N-Propyl-N-Methylpyrrolidinium Chloride: A Ground-Level Look at Its Role and Potential

Historical Development

Synthetic chemists first explored quaternary ammonium salts like N-Propyl-N-Methylpyrrolidinium Chloride as part of their search for more efficient phase-transfer catalysts and ionic liquids in the late 20th century. Not long after, the appeal grew in academic and industrial labs. The practical workhorse quality comes from trial and error—scientists mixing, heating, tweaking, sometimes failing, and sometimes finding success. As the years ticked by, its uses spread, riding on the back of real hands-on research rather than hype. Many graduate students remember it as a regular fixture in the storeroom. People learned its quirks, its limits, and gradually gave it a place in the toolkit that shaped today’s labs.

Product Overview

N-Propyl-N-Methylpyrrolidinium Chloride is a quaternary ammonium salt with clear utility in a range of synthetic applications. Folks using it find it can speed up reactions that would otherwise drag their feet. Once you get past the chemical name, it becomes clear: this material has practical impact in how chemicals come together, break apart, or carry charges. Some labs keep it locked away as an ionic liquid or electrolytic ingredient, relying on its stability when other salts just won’t do the trick. It might not have the glamour of flashier compounds, but its steadiness counts for a lot where consistency matters.

Physical & Chemical Properties

Solid at room temperature, this chloride salt boasts a high melting point and welcomes moisture without turning into a goo. You notice right away its white crystalline form, and it dissolves smoothly in water and polar organic solvents. In practical settings, its ionic nature lets it conduct electricity, which opens doors to electrochemical work and industrial catalysis. The compound doesn’t give off sharp odors or colors that would complicate routine lab handling. With predictable solubility and a robust shelf life, anyone who has worked in a teaching lab can see why it keeps showing up on reagent orders.

Technical Specifications & Labeling

Chemical suppliers keep labeling tight, usually noting purity (often above 98%), batch number, storage conditions, and manufacturer details. Labs buying this salt expect specs on water content, breakdown temperature, and structural verification by NMR or IR. These numbers aren’t just details for the paperwork—they affect real outcomes in multi-step syntheses and quality checks. You spot the lot number, double-check QC results, and know that the details printed right on the bottle can make or break reproducibility in sensitive experiments.

Preparation Method

You combine N-methylpyrrolidine and n-propyl chloride in a solvent (like acetonitrile or ethyl acetate), stir under mild heat, and watch the mixture transform through nucleophilic substitution. Most researchers rely on reflux setups, then cool and filter out the target compound. Impurities get washed away in subsequent purification—often through recrystallization in an alcohol or acetone solution. Lab hands remember these steps for their simplicity and reliability, never too far removed from what you learn in standard practical chemistry classes.

Chemical Reactions & Modifications

Chemists often use this pyrrolidinium salt as a phase-transfer catalyst; it smooths the passage of ions between organic and aqueous phases. People tweak it to build ionic liquids that work under different temperature or voltage conditions, or swap in different anions to pull out new properties. Some groups explore exchanging the chloride with other halides or organics for customized reaction profiles. These modifications usually happen on the benchtop, not in an algorithm—real glassware, gloved hands, and plenty of trial runs. Some research dives into how it holds up under electrolysis or in battery tests, expanding its reach into energy storage.

Synonyms & Product Names

Catalogs report other names, including 1-Propyl-1-methylpyrrolidinium chloride or PMPr-Cl. Trade sources might simplify things to PMPC or just use the full IUPAC name. You find these names sprinkled across research papers and supply lists. Locating the same chemical under various names can trip up new lab members, but once spotted, its recurring presence makes ordering and research comparisons easier to handle.

Safety & Operational Standards

Safety data sheets warn users to avoid breathing dust and to wash contact areas with plenty of water. In the real world, you always don gloves, goggles, and a lab coat, and work in a fume hood. Proper training covers its irritant properties and clear, focused cleanup in case of spills. Storage away from acids, oxidizers, and moisture keeps the salt stable. Emergency protocols remain simple: plenty of ventilation, good housekeeping, and reminders about responsible chemical hygiene. Accidents rarely happen with this salt in hands that follow good habits and respect the real, not hypothetical, risks.

Application Area

Beyond basic research, N-Propyl-N-Methylpyrrolidinium Chloride lands in battery development, electroplating, and syntheses needing highly pure inorganic or organic phases. Energy storage researchers like its stability and conductivity for novel battery and supercapacitor systems. Synthetic chemists value its support in forming and breaking chemical bonds cleanly, especially where water and organic solvents come together. Some industrial processes involve it as a phase transfer agent to up efficiency and product purity, leaving fewer unwanted byproducts.

Research & Development

Daily R&D with this salt focuses on tweaking side-chain structures and investigating temperature stability. Graduate students, postdocs, and process chemists look for new ways to leverage its ionic conductivity. Applications stretch across lithium-ion, sodium-ion, and even zinc-based batteries. People use analytic techniques like NMR, HPLC, and EIS to study performance in real conditions. I’ve seen research groups pivot from unsuccessful solvent blends to ionic liquid systems, finding that even minor modifications to the pyrrolidinium structure can turn a stubborn system into a responsive one. Projects move from beakers to prototype cells and, with luck, to scale-up trials or patent applications.

Toxicity Research

Most published tests flag low acute toxicity; problems usually come with heavy, chronic exposure or poor housekeeping. Eyes and skin suffer irritation if crystals linger, but ingestion and inhalation risks can be managed through basic care. Ecology studies show the need to collect and dispose of waste streams properly. Occupational safety reviews underscore training and regular hazard assessments, not just boilerplate paperwork, to prevent rash, allergic reactions, and accidental exposure. Some labs program regular reviews of literature and MSDS updates into their routines, keeping up with evolving consensus about chemical risks and safe handling.

Future Prospects

Demand for safer, longer lasting batteries keeps researchers searching for supporting salts that beat the status quo. N-Propyl-N-Methylpyrrolidinium Chloride attracts attention as more battery firms branch into ionic liquids for heat tolerance and extended cycle life. I’ve met engineers who believe these salts could edge out current high-voltage systems, once pricing and scale cross key benchmarks. Environmental chemists watch closely, looking for guarantees that breakdown products won’t harm water or soil. As renewable energy shifts from vision to infrastructure, the people aiming to replace volatile solvents and salts expect steady growth in use, research, and refinement of this compound. Training programs stress practical skills, safe stewardship, and a sharp eye for what still isn’t known—a mix built on sweat, experience, and careful collaboration.

Spotlight on Modern Chemical Workhorses

N-Propyl-N-Methylpyrrolidinium Chloride pulls its weight in more than one industry. I started noticing this compound pop up during research on greener solvents in battery labs. Its main tag comes from its ionic liquid traits, which means it remains stable and fluid even when temperatures rocket or drop low. That puts it ahead of classic salts and solvents, making it valuable for cutting-edge work.

Electrolytes and Energy Storage

This compound makes waves in battery technology, especially in lithium-ion and emerging sodium-ion systems, where safety and efficiency drive research dollars. Its thermal stability and low vapor pressure mean engineers can push battery limits without sweating over runaway reactions or fire risks. Folks working in electric vehicle research like stable electrolytes because they cut risk and improve performance, especially during quick charging or heavy loads. The whole shift toward renewables relies on batteries that store more energy and last longer, and compounds like N-Propyl-N-Methylpyrrolidinium Chloride help engineers experiment with new chemistries that hold up under pressure.

Green Chemistry and Solvent Replacement

Toxicity and flammability led many chemists and manufacturers to look for alternatives to traditional solvents. N-Propyl-N-Methylpyrrolidinium Chloride stands out in labs aiming to swap out volatile organic solvents in processes like catalysis, separation and extraction. Its ionic liquid nature allows reactions to run smoother, without the sharp fumes or fire hazards that usually come from other chemicals. Companies tapping into pharmaceutical, flavor, or even fragrance manufacturing see advantage here, since they aim to lower environmental risk without sacrificing precision or yield.

Catalysis and Industrial Reactions

Behind the curtain of many chemical plants, you’ll find engineers using this chloride in reactions that need both heat and a stable liquid medium. N-Propyl-N-Methylpyrrolidinium Chloride lets certain catalysts perform better, especially those that lose kick in water or in old-school organic solvents. That means higher output and less waste, which is a concern anyone in manufacturing or chemical engineering can relate to. I once spoke to a process engineer who cut downtime and raw material costs by switching to ionic liquids; results like that add up across a whole operation.

Electroplating and Metal Processing

Electroplating jobs, especially those involving sensitive electronics or precision parts, call for electrolytes that don’t eat into the substrate or react badly under power. N-Propyl-N-Methylpyrrolidinium Chloride offers good ionic conductivity without bringing in toxic heavy metals or strong corroding acids. Companies that finish circuit boards or specialty metal parts have a strong reason to explore this option, especially under tight environmental rules that penalize outdated chemistries.

What’s Next for Safer Industry

N-Propyl-N-Methylpyrrolidinium Chloride reminds us that industry growth doesn’t always mean higher risk. Technology and research push these alternatives forward, often with cost and safety benefits that give competitive edge. Wider adoption means a smaller footprint in water and air quality, better working conditions, and often cleaner products for end users. That’s goal-oriented progress that pays off on more than just the bottom line.

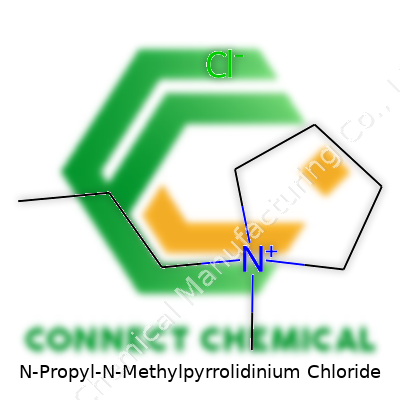

Understanding the Pieces

Diving into the structure of N-Propyl-N-Methylpyrrolidinium Chloride brings back memories of late nights in the organic chemistry lab. This molecule has a five-membered ring – the pyrrolidine backbone – holding onto a nitrogen atom. The nitrogen doesn’t just stand by itself; it’s carrying two guests: a propyl group and a methyl group. Chloride comes in as a counterion. Looking at the chemical formula, it’s C8H18ClN. If you sketch it, the five-membered ring keeps everything tidy while those side chains poke out from the nitrogen, making the whole structure feel balanced yet a bit quirky.

Why These Features Stand Out

Adding a propyl group to the nitrogen doesn’t just change a name on paper. This tweak adjusts the way the compound interacts in different environments. The methyl group makes the nitrogen permanently charged, turning this molecule into a quaternary ammonium salt. The chloride ion floats nearby, balancing the charge and often boosting the compound’s stability in water. These features don’t just sit pretty in textbooks; they give N-Propyl-N-Methylpyrrolidinium Chloride its personality. You see this kind of structure popping up in ionic liquids and specialty solvents, where heat stability and conductivity matter.

Where Science Starts to Care

Ever worked with an ionic liquid in a lab? These aren’t just chemicals—these are the engines that drive certain experiments forward. Researchers lean on compounds like N-Propyl-N-Methylpyrrolidinium Chloride when the usual solvents fail to deliver. Electrochemists measure ionic conductivity using salts like these because the structure strongly influences how ions move. That’s where the ring and the dangling alkyl groups matter. They push the chloride ion to move just right, laying the groundwork for electrical applications. It’s not just theory—these properties shape performance in batteries, fuel cells, and energy storage.

Learning from the Details

It’s easy to gloss over chemical structures as mere diagrams, but years in the lab taught me that the devil’s in these details. Small modifications can push an experiment from bland to breakthrough. Seeing how the placement of the methyl and propyl groups on the nitrogen affects solubility and melting point brings a science class diagram into real life. The chloride ion, often overlooked, can decide whether a salt works in water or gums up a system. The more you work with these salts, the clearer it gets—structure runs the show in practical settings. These tweaks can reduce viscosity, boost compatibility with organic or aqueous layers, or set a melting point just right. In energy and green chemistry, these features aren’t luxuries—they’re requirements.

Building Better Solutions

Working with chemicals that hit their marks in both lab and industry settings cuts down wasted time and expensive troubleshooting. For teams scaling up clean energy tech, choosing a compound like N-Propyl-N-Methylpyrrolidinium Chloride means having confidence that the solution won’t fall apart when conditions shift. That level of trust starts with a solid understanding of the chemical structure. As everyone looks for greener, safer chemical tools, demystifying structures and using them with purpose creates real progress in science and sustainability.

Understanding the Chemical’s Nature and Risks

N-Propyl-N-Methylpyrrolidinium Chloride doesn’t show up in everyday conversation, but for anyone working in a lab or industrial setting, getting the storage right matters. From my own time handling specialty chemicals, I’ve learned that routine safety checks and thoughtful organization pay off. This chemical stands out for being hygroscopic. It’s a fancy way of saying it grabs water molecules straight from the air. Left unprotected, the powder turns clumpy or even dissolves itself in a humid room. When damp air creeps into your storage area, you risk losing both product and reliability. Too often, workers forget that water-loving chemicals love to find the nearest open jar or bad seal.

Temperature: Keep It Steady, Keep It Cool

I remember the debate over temperature. Someone always thinks “room temperature” is obvious, but in my experience, that varies by season or region. Every material safety data sheet reminds us that cool and dry beats almost everything else for long-term storage. Look for cabinets away from heat sources and out of direct sunlight. Even ceiling vents in the wrong spot can warm up a shelf. Ideal spots maintain a steady range, never dipping into freezing or climbing above 25°C, avoiding nasty surprises like degradation or unexpected reactions. Temperature swings mess with stability, and over time, that means lower performance and safety risks.

Airtight Containers: Your First Line of Defense

Hygroscopic chemicals reward careful packaging. I’ve seen too many labs use plastic snap-lids or reused containers. That almost always leads to moisture sneaking inside. Polyethylene bottles with tight closures, preferably high-density ones, block most vapor. Glass jars with PTFE-lined caps work well for long-term stocks. Large supply shops carry quality containers designed for chemical storage, and the cost outweighs the risk of losing a batch to humidity. Seals need to be checked regularly. If you see condensation or clumps forming inside, that’s a warning to improve your setup. Desiccant packs—those little silica gel pouches—give an extra cushion. Toss one in with every jar, then swap them out often for the best results.

Labeling and Documentation Build Safety Culture

Chaos starts with poor labels. In a rush, I’ve seen colleagues scrawl abbreviations or leave containers unmarked for “just a minute.” That often leads to confusion, waste, or worse. Every jar and bottle deserves a clear, permanent label, showing not only the name but also the date, supplier, and hazard details. In regulated industries, a logbook tracks every opening and movement of sensitive chemicals like this one. Even a whiteboard in the storage room helps spot what’s running low or needs more checks.

Training and Housekeeping Go Hand in Hand

New team members sometimes miss old threats. At one lab, a forgotten open bottle ruined a week’s worth of work. Storage training keeps everyone sharp. Sessions covering everyday scenarios—how to report leaks, what counts as “sealed,” how to spot contamination—make all the difference. Clean shelves and spaced-out jars stop cross-contamination and give easy access for inspection. A tidy storage space signals respect for the risks, and over time reduces accidents that come from sloppy setups.

Looking at the Whole Picture

Effective storage protects the product, the people who use it, and the work it supports. Staying vigilant with temperature, moisture, labeling, and smart habits shields everyone from avoidable trouble. In the end, getting these basics right creates a workplace that’s safe and productive.

Getting Familiar With the Chemical

N-Propyl-N-Methylpyrrolidinium chloride often finds a place in research settings and specialty chemical blends. It’s not a household item, nor does it show up in everyday consumer products. Anyone working around this material should take a moment to get familiar with it, since some chemicals can appear harmless until they’re not.

Looking at Health and Safety Hazards

This compound hasn’t received much attention outside research labs. You won’t find pages of studies about its effects in humans or animals. Even so, experience in the laboratory world teaches us that it pays to respect any novel chemical. Similar pyrrolidinium compounds often cause irritation to the eyes, skin, or lungs. I remember working with other ionic liquids years ago where one whiff could set off sneezing fits or leave skin itchy. N-Propyl-N-Methylpyrrolidinium chloride shares a familiar structure with those compounds.

Direct exposure, especially in its pure form, poses the risk you’d expect from most small organic salts: irritation, headaches, maybe a cough if a person breathes it in. No data confirms whether it causes cancer or birth defects. We shouldn’t assume it’s safe just because those studies aren’t published yet. Toxicologists constantly warn us about lagging research, especially for newer specialty chemicals.

Environmental Considerations

Many ionic liquids and their relatives break down very slowly in nature. Labs sometimes choose these materials because they aren’t easily volatile—they stick around where you put them, instead of evaporating away. Over the years, I noticed the environmental persistence of certain ionic liquids caused headaches for waste management. Even small spills can contaminate lab benches, gloves, or tools for longer than expected.

Without strong evidence to the contrary, I treat N-Propyl-N-Methylpyrrolidinium chloride as though it could linger in water or soil. In larger quantities, its presence in wastewater might disrupt bacteria used in treatment plants, a lesson the chemical industry learned the hard way with older synthetic chemicals.

Handling and Risk Management

I follow the principle of minimizing exposure. Nitrile gloves, safety goggles, and chemical fume hoods go a long way whenever handling unknown or under-studied compounds. Product safety data sheets from MChemicals, Sigma-Aldrich, and other chemical suppliers highlight the need for airtight containers and careful disposal. Most university research labs enforce standard safety precautions, but smaller operations sometimes cut corners. This material deserves the same respect as other lab-grade organic salts—don’t eat or drink after handling it, and don’t let it contact bare skin.

Researchers also document procedures and incidents. A shared safety record has prevented injuries where I work—seeing a near-miss on paper makes hazards real in ways that signs and lectures can’t match.

Improving Knowledge and Finding Safer Alternatives

Nobody benefits when a chemical’s hazards stay hidden. Encouraging more open research means future users know what to expect. Industry needs to ask tough questions about whether this specific chloride salt brings something unique to the table, or if more common, better-understood materials do the same job with less worry. From my side, substituting simpler salts or ionic liquids with fuller safety records often keeps day-to-day work smoother and safer. Until studies say otherwise, it's best to treat N-Propyl-N-Methylpyrrolidinium chloride with care and keep searching for more transparent information.

Understanding Purity

N-Propyl-N-Methylpyrrolidinium Chloride stands out as a quaternary ammonium salt used in ionic liquid research, electrochemistry, and other specialized chemical fields. Purity affects performance. Chemical suppliers offer this compound at various suitability levels, with laboratory and industrial grades ranging from 97% to 99%. My experience working with specialist labs has shown that the 99% mark reflects a solid benchmark for most applications—especially ones needing precise electrochemical properties or consistent outcomes in complex reactions.

Contaminants, even in trace amounts, make results murky. Impurities influence conductivity, solubility, and decomposition, so a 99% pure batch assures reproducibility. In some crystal-growth and electrochemical tests, dips below 98% purity have thrown off entire data sets. For critical applications, experienced chemists go straight to Certificates of Analysis, provided by reputable vendors, to verify actual batch purity—never relying on generic product listings.

Not every experiment demands top-shelf purity. For bulk solvent or non-critical industrial blending, 97-98% sometimes suffices. Consider what matters most: reliable outcomes or cost containment. Skimping on purity risks unexplained anomalies or failures later in development—burning time that would get better spent solving real problems.

Available Packaging Sizes and Storage Considerations

Suppliers typically offer N-Propyl-N-Methylpyrrolidinium Chloride in several packaging sizes to meet needs from bench work to small-scale manufacturing. Most labs start with 5-gram or 10-gram vials—handy for exploratory batches, expensive for larger runs. Twenty-five grams fits a standard experiment cycle in many R&D settings. Sometimes, 50- and 100-gram bottles show up on order forms, supporting ongoing work but still easy to handle.

For those scaling up or running pilot lines, packaging jumps up. Commercial suppliers offer 250-gram, 500-gram, and even 1-kilogram containers, most often in high-density polyethylene jars to block moisture and chemical reaction with packaging. High surface-to-volume ratios in small vials give easy access but boost contamination risk if handled without cleanroom discipline. At the other end, a big bottle raises spoilage hazards if left open too long; any moisture creeps in, the salt clumps or absorbs water, and reactivity dives.

Use packaging that matches the research or production pace. Buying 10 grams at a time gets expensive if moving kilotons, but a kilogram in a busy teaching lab may expire before running out. From my own small-scale synthesis trials, splitting bulk orders into several well-sealed containers cuts waste and lowers the risk of accidental contamination. If cold storage gets recommended, always label the date and batch—commercial batches sometimes drift in quality over time.

Choosing the Right Supplier

Professionalism matters. Trusted suppliers, with a history of high-quality chemical deliveries, leave less to chance. Look for clear documentation, transparency about storage and handling, concrete purity details, and responsive customer service. Choose a vendor that fields chemists with experience, not just marketing teams. And always read the safety datasheets—quaternary salts like this one need careful handling, personal protective gear, and disposal plans that keep researchers and the environment safe.

Solid scientific research and industrial reliability start with trustworthy suppliers, the right purity, and smart package sizing. These factors shape safety, save money, and keep experiments running on time.