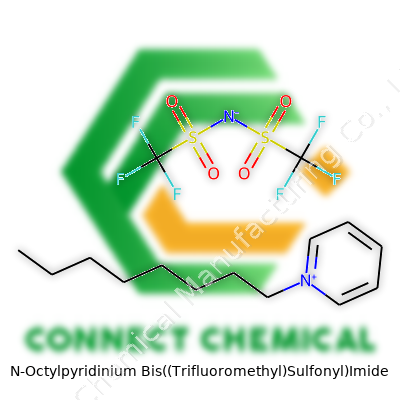

N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide: A Deep Dive

Historical Development

N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide didn’t drop out of nowhere; its story traces to the surge of interest in ionic liquids during the late 20th century. Chemists began chasing molecules that resisted volatility, ignored traditional definitions of solvent and brought a new edge to electrochemistry and green chemistry. The backbone containing an octylpyridinium cation joined with the NTf2 anion came about once researchers realized they needed wider electrochemical windows, higher thermal stability, and lower melting points. This class drew attention during the early 2000s, driven by research at universities across Europe—a push to dethrone volatile organic solvents and rethink synthesis strategies. When I started grad school, the atmosphere buzzed with talk of these “designer ions” promising safer, more tunable laboratory work and greener manufacturing methods.

Product Overview

N-Octylpyridinium NTf2 stands out from the crowd because of its wide liquid range and robustness under electrochemical pressure. In market terms, researchers often turn to this compound for battery research, electroplating, catalysis, and specialty solvents work. The unique cation structure resists breakdown, meaning it sticks around even in harsh lab procedures. The NTf2 anion doesn’t coordinate much, so you get a fluid with low viscosity, thermal stability, and a knack for dissolving both organic and inorganic solids. To anyone who’s ever muddled through stubborn syntheses or corrosive reactions, having an ionic liquid that refuses to decompose or evaporate at common temperatures changes the playbook.

Physical & Chemical Properties

This compound presents as a pale oily liquid at room temperature, refusing to crystallize under common conditions. Even working with gloved hands, you notice it’s slick but heavier than most solvents. Its melting point drops below minus 20 degrees Celsius, so frigid winters don’t stall lab work. The density hovers near 1.3 g/cm³, which puts it in the same league as dense solvents but without the nose-wrinkling fumes. Chemically, it resists hydrolysis and shrugs off many bases and weak acids. Electrochemical windows reach out past 4 volts, making it a favorite for ambitious electrode studies. Water and halogenated solvents barely faze it, and under open air, significant degradation takes weeks not hours—that alone saves time and worry for those running long-term tests or pilot facilities.

Technical Specifications & Labeling

Lab bottles typically list CAS number 820977-03-7 and carry purity certificates hitting above 98%. On the label, safety warnings grab your eye since the compound delivers mild toxicity and should not land on skin or in eyes. The manufacturer's data sheet will lay out storage requirements: keep in a tightly sealed container, dry area, ambient temperature, away from acids and bases strong enough to challenge the pyridinium ring. Viscosity records run around 60-80 mPa·s at 25 degrees Celsius, and the specific conductivity climbs up to several millisiemens per centimeter, which works beautifully for most low- to medium-voltage electrochemical prototypes. If I see these numbers, I know I am working with a genuine NTf2-based ionic liquid, and most researchers who use this in sensitive environments rely on these technical details to prevent cross-contamination.

Preparation Method

Preparation starts with N-octylpyridinium halide and a lithium or sodium bis(trifluoromethylsulfonyl)imide salt. You stir these together in water or ethanol, where a simple metathesis takes care of the rest: halide ions pair off with lithium or sodium, and NTf2 migrates to the octylpyridinium. Extraction follows, typically through dichloromethane or chloroform; after washing out remaining salts with water, you dry the residue over magnesium sulfate and clear the solvent by rotary evaporation. In my own benchwork, this route always wins points for straightforwardness and decent yields (often above 80%), provided you take care to minimize air and water exposure throughout the process. Scaling up means more efficient separations and solvent recycling, both sore spots for waste in academic and industrial labs.

Chemical Reactions & Modifications

If you take this ionic liquid and introduce strong nucleophiles or strong reducing agents, the cation might prove susceptible at higher temperatures or extended durations—though, relative to most organic salts, its stubbornness remains impressive. You can also exchange the octyl group for other alkyl chains, swapping out chain length or branching to fine-tune viscosity, hydrophobicity, and temperature range. The anion (NTf2) sometimes gets replaced in similar syntheses, but most researchers stick to the NTf2 variant for its proven reliability and non-coordinating personality. Adding functionalized side chains (ether, nitrile, fluoroalkyl) increases solubility for custom reagent systems. Every tweak matters for practical work: organic electrochemistry, exotic phase-transfer catalysis, or separation science, all hinge on tuning minor substituents to fix performance headaches.

Synonyms & Product Names

Across catalogs and publications, names can get tangled: 1-Octylpyridinium bis(trifluoromethylsulfonyl)imide shows up, as does N-Octylpyridinium NTf2 and 1-Octylpyridinium bisperfluoromethanesulfonimide. Some suppliers opt for shorthand like OPy NTf2. Even in well-organized labs, clarity in ordering and labeling matters. If a glass bottle comes in with a slightly different name, I always double-check documentation—the risk of misidentification is never trivial with similar-looking ionic liquids on the shelf.

Safety & Operational Standards

N-Octylpyridinium NTf2 won’t catch fire like diethyl ether, but you don’t want to treat it lightly. Direct contact causes mild irritation, and repeated exposure could risk more significant health effects—especially for those with skin conditions. Ventilation and personal protective equipment are not optional; laboratory hoods, goggles, double nitrile gloves, and protective clothing are mandatory according to R&D best practice. Spills wipe up with absorbent materials, followed by chemical waste disposal (no ordinary trash). In my experience, smaller labs occasionally cut corners, but large-scale users follow responsible chemical safety programs, full waste tracking, and regular safety data sheet reviews. For transportation, UN classification and IMDG codes apply, highlighting that even “green” alternatives demand proper stewardship.

Application Area

Research outfits and industry alike flock to N-Octylpyridinium NTf2 for battery development, with its wide electrochemical window making it a front-runner for next-gen lithium-ion and sodium-ion electrolytes. Electroplating, separation science, and catalysis labs embrace this compound because it outperforms volatile organics, leading to safer process rooms and cleaner outcomes. Some pharmaceutical projects dip into this solvent for better reaction yields and simpler purification steps. Analytical labs value its stability when running NMR, mass spec, and FTIR of organic and inorganic species. Industrial coating and polymer engineering have started to toy with this ionic liquid for antistatic and antifouling surfaces, seeing fewer maintenance cycles as a payoff. On occasion, even art conservation labs will use ionic liquids like this for gentle cleaning where traditional solvents pose risks to dyes or delicate materials.

Research & Development

Universities and corporate R&D teams continue to shine lights on alternative synthesis routes, smarter recycling practices, and expanded applications. Computational chemists chip in by modeling interactions with problematic contaminants or tricky electrode surfaces, leading to targeted improvements. Multinational projects have begun collaborating with startups focused on scaling production from kilogram to ton levels, aiming to reduce costs and boost purity. At conferences, poster sessions buzz about application in redox flow batteries or room-temperature fuel cells. Personally, I’ve seen undergraduate projects run successful customizations by adding fluoroalkyl or ether pendants, reporting dramatic shifts in properties that opened new research topics on the spot. These pockets of innovation ripple across disciplines, showing just how much room remains for discovery.

Toxicity Research

Toxicology often lags behind chemistry, but several detailed studies already flag potential risks. Acute oral and dermal toxicity studies on rats and rabbits rank it as mildly to moderately hazardous, with LD50 values suggesting care in workplace handling and disposal. Chronic effects remain under-studied for this specific ionic liquid, yet related pyridinium salts show limited bioaccumulation but some potential for aquatic toxicity. Waste from lab procedures should pass through advanced chemical waste treatment—no dumping down drains. The chemical structure’s resistance to breakdown triggers concern in wastewater plants, prompting regulatory agencies to call for deeper environmental fate studies. Some journals published findings on cell membrane disruption and enzyme inhibition, but gaps remain—this knowledge gap needs plugging through funding for long-term, cross-disciplinary research into both human and environmental effects.

Future Prospects

Frontline chemists and engineers already scout for ionic liquids that solve hard problems. N-Octylpyridinium NTf2 stands ready to leap from specialist labs to mainstream applications. Once cost drops and waste processing technology keeps pace, larger-scale battery production, green processing, and next-gen separations might pull this compound into everyday use. I see growing interest in bio-based syntheses, suggesting that future generations may refine sourcing so it depends less on petroleum feedstocks. Policy pressure for safer chemicals in the workplace will likely tip adoption rates upward. Scientific communities should push toward sharing toxicity and environmental fate data, rewarding open science and better regulatory frameworks. As more knowledge lands on the table, this ionic liquid can become an everyday tool in the modern chemist’s arsenal—so long as we stay honest about risks and improvement needs, the benefits can truly outweigh the costs.

Complex Name, Clear Impact

This tongue-twisting compound shows up in labs and factories where people look for ways to combine stability, safety, and high-tech performance. Just reading the name, you know this isn’t something you grab from a supermarket shelf. Still, it’s making a real difference behind the scenes where advanced chemistry gets things done—especially in batteries, green tech, and materials research.

Better Batteries Start with Smart Chemistry

Rechargeable batteries keep the world untethered—phones, laptops, electric vehicles. Engineers and chemists hunt for substances that help batteries last longer and lose less juice. N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide steps in where ionic liquids get called for. It’s all about changing how ions move, stopping short-circuits, and keeping components stable even when things heat up. Its unique structure lets it handle strong electric fields, which matters for the next jump in battery performance. People who follow battery innovation see new ionic liquids like this one as a ticket to safer, smaller products that need fewer costly raw materials. In this context, researchers use it to improve electrolytes for lithium-ion and beyond-lithium batteries, aiming for better cycle life and resistance to fire.

Green Chemistry’s Helping Hand

Loads of solvents pollute water, air, and soil, but the rules around chemical waste now tighten every year. N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide gives industries an option that doesn’t vaporize or break down easily, cutting exposure and cleanup. It also opens up low-temperature reactions. That means fewer emissions and lower bills for cooling and heating. Some labs use it to pull metals out of solutions, recycle rare materials, or create fine chemicals for drugs and electronics—always with the promise of less mess.

Advanced Materials and Electroplating

The electronics world runs on precision. Making circuit boards and microchips depends on putting down thin, even metallic coatings. With its ability to dissolve tough metal salts, this ionic liquid has shown up in electroplating processes where control and purity decide the outcome. I’ve seen teams use it to experiment with gold, silver, and copper, looking to avoid the toxic by-products of older solvent systems. This has already improved yields while answering calls for “cleaner” technology from both regulators and consumers. On top of that, researchers developing flexible or transparent electronics find themselves reaching for this compound as they test out new architectures or printable circuits.

What Matters Next

Finding safer, greener, and better-performing chemicals keeps science moving forward. As more people realize how important the “invisible” chemistry is to phones, cars, and clean energy, more attention lands on things like N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide. It’s never just the final gadget or battery; it’s the building blocks inside. A push towards supply chain transparency and safety in manufacturing will highlight the need for reliable data on toxicity, biodegradability, and recycling. Partnerships between academia, manufacturers, and regulators ensure these new chemicals meet real-world challenges without just shifting problems elsewhere.

The Weight of Real-World Experience

In labs and in homes, chemical stability divides top-notch products from those best left on the shelf. Over the years, watching how ingredients change or break down after a year, a month, or even a week shapes trust—sometimes for better, sometimes for worse. Frustration creeps in when an expensive powder cakes up long before the expiration date or a solution starts to look cloudy. People reach for products and expect consistency, but the formula doesn’t always behave as the label promises.

Why Chemical Stability Matters

Chemical stability goes beyond keeping a product “fresh.” It protects safety. A bottle of acetaminophen loses potency as moisture seeps in, leaving people guessing about real dosage. In food processing, shelf life is an unspoken contract—products that spoil before the date mean wasted dollars and sometimes unsafe meals. For pharmaceuticals, stability often ties directly to effectiveness and risk. No one can ignore these points if health matters at all.

Take vitamins: overexposure to light or air breaks them down. That means the benefit someone gets from vitamin C drops with every passing week, especially when the seal breaks. Real-world tests show vitamin C can lose half its punch after a few months in a warm, humid bathroom cabinet. The same pattern crops up in industrial chemicals or cleaning agents—oxidation, light, humidity, and heat all play their parts. There’s no one-size-fits-all solution, but storage and packaging play a bigger role than marketing ever admits.

Behind-the-Scenes Factors

Manufacturers keep data on hand for a reason. Accelerated aging studies, temperature cycling, and humidity tests give a window into how quickly a product might break down. For instance, sodium hypochlorite in bleach drops in strength within a year, especially above 25°C. It might look the same, but it won’t clean or disinfect like people expect. Plastic containers, dark-colored bottles, silica packs, or vacuum-sealed pouches represent more than clever design—they ward off the elements that eat away at chemical stability.

Everyday users see the results, even if they don’t notice each factor. Food packaging keeps out oxygen to hold off rancidity. Pharmaceutical bottles stay amber-tinted and airtight. Storage conditions—cool, dry, out of direct sunlight—make a difference that echoes in the results. I’ve lost count of the times someone mentioned “off” flavors in protein powder, or that a household spray stopped working after months under the sink, especially during the summer. Each time, storage and packaging tell half the story.

Practical Ways To Make Products Last

Effective storage and handling remain the most direct answers. For powders and tablets, resealing the package tightly after each use slows down moisture uptake. Teaming up stable compounds with carefully chosen excipients (like silica gel or desiccants) helps stop water from doing its damage. For solutions, keeping product containers tightly closed and away from heat sources has a bigger impact than most realize. Buyers deserve honest shelf life estimates, but also a fair shot at extending product usefulness.

Producers owe transparency about best-before dates, but the burden to safeguard value lands on both sides—those who make and those who use. Whenever possible, store items below 25°C in a dry place, out of direct light. Awareness and small steps stop wasted money and lost potency. Good habits pay off in safer, longer-lasting products, turning routine purchases into something more reliable day after day.

Chemicals Have Stories — This One Isn’t an Exception

N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide isn’t a name folks drop at the dinner table, but those working in chemical research or advanced materials have likely bumped into it. It pops up in projects that push boundaries with ionic liquids or specialty electrolytes. Every chemist or technician picking up a vial wants to know if this compound plays nice or bites back. A quick dig into the literature shows stories of accidents in labs that didn’t prepare well, so respect for this compound isn’t out of place.

Chemical Structure Doesn’t Tell the Whole Story

The name promises a mouthful, and the structure backs it up — organic cation paired with a fluorous, stubbornly non-reactive anion. Lots of folks learn about safety from plain old trial and error, but real experience means reading every data sheet and, ideally, talking to someone who’s handled it before. Fluorinated compounds sometimes mean business, stirring up respiratory irritation or skin sensitization if handled carelessly. The bis(trifluoromethyl)sulfonyl)imide part lines up with other strong anions, usually favoring stability, but the fluoro groups remind me to avoid casual contact.

Anecdotes about similar compounds — even ionic liquids that don’t evaporate easily — often mention skin contact leading to dryness or rash. Solvents or additives in the lab can sneakily draw these chemicals into the air as mists or fine droplets, especially during mixing or sonication.

Safety Data Sheets Can’t Be Skipped

SDS sheets lay it out clearly: Avoid skin and eye contact. Use chemical-resistant gloves, not the flimsy ones. Nitrile works better than latex, based on my own trials, especially for persistent ionic liquids. Faces need shields, not just the simple lab specs — goggles won’t stop a splash. Spills happen during transfers, let’s not kid ourselves, and a shielded bench saves a lot of regret.

Some folks relax around non-volatile liquids, but assuming they won’t find the bloodstream is a risky mindset. Even if vapor pressures look low on paper, splashes can land on surfaces or soak through sleeves without warning. Closed-toe shoes are less about fashion, more about chemical drips we all think won’t happen. Good habits mean long sleeves, tied-back hair, and gloves that get checked for holes.

Ventilation and Waste Disposal Keep Accidents Rare

Open bottles under a fume hood, not just on open bench-tops. Working with these ionic liquids means occasional off-gassing or accidental misting. Fume hoods remove the guesswork. Don’t try to save time by working at an open bench — it isn’t just about this chemical but the cocktail of solvents in many experiments. Waste needs a label, and the container must be compatible; fluorinated anions can react with strong bases or acids in waste streams. I’ve seen incompatible mixing lead to ruined containers and nasty clean-ups.

Reviewing incident reports, accidents usually come from overconfidence, not from the chemicals themselves leaping out of the bottle. Respect the unfamiliar, avoid shortcuts, and always double-check containers before pouring.

Training Protects People, Not Just Protocol

Making safety routine requires consistent reminders and easy access to gear. Every new user should get a hands-on primer, not just a stack of papers. The best-prepared labs make it something you see — gloves at hand, spill kits visible, people reminding others without judgment. There’s a reason labs post emergency shower and eyewash instructions at eye level: it’s about seconds, not hesitation, when something splashes.

N-Octylpyridinium Bis((Trifluoromethyl)Sulfonyl)Imide calls for careful preparation, some investment in proper barriers, and an attitude that respects surprises. Mistakes shrink in well-organized, well-trained spaces. That’s how everyone gets home healthy, every shift.

Why Solubility Actually Matters

Lots of us take solubility for granted, but it punches well above its weight in science, industry, and even daily life. Think about making a cup of coffee: the simple act of dissolving grounds shapes the drink. Translate that into medicine or chemical research, and suddenly, the way a compound interacts with water or organic solvents can send ripples through the whole process.

Understanding the Basics

Water and organic solvents play very different games. Water, with its strong hydrogen bonding and polarity, tends to welcome charged ions and polar molecules. Organic solvents like ethanol, acetone, or hexane feel much more at-home with nonpolar or barely polar substances. Small changes in a molecule's structure nudge it from one side to the other.

The Story Behind Molecular Structure

From years in the lab, it’s clear that the presence of functional groups—like -OH, -NH2, or -COOH—drastically shifts a molecule’s solubility. Add a hydroxyl or carboxyl group to a carbon chain, and suddenly you’re dealing with a far more water-loving (hydrophilic) substance. Aromatic rings or long chains of carbon and hydrogen tend to slip away from water and dissolve much better in something like chloroform or ether.

Take benzoic acid as an example. Instead of sliding straight into water, it finds it easier in a basic solution, because it forms the benzoate ion—now it fits water’s polar world much better. On the flip side, drop benzoic acid into diethyl ether, and the hydrophobic chunk on the molecule helps it blend in much faster.

Real-World Impacts

Skipping over textbook examples, solubility questions don’t stick to the lab. In drug development, a pill that refuses to dissolve in water often runs into trouble inside the body. Pharmaceutics teams face a major headache: tweak the structure, add salt, or search for a better solvent. Some drugs only work if delivered in a very specific form—often a salt version that dissolves better in water-based bodily fluids.

In manufacturing paint, cosmetics, and even cleaning agents, formulas must get the balance just right. Too much polarity and a compound refuses to mix with oils; too little, and water-based applications become impossible. Years in both chemistry and small business taught me that chasing the wrong solvent wastes precious resources, both time and money.

Data-Driven Decisions

Solubility can get unpredictable. LogP (partition coefficient) helps predict how a molecule divides between oil and water, but the results don’t always match real life. Experimentation remains key, supported by published data from government agencies and independent labs. Resources like PubChem and ChemSpider give real measurements—always better than guessing and ending up with stubborn sludge at the bottom of a flask.

Improving Outcomes

Several strategies do improve solubility when stuck. Salt formation stands out in the pharmaceutical field. Others include using co-solvents: mixing a bit of ethanol or DMSO to coax stubborn compounds into dissolving. Simple tricks like gently warming the mixture or altering pH sometimes work wonders. Trying these in a systematic way often solves solubility roadblocks faster than theoretical prediction alone.

The Takeaway of All This

Solubility doesn’t just touch the surface of a science problem—it can make or break an experiment, a product launch, or a promising new treatment. Knowing how a compound dissolves isn’t about hitting a checklist. It’s about anticipating hurdles, leaning on experience, and choosing tools and methods that actually move things forward.

Why Care About Storage and Transportation?

Safe storage and reliable transportation shape the story of any sensitive product, whether it’s medicine, food, or a chemical. Having worked with pharmaceuticals, I’ve watched shipments turn into emergencies just because a truck stalled in the wrong climate for an hour. Keeping strict control over temperature, light, and humidity makes the difference between a safe product and a recall.

Temperature Control: More Than Just a Fridge

A lot of products hold their quality only if kept within a specific temperature range. Vaccine vials, for example, often demand refrigeration between two and eight degrees Celsius. Food-grade probiotics can fail if they slip out of that range. Strong data from the World Health Organization shows that even a few hours above the limit puts patient safety at risk. Temperature-controlled warehouses and refrigerated trailers—cold chain storage—step in as the backbone for these goods.

It’s not always about freezing, though. Some chemicals react poorly if chilled, breaking down into useless or even hazardous byproducts. In labs, I’ve needed to monitor storage spaces with alarms that trigger if things stray by even a degree. Using temperature loggers with real-time alerts gives an early warning if the system drifts.

Humidity and Light: The Silent Spoilers

Moisture creeps in and ruins powders, from dry drugs to specialty food ingredients. Desiccant packs, silica gel, or even dedicated dehumidified rooms all help hold the line. An incident at a supplement factory comes to mind—when a shipment was wrapped in regular plastic in a humid warehouse, tablets clumped into a single mass by delivery. Using foil-lined containers and keeping storage areas well-sealed solved that one.

Light also plays the spoiler, especially for drugs like nitroprusside or food colors. These break down with prolonged exposure. Manufacturers switch to amber glass or opaque packaging. Picking the right warehouse—one with low natural light and proper lighting fixtures—turns out to be critical for stock preservation.

Safe Handling and Labeling

Fragile capsules, dangerous chemicals, or biohazard samples all need thoughtful handling. Training makes a real difference; workers must know how to recognize damaged packaging or odd smells. I’ve sat through short evening sessions where a single story about mishandling led to safer habits throughout the team.

Labels matter more than many think. A plain white box causes confusion. Clear, color-coded labels with hazard symbols, expiry dates, and proper descriptions reinforce safety. Digital inventory systems, like barcoding, speed up checks and remove much of the guesswork.

Transportation: Beyond Trucks and Ships

Getting a product safely across distances depends on thoughtful planning. Not all carriers provide refrigeration. For one vaccine campaign, dry ice and advanced insulated containers made a lifesaving difference. Exported food often spends days or weeks on ships, so robust packaging and thorough customs documentation keep delays and losses to a minimum. Insurance and tracking give peace of mind, with cargo monitored by GPS or even real-time sensors, so surprises stay rare.

Potential Fixes and Smart Approaches

Strong storage and transit systems grow out of simple basics: trained teams, modern packaging, and reliable data. Small investments in climate control and digital tracking save money and prevent product failures. Cross-team drills and scenario planning help people react quickly to a leak or a power outage. Local partnerships and backups—like extra generators or fast alternate suppliers—soften the blow from unexpected situations. These habits build long-term trust, whether the product feeds, heals, or powers the world.