N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate: A Deep Dive

Historical Development

N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate entered the scientific vocabulary in the swell of ionic liquid research at the turn of the 21st century. Early studies found that room-temperature ionic liquids opened routes for green chemistry and safer processing in industries pressed by environmental regulations. Chemists in Japan and Europe spotted the opportunity around pyrrolidinium-based salts because they brought thermal stability and low toxicity compared to existing quaternary ammonium salts. These researchers pushed aside imidazolium types, noting they performed fine but suffered from unwanted side reactions. By the early 2000s, a cluster of patents appeared in applied electrochemistry journals, charting out this compound for energy storage and catalysis. Work at academic labs across Asia and the EU drove refinement in synthetic protocols, making the salt cost-effective for broader adoption.

Product Overview

N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate gained attention because it forms a stable liquid at room temperature and resists moisture better than most early ionic liquids. The salt attracted energy storage engineers hunting for safe, non-flammable electrolytes. In each application, researchers checked how its unique cation and BF4 anion handled current, voltage swings, and temperature spikes. The product sold by major chemical suppliers arrives as a colorless or faintly yellow liquid, characterized by faint odor and easy solubility in both water and many organic solvents. This versatility drew process chemists tired of using volatile solvents or corrosive reagents. The labeling includes warnings related to fluoride exposure—less toxic than hexafluorophosphate cousins, yet far from food-grade. Typical containers range from 10-gram vials up to five-liter jugs, each capped tight to keep out atmospheric water and accidental contamination.

Physical & Chemical Properties

This compound’s standout feature is its liquid state around 20°C, thanks to a melting point below -15°C. The density usually lands around 1.15-1.20 g/cm³—a solid middle ground in ionic liquids. The compound handles a wide electrochemical window stretching past 4 volts, which makes it particularly attractive for supercapacitors and lithium-ion batteries. At the lab scale, technicians notice its viscosity, which usually falls between 60-80 centipoise. Water absorption stays moderate compared to traditional lithium salts, translating to more predictable performance in batteries and sensors. The chemical stability under heat and resistance to hydrolysis impresses those working on harsh process requirements. Despite the name, the liquid can tolerate light mechanical abuse, shaking or stirring for extended periods without breaking down or releasing gaseous byproducts.

Technical Specifications & Labeling

Standard labeling calls out purity levels of at least 98%, a moisture content below 0.5%, and low levels of halide and heavy metal impurities. Reputable suppliers back up these numbers with batch-specific certificates of analysis, critical for labs setting up repeatable experiments. For shipping and industrial use, hazardous material designations include warnings about acute toxicity if ingested, inhalation risks during heating, and the potential for environmental harm in aquatic systems. These specifications don’t stop at the lab bench; industrial buyers look to traceability documentation, demanding that each drum or bottle comes with a verified production lot number and clean chain of custody. Each container should feature clear lexicon for emergency responders and trained operators, noting measures for spills, plus phone numbers for poison control resources just in case.

Preparation Method

Production typically starts with N-methylpyrrolidine, a common secondary amine, and 1-bromopropane or a similar alkylating agent. Manufacturers mix these under sealed, inert atmospheres to prevent side reactions from traces of oxygen or water, pushing the alkylation to completion over several hours. After the cation forms, reaction with sodium tetrafluoroborate or another BF4 donor gels the salt, sometimes as a viscous oil that gets washed, filtered, and dried under vacuum. Each stage has risks: exothermic surges, residual bromide contamination, and the usual headache of keeping everything dry in a typical production environment. Purification often involves passing the crude product through activated alumina or liquid-liquid extraction to strip out colored impurities. Repeated drying, sometimes by azeotropic distillation or under nitrogen, ensures a water-free product—absolutely essential for high-value tech applications like batteries.

Chemical Reactions & Modifications

N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate holds up under a surprising range of conditions. The pyrrolidinium ring resists hydrolysis, so it works in water-rich systems and in processes hampered by other, weaker cations. The tetrafluoroborate anion stays put except under extreme acidic or basic conditions, making the salt tough enough for electrochemical cycling, catalysis, and ionic liquid extractions. Chemists who want still more stability sometimes swap the BF4 anion for less reactive species, or tweak the cation by adding methyl or ethyl groups in the pyrrolidine ring. There’s a quiet arms race in the energy world to see who can bolt on new functionalities without killing performance. In the lab, common reactions include transalkylation to create designer cations, producing new families of ionic liquids custom-made for green chemistry. Some groups try out halide metathesis for better compatibility in lithium metal systems, while others look at covalent modifications for advanced separations.

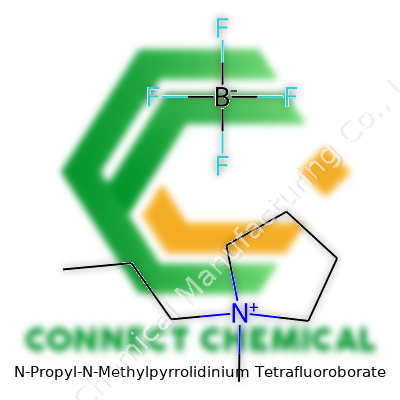

Synonyms & Product Names

This compound takes on a host of names in the literature, depending on the supplier, region, or end-user application. You’ll see N-propyl-N-methylpyrrolidinium tetrafluoroborate listed as [NMPPy][BF4], [C3mpy][BF4], or simply as Pyrrolidinium BF4. Chemists may label it according to IUPAC nomenclature in formal reports, but lab speak gets much lazier, often going with shorthand codes scrawled on vials. In patents and commercial documents, spelling may drift but structure diagrams don’t lie. A handful of suppliers market it under trade names, sometimes bundling it with other ionic liquids or battery-grade solvents, aiming to lock in long-term contracts with OEMs in the electronics and green energy sectors.

Safety & Operational Standards

Lab practice means using gloves, splash-resistant goggles, and pipetting from sealed bottles inside a fume hood. Technicians stay cautious around open flames since the tetrafluoroborate anion can give off hydrogen fluoride during thermal breakdown, which poses severe risks if inhaled. Regular safety audits push facilities to install HF-detection strips and train crews on neutralization protocols for spills—mixing calcium gluconate gel for skin contact emergencies is common sense in these settings. Large-scale plants invest in secondary containment and vapor scrubbing, offsetting not only workplace injuries but also the litigation risk of environmental contamination. Spill response drills aren’t just checked boxes—labs and production sites review them every quarter because comfortable familiarity with emergency procedures saves lives.

Application Area

The range of uses stretches from high-end electrolytes for capacitors and batteries to solvents for rare chemical extractions. Battery engineers use it for both traditional lithium-ion and next-generation sodium- or potassium-ion chemistries. Its non-flammable nature means it gets a closer look for public transit and aerospace battery systems, where safety counts for more than theoretical energy density. Process chemists swap out volatile organics for this ionic liquid during catalysis, improving yields in transition metal-catalyzed reactions and stepping a little closer to sustainable manufacturing. It even finds a role in advanced lubrication, offering thermal stability and low toxicity for niche mechanical applications. Sensor developers like the electrochemical window, tuning the salt to fit into microfluidics and nano-sized detection hardware. Industrial-scale separation systems use it to purify valuable metals, while researchers probe new uses every year.

Research & Development

Innovation takes shape in two main tracks: tweaking either the cation for stability or the anion for compatibility. Groups in China and the EU run parallel projects, aiming to lift ionic conductivity and thermal threshold at the same time. The academic world compares standard forms against lithium hexafluorophosphate electrolytes, pointing out the drop in flammability and fewer decomposition products. Industry groups join forces with universities to test novel salt blends for supercapacitors, measuring cycling stability over tens of thousands of charge-discharge rounds. Open data helps drive improvements, letting chemists identify failure points and push refinements faster than isolated efforts. Cross-disciplinary teams with backgrounds in mechanical engineering, toxicology, and environmental science assess how small changes in structure push the envelope for safety and performance.

Toxicity Research

N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate avoids much of the chronic toxicity seen in earlier generations of ionic liquids, but regulatory scrutiny stays high. Studies run on zebrafish and small mammals reveal low acute toxicity in trace exposures, though nobody relaxes because long-term environmental build-up remains uncertain. Researchers at regulatory agencies test for mutagenicity and chronic organ stress, aware of past mistakes with less stable fluorinated compounds. Reproductive toxicity turns up negligible for most mammals but aquatic impacts call for more data. Flammable decomposition to hydrogen fluoride means both occupational and environmental safety plans must stay robust. Facilities handle waste carefully, using secure drums and partnering with certified disposal outfits that can guarantee treatment standards above what’s legally required.

Future Prospects

Chemistry doesn’t stand still. This compound, once pegged for niche uses, looks ready to move further into consumer technology as battery manufacturers chase the holy grail of cheap, safe, long-lasting cells. As regulations around flammable solvents tighten, ionic liquids that stay stable in air and moisture will see more deployment. Research teams keep pushing to unlock higher ionic conductivities for ultra-fast charging and energy-dense storage. Green chemistry puts extra pressure on producers to close the loop with real recycling and waste reduction programs. Tarnished old processes that gave the field a bad rap now face replacements anchored by this salt. Collaboration across borders—aided by open-access journals and clearer standards—spells steady gains. As more products rely on smart electrification and responsive materials, this ionic liquid looks poised to play a major role in safer, greener, and more efficient manufacturing.

The Quiet Influence in Batteries

N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate doesn’t announce itself like lithium does in headlines, but anyone tracking research on safer, longer-lasting batteries has come across this liquid salt. Most people never get to see what’s inside the battery that runs their phone or car, but beneath all that plastic and metal, small tweaks to the liquid carrying charge make a big difference. Engineers want batteries that don’t burst into flames or fade after a few months. Molecular salts like this one offer clues for getting there. The molecule’s ionic structure lets it replace standard solvents, helping to keep batteries steady through hundreds of charge cycles. Phone and EV makers eye these alternative electrolytes so customers swap devices less often and feel safer using them.

Green Chemistry and Safer Solvents

Lab workers don’t want to breathe in toxic fumes, but so many standard solvents deliver just that. In my time learning organic synthesis, I noticed researchers turning to ionic liquids as options that barely evaporate. N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate appears on lots of lists for this job. Chemists need something stable enough to keep reactions running while stubborn reagents mingle and react. Scientists see this molecule taking on roles in drug discovery and advanced materials work, where old-school solvents just can’t keep the chemistry going without side effects. It cuts down fire hazards and waste headaches. That counts in busy teaching labs or chemical plants, where dozens of runs mean lots of fumes and cleanup.

Help for High-Tech Manufacturing

Everyone expects electronics to get smaller and faster each year. That puts pressure on those who lay down microchips and coatings. Electroplating and etching are two steps that often get overlooked. Memory chips and solar cells need metals layered with absolute precision, and mistakes mean billions wasted on bad product. Engineers found that ionic liquids like this one help put down metals evenly, without pitting or odd grain boundaries. The compound handles changes in voltage and temperature without breaking down, keeping quality high and toxic byproducts low. Semiconductor producers keep looking for ways to control every variable, and using these molten salts brings extra confidence to complex jobs.

Room for Safer Energy

Since I started watching clean energy go from niche to mainstream, research on supercapacitors and other new storage devices keeps popping up. One barrier? Most devices score well on performance or safety, rarely both. Using ionic liquids like this one lets designers raise the bar at both ends. Its stability means the storage device won’t dry out or turn dangerous under strain. Folks working on grid storage or harsh-environment backup systems like seeing numbers that move the needle. It gives hope for safer, longer-lasting power banks – not just for cars or phones, but for wind and solar farms, too.

How to Harness the Potential

Bigger uptake faces old problems: scale, cost, and habit. Factories need more supply and clearer safety guidelines. Labs sometimes struggle to dispose of used salts, and recycling streams haven’t caught up. Industry partners, universities, and regulators must work together to keep the best science moving forward while planning for real-world use. Every promising molecule faces tests in labs, then on the factory floor. If workplace rules and recycling pathways adapt, N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate could help laboratories, factories, and our daily electronics shift to safer, longer-lasting technology.

Real Stories from the Lab

Every chemist learns early: let your guard down with moisture, and you pay the price. N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate (usually called a pyrrolidinium ionic liquid) gives us prime proof. This stuff gets a lot of love in battery research, catalysis, green solvents, and electrochemistry. Despite the fancy name, the big question isn’t just about performance. It’s about survival outside the bottle.

I’ve worked with these ionic liquids plenty of times, and one lesson crops up repeatedly—store them correctly, or your reaction won’t work as planned. The boron-fluorine bond in tetrafluoroborate tries to keep up appearances but, given the chance, will react with water. That moisture in the air? It sneaks right in and causes unwanted side reactions, making the salt break down and driving up impurity levels. We saw this in our own battery research. A batch left loosely capped in a humid storeroom picked up enough water to give wildly inconsistent data. That’s frustrating, but it’s preventable with a little care.

What Happens On Exposure

N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate loves to absorb water—it’s hygroscopic, plain and simple. Not only does this shift the weight and concentration, but it also impacts conductivity and chemical stability. Any team doing sensitive electrochemistry gets knocked off course by a few rogue water molecules. The result: drift in voltage, lower efficiency, corrosion of electrodes, and even bonus hydrolysis products in your cell. In some cases, you can even smell the hydrolysis byproducts if things go badly wrong. My old colleague used to joke that if your battery test smells slightly sweet, it’s time to clean up and try again.

Some argue that a little water won’t hurt. That hasn’t matched my reality. Add enough moisture to these materials, and you change how they perform—not just on paper, but in the quality of the experiment. Ionic liquids are sensitive, and this one doesn’t forgive sloppy handling.

Hard Facts and Easy Fixes

Manufacturers warn about storage for a reason. Analytical data from Sigma-Aldrich and other big suppliers support what old hands know: Pure tetrafluoroborate salts pull in water readily, usually reaching equilibrium with ambient humidity inside hours if left open. If you ever poured this salt out on a humid day, you saw clumping inside minutes. Sometimes the powder even liquefies on the bench if the air is wet enough.

Desiccators save labs from these headaches. A sealed container with enough drying agent (silica gel or molecular sieves) can keep the ionic liquid dry between uses. It’s not about being fancy—it delivers predictable experiments. On top of that, dry-boxes—those glovebox chambers full of dry nitrogen or argon—make life easier for anyone who handles air- and water-sensitive chemicals every day.

Labs working on a tight budget get by with vacuum desiccation containers, which work fine if checked regularly. Repacking chemicals in smaller bottles helps too, limiting how often each bottle gets exposed.

No Substitute for Good Habits

Ignoring moisture with N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate guarantees disappointment. Tap water and even high humidity in the air will damage both the chemical’s shelf life and its ability to do the job. Even brief exposure throws off measurements in batteries, sensors, and synthesis reactions.

There’s no magic fix except careful storage and handling. Based on direct experience and solid supplier data, no researcher ever regretted keeping this salt dry. Everyone I trust in the field echoes the same thing—treat moisture like an unwanted guest, not just another variable you can ignore. In the end, better lab practices make all the difference for results you can trust and reproduce.

Getting Real with Chemical Storage

Anyone who’s handled specialty chemicals in a lab or manufacturing site knows that storage isn’t just about keeping things tidy. N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate, an ionic liquid, brings its own quirks to safe storage. With years around glove boxes and solvent cabinets, I’ve learned the smallest oversight can become costly—or dangerous—fast.

Why This Ionic Liquid Demands Respect

Ionic liquids like this one pop up in batteries, electrochemistry, and solvents for tricky reactions. Their temperature stability draws lots of interest. That said, Tetrafluoroborate-based liquids can react with moisture, giving off toxic gases like hydrogen fluoride if mishandled. No one benefits from an emergency shower with those hazards, so practical steps trump daydreaming about perfect conditions.

Humidity and Air: Keep Them Out

Lab humidity creeps in everywhere—old windows leak, HVAC fails, people leave bottles open. Yet this compound’s shelf life stretches only as long as you guard it from water and air. Screw caps with reliable, chemical-resistant liners add an instant barrier. For longer stints, light aluminum pouches with moisture scavengers make a difference. Some labs swear by glove boxes flushed with dry nitrogen, avoiding even a few parts per million of water vapor.

Personal experience tells me that even ‘quick’ transfers between bottles can ruin a batch. My old lab used colored humidity indicator cards taped to reagent jars. If the card changed, we tossed the lot. Good practice beats wishful thinking every time.

Container Choice: More Than Just Glass Bottles

Glass resists most chemicals, but not every cap delivers a tight seal for months. PTFE-lined screw caps, solid HDPE, or borosilicate vials put a real dent in vapor diffusion. Metal or unlined plastic suffers from corrosion and slow water ingress over time. By the third month on a shelf, a bad seal can turn expensive materials into hazardous messes.

Temperature: Cool, But No Iceboxes Needed

Temperatures above 30°C lend energy to unwanted side reactions—no good for most ionic liquids. On the flip side, freezing doesn’t buy much protection and can make these substances sticky or viscous. Room temperature, somewhere between 15 and 25°C, has kept samples in my care stable for over a year. Keeping heat sources and sun away matters more than aiming for perfection.

Clear Labeling Stops Mix-Ups

Too many times, someone pulls an old container off a shelf and wonders what’s inside. Labels should shout the chemical’s full name, date received or opened, and storage instructions—no abbreviations, no faded ink. Regular review of inventory trims the odds of storing compounds past their prime.

Solutions Rely on Consistent Habits

Routine outpaces overcomplicated rules. Set daily or weekly checks for cap tightness, monitor humidity, and retrain staff if cross-contamination pops up. Auditing storage every quarter catches problems before they hurt anyone. Emergency procedures pinned clearly wherever chemicals sit ensure no hesitation in a bad moment.

Experience as the Real Teacher

Manuals call for dry, cool, and inert conditions—living through chemical leaks or ruined samples teaches those lessons fast. Storage of N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate rewards teams who treat every detail as essential, not optional. My confidence in safe storage comes from wrestling with the mess that shows up when those basics are skipped.

The Name May Be Long, But The Concerns Are Clear

Chemicals with names like N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate rarely turn up in everyday conversation, but their role in modern industries is impossible to ignore. Used in batteries, electrochemistry, and even in some niche solvents, this compound might seem far from our daily lives. Still, the questions around its safety turn out to be very real for researchers, manufacturers, and anyone working where it’s handled.

Looking Beyond the Lab Coat

Safety information hides behind jargon more often than many would like. In dealing with substances like this one, I always check real toxicity studies and safety data sheets—never relying just on supplier assurances. Studies and manufacturer data flag it as an irritant for skin and eyes; that may sound minor, but I’ve seen careless handling in the lab lead to burns and rashes that take days to heal. It’s worse with compounds containing tetrafluoroborate, since they can release toxic gases if heated or mixed the wrong way. You should never ignore basic ventilation just because a chemical seems “routine” or is marketed as being low-hazard in its application.

Hidden Hazards: Beyond Acute Toxicity

On paper, acute toxicity numbers for this substance do look lower compared to other industrial chemicals. That’s only part of the story. My experience shows that repeated, low-level exposure matters just as much as a single large spill. Fine powders and salts hang in the air, and in rooms with poor airflow, workers can end up inhaling more than anybody expects. Chronic effects, like impacts on lungs or the thyroid, tend to show up slower and get recognized too late. The dust itself can linger on surfaces, becoming a risk for everyone from maintenance staff to waste handlers.

Environmental Responsibility Isn’t Optional

Research points to ionic liquids like this one having bigger effects on aquatic life than many realize. Tetrafluoroborate salts don’t break down easily, and what leaves through waste streams can make its way into the water. I feel a responsibility to look for alternatives or safer disposal whenever possible, not just because of the rules but to avoid making the problem somebody else’s. Storing this compound in well-sealed containers, collecting every spill, and treating all waste as hazardous shifts the local risk to something more manageable.

Practical Solutions for Real-World Users

Training stays crucial. In labs I’ve run, a new researcher never handles chemicals like this alone for their first few months. I encourage glove checks, face shields, and goggles every time, even for people who feel “familiar” with the process. When transport or storage goes wrong, the clean-up never falls to one person. It’s about teamwork and backup, not heroics. For those working outside of research, I always recommend reviewing the chemical’s data sheet before every new application, even if it feels repetitive or overly cautious.

Substituting with less hazardous compounds makes sense whenever the process allows. Our group recently replaced several ionic liquids with greener alternatives, which meant adjusting methods but led to less worry at the end of the workday. The real danger often sits in underestimating a chemical, not just in its immediate health risks.

The Importance of Staying Informed

Living with chemicals like N-Propyl-N-Methylpyrrolidinium Tetrafluoroborate isn’t only about avoiding disaster. It’s a matter of respect for the compound’s properties, honest reporting of incidents, and holding ourselves accountable for every spill or exposure. Being proactive—always checking the latest literature and safety developments—keeps both people and the planet safer.

Why Purity Matters in Daily Operations

Years back, I worked in a small lab where even a trace impurity could throw off our results. The chemist on my team spent weeks troubleshooting a failed batch, only to discover it stemmed from a minor contaminant in a “technical-grade” supply. Sometimes, one percent impurity can ruin an entire project, especially if researchers or manufacturers rely on tight margins.

For those working with chemicals every day, purity isn’t just a number. Specialized research, pharmaceutical production, semiconductor manufacturing, water treatment—every application sets its own bar. In semiconductor labs, “electronic grade” purity means parts per billion or better. In the food industry, “food grade” or better is non-negotiable. Pharmacies need USP or EP standards—often 99.9% or higher. An error in purity claims can waste money, damage reputation, or even harm health.

Real-World Implications of Packaging Choices

I’ve seen more than one manager bemoan lost dollars from over-ordering. Few issues irritate like storing a drum for years, collecting dust, because only 200 grams were needed this quarter. Meanwhile, shipping or storage restrictions crush budgets. Smaller packaging size means faster turnaround and less loss from degraded stock. For startups and small-scale researchers, having access to a 5-gram vial or a 25-gram bottle keeps costs in check and storage manageable.

Large-scale producers—the folks running chemical plants or making industrial cleaners—go for different packaging altogether. They want 50-kilogram drums or even one-ton totes. Moving these safely brings its own set of headaches, from regulatory paperwork to handling gear and compliance certifications.

Bridging the Gap: What People Actually Need

It makes little sense to offer purest grade chemicals only in bulk sizes. Sometimes, researchers only need milligrams—the rest becomes hazardous waste or, worse, a safety risk years down the line. Flexibility wins loyalty. I’ve seen suppliers quickly lose business because they offered just one or two pack sizes; smaller, agile companies stepped in and took their share of the market simply by offering practical quantities and clear specs.

Clarity around chemical purity gives customers peace of mind. They know exactly what goes into the process, and it helps them trace failures or safety concerns quickly. Honest labeling, batch-specific purity data, and reliable technical support show that the seller values transparency. This isn’t just about compliance; it’s about building trust in an industry where traceability and documentation mean everything.

Concrete Steps for Improvement

Suppliers can start by clearly stating minimum and typical purity levels, sharing batch certifications, and providing straightforward safety documentation. Offering a range of package sizes—maybe from a few grams to a full drum—serves both small buyers and heavy users. This helps control costs, waste, and risk for everyone.

A feedback loop makes a world of difference. I’ve watched suppliers turn business around by listening to their lab customers. They cut down minimum order quantities, adjusted pack sizes, and started offering more granular documentation. In an industry where precision and responsibility are both non-negotiable, focusing on these details makes the supply side much stronger.

Focusing on purity and packaging isn’t about ticking a box. Getting it right keeps users safe, lowers waste, and builds trust at every link in the chain.