see this ionic liquid named among solutions for corrosion control in metals. In the electroplating world, it can fine-tune how metals coat surfaces, sometimes reducing waste or energy usage. This isn’t just window dressing; in scale-up scenarios, small efficiency gains shave serious costs.

Tackling Safety and Practicality

Whenever the conversation turns to chemicals with complex names, safety pops up. N-Octylimidazolium Tosylate might impress with its low volatility, but it still calls for careful handling. Safety data points out that skin or eye contact demands a quick rinse and good ventilation helps, especially where dust or droplets form. In my lab, safety officers drilled in the importance of gloves, goggles, and sharp attention to storage—less about paranoia, more about consistency over time.

Room for Improvement

Cost and sustainability always follow a new material. Even though ionic liquids like this promise less pollution, their commercial impact hits a snag if they remain expensive or tough to recycle. Green chemistry champions keep digging for ways to make synthesis cleaner and boost reusability. For real innovation, the chemical industry needs to scale up these greener solvents without cutting corners. More suppliers investing in bulk production and waste recapture could move the process from research to routine.

Long-Term Outlook

N-Octylimidazolium Tosylate reminds me that progress often comes out of the lab, not a corporate press release. From batteries to bio-processing, its promise lies in letting us tackle old hurdles with fresh tools. Responsible use, better manufacturing, and a push for real-world testing can turn a mouthful of a name into a regular fixture in industry. The more scientists I meet working with ionic liquids, the more I believe these materials can deliver front-line benefits—if business and research pull together.

Meeting Quality Every Day

A bottle of N-Octylimidazolium Tosylate shows up in a lab. Nobody wants surprises from something as temperamental as chemistry. If this kind of ionic liquid takes on any moisture or reacts with impurities, tests get sloppy and whole batches can end up in the waste bin. Most folks using this material keep it in an airtight container—tight-sealing glass is the classic choice. I know from handling a range of imidazolium salts that plastic jars might cut it for a week, but glass keeps away faint whiffs of water from the air, which keeps the chemistry predictable.

Why Care About Humidity and Temperature?

If you leave N-Octylimidazolium Tosylate out on a windowsill, humidity works its way in. Ionic liquids soak up water if given the chance, and pretty soon that bottle turns sticky. Water in the mix changes how this stuff behaves in a reaction. Nobody gets good results from mystery goo. At room temperature, this salt keeps its stability and shelf life outpaces lots of other lab chemicals. A steady 20 to 25 degrees Celsius does the trick—nothing fancy. Just avoid heat sources, direct light, and wide temperature swings.

It Pays to Mark and Rotate Inventory

You wouldn't eat unlabeled leftovers, so there’s no sense leaving chemicals unmarked either. Every time I open a fresh container, I slap on a date and batch number. It’s simple, but the facts say most contamination comes from using unknown old stock. Rotating your storage means pulling the oldest bottles from the back first, just like grocery stores do. Inventory logs keep mistakes to a minimum and hard-won research money from slipping through the cracks.

Handling Spills and Dealing With Waste

Nobody expects spills but, from experience, they happen. When this salt spills, it’s not something to wipe up with bare hands. A scoop, gloves, and a dedicated chemical waste bin handle the mess without risk. The labs sticking to these habits avoid problems down the line. Proper waste bins, approved by local environmental safety guidelines, mean everything heads out for safe disposal instead of down the drain. Clean benches and prompt labeling cut headaches in half.

Good Storage Means Fewer Headaches

Labs that keep N-Octylimidazolium Tosylate dry and out of the sun avoid breakdowns and unpredictable results. It serves not only safety but budget, too—nobody saves money by losing half a bottle to moisture or by guessing what’s inside an unmarked flask. The facts back this up: ACS and chemical suppliers remind us that following the basics—tight lids, clear labels, dry shelves—prevents most of the hassle. If you want reliable chemistry, attention to storage does more than half the work.

Supporting Safety: Smart Lab Culture

Hard lessons often come from neglect. From my own work, regular checks and a culture of speaking up about dodgy bottles or poorly stored supplies pay off. Sharing reminders and easy-to-read protocols in the workplace means nobody falls back on guesswork. If someone sees a container gone cloudy or collecting dust on a warm shelf, calling it out keeps the whole operation running stronger. Lab safety grows from shared habits, not one-off lectures.

Looking Ahead

Reliable storage for N-Octylimidazolium Tosylate isn’t just about keeping the shelf neat. It means better experiments, less waste, safer colleagues, and a lab that runs on more than just luck. In my experience, it only takes one unplanned reaction to learn that lesson for good.

Getting Past the Chemical Jargon

Hearing about something called N-Octylimidazolium Tosylate draws out the usual mix of confusion and worry. Any name this long sounds intimidating. You might feel a quick itch to google “toxic” or “cancer” just to be sure. That’s natural, especially as stories about chemical safety rattle through the news cycle and remind us that sometimes, one bad ingredient causes real harm. So, let’s pull this salt out of the haze and look at what facts say, how it’s used, and whether it puts you or the environment at risk.

What Do Scientists Know About It?

N-Octylimidazolium Tosylate is a kind of ionic liquid, meaning it stays liquid over a wide range of temperatures. Researchers love liquids like this for their ability to dissolve all sorts of substances. They crop up in labs making new batteries, cleaner chemical reactions, or greener solvents. The upside is real: safer processes, less reliance on oil-derived chemicals, and even more effective electronics.

The real question lies in its effect on people. Research so far suggests these ionic liquids need more careful attention because their safety is nowhere near as well understood as, say, table salt or water. A 2023 study published in “Journal of Hazardous Materials” looked at similar imidazolium compounds. The findings? Some versions proved toxic to aquatic life in lab tests, and skin contact in high doses led to irritation or worse. Not every ionic liquid acts the same, but N-Octylimidazolium Tosylate falls under a category that calls for caution.

Why Public Scrutiny Matters

Back when asbestos or BPA-coated receipts made headlines, stricter rules often came in late. By then, communities felt betrayed. This lesson keeps echoing: if a material is showing up in more products, people want to know it won’t end up killing fish, polluting water, or causing trouble after years of unnoticed exposure. Regulators and researchers have the responsibility to test new materials for both short- and long-term danger—especially if the chemical structure points to risk. Governments in the EU, US, and Japan have begun tracking ionic liquids more closely for exactly this reason.

Challenges: Gaps in Testing and Transparency

Ionic liquids are pouring into new industrial processes faster than scientists can fully test them. A key barrier: animal testing is expensive, slow, and raises its own ethical questions. On the other hand, chemical companies sometimes shield their formulas as trade secrets, which means priority goes to speed and innovation, not always safety. The public often relies on older studies or info that does not reflect how these chemicals interact with real-world conditions—heat, sunlight, plastic pipes, ground water, and skin.

Solutions: Getting Ahead of the Curve

Building trust starts with giving the public more access to research data, not less. That means chemists and companies releasing more information about toxicity, letting independent labs replicate their findings, and funding targeted studies on chronic exposure. Regulators can require full testing before a chemical hits the market, with clear benchmarks for aquatic toxicity, skin exposure, and air release. On a personal level, working with hazardous material every day taught me to trust my senses and demand clear labeling—nothing beats knowing what’s actually in your workspace. Open conversations between scientists, workers, and agencies keep these materials from turning into a silent threat.

N-Octylimidazolium Tosylate won’t show up in every kitchen or toy, but pushing for full transparency and tough testing now keeps both people and wildlife safer later. Chemicals can do plenty of good, as long as everyone gets the facts straight and the scrutiny stays sharp.

Digging Into the Details: Chemistry Matters

N-Octylimidazolium Tosylate, or C16H26N2O3S, is not just a mouthful. This chemical serves as an important building block in the field of ionic liquids, which makes everyday chemical work less dangerous, more efficient, and sometimes much more sustainable. Ionic liquids like this one—made when N-octylimidazolium, an imidazolium ion with an octyl group, pairs with the tosylate anion—go well beyond lab curiosity; they help shape healthier futures for both industry and the environment.

Why the Structure Means More Than a Set of Numbers

C16H26N2O3S covers every atom inside a molecule that pushes researchers to solve big challenges. Ionic liquids such as N-Octylimidazolium Tosylate bring serious value to the advance of green chemistry. Traditional solvents harm the planet and expose workers to real risks. I’ve seen reports pile up over the years, showing how ionic liquids slash toxic fumes and waste, all thanks to tightly controlled molecular formulas. Crafting a chemical starts with sticking to these formulas. Miss an atom, the properties can change fast—safety, stability, even the ability to dissolve common materials shifts away from what’s needed.

Safety, Sustainability, and Real Opportunities

Deciphering the formula of N-Octylimidazolium Tosylate isn’t something left for textbook exercises. This knowledge lands straight into safer synthesis, easier handling, and less environmental fallout. Rather than wrestling with chlorinated solvents or flammable liquids, people now have tools like this one that resist evaporation, don’t burn, and even break down after use. In practical research, these facts play out when developing processes like battery manufacturing or pharmaceuticals. Costly mistakes and safety incidents drop off once you switch to well-defined ionic liquids.

This shift grows more vital as industries reach for cleaner technology. The global move to cut emissions relies on making switches like these. Even in labs I’ve worked in, swapping out one volatile chemical for an ionic liquid like N-Octylimidazolium Tosylate keeps air clean enough that old ventilation setups are never missed. There’s no more guessing whether fumes have seeped into your coat. It’s not a silver bullet, but it’s a concrete step forward.

Facing Current Problems and Finding Solutions

Developing ionic liquids that use clear, simple formulas does create some hurdles. The long hydrocarbon chain in N-Octylimidazolium boosts its solubility, but it can also make manufacturing slower and pricier. It’s easy to overlook problems like lingering environmental impact if these compounds don’t break down in nature. I always emphasize, tighter regulation during development—strong waste management, monitoring at every step—will stop ionic liquids from becoming tomorrow’s pollution headache.

With ongoing innovation, researchers can build variants based on N-Octylimidazolium Tosylate’s formula. That means adjusting the chain length, changing anions, or blending for targeted industries. Public-private partnerships open the path for safer, more efficient products. Routine sharing of lab findings and safety data, so crucial in my own work, helps chemists scale up these greener alternatives with fewer surprises.

Looking Ahead

Molecular formulas are more than numbers or letters on a page. Each formula—like C16H26N2O3S—represents real-world choices in safety, sustainability, and productivity. When industries pick up the pace and chemists work together on smarter compounds, society benefits from advances where risks shrink and progress grows.

Respecting a Modern Chemical’s Hazards

Plenty of research chemists and lab techs run into ionic liquids like N-Octylimidazolium Tosylate. It’s got promising uses thanks to its low volatility and impressive chemical stability, but I’d never let those perks tempt me into dropping my guard. Each new material out of a drum or bottle brings unknown risks, especially with salts and solvents that linger in the environment or slip through ordinary treatment.

Gloves, Goggles, and Good Habits

One thing I learned from years in the lab: no shortcuts with personal protective equipment. Gloves—nitrile handles most organics. Splash goggles beat basic safety glasses, period. Lab coats stay buttoned, sleeves down. Work on a sturdy benchtop with spill trays and keep a spill kit stocked nearby. Fume hoods don’t just look official on walk-throughs; they matter when weighing and transferring chemicals like this one since inhalation risk can creep up with fine particles or aerosols.

Label What You Use

Every label should be clear and current, whether on the original bottle or a squeeze bottle for small transfers. Outdated or missing hazard signs leave the next person guessing about what’s inside after a month on the shelf. I keep inventories up to date for exactly that reason. Walk away from guesswork and you’re betting against a possible accident.

Spills: No Room for Improvisation

A small mess still needs prompt, careful cleanup. Scoop up solids with absorbent pads or spill pillows rated for organic compounds. Seal contaminated wipes in labeled bags or pails—never toss anything in the regular trash. Vent the space well after cleanup and wipe all work surfaces, since traces can leave a nasty surprise for the next shift.

Health and Environmental Risks Deserve Respect

N-Octylimidazolium Tosylate doesn’t show up on many “greatest hits” lists for acute toxicity, but that doesn’t let anyone off the hook. Early research tells us some ionic liquids persist in water, so flushing even small amounts down the drain stacks up over time. Don’t let the lack of an immediate health scare fool you. Chronic exposure or slow leaks add up quietly — take note from legacy problems with other persistent chemicals, like PFAS or heavy metals.

Smart and Legal Disposal

Every container and contaminated pad goes in a designated hazardous waste bin—no mixing with non-hazardous stuff. Lab protocol means logging waste before pickup, filling out waste labels, and calling your hazardous waste officers or vendor for removal. Disposing of ionic liquids such as this requires treatment at a licensed facility. They’ll incinerate or chemically neutralize the material well away from any water supply. Some countries treat it as hazardous under laws modeled on the UN’s recommendations and the US EPA. Letting containers pile up in an unmonitored area can set the stage for a costly cleanup or a regulatory fine.

Better Practices Point the Way Forward

Green chemistry means reusing chemicals or switching to less risky cousins when possible. Sometimes, substitution is simpler than disposal. Research into biodegradable or less persistent ionic liquids looks promising, but until those reach scale, we owe it to our coworkers, neighbors, and the groundwater to do this right every time. Getting familiar with the material safety data sheet is just the baseline. After that, habit, record-keeping, and respect for the stuff you can’t see will keep you and your team out of trouble.