N-Pentylimidazole: A Modern Chemical with a Rich Backstory

Historical Development

Chemistry builds on tiny tweaks and careful choices. N-Pentylimidazole stands as proof of this. Researchers started exploring imidazole compounds in the late 1800s, chasing novel properties for everything from medicine to photography. Scholars recognized that swapping out nitrogen moieties and side chains changed the game for solubility, reactivity, and biological behavior. By the middle of the twentieth century, chemists started tacking longer alkyl chains onto the imidazole scaffold, opening the door to specialty reagents like N-Pentylimidazole. Labs across the globe began using this molecule in assays and industrial syntheses. Historical patents and peer-reviewed journals started mentioning pentyl-substituted imidazoles in the context of catalysts, ligands for coordination chemistry, and even as non-aqueous solvents. N-Pentylimidazole emerged from this rich backdrop, combining utility with a chemical structure that walks the line between lab curiosity and industrial relevance.

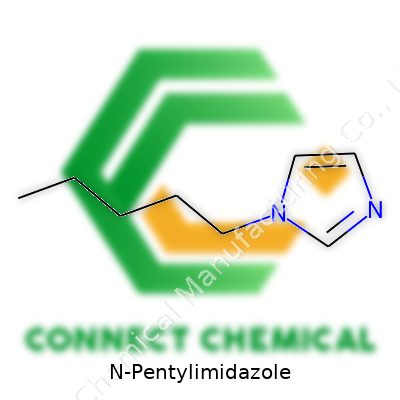

Product Overview

N-Pentylimidazole isn’t just another piece on a chemist’s shelf. This compound, with its pentyl chain fused to the imidazole ring, serves as a versatile intermediate for several sectors—ranging from pharmaceuticals to chemical engineering. Labs reach for it when they want both the base strength of imidazole and a hydrophobic “tail” to influence solubility and activity. Compared to its shorter-chain cousins, it often goes further in tweaking molecular properties. You find it as a free-flowing liquid or a low-melting solid, packed in brown bottles with hazard labels that reflect its working potential. It has an assigned CAS number, but what stands out most is the way its chemistry makes it valuable for both benchwork and commercial-scale projects.

Physical & Chemical Properties

N-Pentylimidazole usually appears as a clear, oily liquid at room temperature, sliding somewhere between colorless and pale yellow. Its molecular formula reads C8H14N2, with a molecular weight hovering around 138.21 g/mol. Boiling point sits near 265°C, and it resists water a bit more than smaller imidazoles thanks to that pentyl side chain. One of its striking properties is its moderate polarity; it dissolves better in organic solvents like chloroform, methanol, or toluene than in water. The basic nitrogen in the ring gives it a measurable pKa that often determines its choice as a catalyst or ligand. Its vapor pressure and density remind you it’s a careful-handling candidate in any kit. These properties let it slip into reactions that demand both solubility and stability.

Technical Specifications & Labeling

Quality control matters when stocking chemicals that end up in sensitive reactions. N-Pentylimidazole usually comes labeled with purity information, often listed at 98% or higher. Suppliers indicate trace water or acetic acid levels, both of which can alter results in catalysis or ligand-exchange chemistry. Bottles display hazard identifications: corrosive, harmful if swallowed, bio-reactive in some screens. Standard labeling follows global norms with pictograms and unique substance identifiers. Some producers add QR codes or batch numbers for easier tracing if a problem pops up in production. One trait you can’t ignore: the requirement for cool, dark storage, since this compound sometimes reacts to light or heat. Always double-check the Safety Data Sheet packed with any delivery.

Preparation Method

The journey to synthesize N-Pentylimidazole starts with a careful pick of reagents. Most procedures involve direct N-alkylation of imidazole, using 1-bromopentane or 1-chloropentane, under basic conditions. The process usually lines up sodium hydride, potassium carbonate, or a similar base to snatch the proton from imidazole, making it ready to couple with the alkyl halide. Organic solvents like DMSO or DMF help coax the reaction forward by dissolving both partners and reducing side reactions. Yields depend heavily on controlling moisture and keeping everything scrupulously anhydrous. Work-ups involve aqueous quenching, extraction, drying over sodium sulfate, and distillation or column chromatography to get rid of stubborn byproducts. At scale, some labs switch to phase-transfer catalysis to speed things up and handle bigger lots without sacrificing quality. Home-brewed syntheses rarely compete with commercial stuff in purity, but they show how approachable this molecule can be for a capable chemist.

Chemical Reactions & Modifications

The imidazole ring in N-Pentylimidazole opens a slate of reactions. Its lone-pair-rich nitrogens attract metals and acids, making this a top pick as a ligand for transition metal catalysis. In oxidation chemistry, the pentyl chain can resist moderate conditions but falls to strong oxidizers, yielding pentanol or shorter-chain fragments. Electrophilic aromatic substitution, while less common due to deactivation by the alkyl group, happens with determined efforts and harsh reagents. Nucleophilic substitutions take place on the pentyl group if exposed to strong bases or radicals. This versatility led researchers to link N-Pentylimidazole with complex drug targets or polymers. Every time someone tweaks the ring or side chain, those changes ripple through physical, chemical, and biological properties, creating analogs that sometimes outperform the original in their intended jobs.

Synonyms & Product Names

A scan of catalogs and literature turns up a handful of synonyms for N-Pentylimidazole. Some sources call it 1-Pentylimidazole, making the attachment point clear. Others stick to pentylimidazole or use IUPAC’s more formal 1-(Pentyl)-1H-imidazole. Occasionally you’ll see trade names when companies repackage it for niche uses—like specialized ligands or reaction promoters. Check for alternate spellings or structure identifiers, as confusion over which nitrogen holds the pentyl group can derail communication. Reliable sellers and journals stick with the standardized format, usually noting the substitution pattern up front to avoid mistakes in multi-step synthesis or in recordkeeping.

Safety & Operational Standards

Lab experiences with N-Pentylimidazole drive home the need for gloves, eye protection, and good ventilation. This isn’t just about avoiding spills—direct contact brings skin or eye irritation, and accidental inhalation or ingestion sends you hunting for the safety shower or eyewash station. The compound lands on hazard lists for both acute and chronic exposures. Fume hoods and chemical splash goggles suit daily use, especially when boiling it or reacting on a hotplate. Spills get handled fast with absorbent pads and solvent-neutralizing agents to prevent vapor buildup. I have watched experienced chemists treat every bottle like it’s seasoned with risk—no complacency, even after years of safe handling. Waste disposal goes through the hazardous stream, never down the drain, since community water systems rarely tolerate imidazole derivatives.

Application Area

Industry and research labs don’t keep N-Pentylimidazole on hand for show. Its strongest draw comes as a ligand in metal-catalyzed reactions. Choosing it over shorter-chain siblings influences solubility in organic versus aqueous solvents, nudging yields and selectivity in cross-coupling reactions or polymerization. Pharmaceutical groups study it for enzyme inhibition and as a hitting point in anti-fungal or anti-parasitic compounds. A few companies look at its behavior in ionic liquids or as an ionic liquid precursor, chasing green chemistry approaches. Materials scientists borrow its structure in building molecular electronics or surface coatings. In each case, N-Pentylimidazole’s unique profile—hydrophobic, basic, structurally robust—makes it the molecule of choice for jobs that punish or sideline less durable options.

Research & Development

Every innovation with N-Pentylimidazole leans on careful R&D pipelines. Chemists map out derivatives by swapping ring substituents and side chain lengths, probing for improvements in catalysis, biological targeting, or physical stability. Medicinal chemistry has branched into antiparasitic and antifungal screens, charting the balance between potency and toxicity. In catalysis, teams chase results in Suzuki, Heck, and other couplings, recording how N-Pentylimidazole stacks up against older ligands. Custom synthesis outfits bring out the best in this molecule for small-scale innovation and sampling. Conference posters and leading journals make clear that the field refuses to stand still. Collaborators outside chemistry—think biologists or materials engineers—keep tapping the expertise of those who know this compound best, sharing lessons and shaping next-generation tools built on the imidazole backbone.

Toxicity Research

Questions always circle around how much is too much. Toxicity research with N-Pentylimidazole started with bench tests on skin and eyes, then branched into cell cultures and whole-animal models. Data points toward moderate irritation on mucous membranes, with the risk rising in aerosols or direct skin contact. No one should treat this as benign. Animal studies suggest that long-term exposure—especially via inhalation or repeat skin contact—could depress certain enzyme activities or disrupt organ systems. Environmental assessments highlight issues with aquatic toxicity, urging labs to keep spills out of wastewater and to use best practices in disposal. Regulatory agencies flag the need for gloves, closed systems, and air monitoring in bigger plants. You won’t hear about large-scale poisonings, but vigilance around this compound prevents accidents and keeps regulatory troubles at bay.

Future Prospects

N-Pentylimidazole hasn’t finished making its mark. Research sharpens focus on its promise as a designer ligand, especially in cutting-edge catalysis where selectivity and green profiles matter. Pharma scouts for analogs with enhanced biological activity but tempered side effects, hoping to tap into the imidazole ring’s history in antifungal and antiviral therapies. Sustainable chemistry projects look to this molecule for reusable catalysts, ionic liquids, and as a scaffold for new functional materials. Advances in computational modeling speed the pace, predicting property shifts with small tweaks. Industry and academia both see a future with more tailored derivatives, clearer safety benchmarks, and applications reaching outside the classical roles for imidazoles. For every barrier that pops up, persistent refinement keeps N-Pentylimidazole squarely in the mainline of chemical innovation.

Filling a Practical Gap in Chemistry

Chemists and manufacturers face endless choices for catalysts and building blocks. Among the lesser-known but no less valuable compounds is N-Pentylimidazole, an organic molecule that blends an imidazole ring—a staple in many pharmaceuticals and industrial processes—with a pentyl group that shapes its solubility and reactivity. There’s a reason a chemist’s workbench might keep a bottle of this stuff tucked near the more famous reagents.

A Key Player in Chemical Synthesis

Drug discovery demands flexibility and durability from its building blocks. N-Pentylimidazole serves as a useful intermediate in synthesizing antiviral, antifungal, and antibacterial compounds. Pharmaceutical research leans heavily on imidazole-based molecules because their ring can trigger important biological reactions. The pentyl side-chain tweaks how the compound fits into larger molecules, allowing scientists to tailor-make medicines with improved properties. In the mid-2010s, studies tracking enzyme inhibitors highlighted analogs of this compound for their ability to cross cellular membranes and fine-tune how drugs interact with their targets.

Catalysis and Coordination Chemistry

Anyone who’s dealt with transition metal chemistry knows it’s about more than brute force; subtle changes in ligands—those molecules dangling off the metal center—can unlock new reactions or tip the balance in favor of one product over dozens of possibilities. N-Pentylimidazole acts as a ligand in research exploring new ways to catalyze reactions, including recent pushes for greener chemistry using less toxic metals. Copper and iron complexes built from imidazoles help speed up key industrial reactions at room temperature. Shifting from toxic and rare reagents to ones based on iron or copper offers a clear benefit: cheaper raw materials and a lighter environmental footprint.

Solvent and Stabilizer Roles

Some compounds play their part not by reacting but by holding things together. In electrochemical research and specialty coatings, N-Pentylimidazole gets credit for dissolving metal ions and stabilizing metal-organic films. Flexible yet strong coatings protect electronics from humidity, scratches, and static electricity. I remember seeing research out of Japan where a tweak as simple as swapping a methyl for a pentyl group on the imidazole ring trimmed the failure rate of circuit boards exposed to salty air.

Safety and Practical Limitations

No tool is perfect. Any chemistry student learns early to respect volatile organic compounds. N-Pentylimidazole brings its own set of safety steps. Direct skin contact isn’t a good idea, and the compound can be flammable when spilled. The usual lab rules apply: good ventilation, gloves, and goggles—no shortcuts, no matter how familiar the substance becomes. Safety data from manufacturers reinforce the point that even a compound known for reliability asks for care.

Getting More Sustainable Results

Academic and industry labs are hunting for greener solutions. Pairing N-Pentylimidazole with abundant metals or using it in recyclable solvents answers some growing calls for sustainable chemistry. One team in Germany blended bio-derived imidazoles with plant-based feedstocks, slicing costs and carbon footprints together. These green approaches don’t just fill regulatory checkboxes—they tap into a mood among researchers who want each reaction to matter for more than yield.

Wrapping Up the Real-World Benefits

Browsing through the latest patents and scientific papers makes it clear that N-Pentylimidazole earns more than a passing mention. In pharmaceuticals, specialty materials, and advanced coatings, it helps solve knotty chemical challenges using a clever bit of molecular architecture. It's not about buzzwords or exotic technologies; it's about choosing the right tool for the job—and this one has proven itself a few times over.

Why Storage Requirements Deserve Respect

N-Pentylimidazole shows up in a variety of chemical applications, especially in research labs or specialized manufacturing. Working around chemicals like this brings a whole set of safety practices, and ignoring proper storage is a shortcut only to trouble. The whole team—from chemists to techs—has a role in keeping things secure, and it all starts with how these substances get stored day in and day out.

What Kind of Place Works Best

You won’t find N-Pentylimidazole sitting next to common office supplies. Rooms built for chemical storage take on fewer risks. Think of a dry, cool spot, well away from sunlight or heat sources. Humidity raises the odds of container corrosion or unexpected reactions. Most folks keep it under 25°C if possible, and anyone who remembers a chemical spill cleanup knows to keep that cap tight and avoid stacking containers.

Shelves get labeled, upright containers rest at chest height, and nothing flammable lives above or below. Fire safety matters here—nobody wants to deal with even the smallest fire in a chemical stockroom. These aren’t rules for the sake of appearances; they make life easier for everyone running inventories or tracking down leaks.

Separation and Containment

There’s no secret sauce to keeping chemicals apart, but it’s crucial. Combining families of chemicals by accident—especially organics and oxidizers—never ends well. N-Pentylimidazole usually stays away from acids, strong bases, and oxidizing agents. Some labs post reminder signs since a mix-up might be just a few feet away. I’ve seen well-meaning new folks slip up, so experienced hands give a quick tour the moment someone joins the crew.

Seal integrity makes a big difference. Loose caps let vapor escape or invite moisture inside. Good containers—usually glass with PTFE-lined lids—do a solid job here. Nobody replaces a damaged container with just any bottle from the storeroom; compatibility charts exist for a reason. Over the years, I’ve learned most incidents happen when shortcuts get taken with containers.

Ventilation and Emergency Preparedness

Ventilated cabinets, or at least adequate exhaust systems, help manage off-gassing. No chemical stays perfectly scent-free forever. For N-Pentylimidazole, volatile vapors sometimes show up, and even a trace can become unpleasant without proper airflow. Portable fans won’t cut it—labs stick to rated exhaust hoods or mechanical ventilation designed for chemical use.

If something does spill, spill kits live nearby. Not shoved in a corner, but front and center with simple instructions. Personal protective gear stays within arm’s reach, not locked up. Open communication among colleagues means spills get cleaned right, but only if gear is handy and folks know where to find it.

Training: Everyone Owns It

Even well-written manuals won’t help if nobody reads them. Ongoing training goes beyond an HR checklist. Hands-on walkthroughs stick with people far better than dense SOP binders. I spent months in one lab where monthly drills kept folks sharp, and the difference showed: everyone felt comfortable asking questions, and near-misses dropped.

Most mistakes come from assumptions or distractions. Having the right storage for N-Pentylimidazole makes things run safer and smoother. Spot checks, regular audits, and shared accountability—these steps build up trust, and that saves trouble down the line.

Getting Familiar With N-Pentylimidazole

N-Pentylimidazole pops up in research labs and industry, thanks to its role in making specialty chemicals. Before anyone worries about handling it, the first thing to clear up: this isn’t a chemical you find in your kitchen cupboard. Most folks outside the lab world probably never hear about it. But that doesn’t mean it escapes scrutiny, especially as chemists, engineers, and regulators chase down risks tied to weird-sounding names.

Looking Under the Hood: Toxicity and Human Impact

Imidazoles form a family of chemicals that scientists have studied for decades. Some flavors of imidazole show up in medications, some in antifungals, some in research tools. N-Pentylimidazole comes with a longer tail than its common cousins, which can change how cells and enzymes deal with it. Data on direct human toxicity for N-Pentylimidazole still sits on the thin side, but by drawing from what’s known about imidazoles, there’s reason to treat it with care. Studies on related compounds report skin and eye irritation. Breathing in high concentrations in the lab causes headaches, dizziness—standard warnings for solvents and reactive chemicals. Not every imidazole spells trouble, though. Pharmaceuticals built from these basic cores save lives every day. The risk often swings on how pure the chemical is, how much a person contacts, and the protection in place during handling.

Why Working Safely Matters

Splashing a chemical like N-Pentylimidazole in your eyes or breathing in vapors in a closed room brings real harm. Even if human studies stay rare, animal tests and the data sheet from suppliers highlight irritation and possible central nervous system effects. It makes sense—our bodies aren’t made to process industrial organics in even tiny doses. My own work in chemistry has shown that rules for gloves, goggles, and fume hoods aren’t just red tape. Nobody wants to end a day with a hospital visit—or a call to poison control. Stories circulate between technicians about someone who got careless, then landed with watery eyes, skin rashes, or worse. Chemical burns and bad reactions shake up any lab crew quickly. It’s this shared experience that forms a culture of caution, built from a long line of near-misses and health scares.

Environmental Angle

N-Pentylimidazole doesn’t escape into the world easily, but spills or improper disposal may trickle into wastewater. Many organic solvents break down slowly, sometimes sticking around to cause headaches for local ecosystems. Fish and invertebrates sometimes show sensitivity to these compounds, even at low concentrations. Companies are under more pressure now than ever before to show how they manage every drop of chemical, tracing movement from delivery to waste drum. Researchers run toxicity tests not only for legal checkboxes but to avoid ugly surprises after the fact. Consider the legacy of solvents from the past—cleanups cost plenty and environmental repair takes years. We’ve got enough case studies to know that letting any lab chemical run loose makes little sense at all.

Toward Real-World Solutions

Reducing the risks with N-Pentylimidazole comes down to good habits and honest procedures. Safety training that shows new hires what a real spill or exposure feels like sticks better than a PowerPoint slideshow. Reliable ventilation, fit-tested masks, robust chemical labeling, and a clear spill process do more than tick a compliance box. In my experience, an extra pair of gloves and a working eye-wash station matter more than any written protocol if an accident strikes. For waste, collection channels keep solvents out of the water cycle, and batch testing spots leaks before they turn into news headlines. More routine research on the long-term impact of N-Pentylimidazole will help, especially as its use spreads. Sharing open data about hazards—what works and what fails—pulls the whole industry forward. No magic bullet here, just incremental progress built on shared experience and sound science.

Breaking Down the Chemistry

Chemistry rarely stops being fascinating. Take N-Pentylimidazole. From the sounds of it, you might picture an obscure experiment buried deep in a lab notebook. Yet, at its core, this compound comes down to a simple molecular arrangement. The molecular formula of N-Pentylimidazole is C8H14N2. That answer can set off more questions: What gives this molecule its unique character? How does knowing its formula matter in today’s world?

From Basic Structure to Real-World Use

Chemists will recognize the formula as a blend between a five-carbon alkyl chain—the n-pentyl group—and the imidazole ring. That five-carbon chain gets tacked onto a nitrogens’ position on the imidazole, and this slight tweak in structure can shift the way the molecule interacts in bigger assemblies of atoms. I first ran across N-Pentylimidazole years ago while shadowing a synthetic chemist. Watching them map out formulas wasn’t just an academic exercise. Each molecular formula was a clue, helping us predict how a compound would react, what regulations it might fall under, and even how it might behave under environmental pressures.

Why the Formula Matters

C8H14N2 provides a shorthand roadmap. It sums up what you’re working with, atom by atom. This isn’t just a tidbit for exam season. If you’ve ever worked with chemical safety, or even dabbled in green chemistry, you know a molecule’s formula can be the key to handling it responsibly. It helps researchers piece together synthesis routes. In pharmacology, the details spelled out by chemical formulas guide decisions that can lead to new medicines or show potential toxicity. The way these atoms fit, the way nitrogen pairs up in this ring structure, all feed into how enzymes, receptors, and other biological machinery respond to the presence of N-Pentylimidazole.

A Responsible Approach to Chemicals

The world does not benefit from chemicals alone—it benefits from responsible use. N-Pentylimidazole, like many alkylimidazoles, finds its place in certain chemical syntheses, sometimes winding up as part of a catalyst or as an intermediate in new material development. There is a growing push in science classrooms and professional labs to make the chemical formula a starting point for seeing the whole picture. Safety sheets, waste management plans, and environmental impact studies lean on that simple string of letters and numbers: C8H14N2. It shifts the conversation from experimentation at any cost to thoughtful consideration.

Building Understanding Beyond Textbooks

Plenty of students have stared blankly at a list of molecular formulas without seeing their relevance. After years outside the classroom, the practical side stands out. When a formula comes across my desk now, I think about lab safety. I think about how research could pivot if a more sustainable alternative came along. For N-Pentylimidazole and similar compounds, more knowledge means smarter upgrades to the ways they are produced and used. Solutions could include swapping out more hazardous solvents in synthesis or investigating how modifications to the core structure impact everything from shelf life to biodegradability.

Understanding a seemingly simple compound like N-Pentylimidazole from the formula up—C8H14N2—opens up room for conversation. That’s where safer chemistry, innovation, and better stewardship of lab and environmental resources all begin.

Purity in Laboratory Chemicals

Working in a chemistry lab, you learn early that chemical purity isn’t just a label—it’s a promise. N-Pentylimidazole usually comes with 97% or 98% purity for research and synthesis. Sometimes, a small bump to 99% gets offered for sensitive work. That difference can become everything when unexpected side reactions cost time, money, or safety.

Higher purity means less interference and more trust. Imagine troubleshooting an experiment, only to find out the culprit was a contaminant you didn’t know existed. Contaminants can change reaction outcomes, affect spectroscopy readings, or compromise a catalyst’s performance. In pharmaceutical compounds or electronics, impurity can stop a process cold. For anyone scaling up, unresolved quality questions early in development may land hard later, when stakes—and costs—are far higher.

Packaging Sizes: What’s Practical Today

On the bench, nobody needs liters of every reagent cluttering shelves. Small bottles—5g, 10g, 25g, or 100g—fit most academic and development labs. For pilot plants or scale-up, a kilogram or more might get ordered. Suppliers like Sigma-Aldrich and TCI offer N-Pentylimidazole in several of these sizes, and technical data sheets list compatible options for ordering. Storage stability goes down if air and moisture get into a bottle, so smaller, sealed containers work better for chemicals prone to degradation.

Shipping regulations drive some packaging decisions. An alkylimidazole isn't as tightly regulated as a flammable acid or cyanide, but if it’s not repackaged safely or the labeling gets lazy, couriers refuse to handle the parcel. Labs on different continents often report having to wait weeks or pay through the nose for reshipping because the original pack didn’t meet IATA or DOT chemical guidelines. Over-packaging wastes money and material, but loose or broken seals risk contamination or even accidents. Nobody likes opening a box to find powder leaking in transit.

Practical Considerations: Price, Freshness, and Waste

Some chemicals lose potency just sitting on a shelf. Buying a larger container because it’s cheap per gram stops making sense when you toss half of it unused at year-end. Old stock might look fine, but by the time it goes into an experiment, something’s changed. Sometimes companies opt to buy smaller packs, pay more per gram, and keep stock fresher. In my own experience, this was especially important on nights juggling multiple reactions at the edge of a PhD deadline. A half-used, moisture-exposed bottle never gave the same reliability as a fresh seal.

N-Pentylimidazole isn’t in every synthesis, but people working with it want the purity in print to match the purity in hand. Quality-control certificates help, along with batch information and storage advice, and vendors answering technical questions before purchase add trust. Mistakes with specialty chemicals get expensive, so honest, transparent information matters just as much as price.

Improving Safety and Reliability

Keeping up with global best practices means paying attention to both purity standards and packaging integrity. Safer shipping containers, batch tracking, and certifications protect users and make auditing easier. Labs benefit from tighter procurement policies: Don’t just hunt for the lowest price. Ask about handling instructions, lot consistency, and see if the supplier stands behind the product. For anyone responsible for chemical inventory, tighter inventory controls and working relationships with trusted distributors reduce risk, save time, and lead to safer, more productive science.