N-Propyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide: A Ground-Level Look at History, Chemistry, and Its Place in Modern Industry

Historical Development

Stories about ionic liquids like N-Propyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide stretch back to the search for cleaner, safer alternatives to conventional solvents in the chemical industry. By the turn of the new millennium, academic circles started to recognize the potential of ionic liquids as conductors, lubricants, and environmentally considerate solvents. Researchers pushed the boundaries using trial and error, grasping at compounds that stood up to thermal and electrochemical challenges. This particular compound emerged as a favorite among engineers and scientists who worked with electrochemical devices, primarily because it refused to catch fire and stood up to heat and voltage without breaking down.

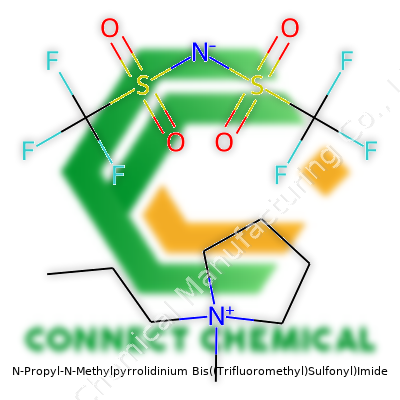

Product Overview

This ionic liquid, often abbreviated as [C3mpyr][NTf2], stands out for low volatility and robustness under tough operating conditions. Its liquid range helps in both low and high-temperature setups, from chilled analytical labs to roaring reactors. The substance doesn’t leave doors open for water absorption or sudden evaporation, building trust among researchers who need repeatable outcomes. Over time, it earned popularity in battery and capacitor development, especially when performance and lifespan sit high on priority lists. Several manufacturers market this molecule under slightly varied names, but end users care most about purity and handling practices.

Physical & Chemical Properties

Looking at this ionic liquid in a flask, most scientists notice its clear, faintly viscous appearance. Touching the vial, you’ll see it resists quick pouring. The density feels higher than simple alcohol or oil. Key chemical figures show a melting point often below -10°C and stability up beyond 300°C. Its non-flammability and almost non-existent vapor pressure lower accident risk on site. Under the microscope, this compound’s ions discourage water molecules from mingling, making it hydrophobic. Unlike many organic solvents, it resists breaking apart under everyday lab or plant conditions—whether exposed to strong acids or bases, the structure endures.

Technical Specifications & Labeling

Spec sheets usually include the chemical’s molecular weight—roughly 422 g/mol for [C3mpyr][NTf2]—plus its CAS number, specific gravity, water content (kept below 50 ppm for high-grade uses), and residual halide numbers. Responsible vendors list emission restrictions, recommended temperature windows, and compatible storage materials. Accurate labeling helps labs avoid cross-contamination with sensitive electronics or battery cells. Batch numbers and trace analysis back manufacturers’ promises of purity, echoing food-grade standards applied now to electronic chemicals.

Preparation Method

Preparation starts with a clean reaction between N-Propylpyrrolidine and methylating agents in anhydrous conditions. Once the pyrrolidinium cation forms, the next step involves pairing it with the bis(trifluoromethylsulfonyl)imide anion, usually via metathesis with lithium bis(trifluoromethanesulfonyl)imide. Each step needs attention to temperature control, water exclusion, and careful handling of byproducts. Industrial-scale processes favor closed systems and high-purity glassware. After neutralization and washing steps pull out unwanted residues, the solvent exchange washes out byproducts, ensuring a high-grade liquid ready for sensitive applications.

Chemical Reactions & Modifications

N-Propyl-N-Methylpyrrolidinium-based ionic liquids serve as a kind of “inert playground” for other chemicals. Their strong anion-cation interaction holds firm during most routine syntheses, refusing to swap partners with weaker guests. If scientists wish to modify the properties—tweaking viscosity, conductivity, or hydrophobicity—they often alter the cation’s alkyl group or substitute the anion. That sort of fine-tuning gives battery designers ways to experiment with conductivity shifts or electrochemical stability, rolling out custom ionic liquids for higher voltage or specific solvent compatibility.

Synonyms & Product Names

You might find this same compound under different banners in supplier catalogs: 1-Methyl-1-propylpyrrolidinium bis(trifluoromethylsulfonyl)imide, [C3mpyr][NTf2], or MPPyr NTf2. These shorthand tags travel section-to-section in storage rooms, so proper cross-referencing matters. A missed detail here sometimes leads to order mix-ups, lost time, or costly process errors, especially for teams working on deadline-driven R&D projects.

Safety & Operational Standards

Ionic liquids, for the most part, catch less fire than organic solvents, giving safety officers some breathing room. That said, they hold their own risks. Extended skin contact or inhalation of aerosols from agitation brings health concerns about chronic exposure. Pure samples spill slower than regular liquids, but their persistence on gloves or counter surfaces calls for careful cleanup. Safe labs mandate splash goggles, gloves rated for fluorinated compounds, and proper ventilation. Suppliers ship [C3mpyr][NTf2] in specialized fluoropolymer bottles to block leaching or chemical interaction during storage. Disposal regulations treat residual liquids like mild toxins that never belong in standard drains.

Application Areas

Over the past decade, [C3mpyr][NTf2] earned a place in lithium-ion battery development, high-voltage supercapacitors, and as a solvent medium in organic synthesis. Unlike volatile solvents, its nearly odorless profile lets chemists focus on yield and selectivity instead of ventilation worries. Electrochemical engineers often reach for it when standard electrolytes hit their limits—its stability under high voltage gives new life to aging battery chemistries. The liquid’s ability to dissolve a wide range of compounds also appeals to teams tackling tricky separations or catalysis. The slow evaporation makes it a prime choice in high-precision, high-temperature operations, like those inside next-gen analytical sensors or advanced lubricants for aerospace systems.

Research & Development

Universities lead the use of [C3mpyr][NTf2] in both fundamental and applied chemistry. Academic labs run lifetime tests on batteries, screen for performance drift, and pose tricky questions about charge/discharge cycles in low-temperature environments. Collaborations with private firms focus on replacing hazardous solvents in large-scale chemical synthesis, aiming to lower workplace risks and long-term costs. The challenge of recycling or regenerating this ionic liquid after use inspires ongoing research—efficient recovery systems offer both economic and environmental gains. Not every experiment pays immediate dividends, but the pipeline of ideas keeps this chemical relevant in published research and patent filings year over year.

Toxicity Research

Though [C3mpyr][NTf2] emerged as a safer alternative to traditional solvents, scientists dig deep into its long-term environmental and health effects. Most acute toxicity tests in mammals show low short-term dangers under laboratory conditions, but slow biodegradation raises flags for aquatic environments. Repeated or high-dose exposure in rodents links to mild liver or kidney stress, especially where breakdown products build up. Regulatory frameworks, especially in the EU and East Asia, call for long-term fate studies and eco-toxicology reports before large-scale industrial deployment. Lab managers keep up-to-date safety training and chemical hygiene plans in place for new hires, aiming to get ahead of regulations and public scrutiny.

Future Prospects

Interest in ionic liquids like [C3mpyr][NTf2] shows no sign of fading. Battery manufacturers in Asia and the US explore new blends packed with this compound for ultra-high-voltage power packs. Environmental chemists press for ways to reclaim and reuse the liquid at end-of-life, arguing for circular supply chains and reduced e-waste. Companies that design specialty ceramics or polymer membranes eye stable ionic liquids to make their processes cleaner and higher yielding. Universities, tasked with training the next wave of engineers, keep [C3mpyr][NTf2] in their curriculum, noting its use cuts across fields—energy storage, synthesis, analytical chemistry, and beyond. Everybody in the field knows the search for better solvents and electrolytes stays alive, as demands for performance, safety, and sustainability keep rising year by year.

Spotlight on a Modern Workhorse

N-Propyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide—often called by its shorthand, one of the “Pyrrolidinium TFSI” ionic liquids—shows up wherever researchers and engineers need a stable, safe, and highly conductive solution. Most folks outside of research labs never hear about it, but its reach keeps growing as technology demands better, cleaner, and less volatile chemical alternatives.

Power Source Innovation: Batteries and Supercapacitors

Over the years, I’ve watched lithium-ion battery research shift focus from simple carbon solvents to custom-made electrolytes. This ionic liquid stands out, especially in energy storage. You’ll find it in the guts of high-performance batteries, where companies and universities rely on its safety and high voltage stability. Traditional electrolytes tend to break down at higher voltages and temperatures, which limits battery lifespan. In contrast, this pyrrolidinium salt holds strong—reducing fire risk and improving efficiency. That’s why teams working on electric vehicles and grid storage have invested time and resources into testing various TFSI salts, including this one, hoping for longer-lasting and safer power packs.

Electrochemical Devices Beyond Batteries

The same attributes that help inside a battery help elsewhere, too. Supercapacitors—peerless when it comes to rapid charging and discharging—use ionic liquids like N-Propyl-N-Methylpyrrolidinium TFSI because of their robust operating window. Industries looking to balance fast energy bursts with equipment safety have seen better performance and fewer failures by shifting away from old-style organic mixes.

Greener Chemistry, Cleaner Technology

Many solvents used to be flammable and hazardous. That’s tired thinking. Modern chemistry demands safer alternatives. My experience in sustainable lab work has shown that ionic liquids don’t evaporate like older solvents, and their thermal stability reduces incidents in both manufacturing and research environments. They rarely end up as air contaminants, unlike classic volatile organics. Companies developing sustainable chemical synthesis processes have noticed that this ionic liquid—thanks to its low volatility—cuts down on workplace hazards and headaches from environmental regulations.

Electroplating’s Unsung Hero

Industrial plating still clings to legacy acids and cyanides, risking both worker health and product quality. The rise of ionic liquids lets plating operations work at lower temperatures, get smoother metal deposits, and—most importantly—reduce noxious runoff. Automotive and electronics sectors gain the edge, especially when striving for higher quality metal coatings without legacy chemicals’ burden.

Research and Discovery: A Lab Favorite

Through my years in multidisciplinary research, I’ve seen the best breakthroughs happen when materials scientists get their hands on a reliable, predictable medium. N-Propyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide gives researchers a dependable solvent that works in custom-designed sensors, electrochemical devices, and experimental catalysis. Flexible, stable, and less toxic than many alternatives, it helps uncover new reactions and supports future tech that’ll run cleaner than anything before.

Where Next?

With mounting pressure for safer, longer-lasting and more sustainable solutions, this ionic liquid will continue to attract attention. By investing in scalable synthesis and upfront research on long-term safety, industry can keep making use of its benefits without stumbling over unknowns. Community engagement between labs, manufacturers, and regulators will make the biggest difference. Knowledge-sharing and open data go further than isolated discoveries, helping this material show its best face both in labs and on factory floors. The story’s still unfolding, but the promise is easy to see wherever safer, more reliable chemistry matters.

Unlocking the Hidden Blueprint

Every compound carries a secret recipe. The chemical structure and formula act as the blueprint showing how the atoms lock together, how the whole thing fits, and why it behaves the way it does. You don’t need a PhD to grasp the basics, but you do need a healthy respect for the small details—little things like where a carbon sits or an extra dash of hydrogen make all the difference.

Take caffeine, the world’s favorite pick-me-up. It might look simple on a coffee mug—C8H10N4O2—but its actual structure weaves atoms into rings and lines that deliver a punch to our brains. That structure lets it wedge into the same spots as adenosine molecules in our brains, tricking us into feeling awake. Miss out a nitrogen or drop a hydrogen, and you land at a completely different compound. Even the taste or effect can change. That’s how much structure matters.

Real life puts these patterns to the test all the time. Drug development happens atom by atom, tweaking molecules until they hit the sweet spot—good enough to cure something, gentle enough not to wreck the rest of the body. I remember looking at aspirin under a projector in high school. A cluster of carbons tied to an oxygen and hydrogen, all crammed together so neatly. Swapping a few parts would turn aspirin into a cousin that relieves pain differently or maybe not at all.

Why Structure and Formula Shape Our World

Understanding chemical structure keeps us safe and healthy. Food science relies on knowing how sugar molecules hook together and how they might react if you swap in something artificial. The difference between harmless vinegar and deadly antifreeze lies in a couple of carbon and oxygen bonds. It’s easy to miss those tiny changes if you don’t pay close attention, but nature won’t forgive those mistakes. The environment, medicine, manufacturing—all spin on the fine axis of chemical structure.

Researchers can’t just guess. They use magnetic resonance, X-ray crystallography, and years of careful pencil-and-paper work. Teams check each other's drawings to avoid disaster. One bad sketch can lead to the wrong chemical getting mixed into a factory run, ending in costly recalls or injuries. Sometimes, it feels like old-fashioned craftsmanship—only with molecules.

Transparency and accuracy matter. People rely on scientists and companies to provide truthful information about chemical compounds. Any shortcuts or sloppy reporting can lead to harm, loss of trust, and, in the worst cases, tragedy. That’s where strict review and regulations step in, keeping the community responsible and honest about what ends up on store shelves or in prescription bottles. As folks who value their health and safety, we press for clear standards in publishing chemical data, and expect companies to back up claims with reliable lab work.

Betting on Solutions That Work

Better science education at every level prepares people for informed decisions. Sharing not just the chemical formula, but also a picture of the structure, teaches both caution and curiosity. I’ve seen young students light up as they snap molecular models together, realizing that chemistry isn’t all jargon and complicated math. It's a puzzle, and solving it makes everyday life safer and smarter.

Open access to research builds public trust. Publishing detailed chemical structures and robust peer review set a standard for the entire industry. That way, everyone—from the city water worker to a nurse at the local clinic—gets answers they can count on. This is real progress, brick by chemical brick.

Why Safety Never Gets Old

Anyone who's ever handled strong cleaning agents or industrial materials knows how unpredictable chemicals can be. Very few products come without strings attached, especially in workplaces or home garages. The small print tucked away on a label isn’t just legal fluff—those warnings grew out of experience, trial, error, and, in some cases, accidents.

Decades of research and shared stories from the workplace have shown that ignoring those safety instructions sometimes leads to skin rashes, lung problems, or even worse. In my own time around labs, a misplaced glove was all it took for a messy afternoon with red hands and regret. Nothing drives a point home like a real-life mishap, and more often than not, it’s the little shortcuts that trip people up.

Why Some Chemicals Make Headlines

Modern products often arrive with a promise—cleaner surfaces, faster reactions, brighter finishes—but many also come packed with harsh solvents, acids, or reactive powders. Each one has its own quirks. For instance, a seemingly harmless powder could turn caustic when mixed with water. Some household spray bottles harbor volatile compounds that turn the air tough on sensitive lungs.

The Centers for Disease Control and Prevention have tracked hundreds of cases each year where accidental exposure led to injury. Workers without goggles, or folks refilling bottles without gloves, make a grim tally nobody wants to join. For families, the presence of bleach under the kitchen sink or solvents in the garage creates a different kind of risk, especially when small kids are around.

Simple Steps With Big Payoffs

Chemical experts and safety educators recommend small actions that produce outsized results. Gloves and safety glasses may seem annoying at first, but they catch almost all splashes. Asking yourself, “Would I want this on my next meal, or in my lungs?” before handling anything new stops plenty of accidents in their tracks.

Good ventilation counts for a lot. Opening a window or running a fan dilutes fumes faster than you might expect. I always remind friends to avoid eating or drinking near their work; decades of studies confirm that cross-contamination sends trips to the doctor soaring. If a spill happens, quick and thorough cleanup prevents lingering trouble.

Facts Above Familiarity

Familiarity sometimes leads to carelessness. Just because someone’s poured the same cleaning solution a hundred times doesn’t make them immune to problems on try 101. A 2022 survey from the U.S. Bureau of Labor Statistics showed that long-term users made up nearly half of all chemical injury cases because they skipped one step they thought wouldn’t matter. Reading fresh instructions and updating what you know pays off.

Disposal also deserves a careful eye. Local waste rules exist for a reason; pouring remnants down the drain or chucking them in the trash can harm the community. A trip to the city’s collection center prevents bigger headaches and keeps water sources cleaner.

What Puts You in Charge

Trusting your own judgment beats relying on luck. Scanning the label for hazard words—like “corrosive,” “irritant,” or “flammable”—makes clear the next move. Keep clean water on standby, study emergency steps ahead of time, and store all products out of reach of kids and pets. Manufacturers and agencies like OSHA and Poison Control keep guides available for a reason: more information rarely hurts, but less preparation almost always does.

Understanding What’s at Stake

For a lot of us, the topic of storing chemicals and sensitive substances brings back memories of overcrowded science lab shelves or maybe a pungent-smelling utility closet. In truth, storage and stability play a bigger role than most people think—affecting performance, safety, and value. I spent quite a few years in academic research labs where a tiny change in temperature or humidity ruined days of work. Over time, I’ve learned there are no shortcuts, just smart, proven steps to help keep things predictable.

Temperature Isn’t Just a Number

Think about how milk spoils if left out. The same logic applies to chemicals. Many substances break down, clump, or change color if the room gets too warm or too cold. For example, certain antibiotics and biologics will last only a fraction of their normal shelf life if stored above the recommended range—sometimes as short as a few weeks. On the other hand, storing below freezing can make some liquids separate, giving you a substance that won’t work as designed.

So, the right approach starts with manufacturers’ guidelines. Usually, they put the recommended storage temperatures right on the container for a reason. Investing in a reliable fridge or temperature-monitored cabinet saves money in the long run. In professional settings, digital data loggers send up red flags when temps stray. It isn’t fancy—just honest work to avoid the headache of compromised stock.

Light, Air, and Humidity: The Silent Spoilers

It’s not just the thermostat, either. Light-sensitive items can break down with just a few hours of exposure so I use tinted glass containers for things that need darkness, like certain vitamins or photosensitive reagents. Even in a windowless room, leaving lids loose exposes products to air and humidity. Oxygen slowly reacts with some ingredients, leaving ugly sediment or bad smells. I learned the hard way that just one night of a poorly sealed jar can force you to toss valuable materials.

For powders and salts, a desiccator—a sealed, dry box—is a simple piece of equipment. In humid environments, I always keep packets of silica gel nearby, even for everyday things like camera film or baking yeast. Most commercial labs monitor humidity just like temperature. It’s not paranoia; moisture can trigger clumping, loss of potency, or even dangerous reactions in some chemicals.

Labels, Logs, and Simple Habits

A sharp label and a logbook worked wonders in my experience. Too many times I watched a colleague grab the wrong bottle because handwriting faded, or dates weren’t clear. Every time a container opens, mark the date. Rotate older material to the front so nothing sits forgotten. Good stock management isn’t just busywork; it lets you spot bad batches, expired product, or changes you might otherwise miss. In industries that ship worldwide, these habits make tracking recalls or quality issues much easier.

Finding Solutions Rooted in Reality

A well-lit, ventilated, locked cabinet works for most household and small-scale needs. In industrial or hospital settings, regulations place a higher bar: backup power, audit trails, batch testing, and often, double containment for hazardous substances. Since regulations keep growing stricter, I’ve learned from colleagues in pharmacy and food production: communicate, train, and update your protocols each year. The folks who keep clear records and stick to the basics rarely waste product or face fines.

Treat every new substance on your shelf like a short-lived ingredient in your fridge. Take the time to learn its habits, and set up storage that matches its quirks. People stay safe, money goes further, and you earn the trust of customers or coworkers who count on your materials to work, batch after batch.

The Lay of the Land for Chemical Procurement

Some chemicals come with names that twist your tongue and challenge your memory, and N-Propyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide certainly lands high on that list. This compound sees use in research labs tinkering with ionic liquids, often in battery research and advanced electrochemistry. Finding a supplier is step one. Science never happens in a vacuum, so let’s look at what makes the process trickier than a few clicks on your phone.

Licensing and the Realities of Access

Buying specialty chemicals isn’t like ordering groceries online. Before looking for suppliers, anybody purchasing this material needs a research purpose—a university project, battery company work, or product development at a business. Most reputable suppliers won’t even quote you a price without proof of affiliation with such an institution. This isn’t just about keeping standards high. Regulations worldwide push for traceability, product stewardship, and safe handling. Europe and the U.S., for example, weigh every transaction against REACH, TSCA, and other rules.

Tracking Down Reliable Suppliers

Ordering the right material depends heavily on picking the right supplier. Sigma-Aldrich, TCI, Alfa Aesar, and some Asian chemical manufacturers offer this ionic liquid. Their catalogs cover industries ranging from energy storage to catalysis research. My own experience hunting down such chemicals for university research—never underestimate the value of reaching out to suppliers directly by phone or email. Online portals sometimes fall short for small-batch orders or rare specifications.

Sizing Up Available Packaging

Lab-scale use demands different quantities than what a factory pilot project might call for. Most chemical suppliers break their inventory into standard bottles. The smallest common offering runs around 5 grams. This amount suits researchers running initial scouting studies. More established labs, or those repeating tests, scale up to 25 grams, 50 grams, or 100 grams. Bulk options (500 grams, 1 kilogram, or even more) appear for commercial research partnerships or product development.

These solvents usually come in tightly sealed amber-glass bottles. Avoiding contamination or photodegradation remains key. You won’t get this shipped in plastic jugs. Dry ice or insulated packaging kicks in if the material has temperature sensitivity or air instability. Handling and storage guidance comes with every shipment. I remember my own nervy wait for a fifteen-gram delivery, sweating it out in the summer heat, only to be relieved when a cold-pack-wrapped, glass-sealed bottle showed up in perfect condition.

Making an Informed Choice

It’s easy to get tripped up comparing suppliers with vastly different price tags. Dig into the material safety data sheet (MSDS), check for documentation like certificates of analysis, and ask about tested purity (commonly 99% or higher for research use). Look for transparent records on shelf life and handling. Bulk isn’t always better if you lack storage or the infrastructure for safe handling.

Practical Strategies for a Smooth Purchase

Reach out to your institution’s purchasing team. Use their relationships with suppliers to avoid delays or markup. If you’re ordering for the first time, insist on a smaller pack size. It helps conserve budget and gives a chance to evaluate the actual product without risk of excess waste. Sometimes I pulled in help from fellow grad students who’d made similar purchases. Tapping into lab networks, both local and online, can be priceless when navigating unfamiliar suppliers or negotiating lead times.

Staying Safe and Compliant

Chemicals like this one may promise cutting-edge research, but they come with safety considerations—think storage, labeling, disposal, and record-keeping. Good suppliers walk you through local laws and hazard warnings. They also indemnify buyers with clear return and incident protocols. Don’t cut corners, not even for convenience or a lower price—oversights can trip up a research project or worse, endanger a lab.