N-Propyl-N-Methylpyrrolidinium Bromide: Beyond the Lab Bench

Historical Development

N-Propyl-N-methylpyrrolidinium bromide tracks its roots back to the growing interest in ionic liquids and quaternary ammonium compounds of the late 20th century. Early studies on alkylpyrrolidinium salts looked to meet demands for more stable, tunable organic cations in the fields of electrochemistry and green synthesis. Researchers soon started tailoring alkyl side chains on the pyrrolidinium ring, hitting on variations like n-propyl and methyl substitutions to balance solubility, ionic conductivity, and chemical stability. The bromide counterion became favored in many synthesis routes for its ability to form solid, highly-pure salts without introducing complex reactivity. Organic chemists incorporating these materials into battery electrolytes or as phase transfer catalysts drove development. Publications in the late 1990s helped bring this salt onto the wider stage, marking its transition from chemical curiosity to practical laboratory staple.

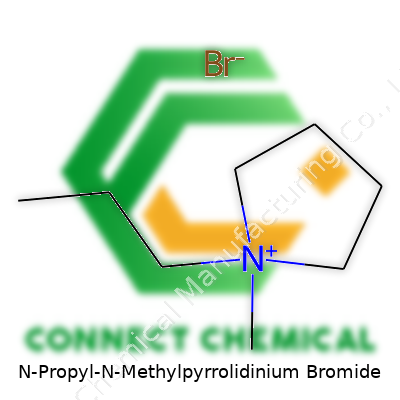

Product Overview

What sets this compound apart? The n-propyl and methyl groups attached to the pyrrolidinium ring offer a careful balance of hydrophilic and hydrophobic properties, giving it broad appeal in synthetic, analytical, and energy applications. The bromide form provides stability and easy handling, helping laboratories that want predictable, safe compounds for reaction development. It tends to arrive as a white crystalline solid, and suppliers often push its use in both organic synthesis and as a supporting electrolyte, reflecting its dual role as both a functional reagent and a building block for more complex ionic liquids.

Physical & Chemical Properties

N-Propyl-N-methylpyrrolidinium bromide melts between 75 and 85°C, offering straightforward transitions from solid to liquid during handling. It dissolves well in polar solvents like water, methanol, and dimethyl sulfoxide, which reflects the polar cation and the ionic nature of bromide. This profile makes it handy for work in both aqueous and organic media. Density comes in at just over 1.1 g/cm3, with little vapor pressure—important for safe benchwork and reducing losses in open containers. Chemically, the compound resists hydrolysis and oxidation under ambient conditions, so it stays stable on the shelf. bromoalkanes don’t break down, hinting at decent shelf life. Strong bases or nucleophiles can cleave the molecule at higher temperatures, presenting risks in overly aggressive syntheses.

Technical Specifications & Labeling

Suppliers present this chemical with clear CAS numbers, molecular formula (C8H18BrN), and purity often above 98%. Manufacturers usually provide a certificate of analysis detailing water, halide, and organic impurity levels. Labeling includes hazard pictograms because bromide salts can trigger irritation if handled poorly. Storage recommendations call for cool, dry conditions and careful sealing to keep out water. Product lots feature batch traceability, so labs can dig into the details if quality comes into question.

Preparation Method

Industrial and laboratory synthesis relies on alkylation of N-methylpyrrolidine with n-propyl bromide under anhydrous conditions. Researchers usually mix the pyrrolidine base and the alkyl bromide in a polar aprotic solvent such as acetonitrile, with a mild exotherm marking the quaternization process. Time and temperature control matter for high yields and low by-products. Filtering, washing, and recrystallization follow synthesis, driving off the excess solvent and trapping the pure solid. Those that skip purification steps often see a yellow tint or persistent odor—clear signals of leftover side-products that could ruin sensitive reactions.

Chemical Reactions & Modifications

N-Propyl-N-methylpyrrolidinium bromide offers a strong foundation for follow-up chemistry. Metathesis reactions let technicians swap the bromide anion for less-coordinating partners like bis(trifluoromethylsulfonyl)imide (NTf2), boosting thermal and electrochemical performance for advanced battery applications. Under high temperatures, strong nucleophiles break the quaternary ammonium salt into smaller amines and alkenes, forming potential side-products or reactants for further modification. Researchers sometimes reach for the molecule in multi-component reactions to introduce both cationic and alkyl characteristics into larger organic frameworks. Electrochemical studies lean on its high ionic mobility, which makes it valuable in cell design, especially in systems sensitive to common contaminants like alkali metals or traditional ammonium ions.

Synonyms & Product Names

Companies label this salt under various names, mixing systematic and trade conventions. You’ll spot it on labels as 1-Methyl-1-propylpyrrolidinium bromide, NMPPyBr, or simply Pyrrolidinium bromide (n-propyl, N-methyl). Many catalogs keep the prefix “quaternary pyrrolidinium bromide” for cross-indexing with similar cations differing by only one alkyl group. Trade-level brands might boil down to code numbers, but chemical structure always stays front and center for researchers comparing products.

Safety & Operational Standards

Handing safety starts with understanding the bromide and quaternary ammonium nature of this compound. Direct contact with skin or eyes can trigger moderate irritation, calling for gloves, goggles, and standard lab attire. Inhalation risk runs low due to its zero volatility at room temperature, but dust can pose risks when handling large amounts. Spills clean up with water, but thorough rinsing avoids residue that might interfere with sensitive syntheses downstream. SDS sheets warn against mixing with strong oxidizers or bases, both of which degrade the pyrrolidinium ring and open up unplanned chemistry. Waste needs packaging in accordance with hazardous materials guidelines due to the persistent bromide ion and potential aquatic toxicity. Training and facility checks play a big part—nobody wants to see preventable accidents with an otherwise straightforward reagent.

Application Area

This chemical lands in a surprising number of settings. Laboratories use it as a phase transfer catalyst to shuttle polar anions between solvents that don’t naturally mix. In electrochemistry, it stands out for its ability to support high-conductivity environments in both protic and aprotic cells, showing up in batteries, capacitors, and fuel cell development. In organic synthesis, the compound's quaternary ammonium center stabilizes intermediates, speeds up nucleophilic substitution, and sometimes unlocks new selectivity pathways for researchers chasing high yields. Environmental scientists eye the salt as a model compound for understanding ammonium mobility. It also finds use in solvent design, especially for new ionic liquids custom-made for extraction, chromatography, or high-precision separations.

Research & Development

Research keeps turning up new angles for this salt. Scientists push into new syntheses of battery electrolytes, hunting for thermal stability and electrochemical windows that widen the scope of non-aqueous cells. Drug delivery teams are looking at structural cousins to N-propyl-N-methylpyrrolidinium bromide thanks to their tunable solubility and low volatility. As hybrid catalysts, these salts drive rate increases by pairing the mobility of an ionic liquid with the selectivity of engineered anions. Research output over the past ten years keeps growing, especially as institutions dive deeper into the intersection of green chemistry and advanced materials. Each tweak of the pyrrolidinium structure seems to spark a wave of studies aiming to measure surface tension, stability, and compatibility—all matters that move out of the journal pages into commercial product lines.

Toxicity Research

Toxicological profiles get ongoing updates. Tests show oral and skin toxicity rates remain fairly low, especially compared to short-chain alkylammonium compounds, but aquatic risks crop up with larger spills. Pyrrolidinium salts as a group resist biodegradation, flagging long-term ecological persistence. Rats exposed to high concentrations develop mild liver and kidney stress, underscoring the need for careful handling and responsible disposal. Long-term effects remain limited by few published studies, suggesting a gap in how industry and academia understand the risks facing workers and downstream users. Labs working with large quantities need protocols that extend beyond the standard glove box—air filtration and regular medical monitoring help prevent chronic exposure incidents.

Future Prospects

Future outlook for N-propyl-N-methylpyrrolidinium bromide ties to several frontiers. Battery innovation keeps raising the bar, with new ionic liquids based on this cation finding their way into pilot projects for next-gen storage. Regulatory changes around persistent organic pollutants might force a closer look at breakdown paths, so chemical engineers already watch for more biodegradable or recyclable forms of the compound. Some researchers push combinations with fluorinated anions and longer alkyl chains, eyeing room-temperature stability or new solubility trends. Artificial intelligence platforms analyzing synthesis reports will likely streamline testing for new reaction environments. Agriculture, wastewater, and solvent recovery sectors now see the potential for these compounds to act as performant, customizable process additives. Students, start-ups, and major labs all face the same challenge—harnessing the known advantages while carefully mapping out environmental impacts and keeping safety at the center of new uses. Every time a fresh study hits the journals, new hands wheel out flasks and notebooks, eager to prove or challenge what’s known, all to push the story of N-propyl-N-methylpyrrolidinium bromide into tomorrow’s breakthroughs.

The Core of the Question

Most people don’t spend time thinking about chemical formulas unless they’re deep into chemistry or chemical engineering. N-Propyl-N-Methylpyrrolidinium Bromide isn’t a household name, but it matters in many research labs and industrial settings. For folks in the field, nailing down the correct formula helps guarantee that work stays safe and that results make sense.

Getting the Formula Right

N-Propyl-N-Methylpyrrolidinium Bromide comes from a family of compounds often used for ionic liquids and specialty solvents. Its structure brings together a pyrrolidinium ring, a methyl group, a propyl group, and a bromide anion. From a practical point of view, this means its chemical formula reads as: C8H18BrN. Each letter and number in that string gives vital clues about what chemists work with.

Why Details Like This Aren’t Just Trivia

The formula isn’t just a bit of trivia for exams. In research, I remember how a single wrong atom on a chalkboard changed the entire outcome of a synthesis experiment. You run the numbers, measure the reactants, and suddenly, an error means hours lost. The correct formula lets professionals predict molecular weight, toxicity, solubility, and even how a compound interacts with others. This isn’t just about academic precision—it’s about safety and cost. A slip-up can waste thousands in a production run and cause regulatory headaches.

Supporting Evidence and Experience

Labs publish their results with confidence because the chemistry world relies on peer-reviewed sources and established databases. The National Center for Biotechnology Information (NCBI) and PubChem list the formula as C8H18BrN. Cross-checks in Sigma-Aldrich’s catalogs and Merck Index back up this number. When laboratories verify a structure through tools like NMR or IR spectroscopy, the expected formula gives them a reference for matching spectral lines. This is the nitty-gritty that supports safe product development and reliable science.

Errors Ripple Outward

Imagine mixing up compounds with similar names but different formulas, especially during pharmaceutical or electrolyte formulation. Outcomes could swing from poor battery performance to failed clinical results or worse—harmful exposures. Years ago, a mistake in a published paper about a related ionic liquid led to a manufacturing halt and a product recall. Clear communication and strong fact-checking stop those costly and dangerous mistakes before they start.

Pushing for Clarity and Better Systems

Digital databases and chemical inventory tools speed up fact-checking. They weeds out old habits like copying from dog-eared lab notebooks or faded textbooks. Some platforms now use machine learning to flag possible inconsistencies in structures and formulas. There’s still a need for boots-on-the-ground skepticism and manual verification—no shortcut beats a careful human double-check. Mentors in my own lab drilled into us the value of always taking a step back before moving forward, especially for chemicals with complicated names or multiple forms.

Wrapping It All Together

Getting the formula for N-Propyl-N-Methylpyrrolidinium Bromide right reflects a bigger principle. Reliable science and safe industry practice depend on precision and steady commitment to accuracy. Easy online access to trusted resources gives today’s researchers and technicians the tools they need to work smart and stay safe. That helps the entire scientific community and the people who depend on the products built from these formulas.

Inside the Lab: Building Blocks for Innovation

Chemistry has plenty of complex names, but N-Propyl-N-Methylpyrrolidinium Bromide steps into research labs for good reason. Labs choose this compound as an ionic liquid—one of a family of salts that turns into a liquid at room temperature. Working alongside traditional organic solvents, it comes in handy during experiments chasing after better batteries, safer drug delivery, and even cleaner power sources.

Researchers like its stable structure. I’ve seen teams work with ionic liquids because old-style solvents can evaporate or get flammable fast. N-Propyl-N-Methylpyrrolidinium Bromide doesn’t disappear into thin air so easily, which helps keep studies consistent. Folks value that stability when chasing long, tricky reactions that can last days or even weeks.

Toward Greener Chemistry: Cleaner Solvents

Sustainability is more than buzz; it’s a demand from consumers and companies alike. Traditional solvents in chemical factories pollute water, fill air with fumes, and make waste a nightmare. This pyrrolidinium salt offers a shot at something cleaner. Its ionic nature helps dissolve both polar and non-polar compounds, acting almost like a universal solvent, but without the same environmental baggage.

Universities and cutting-edge startups use it to swap out more toxic compounds, aiming at processes that create less hazardous byproducts. Back in my grad school days, solvent safety briefings stressed how one spill could mean trouble in air quality. N-Propyl-N-Methylpyrrolidinium Bromide helps ease the risk, which makes a difference if you’re around chemicals every day.

Battery Development and Energy Storage

The search for better batteries pushes companies to rethink electrolyte mixtures. Ionic liquids pop up again and again, with this pyrrolidinium salt offering strong conductivity and resistance to water. Those properties matter for lithium-ion and flow batteries, especially as more folks install solar panels or drive electric cars.

Standard battery electrolytes break down when too hot or exposed to humidity. This compound holds up in tougher conditions, with research showing it extends battery cycle life. Engineers and chemists keep testing it to create devices that last longer and charge faster, in hopes of powering remote villages or the next fleet of city buses. I’ve seen how new electrolytes can breathe life into tired tech, and how excited people get when battery failures drop.

Drug Delivery and Pharmaceutical Synthesis

Speeding up drug development means relying on reliable intermediates. N-Propyl-N-Methylpyrrolidinium Bromide helps steer chemical reactions, especially those that need unique environments. Medicinal chemists like its ability to dissolve problematic ingredients, opening doors for hard-to-formulate medicines.

More pharmaceutical startups and big companies bring these types of ionic liquids into their synthesis steps to improve yields and lower contaminants. Patients benefit, as costs drop and unexpected impurities become rare. From experience, I know even tiny refinements in synthesis can slash months and dollars from the process, giving real hope for people waiting on treatments.

Barriers and Hopes for Widespread Adoption

Despite its promise, N-Propyl-N-Methylpyrrolidinium Bromide brings cost and supply chain headaches. Not every plant or company can source it, and regulatory agencies want thorough safety profiles. Solving these bottlenecks falls to chemical companies and policymakers. Investment in cleaner, scalable production could put this material to work in more factories, labs, and even households someday.

More open data about toxicity, long-term stability, and environmental impact would speed adoption. Training new chemists to handle and dispose of ionic liquids responsibly matters too. Solutions start with solid science and keep rolling with smart policy and honest conversations across the supply chain.

Understanding the Risks

Few folks walk into the lab expecting trouble, but even experienced chemists can underestimate what seems like a mild-mannered salt. N-Propyl-N-Methylpyrrolidinium Bromide may not be the most notorious chemical in the cabinet, but that doesn’t make it harmless. This compound brings risks that reach well beyond small spills or itchy skin. A slip in handling can mean reactions that burn or blind, so every bottle deserves attention.

Personal Protection Makes All the Difference

There’s nothing “optional” about goggles or gloves when this stuff comes out. Eye protection blocks splashes from causing real harm. Even a gram in the eye can cause a day to end in the emergency room. Nitrile gloves keep the compound off your skin, since the stuff absorbs fast and irritates. An open window doesn’t cut it for ventilation. Fume hoods suck up vapors and bromide dust before they sneak into your lungs. I’ve watched allergic reactions unfold, and nobody calls that a learning experience—they call it a mistake.

Smart Storage: Containment Over Convenience

It’s easy to cut corners and stack bottles on a shelf, but letting moisture sneak in risks caking and chemical breakdown. Store this salt in dry, tightly sealed containers and keep them out of sunlight. Glass bottles work well, but plastic stands up fine as long as caps seal tight. I always label the hazard—nothing fancy, just plain language so a new face in the lab doesn’t get a surprise.

Cleaning Up Hazards Before They Spread

Spills mean action, not panic. Small amounts come up with paper towels and plenty of water, but big messes call for spill kits—absorbent pads and neutralizers. Wiping a fine powder into the air just spreads the problem. Vacuum with a filtered system, don’t sweep. Any contaminated gloves or rags get bagged and tagged right away, not tossed in open bins.

Waste: Don’t Let It Linger

Pouring leftovers down the drain doesn’t just break the rules, it risks water safety and fines. Containers marked as “hazardous chemical waste” keep things clear for the next person. Turn the waste over to professionals. Letting a bottle linger in the back corner creates more danger with age. Routine disposal rounds in the lab stop clutter and confusion before it grows.

Training: Read, Watch, Ask

Reading the safety data sheet isn’t busywork—it’s self-defense. New employees need a hands-on walk-through with a seasoned worker before trying solo. No one knows everything, and asking a question says more about safety than silent guessing ever will. Regular retraining and chemical safety reviews cut down on mistakes. That’s how injuries get rare, not by luck but by respect and repetition.

Learning From Years in Hoods and Gloves

Living through near-misses changes the way you handle chemicals like N-Propyl-N-Methylpyrrolidinium Bromide. I’ve seen burns from rushed cleanup, rashes from carelessly touched knobs, and one fire from bad waste storage. None of those moments came from ignorance—they all came from moving too fast or relaxing the rules. Proper care always takes more time, but it’s the only way out of the lab at the end of the day, healthy and ready to come back tomorrow.

Understanding Product Purity

People often ask about purity when making big decisions about chemical or material orders. Whether in science labs, manufacturing, or agriculture, the level of purity often sets the stage for how a material performs. For example, pharmaceutical companies can’t cut corners on the quality of their ingredients — not when traces of impurities could change outcomes for patients. Purity acts as a guarantee, almost like a handshake between buyer and seller. Most reliable sources supply detailed specifications backed by third-party testing, sometimes through certificates of analysis. Reputable vendors publish clear numbers: 99.5%, 98%, or even higher, giving buyers confidence before they order.

Low-quality raw materials sometimes find their way into the supply chain, often because someone traded purity for price. Scientists working with chemical compounds see the impact firsthand. An experiment that fails because something unknown got mixed in can waste weeks, or even months, of work. In industries like electronics—lithium for batteries, silicon for chips—the tiniest impurity can throw off the entire process. Taking shortcuts can drive up costs that never make it to the invoice.

Packaging: More Than Just a Container

Packaging gets less attention than purity, but the impact ripples through every level of the supply chain. Working in a warehouse taught me how improper packaging leads to disaster: a leaking drum, a busted bag, or worse, a contamination incident that puts people at risk. Suppliers offer a range of standard packaging sizes for a reason. Small bottles, one-kilo bags, 25-kilo sacks, and drums up to 200 liters keep storage practical and costs in check. Some industries use bulk containers, like 1-tonne intermediate bulk containers (IBCs) or tanker trucks, when moving ingredients across borders or into high-volume operations.

A pack size matters to the end user. A research scientist might only want 100 grams of a compound so nothing sits around going bad. Factories need pallet-loads or tonne containers to keep up with round-the-clock production. Buyers save money and headaches by sizing orders to match real needs. I’ve seen too many places dump expired product because they thought bigger always meant better value.

Why Transparency Matters

Good suppliers post detailed purity data and give real choices on packaging. By doing so, they help buyers avoid surprises that lead to expensive delays. Transparency builds trust, especially as more countries demand traceability in their supply chains. In 2023, the U.S. Food and Drug Administration cited dozens of cases where vague purity claims let adulterated goods into mainstream circulation, leading to recalls. Trust builds on facts: numbers from lab tests, clear expiration dates, and package tracking.

Solutions lie close at hand, with open communication and digital documentation. Asking suppliers for specifications up front—down to batch numbers and source country—puts power back in buyers’ hands. Quality checks before products leave the facility shrink risks. Pushing for recyclable packaging or returnable drums can cut both costs and a company's carbon footprint.

Looking Ahead

Growth in global trade demands careful balance between speed and reliability. Tracking purity and packaging options will only get more important. Those who pay attention to details early keep operations running, workers safe, and customers satisfied.

Why Storage Matters

Most chemists encounter a long line-up of specialty salts, but only a few end up complicated. N-Propyl-N-Methylpyrrolidinium Bromide does not get much attention, yet it shows up in labs working on electrochemistry and organic synthesis. Preserve quality on the shelf by protecting it from heat, moisture, and stray light. Ignore these and purity drifts, research budgets feel the cost, and staff face extra headaches. Many compounds degrade quickly, but the right environment can give you more time to use what you have.

Temperature Makes a Difference

My own shelf life struggles usually start with temperature slips. This pyrrolidinium salt stays most stable in cool, dry cabinets. Aim for a spot at room temperature or under—think 20–25°C. Set the container away from heating vents and sunlit windows. Small fluctuations usually do not wreck everything, but constant warmth speeds up unwanted reactions. Chemical suppliers echo that advice for a reason. Experience in old campus labs taught me that warm storerooms invite water seepage and faster chemical breakdown, especially as humid air circulates.

Humidity Hurts More Than You Think

Bromide salts, especially those with organic side groups, tend to soak up moisture out of the air. If humidity sneaks in, expect sticky clumps or even slow chemical changes. Store the bottle tightly closed, ideally using desiccants in the jar or cabinet. Workspaces in tropical climates fight this fight daily—leaving materials out just an afternoon sometimes ruins a whole batch. Desiccator cabinets or silica gel packets work reliably, and a once-a-month check on your stash prevents long-term surprises.

Light and Air Are Sneaky Enemies

Never trust a transparent bottle for long-term stability. Both UV and visible light give bromides trouble, driving discoloration or byproduct formation. Opaque or amber glass bottles shrink light exposure. Exposure to air also means slow oxidation and sometimes loss of function, even for small amounts. Every time the lid comes off, minimize time in open air. Refill under nitrogen or argon if you can; most laboratories find inexpensive ways to hook up a dry gas line or get disposable gas canisters.

Labels and Stock Rotation

A friend’s lab tossed half its salt stock last year when they discovered outdated labels. Always list the date of receipt and opening. Rotate older containers to the front so nothing lingers past its best. Keep an up-to-date storage log. A misplaced bottle sometimes goes years without notice until the day a student wastes hours on a failed experiment.

Better Storage, Better Results

Raw material cost and purity control get plenty of discussion, yet storage habits do not always follow. Reliable chemical outcomes stem from more than just careful handling at the bench. People get distracted by crowded shelves or forgotten supplies. Take basic steps: store cool, seal tight, protect from light, keep a vigilant log. It all stacks up to longer shelf life and less waste. Each time a bottle does not have to get replaced, everyone in the lab saves both money and frustration.