N-Octylpyridinium Hexafluorophosphate: Ground-Level Insights and Future Moves

Historical Development and Product Overview

Step into any modern chemical lab and odds are you’ll find a story behind almost every reagent. N-Octylpyridinium hexafluorophosphate has a tale rooted in the rise of ionic liquids and advanced phase transfer catalysts. Chemists in the 1990s began to search for stable, tunable salts for electrochemistry and separations. One bright mind stumbled onto the idea of mixing pyridinium rings with long alkyl chains, then pairing them with robust anions like hexafluorophosphate. The result: a salt that remains solid under most temperatures but is brush-stroke smooth in the way it dissolves in polar organic solvents. Today, bottles of this compound show up in catalogs under names like N-octylpyridinium hexafluorophosphate, 1-octylpyridinium hexafluorophosphate, and its synonyms in different markets. The product grew from bench curiosity to reliable workhorse for folks tinkering with battery electrolytes, phase transfer, and more.

Physical & Chemical Properties

With its blend of pyridinium cation and PF6 anion, this compound demonstrates that small structural shifts mean large effect swings. Typically, the salt forms off-white to light-yellow crystals, easy to spot when scooping out of an amber flask. You’ll catch a slight odor if you pay close attention. As for melting point, N-octylpyridinium hexafluorophosphate keeps things in the 50–70°C range, sensitive to moisture in a lab with cheap air exchange. Solubility tells another chapter. Drop it in DCM, methanol, or acetonitrile and it vanishes fast. Leave it in water and it holds its ground, refusing to dissolve thanks to both hydrophobic chain and the PF6 anion’s trickery. Chemically, you get a stable salt, but that doesn't mean it's resistant to everything; strong bases can break pyridinium apart, while strong acids might exchange anions if you aren’t careful.

Technical Specifications & Labeling

Most chemical suppliers put their stamp on this compound with purity grades running 98% or higher. Labels usually call out batch reference, purity by NMR or HPLC, and sometimes moisture content. If you grab an SDS sheet, expect details about combustibility, chemical incompatibilities, and advice for PPE that keeps the dust off your hands. Some labs check melting points and IR spectra just to keep their paperwork tight.

Preparation Method

Making the salt takes careful planning but follows a classic metathesis route. The chemist starts from N-octylpyridinium halide, usually the bromide or chloride. React that with a soluble hexafluorophosphate donor, often potassium hexafluorophosphate, in acetonitrile or ethanol. The two salts trade ions. Out comes potassium bromide or chloride along with N-octylpyridinium hexafluorophosphate, which drops out of the solvent. Filter off, wash with ice-cold ether or water to strip away the other salt, and dry it under vacuum. At this point, the yield tells how good the technique is—ranging from 80% for the careful, down to 50% if conditions slide off mark. Over time, chemists have found better solvents and reactions, but the basic chore hasn't changed much.

Chemical Reactions & Modifications

Once on the lab shelf, N-octylpyridinium hexafluorophosphate wears several hats. Under reductive conditions or with nucleophiles, the pyridinium ring sometimes opens, though it resists attack from most mild bases. Chemists have tried to swap out the octyl chain for longer or branched versions, changing solubility and electrochemical properties along the way. PF6- itself sometimes gets switched for BF4- or other anions to make cousins with similar uses. Most well-known reactions involve acting as a phase transfer catalyst. In these cases, it tunnels ions from one layer to another, speeding up reactions otherwise stuck at the boundary.

Synonyms & Product Names

Buyers often know chemical products by whichever name slipped through the regulatory cracks first. For this salt, synonyms like N-octylpyridinium hexafluorophosphate, 1-octylpyridinium hexafluorophosphate, and octylpyridinium-PF6 all point back to the same bottle. Some registries clamp onto CAS numbers to keep everything organized, making it easier to double check safety data and supply streams.

Safety & Operational Standards

Safety doesn’t get much glamour but skipping goggles means paying the price. N-octylpyridinium hexafluorophosphate, while more stable than many reagents, poses risks if heated too sharply or left in acids. PF6- itself can break down to release HF under strong acidic or hydrolytic conditions—a real concern in cramped hood spaces. Standard operating procedures encourage gloves, splash-proof goggles, and good ventilation. Spill kits should always be reachable. Any reactive work with the base or with concentrated acids means prepping for possible off-gassing and breakdown. Regulations require keeping tight logs for flammable or noxious materials, so every operator needs to follow local storage and waste rules. Sometimes the real danger comes from smaller slip-ups: mixing with incompatible waste streams or ignoring faint odors that signal decomposition.

Application Area

Not every salt makes a splash, but N-octylpyridinium hexafluorophosphate found niches in battery research, organic synthesis, and catalysis. Electrochemists count on it when building non-aqueous electrolytes, thanks to its wide liquid range and conductivity. It works especially well where classic salts like lithium perchlorate prove too reactive or risky. Those in organic chemistry lean on it as a phase transfer catalyst, moving ions across immiscible layers and saving time in stubborn reactions like alkylations or oxidations. In the world of analytical chemistry, it pops up as a supporting electrolyte for voltammetry. More recently, green tech labs experiment with ionic liquids for less-volatile solvents, making this salt part of efforts to clean up solvent footprints. Each field tweaks purity, grain size, and solubility aspects to match what the application demands.

Research & Development

R&D on N-octylpyridinium hexafluorophosphate grew up alongside the boom in ionic liquids. Lab groups tested dozens of pyridinium salt variations to push boundaries in conductivity, thermal stability, and toxicity. Sometimes, research focused on swapping out the octyl group for better hydrophobicity or even branching to dodge crystallization at working temperatures. Cross-discipline work with physical chemists and engineers led to improved battery lifespans and safer electroplating setups. Analytical chemists took up the salt for its role in sample prep, especially in separating organic and inorganic mixes where standard solvents fall short. Testing keeps pushing boundaries further, with researchers checking lifespan, recyclability, and breakdown products in real industrial streams.

Toxicity Research

Toxicity sets the real-world limits for any technique or material. N-octylpyridinium hexafluorophosphate mostly flies under regulatory radars, but research points to hazard if the compound or its breakdown byproducts build up in soil or water systems. Some animal studies highlight moderate toxicity, especially if PF6- breaks apart into fluoride ions. Inhalation and prolonged skin contact are the fastest ways for harm—a lesson many techs learn after skipping gloves or not cleaning spills promptly. Good ventilation and regular wash-outs make huge differences. Work in my own lab flagged the risk when scaling up phase transfer reactions; what’s safe at 0.1 grams looks different at 100 grams with concentrated acids or bases in play. Regulatory agencies call for more toxicity data before large scale adoption, especially with increasing use in battery and catalysis fields. These flags push researchers to design safer analogs and to probe for long-duration chronic effects.

Future Prospects

Green chemistry and energy storage stand out as the brightest prospects for this salt. As batteries stretch for longer charge cycles, salts like N-octylpyridinium hexafluorophosphate offer unique combinations of low volatility and high conductivity. Work continues in replacing or recycling PF6- to lower environmental impact, and researchers keep an eye on degradation pathways to limit environmental footprint. Pushes in catalysis target better recyclability, aiming for salts that can be recovered and reused many times without breaking down or losing performance. On the regulatory side, gradual shifts push labs to monitor breakdown products more closely and to investigate possible chronic toxicity effects both to operators and to waste water streams. As tech and safety data align, this family of salts will keep driving innovation for those working in advanced chemistry and green energy.

Digging Into the Details

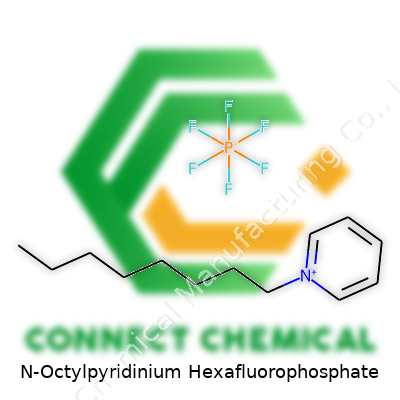

Many scientists, researchers, and chemistry students bump into N-Octylpyridinium hexafluorophosphate at some stage while exploring modern ionic liquids or advanced electrolyte systems. In everyday language, this chemical stands out because it combines two unique ions: an organic cation that looks a little like something pulled from a bottle of surfactant, and a seriously robust anion that resists water like rain bouncing off a car hood. The cation, N-Octylpyridinium, carries a positive charge thanks to a nitrogen atom sitting in a six-membered aromatic ring called pyridine. Stretching out from this ring, an octyl side chain (eight carbon atoms in a row) adds length and bulk. The formula for this cation is C13H20N+.

The anion, hexafluorophosphate, PF6-, pops up in many electrochemical studies for its chemical stability and low nucleophilicity. Toss these together, and you end up with a salt that is recognizable for both its ionic liquid properties and thermal stability, key for researchers working with batteries, organic synthesis, or antimicrobial work. So, the solid answer: the formula for N-Octylpyridinium hexafluorophosphate is C13H20NPF6.

Real-World Significance

Putting the right formula in your notes means more than ticking a box or acing a quiz. Reproducibility stands as a major building block in science. Getting that formula right, using it on labeling, storage, or prepping stock solutions, leads to fewer mishaps and more trust in your work—came across enough headaches myself after spotting mislabeled vials or typo-ridden lab notebooks to preach this lesson. Scientists rely on shared data, and accuracy isn't just a personal virtue, it's a responsibility to others who pick up the baton on your project years from now. If you work in the pharmaceutical sector, think of how a single slip can lead to failed tests or regulatory headaches. Newspapers never run stories about the thousand everyday times chemists get formulas right—those slip-ups, though, can make headlines.

Understanding Beyond the Textbook

Beyond the formula, this salt shines for how it behaves in the lab and industry. As an ionic liquid, it won’t catch fire or evaporate easily, making it a favorite in green chemistry for solvent systems less polluting than the old-school organics. That non-flammable, non-volatile profile pays off in both lab safety and environmental impact. Combine this property with the antimicrobial and antifungal activity of pyridinium-based salts, and you see why various research groups chase down new versions for coatings, water treatment, or even wound care. If you work in battery development, the robustness of PF6- supports electrolytes that face punishing cycles without breaking down.

How to Avoid Common Pitfalls

Staying sharp about chemical formulas calls for a habit of cross-checking. Textbooks and reputable databases, like PubChem or the Merck Index, save time and protect your reputation. Don’t overlook material safety data sheets (MSDS) or certificates of analysis; these documents exist for a reason, especially once chemicals move from the research bench to scaled-up applications. If a discrepancy shows up, old hands in the lab double-check against IUPAC naming standards or structural diagrams, not just names. I learned long ago, even trusted colleagues sometimes misread a label in the rush of a busy day, so a minute spent checking pays off.

Moving Forward with Confidence

Reliable information makes collaboration safe and productive. Whether you build a new electrolyte for lithium-ion batteries or prepare materials for a surface coating, spotting and using the precise C13H20NPF6 formula helps everyone from entry-level students to seasoned chemists avoid time-wasting errors. Open communication about findings—and mistakes—fosters a culture of learning instead of blame. We can push the boundaries of what ionic liquids achieve when attention to fundamentals, like chemical formulas, forms the bedrock of every project.

Unlocking Versatility in Chemical Labs

Among specialty chemicals that show up in the lab, N-Octylpyridinium Hexafluorophosphate draws attention with its mix of stability and function. Its structure—balancing an organic cation with a robust inorganic anion—makes it valuable in a range of experiments. In my own lab work, the move from classic salts to more modern ionic liquids often brings up this compound as a reliable choice, especially where moisture sensitivity and thermal stability matter.

Role in Electrochemistry

Electrochemical research keeps reaching for new supporting electrolytes that won’t break down or skew measurements. N-Octylpyridinium Hexafluorophosphate steps in here. It dissolves well in organic solvents, showing off a wide electrochemical window. For those studying battery chemistry or redox systems, this salt allows experiments with less chance of unwanted side reactions—a big deal when mapping out electrode behavior or exploring new energy storage ideas. According to a study from the Journal of Power Sources, using this compound in ionic liquid forms boosts battery cycle life and improves current efficiency.

Catalysis and Synthesis Support

In my experience handling organic synthesis, clean separation of products often makes or breaks the process. N-Octylpyridinium Hexafluorophosphate works as a phase-transfer catalyst, moving reactants across the interface between water and organic solvents. This quality shortens reaction times and often leads to better yields. Many chemists prepping fine chemicals or medicines rely on this approach, especially when dealing with substrates that resist mixing. Several published synthesis protocols highlight it as an effective tool for coupling and alkylation steps.

Closer Look at Analytical Use

Instrumental analysis benefits from less background noise and stable conditions. In high-performance liquid chromatography (HPLC), N-Octylpyridinium Hexafluorophosphate enters as an ion-pairing agent. It teams up with the analyst to separate complex mixtures by forming neutral pairs with charged analytes, sharpening peaks and boosting sensitivity, even at low concentrations. Having been hands-on with sample prep, I’ve seen how this improvement can mean the difference between clear results and a sea of overlapping signals.

Future Horizons in Green Chemistry

More attention is turning toward “greener” solvents and reagents. N-Octylpyridinium Hexafluorophosphate fits into this shift. As the industry moves away from volatile organics, the search is on for ionic liquids with lower toxicity and environmental risk. Several government agencies now sponsor research on recyclable salts that cut hazardous waste. While ongoing assessments look at long-term safety and breakdown in the environment, today’s labs see this salt as a step toward reducing their chemical footprint.

Improving Access and Knowledge

Complex materials sometimes stay within research circles. Outreach and better documentation can help small labs and teaching facilities catch up. Publishers and suppliers now share clearer guidelines on safe handling, disposal, and alternatives. This openness encourages more responsible use, guides safer procurement, and supports scientists crossing from classic methods into fields like electrochemistry and catalysis.

Understanding the Risks

N-Octylpyridinium hexafluorophosphate might sound like something out of a chemistry textbook, but it appears in real labs and workplaces. This chemical’s tricky nature goes beyond its long name. Its toxicity, possible corrosive effects, and handling challenges mean users must approach it with serious caution. A friend once told me about a nearby lab incident where skipping gloves led to a skin reaction nobody wants to repeat. Simple errors snowball quickly.

Basic Safety Gear

Personal protective equipment protects more than just your job—it keeps your eyes, lungs, and skin intact at the end of the day. For this chemical, gloves rated for chemicals (not just generic disposables), a sturdy lab coat, and eye protection become basics rather than options. Splash-proof goggles offer better coverage than regular safety glasses. More protection, less regret.

Importance of Good Ventilation

A small spill of N-Octylpyridinium hexafluorophosphate can release vapors that taser your nose and throat. Fume hoods kite vapors away before they take hold. Dust or powder drifting into the open atmosphere can compromise everyone in the room. I’ve watched fresh air and good hood practices take the bite out of accidents that might otherwise shut a lab down for hours.

Handling and Storage

Storing this compound on an upper shelf never ends well; accidents involving gravity and human error can ruin a week’s work and someone’s health. Shelves at waist height with chemical-resistant secondary containers minimize harm. Every label should be bold and clear. Secure lids, store away from moisture, and avoid mixing near acids or other incompatible chemicals. Getting lazy about storage often comes back to haunt you, especially in busy labs.

Chemical Spills and Response

Nobody likes getting a call from building safety about a box leaking powder. I’ve swept more than one spill myself, and lessons from each case stick with you. Grab a chemical spill kit matched for this type of compound. Use absorbent pads with resistances to strong acids and fluorides. Work from the outside inward, never spreading the mess further. Ventilate the area, double-bag the waste with clear labels, and inform your safety team right away. Cleaning up in secret only guarantees future problems.

Medical Concerns

Direct skin or eye contact brings burning and irritation. Rinse with water for minutes, not seconds, and don’t assume a brief contact means low risk. Inhaling dust deserves a health check—not everyone shows symptoms right away. Be upfront with health professionals about what happened and which chemical was involved. Time matters with compounds that can pass through tissue quickly.

Training and Constant Vigilance

Training sessions should leave everyone in the room knowing what to do and who to call. Regular refreshers help more than a few posters ever could. Having an emergency contact list posted at eye level saves lives in the chaos of a spill or exposure. Skipping safety steps because “it’ll only take a minute” is the oldest risk in the book.

Seeking Safer Alternatives

Some labs have switched away from hazardous salts like N-Octylpyridinium hexafluorophosphate when new research allows. Reviewing whether such risks are justified belongs in every monthly safety meeting. In my own experience, discussing swap-out options keeps risk low and conversations honest—nobody signs up for extra danger without good reason.

Cracking Open the Solubility Puzzle

Anyone who’s tried working with N-Octylpyridinium Hexafluorophosphate in the lab knows there’s no skipping the solubility question. Watching a white powder just sit there in water without dissolving tells you what textbooks confirm: this salt wants nothing to do with water. It comes down to how the molecule balances its parts. The octyl group’s long tail is about as hydrophobic as they come. Water molecules stick to themselves and push out that tail, making it useless to hope for any significant aqueous solubility.

Numerical figures often pin its solubility in water far below 1 g/L, sometimes barely above trace levels. I’ve seen situations where someone keeps stirring for an hour, waiting for the salt to disappear, only to find undissolved lumps at the bottom. This behavior lines up with the way other similar onium salts act—their hydrophobic stretches fight against being surrounded by water. In practice, most people steer clear of using N-Octylpyridinium Hexafluorophosphate where water is the main event.

Organic Solvents: A Friendlier Home

Now, put that same salt in an organic solvent like acetonitrile, methanol, or even dichloromethane, and the story shifts. The hexafluorophosphate anion isn’t tightly held by most organic solvents, and the octyl chain mingles well with non-polar surroundings. I’ve dissolved this compound in acetonitrile and watched it go clear in seconds—no stubborn residue at the bottom. Literature puts solubilities in acetonitrile or methanol close to the gram-per-milliliter mark, sometimes higher. These numbers point towards its true home in organic reaction workups and electrolyte formulations.

Even in solvents like chloroform or ether, N-Octylpyridinium Hexafluorophosphate easily mixes in, making it practical for extraction work or non-aqueous electrochemistry. Electrolyte researchers rely on this behavior. They value that the salt can help raise conductivity in non-polar solvents, or serve as a phase-transfer catalyst, without clogging up the process with undissolved solids.

What Matters for Real-World Research and Applications

Solubility may sound like a dry topic until you hit a wall in the lab. I’ve seen colleagues waste days trying to coax stubborn salts into water, only to realize the structural basics point another way. These moments teach a lesson: you can’t force hydrophobic and hydrophilic worlds together just because a protocol calls for it. Lab workers want reliability and reproducibility. Running a complex reaction with an undissolved salt often means variable results, unclear yields, and headaches during purification.

I’ve found a simple solubility screening step pays off before diving into a major synthesis or battery test. Using test tubes and a short solvent panel, you can spot which solvent takes up the salt and which leaves it behind. Lab notebooks filled with these small checks save months of troubleshooting. For newcomers who don’t want to comb through dense data tables, this direct approach often leads to “why didn’t I try this sooner?” moments.

From an environmental angle, it’s worth noting that low water solubility can make cleanup easier in some cases but will also mean watching out for accumulation, especially since hexafluorophosphate isn’t exactly known for breaking down quickly in nature. More attention is going towards greener organic options, searching for solvents that both dissolve salts well and tick sustainability boxes.

Rethinking Approaches: Solutions and Smarter Choices

Solubility questions don’t just affect small-scale chemistry. Companies looking to scale up a process can end up saving resources by matching their salt and solvent choices. Chemists now try to combine screening data with predictive software. Storming through early solvent testing helps avoid wasted batches and expensive do-overs.

No magic answer fits every system, but grounding research in practical solubility checks, clear-eyed about how long alkyl chains and anions behave, protects against wasted effort. Real progress comes from mixing empirical checks with an open mind about alternative solvents, aiming for safer, more efficient lab work.

The Chemistry Behind Stability

Some compounds play nicely in just about any setting, but N-Octylpyridinium Hexafluorophosphate belongs in a category where care pays off. Working in a university lab, I learned that chemicals with complex ions—especially ones containing fluorine like this one—call for storage with precision. Moisture and air aren’t friendly to many phosphorus and fluorine-based salts. Even a light dusting of humidity or a little air can nudge decomposition. Not dramatic at first, but subtle instability builds up, and this undercuts reliability for everything from research to manufacturing.

What Dry Means in a Lab

A lot of people toss around the idea of storing chemicals “in a dry place.” With N-Octylpyridinium Hexafluorophosphate, dry doesn’t just mean a cupboard. I remember my first head chemist laying out the difference between a regular storage cabinet and a desiccator: silica gel, tight seals, zero excuses for water to slip in. Any water vapor can shift the chemical’s composition, so keeping humidity under 10% matters. Folks skip this step and then wonder why their results can’t be repeated. A controlled cabinet with a hygrometer does wonders, but a glove box full of inert gas gives an extra edge for long-term preservation.

Picking the Right Temperature

Some salts barely flinch at summer heat waves or cold storage. N-Octylpyridinium Hexafluorophosphate isn’t the type you toss next to the coffee machine or under the fume hood. At room temperature, it keeps its shape and won’t melt or evaporate. Still, fluctuations can chip away at its purity, so a consistent, cool room—defined by researchers as 15–25°C—strikes the right balance. Extreme cold doesn’t bring any bonus stability, and humid refrigerator air adds risk, not protection.

Keep It in the Right Light (Or the Lack of It)

Working late nights, I saw how light affects different compounds. N-Octylpyridinium Hexafluorophosphate doesn’t crave sunlight or fluorescent light beaming down. Ultraviolet exposure kicks off reactions in many ionic salts, ones that you won’t spot until your experiment fails. Amber-colored glass bottles or opaque plastic jars block harmful rays almost entirely. I learned fast that even a day on a cluttered benchtop can make a subtle difference, so it’s worth labeling a storage spot and keeping the lid tight except during use.

Minimizing Contact with Air

Oxygen can wear down certain organic compounds, but for this salt, the real challenge lies in stopping airborne contaminants. Double-bagging in resealable polyethylene bags and tucking the sealed jar in a secondary container keeps unwanted visitors—like dust, minuscule bits of moisture, or even the whiff of an acidic cleaner—out of the picture. Strict labeling, including the date the jar was opened, helps catch any hiccups before the bottle is empty and keeps chemicals traceable in professional labs.

Simple Solutions Go a Long Way

The basics haven’t failed yet. No one wins by overcomplicating storage. Clean, tightly closed bottles, dry air, steady temperature, and minimal handling keep N-Octylpyridinium Hexafluorophosphate exactly how it came from the supplier. For anyone running a lab—or even just starting out—setting rules for storage and following them prevents wasted time, wasted money, and lost results down the line.