N-Pentyl-N-Methylpyrrolidinium Bromide: Insights from the Lab and Beyond

Historical Development

N-Pentyl-N-Methylpyrrolidinium Bromide marks one of those junctures in the journey of ionic liquids and quaternary ammonium salts, showing up alongside the exploration of new solvents and phase-transfer reagents in the late twentieth century. Chemists pushed into uncharted territory back then, not just for novelty, but with their eye on efficient synthesis and safe alternatives to volatile organic compounds. I remember one senior scientist pointing out in old notes that tweaking molecular structures like this reshaped what laboratories trusted for solubility, stability, and versatility. By the time ionic liquids started winning fans for their low volatility and customizable nature, N-Pentyl-N-Methylpyrrolidinium Bromide stood out as a dependable option, fitting in both research-grade and pre-industrial settings without much fuss from regulators.

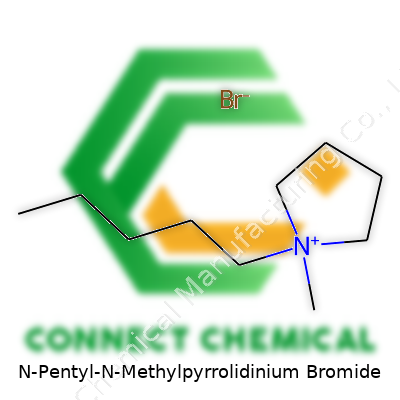

Product Overview

The compound itself belongs to the family of pyrrolidinium salts, with a molecular formula of C10H22BrN. It brings together a five-carbon pentyl group and a methyl group on a pyrrolidinium ring, paired with a bromide counterion. This design places the compound in the hands of chemists looking for stable, room-temperature ionic liquids or phase transfer catalysts. From a practical point of view, its structure lets researchers swap solubilities and surface activities just by adjusting side chains or swapping anions, giving a high degree of flexibility—something you really want in a crowded lab shelf. Makers ship this material as a high-purity solid with clear labeling to help both large-scale buyers and academic labs assess compatibility with their existing setups.

Physical & Chemical Properties

Holding N-Pentyl-N-Methylpyrrolidinium Bromide, you’d notice a white to off-white crystalline powder, pretty stable to air and nearly odorless. The compound dissolves well in water, methanol, and other polar organic solvents, giving it a leg up in many synthetic paths. It melts well below one hundred degrees Celsius, which reflects the characteristic low-melting nature tied to pyrrolidinium salts. Importantly, the bromide ion helps boost solubility in polar environments, making this salt useful for both biphasic reactions and homogeneous systems. Chemically, its structure resists oxidation and hydrolysis across a wide range of conditions—key for anyone tired of losing a week’s work to unexpected degradation.

Technical Specifications & Labeling

Labs buy this chemical with typical purities above 98%. Bottles come marked with proper hazard pictograms, chemical formula, batch numbers, and recommended storage conditions, which means opening a fresh package brings no confusion. Material safety data accompanies shipments—detailing not only recommended procedures in case of spills, but also outlining compatibility notes and first aid measures. Labels reflect international nomenclature standards, using not just IUPAC names but often including common trade identifiers to keep ordering and handling streamlined.

Preparation Method

Synthesizing N-Pentyl-N-Methylpyrrolidinium Bromide usually starts with N-methylpyrrolidine, which reacts with 1-bromopentane in a suitable solvent like acetonitrile or toluene. Under reflux and careful stirring, the reaction pushes toward quaternization, forming the ionic salt and dropping out the solution as the product builds up. Crude material often gets washed, recrystallized, or vacuum-dried to reach analytical purity. In settings where greener chemistry gets priority, solvents and washing steps change, but the basic approach stays the same—alkylate, isolate, purify. Making a good batch relies on accurate temperature and stoichiometry; slip-ups yield messy mixtures, and that’s a headache no one enjoys sorting out at scale.

Chemical Reactions & Modifications

N-Pentyl-N-Methylpyrrolidinium Bromide’s stable core lets it take a supporting or reactive role in organic synthesis. One common application involves swapping the bromide for another anion through metathesis, usually with salts like lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) or sodium hexafluorophosphate (NaPF6). The pyrrolidinium ring doesn’t react much under most conditions, making it almost like a molecular scaffold. That stability gets exploited during catalysis or as a solvent, where the cation steers microenvironments without itself falling apart. In electrochemical cells, researchers modify the pentyl or methyl groups to tweak melting point or conductivity, opening up broader utility in battery and capacitor research.

Synonyms & Product Names

You might see this compound listed under other names, including N-Methyl-N-Pentylpyrrolidinium Bromide, 1-N-Pentyl-1-Methylpyrrolidinium Bromide, or abbreviations like [C5MPy][Br]. Various suppliers use their own catalog codes, but I’ve learned never to trust those alone—always check the molecular formula to avoid costly mix-ups between very similar salts. In product catalogs dedicated to ionic liquids or synthetic reagents, the naming helps identify not just the main cation-anion pair, but often hints at the usual purity and physical form, which saves time searching through technical data sheets.

Safety & Operational Standards

Every time I’ve handled this compound in the lab, gloves and lab coats stayed on. The ionic nature and low volatility keep its direct risk profile lower than many common organic solvents, though concentrated dust or improper mixing can irritate mucous membranes and skin. Material safety sheets urge storage in cool, dry places—away from direct sunlight, acids, and oxidizers. Laboratories handling this material enforce regular ventilation checks and avoid static discharge near fine powders. Disposal practices follow regional chemical waste guidelines, but from experience, routine work with pyrrolidinium salts never sent toxic fumes across the bench or required heavy-duty respiratory gear, making them favored in settings sensitive to staff health and environment.

Application Area

N-Pentyl-N-Methylpyrrolidinium Bromide turns up in multiple corners of applied chemistry. I’ve seen it listed as a phase-transfer catalyst helping drive nucleophilic substitution and alkylation reactions that stubbornly sit at two-phase boundaries. In electrochemistry, it acts as an electrolyte component in nonaqueous batteries and supercapacitors, leveraging its low melting point and good ionic conductivity. I worked on one project pairing these salts with complex metal surfaces to test corrosion protection—outcomes showed better lifetimes for certain alloys. More recently, the biomedical crowd explored analogous compounds as antimicrobial agents, which might open doors for this family in formulations resisting bacterial growth on surfaces and textiles. Solvent innovations also call upon it to dissolve polymers or facilitate “green” reactions avoiding more toxic halogenated solvents.

Research & Development

A recent burst of research brought compounds like N-Pentyl-N-Methylpyrrolidinium Bromide under the microscope for their tunable ion-pairing properties. Because chemists can adjust the alkyl side chains, the family makes a sort of modular tool kit for designing room-temperature ionic liquids. Science teams push into optimizing transport properties for next-generation batteries and fuel cells. Others run with the phase-transfer angle, finding niche syntheses that buzz along faster and yield cleaner products with tailored salts. The sheer pace of preprint papers and patent filings points to an active field—students now see pyrrolidinium frameworks as an everyday option, not an exotic curiosity.

Toxicity Research

Long-term safety studies don’t get as much spotlight as shiny applications, but I’ve read into several toxicology reviews on pyrrolidinium salts. Many tests suggest low acute toxicity, especially compared to aromatic or halogenated organic solvents, though ingestion and major skin contact cause local irritation and should get prompt medical follow-up. Chronic exposure studies offer less clarity; ongoing research looks at degradation, bioaccumulation, and downstream effects in wastewater streams. Lab practices err on the side of caution, minimizing inhalation and direct skin contact until comprehensive occupational health studies run their course. Waste disposal plans remain in step with authorities, since, despite low volatility, long-term effects still carry uncertainty.

Future Prospects

N-Pentyl-N-Methylpyrrolidinium Bromide’s story doesn’t end with classical uses. The march toward safe, “friendly” electrolytes for batteries, capacitors, and emerging sensors means tweaking these salts for better performance. I see rising interest in biorenewable feedstocks—imagine making pyrrolidinium cores from bio-based precursors and slotting them into solvent-less manufacturing lines. Over in materials science, teams look to these salts for creating gels, dispersions, and thin films where softness and conductivity must coexist. Regulatory attention on sustainable chemistry pushes for more live testing, especially as these salts edge into wider consumer goods. In all these settings, the practical balance of cost, tunability, and manageable safety profile keeps N-Pentyl-N-Methylpyrrolidinium Bromide on the shortlist for further development.

Chemical Building Blocks in Research and Industry

I’ve spent years following the stories behind lab chemicals and recognizing which ones quietly keep scientific progress moving. N-Pentyl-N-Methylpyrrolidinium Bromide is a fine example. This compound pops up most in research laboratories and advanced material science projects. Its value comes from the special structure—basically a type of quaternary ammonium salt with a five-carbon (pentyl) chain and a methyl group linked to a pyrrolidinium ring. This setup gives it useful traits for chemists focused on crafting new ionic liquids.

Building Ionic Liquids and Supercapacitors

Talk to researchers in electrochemistry, and you’ll hear about the endless search for better ionic liquids. These liquids open new possibilities in energy storage, electronic displays, and chemical separations. N-Pentyl-N-Methylpyrrolidinium Bromide steps in as a key ingredient. Mixing it with other salts, scientists tailor the electrical and thermal properties of these liquids. The resulting formulas often wind up in experiments aimed at creating safer, more reliable rechargeable batteries or better performing supercapacitors.

Transformation in Green Chemistry

As someone who cares about the environment, I keep an eye on how chemical innovations can cut pollution. Traditional organic solvents, still common in industry, release toxic fumes and leave a heavy carbon footprint. Ionic liquids made from chemicals like N-Pentyl-N-Methylpyrrolidinium Bromide are less likely to evaporate and show much lower flammability. Teams developing greener chemical reactions have started using this compound to replace more hazardous ingredients during test tube synthesis—reducing both emissions and workplace risks.

Progress in Pharmaceuticals and Analytical Chemistry

Another point worth sharing comes from pharmaceutical labs. While many drug makers rely on familiar solvents or salts, some step away from the routine to improve their purification steps or drug delivery systems. Salts like N-Pentyl-N-Methylpyrrolidinium Bromide serve as phase transfer catalysts, speeding up reactions or helping to separate small amounts of product from complex mixtures more effectively. This speeds development of medicines and can even improve their safety, since fewer impurities sneak through.

Safety and Handling Considerations

Safety always deserves a spotlight. As with all laboratory chemicals, the handling of N-Pentyl-N-Methylpyrrolidinium Bromide demands respect and good habits. Protective gear keeps skin and eyes away from powders and solutions, and fume hoods help steer clear of inhaling dust. While toxicity data remains limited, early studies signal the need for careful handling and disposal, especially if large quantities enter the waste stream. Government rules around hazardous materials encourage anyone using this compound to follow strict protocols, which helps control risks to workers and the environment.

Expanding Possibilities, Honest Reflections

In my view, the value of N-Pentyl-N-Methylpyrrolidinium Bromide hinges on its versatility. As laboratories chase new battery breakthroughs or search for ways to cut harmful emissions, this unassuming salt finds itself repurposed again and again. At the same time, safe handling and environmental stewardship matter just as much as technical progress. Everyone using this chemical—whether tinkering with energy storage or refining drug manufacturing—owes it to themselves, their colleagues, and their community to keep health and safety on the front burner.

Sources:- ACS Publications: "Quaternary Ammonium Salts in Energy Storage Devices"

- Royal Society of Chemistry: "Ionic Liquids and Their Environmental Impact"

- Chemical & Engineering News: "Going Green with Safer Solvents"

- European Chemicals Agency: Chemical Safety Information

Chemical Formula: Unlocking Structure and Function

N-Pentyl-N-Methylpyrrolidinium Bromide lines up as an organic salt—an ionic liquid in the world of chemical compounds. Its formula breaks down to C10H22BrN. I’ve worked with similar chemicals in a university lab, watching these “designer” salts bridge the world of organic and inorganic chemistry. This one’s name explains much of its structure: a pyrrolidinium core, holding a methyl group and a straight pentyl chain. Toss in a bromide anion, and you get a highly tunable compound, showing up in everything from solvent mixes to research on sustainable batteries.

Not long ago, ionic liquids were a curiosity, labeled “green solvents.” Researchers like to point out that you won’t catch a whiff of traditional solvents, and you’re not left cleaning up hazardous fumes. This compound, with its bromide and nitrogen arrangement, carries that benefit. Some of the big names in chemistry, including groups at Lawrence Berkeley National Laboratory, have highlighted how ionic liquids like this can dissolve whole cellulose fibers, giving a jumpstart to biofuel innovation. The formula isn’t just a string of letters and numbers—it’s a flashlight beam for scientists, guiding them toward milder, smarter operations.

Why the Structure Matters

Give this salt to any chemist, and they’ll nod knowingly at its molecular handshake: a charged nitrogen inside a five-ring pyrrolidine, balanced by a bromide ion. The pentyl tail and methyl group do more than decorate—they tune the liquid’s viscosity, melting point, and solubility. My personal experience handling these compounds showed how the smallest tweak to an alkyl group can mean the difference between something that pours like syrup and something that stands up like a gel.

Real value comes from the way these ions interact with each other. Instead of brittle, crystalline salts, N-Pentyl-N-Methylpyrrolidinium Bromide stays fluid at relatively low temperatures. Laboratories and start-ups like to use it as an electrolyte in electrochemical cells. Traditional salts support hard, toxic solvents—this bromide compound can pair with less hazardous, more biodegradable options. This isn’t just a win for science; it’s a lifeline for workers tired of dealing with volatile organics.

Challenges in Handling and Sustainability

Chemistry doesn’t always deliver a free lunch. Despite the environmental upsides, producing these ionic liquids uses up a respectable amount of energy and gives off waste you can’t sweep under the rug. After working with these compounds, I see the push for cleaner synthesis. Sheffield and Cambridge university researchers have published promising work on solvent-free processes.

Another real-world problem: cost. Every clever organic molecule needs raw feedstock, careful purification, and safe handling. Right now, N-Pentyl-N-Methylpyrrolidinium Bromide commands a price high enough to give industrial users pause. Scale-up efforts, such as swapping out halogens or engineering better catalysts, can set this class of compounds on a more practical path.

A Path Forward: Greener, Smarter Chemistry

Improving these compounds calls for teamwork between industrial chemists and academic specialists. Swapping the bromide for less toxic anions not only cuts down on environmental impact but can improve the recyclability of spent ionic liquids. Support for closed-loop synthesis in production facilities could help prevent chemical losses and preserve valuable resources. With more investment in sustainable feedstocks and a focus on full life-cycle analysis, future versions of N-Pentyl-N-Methylpyrrolidinium salts will look much more compatible with a circular, greener economy.

Understanding What Chemicals Bring Into Our Lives

Stories about chemical hazards shouldn’t feel distant from daily life. At one point, I took for granted everything in the lab, believing the biggest dangers always wore yellow hazard tape. My experience changed the day a colleague had a mild but sudden skin reaction during routine cleanup. That memory never faded; it changed how I see common lab reagents, including compounds like N-Pentyl-N-Methylpyrrolidinium Bromide.

Facts: What the Science Says

N-Pentyl-N-Methylpyrrolidinium Bromide isn’t a household name. Most folks will never see it outside a lab or a research article. This compound often shows up in the development of ionic liquids and advanced materials. Its main risk profiles draw from similar quaternary ammonium salts, which share a reputation for triggering irritation in skin, eyes, and lungs.

Direct skin contact leaves a burning, itchy sensation for hours. I’ve felt it with compounds in the same chemical family. The irritation isn’t extreme by industrial standards, yet it signals a bigger message: Personal protective gear isn’t optional—not with this class of chemicals.

Real Hazards, Not Just Lab Talk

Some folks on research teams tend to let their guard slip after months without problems. It happens everywhere. Just because a chemical sits quietly on a shelf, its risks haven’t faded. Accidental spills of pyrrolidinium bromides often release vapors that lead to coughing bouts and watery eyes, especially in small, poorly ventilated rooms.

Improper storage heightens risks, as this salt and its relatives often absorb moisture from the air. Damp bottles leak more easily, posing contamination risks for anyone in the work area. Each year, dozens of minor incidents across research labs go unreported because these reactions seem mild—just a sneeze or an itch. Long-term, repeated exposure to such substances can compound effects. Nobody wants breathing problems or chronic skin issues from a desk job or a few research projects.

Mitigating Risk: Habits Over Hype

Using personal stories to stress a point: Safety guidelines feel tedious until they save someone you know. Key protection strategies work far better than overcomplicating things. Gloves, goggles, and an actual working fume hood handle most risks with this compound. Storing bottles in sealed containers, away from water sources or acids, prevents a lot of hassle.

Disposal deserves extra effort. Pouring leftover chemicals down the sink never crosses my mind after watching a simple sewer mishap lead to days of unnecessary stress. Collecting small amounts of chemical waste and handing them off for specialized disposal keeps the workplace—and community—safer in the long run. Schools and small labs often skip these steps, not because they don’t care, but because habits are hard to change. Knowledge shared early helps form safer routines.

Better Information, Better Decisions

Many folks would benefit from a clear, accessible database detailing hazards, not just thick safety data sheets filled with jargon. In my experience, the more your team knows about the chemicals they handle, the fewer incidents crop up. Policies built on actual risk, instead of broad fear, foster both productivity and health. Handling N-Pentyl-N-Methylpyrrolidinium Bromide can be safe, but only with vigilance and respect for the facts. Small habits save lives even if the hazard never makes headlines.

Why Storage Choices Make or Break Lab Safety

Once, after a long week in a research lab, I learned firsthand how small storage missteps can create big problems, especially with reagents like N-Pentyl-N-Methylpyrrolidinium Bromide. This compound, widely used for its role in ionic liquids and specialty syntheses, brings a responsibility that can’t be shrugged off. Wrong storage can spoil months of work and risk health and safety. Reports from the American Chemical Society highlight spills and contamination in cases where labs skipped basic storage discipline. Those lessons stuck, and now I share them every time someone asks about safe chemical handling.

Understanding the Risks and Needs

This compound won’t explode on contact with air, and it doesn’t release clouds of dangerous vapors under normal conditions. That said, its hygroscopic nature means it will suck up water from air unless kept tightly closed. Moisture changes its consistency and purity, throwing off experimental results. Its reactivity doesn’t stop at water—light and heat both mess with its composition. If a flask sits on a sunny shelf one afternoon, you may come back to find the contents degraded, requiring a fresh order and new budget request.

The Ideal Storage Routine

Every researcher gets a familiar ritual: glove, mask, check the label, and double-check the stash spot. Dry, cool, and shielded from both sunlight and humidity—this isn’t a mantra, it’s self-preservation. I always pick a chemical storage cabinet (preferably metal), seal the bottle, and make sure silica packs rest inside every container if possible. The best labs run routine humidity checks using inexpensive meters. High-quality, desiccated containers cost a bit more up front, but the savings in uncontaminated chemicals justify the price.

Labeling—The Hard Lesson We All Learn

It’s hard to stress enough: never settle for faded or generic labels. Use the full IUPAC name, hazard codes, and the date the bottle was opened. That sticky piece of tape with initials and a scribbled date can mean the difference between safe handling and a trip to the emergency shower. The CDC and OSHA have published free labeling templates for a reason—ignoring them courts disaster.

Emergency Routines Save Time and Lives

Once, a bottle cracked on a cart because someone left it near the edge—basic inattention. Spills happen, even with good storage, but if staff know where the containment kits are and the procedure for small spills, everything gets handled quickly and calmly. Simple routines like keeping spill response kits easily accessible and regularly practicing emergency procedures reduce panic and waste.

Training Matters More Than Fancy Equipment

Inexperienced staff sometimes assume an expensive cabinet solves every risk. In reality, clear policies, regular retraining, and peer reminders give better protection than any lock. I've mentored new lab workers, walking them through actual bottles and labels. Practice trumps theory—handling the containers, reading the hazard sheets, learning which chemicals can’t sit close together. These habits persist long after a person leaves my lab. Just following the rules means nothing without real-world demonstrations and explanations tailored to real people, not perfect conditions.

Practical Steps Anyone Can Apply

The takeaways don’t require high-tech solutions: keep things dry, cool, and labeled; involve everyone in the storage routine; and make emergency drills a regular part of the lab culture. Each good habit protects both results and people, and over time, safe storage of chemicals like N-Pentyl-N-Methylpyrrolidinium Bromide becomes part of the lab’s DNA—not because of regulations, but because experience proves careless storage always costs more in the end.

Understanding Purity in Chemical Supply

In the world of research and chemical production, purity isn’t a background detail. Purity shapes every experiment, every reaction, every measurable result. Working in a university lab taught me early on that even small impurities in a reagent can derail a project, skew results, and waste hard-earned funding. When suppliers list N-Pentyl-N-Methylpyrrolidinium Bromide at >98% purity, they signal reliability for complex syntheses, battery research, or drug development.

Why High Purity N-Pentyl-N-Methylpyrrolidinium Bromide Matters

Electrolyte work, particularly for cutting-edge battery tech, often uses pyrrolidinium salts. Unwanted byproducts or trace metals can throw off electrochemical profiles and reduce lifespan. Some groups have even published cases where impurities altered conductivity, forcing months of troubleshooting. With a high-purity standard—often set at 98% or above—these setbacks are less likely.

Pharmaceutical or biotech teams need similar confidence. Even minor contamination can affect toxicity studies or molecular interactions. I’ve seen failed panels traced back to a single batch of reagent that fell just short on purity, costing credibility and weeks of progress.

How Purity Gets Verified

Reputable suppliers use real data to back up their numbers. Certificates of analysis should detail moisture levels, heavy metal screening, and possibly even chromatograms. Labs counting on a bromide compound to anchor ion-exchange processes or fuel synthesis routes shouldn’t settle for vague assurances. Ask for specifics—NMR data, HPLC traces, ICP-MS reports—to sort real quality from marketing fluff.

Labs dealing with stringent quality management standards, like Good Laboratory Practice (GLP) or ISO certification, need paper trails. I’ve watched audits hinge on having those documents immediately available. No analyst wants to explain why the compound they relied on came with more wishful thinking than hard evidence.

Cutting Corners Carries Risks

Trying to save money by going with a source offering <95% purity brings risks. Five percent contamination might not only muddy your data—it can generate hazardous byproducts or trigger unwanted reactions. The long cleanup and troubleshooting hours cost more than what gets saved upfront. A failed experiment feels frustrating, but discovering the issue started with reagent purity hurts even more.

What Can Be Done?

Cutting through the noise starts with two steps: asking for third-party test results and evaluating a supplier’s track record. If a supplier can’t immediately produce objective proof of purity, it’s time to look elsewhere. Collaboration with nearby labs or checking published studies for sources can also steer teams to proven suppliers.

For buyers, aligning orders with large, reputable chemical suppliers lowers the risk of surprises. Some even offer custom certifications or extra purity screening. In my experience, a phone call or email often triggers a deeper conversation about needs, letting the supplier explain batch-to-batch consistency and point out possible pitfalls.

No experiment deserves to fail because of hidden contaminants. Purity holds the door open for discovery, efficiency, and breakthroughs—ignoring it shuts that door for everyone. Choosing high-purity N-Pentyl-N-Methylpyrrolidinium Bromide puts every project on firmer ground.