N-Propyl-N-Methylpiperidinium Iodide: A Closer Look From Past to Future

Historical Development

Chemists started working with quaternary ammonium salts back in the early twentieth century, fascinated by the changes these compounds brought to both medicine and chemical engineering. N-Propyl-N-Methylpiperidinium Iodide surfaced as part of this effort to broaden the family of piperidinium-based salts. Development started in academic laboratories where researchers probed for new ways to control chemical reactivity—always looking for that stability that comes with adding various alkyl groups to piperidinium cores. By the 1970s, documentation on this iodide salt became more common across patent filings and journal articles; people in both industry and academia started paying attention to its unique blend of characteristics. Researchers noticed how it changed the dynamic in reactions involving nucleophilic substitution or alkyl transfer, giving them new levers to pull in synthesis and separation work. Today the current understanding and synthesis routes owe a lot to those early collaborative experiments between industrial chemists and university labs, with protocols evolving each decade as purification and safety improved.

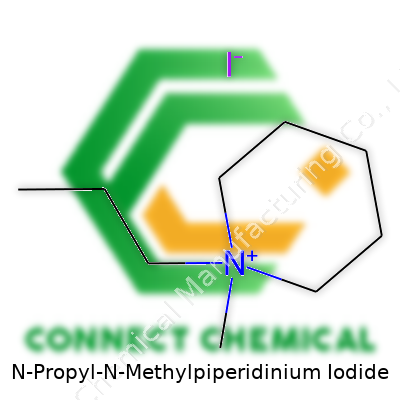

Product Overview

N-Propyl-N-Methylpiperidinium Iodide shows up in research catalogs as a specialty compound—one that chemists reach for during tough moments in synthesis or electrochemistry labs. With its piperidinium backbone carrying a propyl and a methyl group, plus an iodide counterion, the molecule serves as a key ionic building block. Labs use it for its predictable performance and moderate cost. Sometimes, in my own work, I’ve seen chemists choose it over better-known salts simply because it brings the right mix of solubility and nucleophilicity. The demand is steady but specialized, not aimed at volume manufacturing but at solving persistent challenges in organic and inorganic synthesis.

Physical & Chemical Properties

This salt appears as a white to off-white crystalline solid, typically handled in anhydrous form to avoid clumping or degradation. The melting point hovers around 180-185°C. Like many iodide salts, it dissolves well in water and polar organic solvents, including acetonitrile and methanol. It doesn’t react strongly with most neutral organics, but iodide brings a risk of oxidative change when exposed to peroxide or strong oxidizers. From a chemist’s viewpoint, consistent batch purity and moisture sensitivity matter most—nobody wants a reaction to fail because the iodide was impure or took up water. I’ve found it keeps well in a tightly sealed container with a desiccant, sometimes for years, as long as the cap isn’t left loose for too long during sampling. These practical details often matter more to researchers than technical data points on paper.

Technical Specifications & Labeling

Suppliers usually package this compound in amber glass or high-density polyethylene bottles, clearly labeled with structure, purity (often >98%), lot number, molecular weight (277.20 g/mol), and safety codes. Labels warn of thyroid risk and to avoid inhalation or skin contact due to toxicity associated with iodides and piperidine derivatives. Material Safety Data Sheets highlight storage away from light and moisture, handling with gloves and goggles, and documented batch traceability. I once flagged a mislabeled bottle during a routine audit—a simple error that led to confusion because some closely related salts look almost identical at a glance. Technical data sheets commonly include FTIR spectra, HPLC purity certs, and instructions for waste disposal, which speaks to growing pressure on labs to minimize both hazardous exposure and environmental impact.

Preparation Method

The typical route starts by alkylating N-methylpiperidine with 1-iodopropane under controlled reflux, using an inert solvent like acetonitrile or dry ethanol. The reaction generates N-Propyl-N-Methylpiperidinium Iodide as a white precipitate or oil, depending on solvent choice and reaction scale. Scientists have debated optimal temperature and stoichiometry—too much base leads to elimination products, too much iodide shifts solubility. Purification usually relies on repeated crystallization, filtration, and vacuum drying to reach analytical grade. During process development, chemists learned to minimize the formation of side-products by tweaking order of addition and acid/base controls; this kind of practical adjustment reflects daily experience much more than textbook procedures suggest. If scale-up is needed, inert atmosphere and hazard monitoring become essential, since morphed conditions boost the risk of runaway exotherms or unwanted byproducts.

Chemical Reactions & Modifications

N-Propyl-N-Methylpiperidinium Iodide stands out for its stability towards bases but reactivity under strong nucleophilic conditions. It regularly acts as a phase-transfer catalyst in two-phase systems and can mediate difficult substitution or elimination reactions. Researchers use it as a starting point for further functionalization, swapping the iodide for other anions via metathesis or treating the cation with alkyl halides for additional substitution. Combination with strong reducing agents calls for caution; I’ve seen first-hand how exothermic decomposition can result from careless mixing with lithium aluminum hydride. Under milder conditions, it's more predictable: acylation, deprotonation, and even selective quaternization proceed smoothly. Its use in nonaqueous redox flow batteries stands out as a modern trend, with the propyl group giving the right balance between hydrophobicity and charge mobility.

Synonyms & Product Names

This substance goes by several names—N-Propyl-N-Methylpiperidinium Iodide, 1-Methyl-1-Propylpiperidinium Iodide, or even simply PMP-Iodide in shorthand. Trade catalogs sometimes list it with reference numbers instead. These minor name changes have tripped up more than a few experiments, especially back in the days before CAS numbers clinched its identity (CAS: 70934-17-7). There’s no substitute for keeping a careful notebook, as researchers who confuse variants often end up repeating lengthy runs just to confirm which salt played the pivotal role.

Safety & Operational Standards

Standard lab protocols apply: always work in a fume hood, use nitrile gloves, and wear splash-resistant goggles. Iodide can sensitize the thyroid, while contact with piperidine or its salts may irritate skin and mucous membranes. Unsealed containers pick up water and may degrade; leaks lead to strong odors or more serious contamination headaches. Training staff on safe handling and fast cleanup for accidents remains the front line of protection. Waste disposal follows hazardous organoiodide guidelines; I’ve known teams that paid fines for accidental drain disposal due to poorly labeled containers. Companies updating their chemical hygiene plans include robust reminders for double-checking labels, working in pairs during weigh-outs, and restricting access to personnel trained in quaternary salt handling. Keeping detailed logs becomes the habit that saves labs time and money during inspections or audits.

Application Area

Most researchers working with N-Propyl-N-Methylpiperidinium Iodide operate in the specialty chemical, electrochemical, or pharmaceutical arenas. The salt’s role as a non-coordinating ionic conductor makes it useful in advanced battery work and as a supporting electrolyte in electrochemical cells. Another large slice of demand comes from medicinal chemistry, where it can influence drug-receptor interaction or help resolve complex organic morphologies. Its use as a phase-transfer catalyst reflects the trend toward greener, more selective reactions, cutting waste and boosting yields without exotic conditions. In my experience, practical value often wins over theoretical promise—labs keep reaching for this salt year after year because it performs reliably where others fail.

Research & Development

Research groups have been investing in more efficient preparation methods, greener purification protocols, and structural modifications that expand the salt’s utility. One area attracting attention focuses on swapping the iodide for less hazardous anions, either to make downstream handling safer or to unlock novel solubility and transport characteristics in advanced batteries. Another research path investigates the use of substituted piperidinium cations to design new ionic liquids, with applications from CO2 capture to advanced separation technologies. Teams routinely partner with industry to fine-tune production runs, manage impurity profiles, and develop analytical methods that offer trace-level detection—a sign of the growing regulatory focus on purity and safety.

Toxicity Research

Earlier studies documented the acute and chronic effects of piperidinium derivatives and iodides, focusing on thyroid function, skin irritation, and long-term neurological risk. The data sent a clear message: handle with care. Animal studies flagged both reversible and irreversible effects at increasingly lower concentrations. Toxicity thresholds prompted new safety benchmarks, leading to shelving some commercial projects and prompting stricter handling procedures. Modern toxicity screens leverage both in vitro and in vivo methods—routine bloodwork sometimes reveals markers of chronic low-dose exposure in occupational settings. Talking with peers, I’ve learned that the most significant safety improvements come from routine monitoring, tight engineering controls, and practical training—precautions that outpace technological innovation by keeping the human factor front and center.

Future Prospects

Researchers see plenty of runway ahead for N-Propyl-N-Methylpiperidinium Iodide, especially if new synthetic and purification advances can bring down cost and environmental risk. Growth in lithium-ion battery research and specialty organocatalysis seems set to boost demand for ionic salts with tunable properties, and modifications to the piperidinium core look likely to open new doors in both green chemistry and drug development. I hear from colleagues that pressure from regulatory bodies now shapes R&D more than ever: new-generation salts must balance high performance with low toxicity and minimal ecological footprint. Labs investing in continuous-flow synthesis, intensified purification, and computer-aided salt design are shaping the next wave of innovation; practical advances at the bench level will ultimately determine if this compound stays a specialty item or shifts toward broader daily use in chemistry, medicine, and clean energy.

Chemistry on the Lab Bench

In my own time in chemical research, certain salts came up as regular workhorses, and N-Propyl-N-Methylpiperidinium Iodide landed in more reaction schemes than people might expect. Its real value shines in organic synthesis, where chemists count on stable quaternary ammonium salts. This one acts as a reliable phase-transfer catalyst. It helps chemicals that wouldn’t usually mix interplay so reactions finish quickly and thoroughly. If you spend even a month in a synthetic lab, you'll notice how catalysts like this make or break a process, cutting down on waste and cost.

Pharmaceutical companies grab hold of it for the same reasons. They focus on yield, purity, and safety, especially while scaling up a bench process for eventual human use. N-Propyl-N-Methylpiperidinium Iodide doesn’t just keep reactions running smoothly; it also skips over the byproducts that so many lesser catalysts leave behind. Cleaner products mean less work later picking out impurities, which seriously improves efficiency as well as safety.

Emerging Role in Energy Research

Chemists have a growing fascination with how ionic liquids shape battery technology. During my time reading up on new battery materials, this compound’s name kept cropping up. It brings strong stability, which is no small thing when electrolytes face the heat and stress inside a lithium battery. Electrolytes based on ammonium salts can handle harsher cycles, stretching out battery life and offering a sturdier alternative to more common options.

The conversation around energy always circles back to storage. People want electric cars that drive farther and phones that charge faster. Ionic liquids, based on molecules like N-Propyl-N-Methylpiperidinium Iodide, sometimes push boundary in supercapacitors, too. A recent study in the Journal of Power Sources pointed out improved charge/discharge rates thanks to their flexibility and steady performance under real-world conditions. With more testing and design tweaks, scale-up may actually work for future commercial batteries.

Specialty Applications in Materials Science

As research digs into new types of polymers and composites, moisture and temperature sensitivity jumps out as major hurdles. This compound stands up to those challenges. In my own undergraduate project, just swapping a less stable ammonium iodide for the piperidinium cut down on failed runs. Advanced materials—from medical sensors to smart packaging—rely on predictable performance. As a result, N-Propyl-N-Methylpiperidinium Iodide shows up in unusual places, lending a hand in shaping film surfaces or controlling conductivity.

Analytical labs sometimes prefer this salt for preparing samples before testing. Its presence helps dissolve tricky organics or blend with solvents, letting instruments like NMR or mass spectrometers get better, clearer answers.

Moving Past the Lab—What Could Make It Better?

From what I’ve seen, the main complaint revolves around iodide cost and possible environmental impacts after disposal. If manufacturers lean on greener iodide production, or recycle the spent material, that could swing things in favor of broader use. Keeping an eye on toxicity data and waste treatment helps address these gaps so chemists can keep innovating responsibly.

Reliable chemistry depends on workhorses like this one, bridging everything from the test tube to next-gen technology.

Chemical Formula and Its Value

N-Propyl-N-methylpiperidinium iodide goes by the chemical formula C9H20IN. The details behind that formula tell us a lot, even if they don’t come with bright warning labels. Every atom in the structure has work to do. Three core elements — carbon, hydrogen, and nitrogen — set up the organic framework, while iodine rounds out the identity and boosts the molecule’s relevance for chemical applications.

Breaking it down: you get nine carbons, twenty hydrogens, one nitrogen, and an iodine. No guesswork—just a straightforward formula accounting for every piece in the molecular puzzle. This matters because knowing the exact formula avoids headaches for anyone handling the substance, whether you’re verifying your materials in a synthesis lab or double-checking quantities for an industrial process.

Molecular Weight: Why It Matters

C9H20IN clocks in at a molecular weight of 269.17 g/mol. People working in chemistry or pharmaceuticals use molecular weight for everything from calculating how much of a substance will react in solution to planning a synthesis route. Skip this value, and experimental plans fall apart. The precise molecular weight supports reproducibility, lets labs scale reactions safely, and helps analysts recognize the substance in samples.

Chemists won’t waste time repeating failed experiments if they’ve confirmed what’s on their bench. The weight ties in with purity checks and inventory management too. From my own experience, a missed decimal in the molecular weight can mean ruined weeks in a lab. So, the exact number—269.17 g/mol—serves as more than trivia; it’s a pillar for good work.

Practical Impact of the Structure

N-Propyl-N-methylpiperidinium iodide sits in the family of quaternary ammonium salts. These compounds crop up in catalysis, phase-transfer reactions, and even medical research. Thanks to the piperidinium backbone, you get a stable five-membered ring that resists breakdown in a range of solvents. The addition of the bulky iodine anion doesn’t just make it heavy; it delivers a punch of reactivity and solubility characteristics that prove useful in different scenarios.

From one perspective, I’ve come across similar salts doing the heavy lifting in separation techniques, such as ion-pair extraction. They help shuttle ions from one phase to another, turning a messy process into an efficient one. That matters for industry, but also for basic labs managing tricky separations.

Attention to Handling and Safety

Any compound containing iodine or piperidinium warrants careful handling. Iodides can act as skin and respiratory irritants, and quaternary ammonium salts sometimes impact nervous tissue at high doses. Anyone working with these materials should wear gloves, use good ventilation, and label storage containers clearly. I’ve seen accidents where assumptions led to exposure or improper waste disposal. Taking that extra minute to check a label can save hours of cleanup and investigation.

Potential Issues and How to Tackle Them

Sourcing this kind of salt looks straightforward, but supply chains can falter. Purity threats—such as hydrolysis or contamination—turn up in batches that sit too long or don’t get stored properly. Regular quality checks, sustainable sourcing, and supplier audits can buffer these risks. Labs and manufacturers may want to collaborate with suppliers for transparency in the buying process. Clear communication outpaces any written protocol, and sets the groundwork for fewer mistakes.

Continued Relevance for Research

Research trends keep tuning into quaternary ammonium compounds like this one. Whether aiming to develop better catalysts, investigate antimicrobial properties, or engineer novel drug delivery systems, knowing both the chemical formula and molecular weight at the outset means projects launch from solid ground. Those who take these basics seriously end up minimizing costly errors and maximizing the value of each experiment.

The Trouble with Uncapped Reagents

Anyone who’s handled specialty chemicals knows that poor storage can turn a reliable reagent into a risky pile of unknowns. N-Propyl-N-Methylpiperidinium Iodide is not just another salt; it's made for researchers and technologists seeking reproducibility and accuracy. Experience in labs has taught me the hard way that the finer details – humidity, temperature, light exposure – make all the difference between a clean experiment and a headache.

Humidity is the Enemy

Moisture creeps in fast, especially in summer months. Ionic salts like this one can pull water right out of the air, which changes their weight, clumping them up and affecting concentration. Every chemist who has watched a bottle from a shipment turn sticky after a week on the bench understands. Store this compound in a dry container; I like to toss in a silica gel packet for backup. Keep the cap closed tight and avoid opening it unless you really need to measure out material.

Temperature: Steady Wins the Race

Lab refrigerators are full of surprises, but temperature swings shouldn’t be one of them. If the label says room temperature, that means out of the sunlight and away from any heating vent. In cooler climates, a shelf in an insulated cabinet works well. In warmer places or buildings with spotty climate control, look for a cold, stable corner. Researchers at Purdue ran stability tests and saw degradation rates climb fast at 35°C compared with ambient conditions. Shooting for a consistent 18–25°C will keep things stable for months.

Light Dulls the Edge

Iodide compounds can take a beating from stray photons. Light breaks them down, sometimes unnoticed at first, but over weeks you’ll spot the color shifting and the reaction yields dropping. Stores use amber bottles for a reason. I’ve salvaged half-degraded samples by moving them into the dark, but if you start that way, you never have to fix the problem. Keep containers in the box or use a cupboard that stays shut unless you’re working.

Keep It Clean

Cross-contamination ruins more materials than people like to admit. Dedicated spatulas, gloves, and bench paper protect not just you but the quality of your supplies. This iodide is no exception. Scooping with gear that touched other powders or reagents can introduce trace impurities, and those show up in data down the road. My routine: glove up, open just what I need, and never return excess to the original bottle.

Labels and Dates

Labels matter. I’ve seen some labs track bottle openings with a strip of masking tape and a marker. Note the date you first open a pack and update it every time you break the seal. This habit makes it simple to toss old material before it leads to a failed experiment or unsafe side reaction.

Solutions for Real-World Labs

For smaller labs or teams with infrequent use, buy the smallest packs you can get. Split larger lots into airtight vials the day they arrive. If budget and space allow, a small, fanless desiccator box on a cool shelf works wonders.

Building Reliable Protocols

The best results come from a bit of planning, a lot of follow-through, and respect for the quirks of each chemical. These aren’t optional steps. Proper storage protects investments, keeps staff safe, and upholds experimental value. Consistent basics – dry, cool, dark, and clean – add up to longer shelf life and stronger, more trustworthy outcomes.

The Truth About This Chemical

If you’ve ever stepped into a chemistry lab or handled specialty chemicals for research, you probably respect the long names on those reagent bottles. N-Propyl-N-Methylpiperidinium Iodide sounds complicated, but its dangers come down to basics: it poses health risks and requires solid habits to work around safely.

Take a look at stories from people who work with similar compounds; nearly everyone has heard about colleagues dealing with accidental splashes or inhalation. Painful skin irritation and breathing problems make an impression. This isn’t just paranoia—safety data sheets mark this compound as harmful if swallowed, inhaled, or spilled on skin. Piperidinium salts in general draw attention for their ability to irritate mucous membranes and the respiratory tract. It takes just one mistake to end up visiting an occupational health nurse.

Don’t Skip the Basics: Gloves and Eye Protection

No matter how comfortable you get with routine lab work, gloves still matter every time. Nitrile gloves last through typical handling of this chemical. If I expect direct contact, double-gloving adds some peace of mind. The point of wearing proper lab coats, long sleeves, and closed shoes keeps risky compounds off your skin and street clothes. That small step will save a lot of trouble if a tube breaks or powder kicks up unexpectedly.

Splash goggles or, for extra protection, a face shield help against droplets hitting your eyes. Once saw a graduate student get some fine powder under their contact lens and spend the afternoon in the clinic. Never forgot the look on his face—total misery. Keep the eye wash nearby, but don’t give yourself an excuse to need it.

Take Airborne Hazards Seriously

Crystalline powders often make fine dust, which sneaks into lungs faster than you expect. The safest route goes through a chemical fume hood, not the open bench. A sash between you and the chemical actually makes a difference. If the air smells odd or your eyes start to sting, that’s a warning sign to pause and fix your ventilation setup.

Iodide salts sometimes release a sharp odor that tells you about possible volatility or decomposition. Good practices mean sealing up storage bottles right after use, clearly labeling everything, and double-checking containers for leaks. Working in ventilated spaces cuts down the chances of breathing in stray particles, especially in a shared lab where you can’t always control what the person next to you is doing.

Spill Response: No Room for Hesitation

Every lab should rehearse spill responses. Once saw a classmate freeze up after a small pile of powder landed next to the hot plate—bystanders hesitated, too, which only let the dust spread. Training matters. Granular spill absorbents, disposable towels, and a waste container just for contaminated materials make cleanup swift and thorough. Immediately removing soiled gloves keeps accidental transfer to a minimum. Washing affected skin or eyes with water might seem basic, but it’s the fastest route to reducing exposure.

Long-Term Health: Don’t Take Unseen Risks

“Invisible injuries” add up over time. Long-term handling without protection raises the risk of chronic irritation, allergic reactions, or even organ damage, depending on the exposure pathways. OSHA and university EHS offices publish easy-to-understand guidelines, which can feel repetitive but often save trips to the doctor. People tend to work alone after hours—letting others know your planned experiments and having check-ins can’t be overrated.

Culture of Care: Supporting Each Other

Experience in real labs shows the best teams give honest reminders, check on each other, and offer corrections without blame. Sharing tips on PPE or noticing that a glove has a pinhole doesn’t slow down research; it actually builds trust. Chemicals come with big risks, but a crew that watches out for everyone’s safety finds more success, fewer accidents, and real peace of mind when the day ends.

Digging Into the Hazards

N-Propyl-N-Methylpiperidinium Iodide isn’t in many headlines, but it finds a spot in the toolkit of synthetic chemists and specialists working on ionic liquids or phase transfer catalysts. Even though it's not a household name, every lab tech or chemist encounters a list of cautionary notes about handling chemicals with iodide ions or quaternary ammonium structures. This mix in particular brings up specific safety flags, both in terms of incompatibilities and dangerous reactions worth knowing about.

Combining with Strong Reducers Brings Risks

One reality after spending time with trial-and-error syntheses: alkyl iodides do not play nice around strong reducing agents. Iodide ions, when tossed in the mix with strong reducers like sodium metal or lithium aluminum hydride, have started reactions that get out of hand, even depending on temperature. Each time I've seen a bottle marked "iodide," I remember stories where heat, sometimes fire, resulted from casual mixing with metal powders. It's not just the loss of your reaction—those are moments you do not forget, and the risks to health and property linger long after. Reading up on incident case reports, you'd catch patterns: release of methyl iodide and other toxic gases during decomposition, especially at elevated temperatures, isn't a hypothetical concern.

Oxidants Are Not Friends

I can’t overstate the importance of double-checking for strong oxidizers on the bench when planning a reaction. Quaternary ammonium compounds, with an iodide counterion, face incompatibility with agents like peroxides or nitric acid. Mix-ups have led to formation of iodine, a pungent and harmful vapor, and in some cases, oxidative decomposition that spirals beyond thermal runaway. The smell of iodine in the air after an accident is a sharp reminder to clarify storage rules and keep inventories segregated based on the chemical class. Reports in chemical safety literature back up these lessons, highlighting unplanned releases due to mismanaged waste containers and bottle mislabeling.

Environmental and Long-Term Concerns

Years in labs taught me the pause you get before pouring any iodide-containing solution down the drain. Environmental agencies don’t just set limits for fun—quaternary ammonium salts persist and bioaccumulate, and iodides in general can disrupt local aquatic life. Even a small spill in a poorly ventilated area exposes techs to thyroid-disrupting materials. So disposal steps need thoughtful execution, not haste.

Smarts for Safer Handling

Published safety data sheets stress gloves, goggles, and reliable fume extraction. I stopped thinking of those as optional after watching a spill foam up and react when a coworker absentmindedly wiped it with a tissue that likely had cleaning solution traces on it. Labs with good habits—regular safety drills, clear hazard labeling, and dedicated waste streams—cut down on near-misses and exposures.

Changing the Game with Inventory and Education

No one expects danger from small quantities, but experience and evidence suggest otherwise. Comprehensive chemical inventories, training that goes over real case studies, and investing in compatible storage transform workplace safety culture. With materials like N-Propyl-N-Methylpiperidinium Iodide, the people who ask questions and double-check references protect themselves and everyone around them. Being well-versed in chemical compatibility and understanding the health impacts of exposure carries more weight than relying on instinct or shortcuts.