N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate: More Than a Mouthful

Historical Development: From Lab Curiosity to Advanced Material Staple

It feels a little strange to think that some of today’s most advanced materials started life on the margins of chemistry, but that’s just what happened with N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate. The roots go back to the expansion of ionic liquids in the late 1990s, at a time when research groups all over the globe started seriously tinkering with quaternary ammonium salts. Most chemicals in this family got a shot in battery and electrochemical circles, especially as folks grew dissatisfied with classic organic solvents and old-school lithium salts. Synthetic routes evolved alongside new interests—nobody wants something that’s hard to make or inconsistent, and demand for safer, more stable batteries forced the push. With each conference, I would see more labs switching gears, chasing the promise of nonflammable, highly conductive, and thermally stable solutions for electronics and energy storage.

Product Overview: A Place in the Modern Lab

I’ve poured over dozens of product sheets over the past decade, and N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate keeps cropping up as a top-shelf ionic liquid. Chemists prize it for solid lithium salt compatibility and its knack for dissolving difficult compounds. Its structure blends the butyl chain flexibility with a strong, stable trifluoromethanesulfonate anion. You spot it in electrolyte blends, sample prep, chromatography, and sometimes as a specialty additive. The supply chain for this compound has improved, too. Ten years ago, a 100-gram sample could set you back weeks; now, you can order a standardized bottle from reputable suppliers—labeling lists not only the chemical purity but also direct handling cautions and lot-specific trace analyses.

Physical & Chemical Properties: Designed for Tough Jobs

If you like working with chemicals that don’t take the easy way out and boil at room temp, this one delivers. The trifluoromethanesulfonate group gives strong ionic dissociation in polar solvents. The melting point always varies a bit depending on precise formulation, but a clear liquid phase at room temperature remains standard for high-purity samples. Density falls above water, making separation straightforward in biphasic systems. Solubility impresses as well, especially compared to older quaternary ammonium compounds. You get strong electrochemical stability, often above 4.5 volts vs. Li/Li+. High decomposition temperature unlocks processing at elevated ranges useful for batteries and capacitors. In the glovebox, it doesn’t fume or corrode stainless steel; that matters when working in labs that worry about longevity of expensive hardware.

Technical Specifications & Labeling: No Room for Guesswork

High standards drive the technical specs for this compound. Top suppliers quote chemical purities above 99%, water content locked below 100 ppm, and minimal halide contamination. Proper packaging demands amber glass bottles, and cold chain logistics keep it away from sunlight and extremes. Safety data sheets line out PPE requirements, first aid instructions, and disposal practices. Lot tracking and COA documentation support product consistency—regulatory compliance in OECD and ISO laboratories depends on this level of transparency. Real-world applications require not only a reliable compound but also documentation backing up every claim; most users request NMR, FTIR, and elemental analysis for quality assurance.

Preparation Method: Labor in Small Bottles

To get a clean N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate, syntheses start with N-Methylpyrrolidine—usually made from 1-methylpyrrolidine and an alkylating agent like 1-bromopropane. Once the cation is ready, careful metathesis with silver trifluoromethanesulfonate or direct acid-base reaction with trifluoromethanesulfonic acid follows. Reactions run under inert atmosphere to steer clear of water and extraneous ions. Afterward, several drying steps with vacuum and mild heating help cut water content. Product purification uses filtration, sometimes liquid-liquid extraction, and final drying under high vacuum. Manufacturers lean on this sequence for repeatability, but even small slip-ups in stoichiometry will compromise the product’s conductivity and shelf life.

Chemical Reactions & Modifications: Building Blocks for Specialists

Across my time in organometallics, these pyrrolidinium ionic liquids figured strongly in cross-coupling, alkylation, and catalysis studies. Their ionic strength and solvent compatibility let them dissolve transition metal complexes or act as co-catalysts. Chemical modifications rarely go untouched. Researchers introduce fluorinated or aromatic groups to the pyrrolidine ring, tweaking viscosity and conductivity for tailored performance. Anion exchange remains popular—a base compound of N-Propyl-N-Methylpyrrolidinium can be paired with TFSI, PF6, or other large anions to shift the electrochemical and solvency profile for next-gen applications.

Synonyms & Product Names: Navigating the Market

It can get tricky trying to keep names straight. The full IUPAC name gets heavy fast, so you see shorthands like “N-Methyl-N-Propylpyrrolidinium triflate”, “PMPYR Triflate”, or CAS swaps. Big chemical distributors have brand names in their catalogs, and smaller players use cryptic codes that only insiders recognize. For a field tech or research chemist, getting a grip on the correct synonym prevents frustrating supply mix-ups. Regulatory bodies insist on clear, unique identifiers to sync up shipments and storage records; no one wants a key experiment ruined by a mislabeled bottle.

Safety & Operational Standards: Put Gloves On, Read the Sheet

Lab safety always kicks in fast with new materials, and trifluoromethanesulfonate salts pose real risks if handled haphazardly. The compound won’t burn like classical solvents, but contact with skin or mucous membranes irritates fast. Ventilation in synthesis labs cuts down on exposure to fine aerosols or accidental spills. Additional safety rounds come in during scale-up, especially for electrochemical or pilot plant runs. Disposing of unused or contaminated samples relies on approved hazardous waste protocols, keeping both humans and the environment out of harm’s way. Goggle fog and glove crinkle are daily reminders of the importance of not skipping the safety briefing.

Application Area: Tools for the Energy Century

In battery work, this ionic liquid creates stable, efficient electrolytes for lithium-ion and lithium-metal designs—two technologies in a tug-of-war for the electric car market. Supercapacitor groups chase its high voltage stability, hoping to extend service life in everything from grid storage to mobile devices. Chemists reach for it as a “designer solvent” for green chemistry, cutting hazardous emissions while opening up new synthetic routes. Analytical labs use it for sample extraction and as an additive in separation techniques; I’ve watched teams shave hours off purification work thanks to its unique solubilizing power. Other spots include aluminum plating, surface modification, and controlled polymerization—all points where an adaptable ionic liquid changes the calculus for equipment, safety, and performance.

Research & Development: Eyes on the Cutting Edge

Labs churn out new data on pyrrolidinium ionic liquids every year. Much of the investment from private firms and universities aims at super-efficient batteries, longer cycling capacitors, and less volatile electrolytes for critical electronics. Advanced spectroscopic work drills into ion pairing and solvent interaction patterns—data that informs every next-generation formula pitched to automakers or device designers. A growing number of grants underpin projects focused on optimizing the synthesis pipeline, trimming byproducts and energy use to keep costs manageable. My own contacts in academia rarely run short of creative tweaks, sending new derivatives through the publication pipeline in pursuit of lower viscosity or broader electrochemical windows.

Toxicity Research: Know the Risks, Not Just the Hype

Despite a long wish list of benefits, this family of ionic liquids draws attention from toxicologists. Excessive exposure to pyrrolidine-based salts—either through inhalation or skin contact—brings documented issues, especially in high-throughput manufacturing. Bioaccumulation tends not to match traditional halogenated solvents, but aquatic toxicity can spike if disposal is careless. Recent animal studies, in vitro and in vivo, test pathways for metabolic disruption, organ load, and potential cytotoxicity. These data drive regulatory review and lab protocols; while the popular press talks about “green solvents,” the actual picture demands constant vigilance and peer-reviewed statistics.

Future Prospects: Bigger Roles, Bigger Responsibilities

Industry insiders put smart money on wider adoption, especially if the push for electric transportation keeps pace and new material demands trickle into construction, communication infrastructure, or even aerospace. Adjustments in synthesis cost, recycling processes, and toxicity management stand between labs and full-scale factories. Some researchers dream up entirely biodegradable versions or hybrids with organic carbon frameworks that retain all the perks of current ionic liquids without lingering impact. Robust data, open standards for reporting, and collaborations between academia and private sector players all point toward a field ready for prime time—if the safety and environmental questions get as much attention as the glowing technical reports.

Where It Works: Inside Our Batteries and Labs

Years of reading research papers and digging through chemistry forums can teach anyone a lot about the chemicals shaping tech and energy. N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate, or PMP-Tf for short, has quietly made itself useful in fields that crave safe, steady power. If you use a smartphone, drive an electric car, or read about progress in wearable health devices, this salt affects you more than you might think.

I remember talking to a battery engineer who smiled in relief when electrolytes like PMP-Tf came up. Traditional electrolytes catch fire, react with air, and break down after too many charges. PMP-Tf belongs to a family of chemicals called ionic liquids, meaning it stays liquid at room temperature, doesn’t evaporate, and barely catches fire. Battery makers turn to it for lithium-ion batteries and even next-gen sodium batteries, hoping to pack in more power without risking safety.

Breaking Down The Chemistry—And The Benefits

PMP-Tf stands out for more than just fire safety. Its molecules don’t fry circuit boards or corrode sensitive battery parts. I’ve seen tests where standard salts chew up cell separators, making batteries fail faster. PMP-Tf brings a calm steadiness, keeping the inner workings free from breakdown. Its high ionic conductivity—think of it like fast-moving traffic for electric charges—helps batteries deliver more energy in a smaller package.

Energy storage isn’t the only playground. PMP-Tf shows up in supercapacitors, those small but mighty devices in anything from power tools to backup servers. By letting charged particles race quickly between plates in a capacitor, PMP-Tf helps these devices deliver bursts of power on command. My own experience with hobbyist electronics taught me how important stable electrolytes are for a long-lived, safe circuit.

Laboratories Put This Salt to Work

Years spent watching lab groups test green chemistry methods taught me that ionic liquids like PMP-Tf don’t just live inside batteries. They appear in chemical separations, where you need a selective, nonvolatile medium. PMP-Tf dissolves metals and organic molecules that fight with other solvents. Extraction companies use it to separate rare earth metals, or in pharmaceuticals to improve purity, sidestepping harsh acids or explosive solvents.

Sustainability and Hurdles

For all its benefits, PMP-Tf doesn't come without downsides. Manufacturing it still relies on fluorinated chemicals, which don't break down easily in the environment. I’ve seen researchers look for friendlier options, but so far, alternatives don’t match the same mix of safety, stability, and performance. Cost stays on the higher side too, and companies weigh the price against the longer battery life and lower risk.

Pushing Forward

Battery fires on the evening news, reminders of toxic spills, and growing stacks of electronic waste keep scientists motivated. More people from universities and start-ups have shifted attention to materials like PMP-Tf, hunting for tweaks in the molecular structure that give green performance without high costs. Supporting academic-industry partnerships cracks the door for new chemistries while reducing the environmental toll.

Every step toward safer, stable electrolytes like PMP-Tf stands to cut risk and stretch the life of batteries. Advances here ripple out to everything from renewables feeding the power grid, to the next wearable device that lasts just a little bit longer before charging.

Looking Past the Name

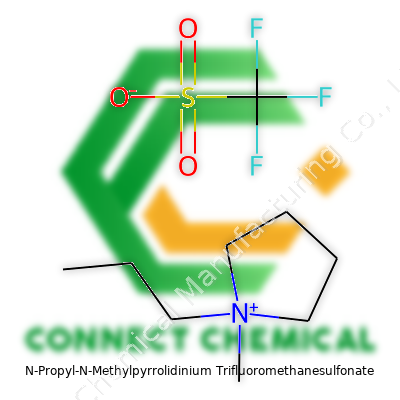

A long name often sends people running, but beneath that tongue-twister—N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate—sits a fascinating compound with a clear chemical formula: C9H18F3NO3S. The molecular weight comes in at 293.31 grams per mole.

The formula lets us see the nuts and bolts: nine carbons, eighteen hydrogens, three fluorines, a nitrogen, three oxygens, and a sulfur. These combine to offer far more than a chemistry lesson; this salt, often grouped with ionic liquids, sits at the crossroads of clean energy, batteries, and advanced materials.

Why the Chemistry Matters

Ionic liquids don't rush to evaporate under regular conditions. That makes compounds like this one more stable and less likely to contribute to air pollution. Anyone in a lab, or anyone producing anything on a large scale, learns pretty quickly that vapor means wasted product and tougher safety concerns. Companies seek out stability and reliability—key attributes of this salt.

The methyl and propyl groups on the pyrrolidinium ring also adjust how the material behaves. That means it works well as a solvent, or as an electrolyte in things like lithium batteries or supercapacitors. Folks designing better batteries for cars or grid storage need materials that don't break down quickly, or react when they shouldn't. Here, both the backbone of the molecule and those functional groups handle the job.

The Real-World Pressure

Tech leaders talk about the next battery breakthrough, but the problem often boils down to finding something to carry a charge safely and efficiently. Traditional solvents in electrochemical devices—think old-style batteries or fuel cells—don't always play nicely with high voltage or frequent cycling. Flammable organic solvents bring fire risk. Water limits voltage. Here’s where the N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate steps up: stable, not easily flammable, with high ionic conductivity and wide-ranging electrochemical windows.

Years working in laboratories taught me that many industry projects stall out over safety or lack of performance. New chemistry like this opens the door to performance combined with responsible handling.

Challenges and Solutions

Despite these strengths, accessibility creates headwinds. Synthesis calls for careful handling. Commercial availability depends on scalable, cost-effective production and regulatory confidence in the environmental impact. For widespread adoption, the path forward includes investment in better synthesis routes: fewer steps, less waste, and less reliance on expensive feedstocks. Open data on safety and life-cycle assessments help reassure investors and regulators.

Collaborative research—industry working with academia, and companies sharing their findings—often accelerates this process. I've seen progress jump ahead when groups pool resources instead of isolating knowledge. Getting this compound out of the rarified air of specialty labs and into the hands of mainstream manufacturers means focusing on education and transparency. Companies who make it a priority to share safety data and best practices usually win trust faster.

Bridging Chemistry and Society

A simple formula on a page carries weight well beyond the chemistry. It touches how much energy gets lost on power grids, who can develop safer medical devices, and how reliably we move towards climate goals. The way forward relies as much on thoughtful relationships and clear, credible information as on smart chemistry. That’s how a once-esoteric compound becomes part of the solution for better batteries, safer factories, and a more sustainable future.

Why Thoughtful Chemical Storage Matters

Handling specialty chemicals has never been a simple task. Every storage decision speaks to safety, investment protection, and responsibility toward the people working close to those compounds. N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate—used in electrochemistry and as an ionic liquid—serves as a perfect example for showing why careful handling isn’t only for the lab’s benefit, but for the well-being of everyone involved.

Understanding What Makes It Tricky

This specific compound falls within a family of chemicals famous for their stability and non-volatility, well suited for high-tech uses. Just because something doesn’t fume or combust instantly doesn’t turn it into a teddy bear. N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate’s salt structure stands up to moisture in daily air, but it can still react with water over time, leading to impurity buildup and unpredictable results in experiments or process lines.

Temperature and Environment: Getting It Just Right

Put it in a warm, humid spot and you’re asking for trouble. Long-term exposure to anything above normal room temperature accelerates unwanted reactions. Standard advice from colleagues in industry and academia: store this salt in tightly sealed containers, away from both sunlight and heat sources. Stainless steel cabinets or tightly sealed glass jars in climate-controlled rooms work well. Every facility I’ve checked has also used desiccators filled with silica gel to keep things extra dry. That small step stops accidental moisture from getting in—a lesson reinforced every time a new student forgets to close a lid and finds chunky residue a week later.

Labeling and Security: Respecting the Material

Chemical storage always means tracking and labeling. This salt can get confused with other white powders, so never skip the label. Write the full name and open date on the jar. With chemicals like this, someone eventually inherits the shelf, and they deserve to know exactly what’s inside.

Security plays a part, too. Even if there’s no major hazard posted on the door, proper access control prevents theft or misuse. In labs I’ve worked with, access always comes with training—not just a key. One slip can cause a cascade of wasted batches or, in unlucky cases, injury. There’s a responsibility to each other behind every locked cabinet.

Common Mistakes and Better Habits

It’s tempting to toss a container on a random shelf in a busy workday. I’ve made that mistake during graduate school, stacking compounds by convenience, not compatibility. Once, a careless mix-up ruined a whole experiment run, setting my schedule back a week. It’s a hard-learned lesson on order and double-checking. Dedicated shelves organized by chemical class make all the difference. Teaching new team members using real-life storage failures sticks better than long slideshows.

Supporting Safe Practice Through Training

Relying on workplace culture and training pays off. The labs with the best safety records make ongoing education routine—every new batch of students or staff gets real, hands-on guidance. No checklists forgotten at the back of a binder; instead, routine walkthroughs and open conversations. Transparency with incidents, not shame, drives better storage every year.

Room for Improvement: How Industry Can Step Up

Even with clear guidelines, accidents happen. Reducing these means work doesn’t finish after purchase and delivery. I’ve seen companies supply ready-to-use safety sheets and even include sample containers for proper transfer from shipping bottles. Removing excuses for sloppy practice makes all the difference.

Keeping N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate in good shape starts with respect for chemistry, but ends with commitment to real human safety. The more teams support each other, share hard lessons, and take pride in well-labeled shelves, the better those high-tech results will be.

What Is N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate?

Science has a knack for odd names, but they usually carry a story. This chemical, often tagged for short as a pyrrolidinium ionic liquid, finds regular use in the world of batteries and electrochemistry. Companies and researchers value it for its stability and conductivity, especially in lithium-ion cells.

Understanding the Concerns

Any time a new compound slides into labs and factories, folks working with it deserve straight answers about safety. Safety data for N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate feels a little thin compared to the household chemicals many of us grew up around. That raises a flag because lack of information sometimes hides real risk.

I remember the early days of lithium batteries. We treated them as safe, only later learning about runaway reactions and fires. It’s pretty common for new materials to reach the market before long-term testing settles the truth.

Toxicity: What We Actually Know

Most research lands on this chemical being at least moderately toxic. In animals, exposure to pyrrolidinium ionic liquids often leads to mild to moderate organ damage, especially when the doses jump. Some tests point out harm to the liver and kidneys. No one is serving up a glass of this at dinner, but just handling it can pose risks.

Contact with skin can cause irritation. If it gets in the eyes, people can suffer burns or serious irritation. Breathing in its dust or vapor for long periods could bother lungs, based on related chemicals. Long-term studies in people are missing, but comparisons to better-studied ionic liquids suggest that chronic exposure could spell trouble.

Environmental Effects

These ionic liquids gained hype for seeming “greener” because they don’t evaporate easily. Low volatility cuts back on air pollution. But what happens after spills or leaks into water or soil? Some research says these compounds hang around longer than hoped, which makes them a headache for cleanup. They can harm aquatic life, stunting growth and killing smaller creatures. That fact sticks with me, because I’ve seen how hard it is for rivers and lakes to bounce back when they get a new dose of contamination.

Staying Safe

Anyone using this stuff in a real-world setting ought to wear gloves, eye protection, and lab coats—basic gear by lab standards. Working with a fume hood slices risk, since fumes and dust don’t linger in the room. It’s best if workplaces train people using up-to-date data sheets and stick to small amounts unless absolutely necessary.

Disposal can’t head down the closest drain or trash chute. Instead, special waste handling routes should kick in, just like for other industrial solvents, so it doesn’t end up in waterways or soil.

Finding a Better Way Forward

Regulators need to push for clearer labelling and support independent toxicity studies. Big companies have a habit of testing for what they want to see, so third-party research fills in gaps. More animal-free testing—using computer modeling or cell cultures—can answer big questions before people get hurt.

Down the line, chemists could look for tweaks to make ions that do the job but break down faster in nature. That way, innovators don’t have to sacrifice safety for performance.

Looking at What’s in the Bottle

Working in the lab, you start to notice some compounds come with more headaches than others. N-Propyl-N-Methylpyrrolidinium Trifluoromethanesulfonate shows up as a promising ionic liquid for electrochemistry and battery research. Researchers reach for it when looking for an electrolyte that can handle high voltages or tricky organic syntheses. Lab performance doesn’t just depend on the name or formula; you quickly learn the label’s purity can make or wreck an experiment.

Suppliers advertise purities in the 98% to 99% range, sometimes up to 99.5%. As someone who has squinted at lab certificates and GC-MS traces, these numbers matter. Small electrolyte impurities in ionic liquids often sneak into your results, clog up instruments, or add hours of extra troubleshooting. I’ve seen what an extra percent of purity can change in a battery performance test. Going for 99% or above usually keeps things clean enough for sensitive electrochemical work, but that bump in purity also shows up on the invoice.

Sourcing Beyond Catalog Numbers

Availability of this salt has picked up in the last decade. European chemical distributors, several US specialty suppliers, and some Asian producers keep it in their electronic materials lines. We used to chase after small 5g or 10g vials for pilot projects, waiting on customs or project budgets. It’s not bulk sodium chloride—orders above 100g tend to come with lead times and painful pricing. Some suppliers keep stocks on the shelf, but the shelf sometimes feels pretty far away, buried behind supply chain paperwork. E-commerce has softened these issues a bit, but labs still lean into a bit of a scavenger hunt for specialty ionic liquids.

Shipping adds another layer of pain, since these salts sometimes fall into the hazmat category for certain countries. That can mean extra courier fees, delays, or paperwork. If you’re looking for fast turnaround, I’ve found that local academic consortiums and university purchasing groups move things faster than solo buying. Sharing surplus or swapping bottles between research groups helps blunt the impact, especially for basic studies or method development work.

Why Purity Matters in the Real World

People outside materials science sometimes wonder why a few tenths of a percent make any difference. I used to think the same, right up until an unexpected failure in an organic electrode test. Turns out, trace bromides or water from a lower-grade batch throw off conductivity, and side reactions can spiral out overnight. I now find myself looking for thorough certificates of analysis—NMR, ion chromatography, or Karl Fischer results—before shaking hands on a purchase order. Some low-cost sources skip these details, which means labs with tight QA standards do their own extra rounds of purification. In-house drying, repeated recrystallization, or vacuum distillations aren’t glamorous, but they let you tailor the chemistry to fit the project.

Solutions for the Purity Puzzle

One approach I’ve tested in crowded university labs is pooling demand. Researchers from different projects band together and place a quarterly, larger-volume order. The supplier responds better when they see a 250g recurring order, and you get fresher batches. Documenting and sharing the purification process among groups also goes a long way—a file cabinet of best practices outperforms assuming every bottle is flawless.

Open communication with suppliers helps catch lot-to-lot variability before it bites you. Some labs keep a standing dialog and even request pre-shipment samples. If you hit roadblocks, turning to specialty chemical brokers has helped in a pinch. Sometimes the personal connection with a local sales rep wins out over the most polished web store. As research pushes into more demanding applications, the demand for higher-purity, well-characterized batches will only rise.