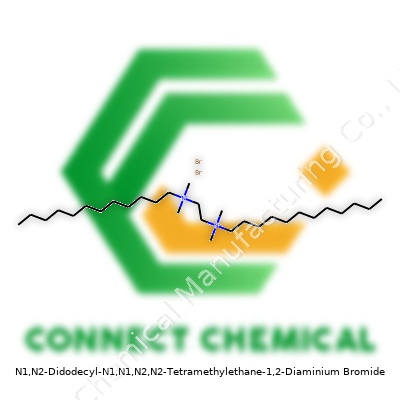

N1,N2-Didodecyl-N1,N1,N2,N2-Tetramethylethane-1,2-Diaminium Bromide: Insights and Perspectives

Historical Development

Chemists didn’t stumble upon N1,N2-Didodecyl-N1,N1,N2,N2-Tetramethylethane-1,2-diaminium bromide by accident. The molecule comes from decades of systematic work exploring quaternary ammonium compounds. Since the early 20th century, researchers have tracked the behavior of dialkylated and tetraalkylated diamines, hoping to find something that stands out in terms of surfactant properties or antimicrobial ability. By the late 1980s, experimentation began to branch toward larger alkyl chain substitutions, and someone in a well-outfitted lab decided to twist the ethylenediamine core into something bulkier, yielding this compound. In many ways, this represents the intersection of classic organic synthesis and the push to solve tough problems in surface chemistry and materials science.

Product Overview

What sets this diaminium bromide apart from its peers is the pairing of two dodecyl chains with a compact tetramethyl backbone, all wrapped up with bromide counter-ions. You end up with a substance that acts as a strong cationic surfactant and can disrupt biological membranes or stabilize emulsions in research and industry. It’s not just a variant among quaternary ammonium salts but a targeted tool to modulate surface tensions and even direct the growth of nanomaterials. Some industries use it for its distinct amphiphilic character, finding value in how readily it dissolves in organic solvents while displaying limited water solubility, which can come in handy while fine-tuning dispersion processes or controlling phase transfers.

Physical & Chemical Properties

The first impression this compound gives in a lab is its pale, waxy solid form. At room temperature, it remains stable, practically odorless, and melts in a narrow range around 40-60°C depending on purity. Its density hovers just above that of water, while its solubility pattern strikes with predictability—readily dissolving in alcohols, acetone, or chloroform, yet resisting breakup in cold water. The dodecyl chains contribute significantly to its hydrophobic interactions, influencing micelle formation. As a bromide salt, its ionic character can pull or repel other charged species in solution, a trick that formulators lean on to change particle organization.

Technical Specifications & Labeling

Manufacturers describe the compound with a simple purity percentage, almost always above 97%, as lower grades compromise its role as a benchmark surfactant. Analytical reports tend to show minimal volatility and negligible water content, which means the molecule delivers consistent results without fuss. Safety labels mention irritation hazards for skin and eyes, plus guidance on storage away from oxidizers and moisture. Some suppliers stamp the bottle with a UN shipping number, highlighting its chemical nature for anyone tracking inventory. For research, knowing the lot number and preparation date means you can trace back anomalies if a run fails.

Preparation Method

Lab synthesis starts with ethylenediamine and works up through methylation, usually with methyl iodide—though in some updated setups, methyl bromide now gets the nod due to waste concerns. Dodecyl bromide enters the scene as the alkylating agent, creating that prized dodecyl stretch on both nitrogen atoms. The quaternization step runs in an organic solvent under mild heat, and the resulting thick mixture eventually cools, allowing the diaminium bromide to crystallize. Filtration and washing remove most impurities, and vacuum drying finishes the compound for bottle-up. Upscaling takes careful hazard controls thanks to the reactivity of methylating agents, something every production chemist respects after the first splash incident.

Chemical Reactions & Modifications

Once on the bench, this diaminium is anything but dull. Chemists have found the cationic nature lets it act as a phase-transfer catalyst, picking up negative ions and transporting them into places they wouldn’t otherwise go. The long alkyl chains can take part in further substitution reactions, and the methyl groups hold firm under moderate conditions. In specialized work, sections of the molecule have been swapped for aromatic groups or altered to tune the critical micelle concentration, giving rise to variants for emerging green chemistry approaches. It’s steady in the presence of mild bases but starts to break down when hit with concentrated acids or strong oxidizers, a limitation you can’t ignore when scheduling downstream syntheses.

Synonyms & Product Names

You quickly learn that naming conventions in this world can tangle even an experienced scientist. Outside formal registries, the compound runs under aliases like ditridecyl tetramethyl diammonium bromide or just DD-TMDA bromide. Some chemical houses slap proprietary numbers on the label, complicating searches for safety data or technical details. When scanning literature, cross-checking CAS numbers usually straightens things out, but brand confusion has led more than one researcher to late-night frustration over an unexpected melting point.

Safety & Operational Standards

Spend a bit of time handling quaternary ammonium compounds, and one lesson stands out: safety protocols matter. N1,N2-Didodecyl-N1,N1,N2,N2-tetramethylethane-1,2-diaminium bromide may not carry the acute toxicity of more notorious lab chemicals, but even a single spill can provoke itching or rash—standard nitrile gloves and splash goggles make an easy habit. Lab ventilation trims down inhalation risks during weighing and transfer. Waste gets collected separately, routed for specialized disposal because environmental authorities treat bromides with caution. For industrial use, continuous monitoring helps keep dust and fine particulates away from operators, especially since chronic exposure studies remain on the sparse side.

Application Area

My experience in a university research lab gave me firsthand exposure to the compound as a template in nanoparticle synthesis. Its surfactant qualities shape the growth of silver and gold nanocrystals, letting us control both size and morphology with reliability. In other hands, the molecule finds itself in the center of emulsion polymerization, cosmetics formulations, and even as a biocidal agent in small-scale water treatments. Textile chemists value its antistatic and softening features, which arise from the dual dodecyl chains embedding in fibers. Electronics researchers employ it to stabilize dispersions of conductive materials or as a support for novel sensor surfaces. As regulatory scrutiny increases, clear labeling and batch traceability keep quality high across sectors.

Research & Development

The pace of research on this diaminium bromide has picked up recently, especially where greener chemistry and biomedical use are on the agenda. Groups across Asia and Europe report new synthesis pathways aiming to ditch hazardous methylating agents or swap out bromide for less persistent counter-ions, cutting down environmental impact. Hardcore materials scientists push the molecule into self-assembly experiments, while biotech teams scrutinize its ability to interact with membranes and proteins. Partnerships between academia and industry sometimes yield new patents, typically in specialty coatings or advanced composites. Collaboration stands out more than competition in this field, as most groups share a drive to lower costs, raise safety, and open new product avenues.

Toxicity Research

Health and safety studies on quaternary ammonium bromides tell a mixed story. Acute toxicity falls well below pesticides and older generation antimicrobial agents, but extended skin or eye exposure still delivers irritation. Animal trials show low oral toxicity at research doses, yet waterborne residues deserve attention as they linger and threaten sensitive aquatic organisms. In my lab, we relied on fume hoods and clear labeling, and kept detailed records for local chemical safety authorities. Some promising research looks at rapid breakdown under sunlight or with simple oxidants, aiming to keep aquatic impacts in check. Regulatory agencies in regions like the EU or California now pry a little deeper into environmental fate, signaling that future use may depend on further innovation in green chemistry—or at least better end-of-life handling.

Future Prospects

Looking ahead, the direction for N1,N2-didodecyl-N1,N1,N2,N2-tetramethylethane-1,2-diaminium bromide will ride on advances in responsible manufacturing, safer synthesis, and fine-tuned applications. Researchers seek replacements for bromide counter-ions and extend the molecule’s utility in smart surfaces or biomedical delivery, knowing regulatory hurdles won’t ease up. Safer synthesis routes pairing renewable feedstocks with lower-impact reagents tempt innovators who want both high performance and social license. In the next decade, I see this class of molecules taking root in responsive materials, targeted drug delivery, and sustainable industrial processes—provided the field commits to tracking health and environmental impacts, and makes data open for peer scrutiny. Moving from "just another surfactant" toward solutions for pressing modern challenges, the molecule’s future looks layered with both opportunity and responsibility.

An Industry Workhorse with Quiet Influence

People working in laboratories or factories may not glance twice at a chemical labeled “N1,N2-Didodecyl-N1,N1,N2,N2-Tetramethylethane-1,2-Diaminium Bromide.” It doesn’t leap from a page in the same way as silver or sulfur. Still, deals get done, goals get met, and production lines keep running partly because of compounds like this one. In my experience at tech and material startups, I noticed how important it is, even if it doesn’t get the spotlight.

Driving Power in Surfactants and Detergents

This compound shows up as a trusty surfactant, with two big dodecyl chains that break up oils and grease. Surfactants make everyday products clean better—everything from shampoos to floor cleaners. Formulators look for something that can split up grime reliably and speed up rinsing. People want their laundry to come out fresh and don’t want to scrub tile grout for hours. Thanks to cationic surfactants like this one, formulas keep dirt suspension under control and get rinsed faster by water.

Enabling Better Delivery in Medtech

Some might shrug off specialty surfactants, but in drug research, this type of compound helps move medicine to the right target inside the body. In work with pharmaceutical developers, I saw scientists using cationic compounds to package delicate drug molecules. They wrap the medicine in a layer, help it slip past barriers in the body, and let it release its payload right where it counts. This keeps medicines potent—which is a big deal for gene therapies or RNA-based treatments.

Antimicrobial Punch for Hard Surfaces

People often forget how tough some microbes can get on countertops or industrial machines. Quaternary ammonium compounds, including this one, give an edge to disinfectants and sanitizers, especially under tough conditions. Hospitals, food plants, and schools lean on such chemistries to knock out bacteria and some viruses, keeping outbreaks in check. These products often find a home in custodial closets and industrial kitchens—not because they look special, but because they get results.

Improving Electronics Manufacturing

If you’ve ever handled a tiny electronics board, you know clean starts matter. Electronics production uses this diaminium bromide as an antistatic agent and a cleaning aid. Electrically charged dust or static shocks can kill microchips during production—ruining expensive work. Coating surfaces with a film of antistatic surfactant like this one prevents static charge build-up, saves on costly production errors, and ensures sensitive parts actually work when they’re shipped out.

Paving the Way for Green Alternatives

With stricter environmental rules, more companies keep a close eye on the chemicals they use. The journey toward greener surfactants isn’t easy, but lessons from solid performers like this one help guide the development of safer, plant-based alternatives. Tracking its stability, effectiveness, and ease of removal from wastewater teaches researchers what boxes still need checking for the next generation of sustainable products.

Finding the Balance

As demand rises for products that work harder, last longer, and do less harm, real progress comes from understanding what each ingredient brings to the table. N1,N2-Didodecyl-N1,N1,N2,N2-Tetramethylethane-1,2-Diaminium Bromide earns its place through reliability in surfactants, drug delivery, disinfectants, and more—yet its story also says something about how industry balances strong performance with tomorrow’s safety standards.

Solubility Shapes Results

Chemistry class taught me that getting a compound to dissolve feels like detective work. Some stuff vanishes right into water, other bits stubbornly cling together, refusing to disappear unless you bring out the tough solvents. Plenty of people wrestle with this puzzle every day; whether they’re mixing medicines, making coatings, or checking contaminants, knowing where a compound dissolves makes or breaks the outcome.

The Basics Matter: Structure Tells the Story

Dissolving a compound boils down to molecular teamwork. Water likes substances that either carry some charge or form hydrogen bonds. Salt, for example, tumbles apart in water without trouble. Sugar, with all those oxygen atoms, disappears in a glass pretty quickly too. But show water a chunk of wax, and the show’s over—the wax keeps floating, no matter how hard you stir.

Take a good look at a compound’s structure before deciding where it dissolves. More oxygen, nitrogen, or charged pieces? Water usually wins. More long chains of carbon and hydrogen? These show up in greasy spills, gloppy oils, or many plastics. Such molecules hang together, and water can’t pry them apart. You need an organic solvent like acetone or hexane—these can get into the tangle and loosen things up.

Practical Choices: Why It Matters in Real Life

I once helped with an old paint spill in a garage. Pouring water over it did nothing, but a dash of mineral spirits lifted the stain right off the floor. In the pharmacy world, getting a medication to dissolve in water means someone can swallow a tablet or mix it in a drink. Solubility affects safety, effectiveness, and shelf-life. It’s the same story in environmental science. If a pollutant dissolves in water, it rides with rain into streams and rivers. Oils and other fats stick around, creating slicks or greasy residues.

Problems show up when people guess wrong about where something dissolves. Wasting time with the wrong solvent can mean ruined experiments, wasted money, or worse, missed toxins in drinking water. It pays to skim the safety data sheet or reach for a solubility chart before getting started. Even a splash of water, a pinch of salt, or a drop of vinegar in the right mixture changes solubility—sometimes for better, sometimes for worse.

Getting the Answer: Tools and Solutions

Scientific teams often use a toolkit: observing how much of a compound dissolves, measuring the cloudiness, or running it through a spectrometer for the fine details. In many workplaces, people keep lists of solubility rules on hand. Something as simple as “like dissolves like” gets tossed around a lot because it’s true: oily substances stick together, water-loving compounds cluster with water.

Promoting better chemical literacy would smooth out many bumps. Schools could offer hands-on time with solvents and real examples instead of just textbook diagrams. Industries ought to share clear data on product labels, not bury it in dense technical language. Even at home, folks handling cleaners, paints, or garden products benefit from knowing what will, or won’t, come off their hands in the sink (hint—some stains need more than a scrub with soap).

Moving Toward Better Choices

More eco-friendly solvents are picking up momentum. Green chemistry focuses on substances that clean up easily, degrade quickly, and don’t leave behind toxic surprises. With growing pressure to protect health and the planet, people should expect to see more products designed to work well in both water and safer organic liquids.

Checking solubility isn’t just about following rules. It’s about understanding how small decisions ripple out into big results, in labs and everyday life.

Respecting Product Instructions Isn’t Just for Show

Every time you pick up food, pharmacy items, or anything that claims to “do a job,” storage directions show up somewhere on the label. Some people scroll past these as fine print or toss out the exterior packaging before glancing. In practice, those short sentences about where and how to store a product can mean the difference between safe use and disappointment—or worse, a health event.

Heat, Light, Moisture: Everyday Hazards for Good Products

Nobody walks around with a full-blown scientific lab at home. Still, keeping items away from heat sources and direct sunlight pays off. Many medicines, for example, lose their punch if exposed to high temperatures. The same goes for foods that rely on preservatives to hold up on the shelf. Too much light can affect anything stored in clear containers. Those amber bottles in the pharmacy? They block out damaging rays.

Humidity brings its own set of problems. Dried foods can clump or spoil. Pills can become soft and start sticking together. That’s how mold gets a foot in the door. I once threw away a whole packet of vitamins after keeping them in a steamy bathroom drawer. The original bright orange color faded, and a sour odor warned, “Don’t even think about eating this.”

Following Instructions Protects Your Wallet

Roughly one third of all food produced winds up in the trash. Sometimes people lose track of what’s in the fridge, but bad storage plays a role too. I’ve watched cheese go moldy in just a few days when left out after hosting friends. Bread goes from fresh to stale within hours if not wrapped tightly and kept out of sunlight. Shelled nuts taste bitter and stale much sooner than the date on the package if humidity creeps in. These losses add up. For many families trying to manage budgets, following storage advice means less waste and more money in your pocket.

Health Risks Don’t Always Show Up Right Away

Foodborne illness isn’t just about visible green fuzz. Some bacteria grow without much warning. Dairy, meat, and leftovers should stick to the cold recommendations on the label. Listeria and salmonella don’t always give off a smell. Unsafe products can look completely normal. I learned this the hard way as a college student ignoring "refrigerate after opening" on a jar of salsa. Let's just say that weekend didn’t end well.

Simple Steps Work—If You Stay Consistent

Getting storage right just means following clear, simple rules. Keep most medicines at room temperature, in a dry place, away from direct sunlight. Use airtight containers and wrap perishable goods tightly in the fridge. Don’t store chemicals or cleaning products near food or kids. For supplements or specialty items—protein powders, probiotics, sensitive skincare—manufacturers test their own products for shelf-life at specific temperatures and humidity ranges. Their recommendations aren’t just for legal reasons—they know what keeps things fresh, safe, and working as promised.

Real Solutions: Don’t Guess, Just Check

Labels matter. If a product says “cool, dry place,” that means not on top of your fridge, not in a steamy bathroom, and not in the trunk of your car. You don’t need special equipment. Take a moment to read the small print, follow the advice, and trust that the people who created the product invested time figuring out what works.

By taking storage guidance seriously, anyone can protect themselves and their families, avoid waste, and stay healthier in the long run.

Everyday Hazards in Unlikely Places

Pick up a bottle of cleaner, a battery, or even a new appliance, and tucked somewhere in the fine print you'll spot safety advice. Most folks give it a quick glance and toss it aside, yet ignoring those warnings leads to real problems over time. Take it from someone who once decided that "protective gloves recommended" sounded excessive—one careless spill on my skin, and I learned the hard way that manufacturers write those lines with reason.

Knowing What You Handle

Why do these products always carry such a laundry list of dos and don’ts? Household chemicals, rechargeable batteries, and even common garden fertilizers carry more risks than most expect. The Centers for Disease Control and Prevention report thousands of emergency room visits every year linked to accidental exposure, whether from mixing cleaners or storing solvents next to food. Sometimes a product looks so ordinary it lulls you into a false sense of security. That’s where clear labeling and following instructions matter most.

Lessons Learned Through Oversight

Direct sunlight on a spray can or tossing expired batteries into kitchen trash both cause more headaches than the slight inconvenience of a moment’s attention. I once left a small butane torch in a car glove box during summer. It shifted around, overheated, and left a mess of melted plastic and burned upholstery. Small shortcut, big price. Little choices, like storing solvents in original containers instead of mason jars, have saved me far more trouble than riskier shortcuts ever did.

Creating Safe Habits at Home and Work

Basic steps make a solid difference. Closing containers after each use, washing hands after handling any chemical, and keeping products away from food or kids—these daily rituals keep my family and co-workers out of trouble. The National Fire Protection Association points out that simple habits like separating combustibles from heat sources sharply reduce home fire incidents. I keep spill kits and baking soda near my workbench, not just because the label says so, but because I’ve seen minor mishaps spiral due to wishful thinking.

Why Communication Matters

Kids and pets rarely understand why some stuff belongs on a high shelf and not under the sink. I make it a point to talk through hazards and model safe practices, especially after a friend’s child found an open paint thinner jar and wound up in the ER for inhalation. Clear conversations build habits that safety checklists alone can’t guarantee.

Solutions That Stick

Most of us juggle busy lives and get tempted to skip labels or ignore storage warnings. Keeping reminders near products, using color-coded bins, and even setting up simple disposal guidelines at home or work help reinforce habits. I take cues from workplace safety rules—gloves, goggles, and ammonia never mix with bleach—because those lessons transfer directly into my garage and kitchen. By treating every chemical or gadget with respect, I cut down on overruns, spills, injuries, and—just as important—unexpected worry.

Looking Forward

Big improvements happen through small changes. Teaching careful handling, staying alert to warning symbols, and replacing shortcuts with safer routines mean fewer trips to the hospital, fewer emergencies, and more peace of mind. Safety guidelines protect more than health—they protect time, money, and everyone around us.

Why Purity Matters in Chemical Logistics

In the world of shipping chemicals, folks working in labs, factories, and warehouses will tell you straight: purity is front and center. Take sodium chloride, for example—table salt for most, but inside a lab, any impurity makes a dent in precise results. A chemist trusts a label marked 99.5% or higher. Anything less, and the batch might as well stay on the shelf. A slight slip in purity can skew medicine formulas, mess up a food process, or throw a wrench in a tech manufacturer's work. Pharmaceutical giants, for instance, stick close to grades that meet pharmacopeia standards, sometimes pushing above 99.9%, just to dodge questions about safety.

My stint in a chemical supply warehouse showed me why customers dig deep into the lab reports before signing off on deliveries. In bulk industries, 95% might serve the purpose, like in de-icing or textile production, but work with electronics and you’ll see folks asking for "five nines" (99.999%). The difference appears small on paper, but factory engineers lose sleep over even a whiff of contamination. If a chip foundry receives material not as pure as promised, they lose more than product—they lose trust, and that’s a tough stain to wash out.

Shipping: More Than Just a Cardboard Box

Many outside the business might picture a simple bag or barrel, but packaging gets technical fast. Dry chemicals, like powdered acids or salts, usually go into lined fiber drums or sturdy plastic buckets. These aren't picked at random. Warehouse workers prefer high-density polyethylene drums for harsh weather and long journeys. I’ve hoisted thirty-gallon containers coated inside with special liners to stop moisture sneak-ins or save a team’s hands from corrosion. Smaller amounts come in thick-sealed pouches or glass jars, especially if the product grabs water from the air or reacts to light.

Liquids call for even more careful handling. You’ll spot UN-rated steel, tough glass bottles, or specialized plastic carboys rolling out for shipment. Solvents with low flash-points demand tight screw caps and sealed shrink wraps, reducing risk on highways and at docks. For big buyers, tankers or Intermediate Bulk Containers (IBCs) cut down time and save cash, but every driver checks paperwork twice for leaks and cross-contamination risks. Anyone who has mopped up a chemical spill knows what a mess a cracked drum can create—both in safety and cost.

Cutting Corners Comes at a Price

Cutting corners on purity or packaging winds up costing time, money, and sometimes public safety. Cases crop up every year where mislabeled or under-packaged chemicals lead to warehouse fires, product recalls, or even injuries. The big lesson I learned: shipping isn’t just about moving goods from A to B; it's about guarding reputations, jobs, and sometimes even lives.

Improving Chemical Shipping

Companies making progress lean on third-party audits, keep strict supply chain checks, and tie up loose ends with digital tracing. On the warehouse floor, old hands swear by color-coded labels, tamper-evident seals, and regular surprise audits. Customers today don’t just look at price per pound; they call for proof, ask about test results, and check how the package looks before signing for it.

It comes down to trust: if you shortchange purity or try to save pennies on shipping, the marketplace finds out fast. Those who build their business on honest grading and tight packaging stay around longest.