Octadecyltrimethylammonium Bromide: A Commentary on Its Journey and Relevance

Historical Development

Looking back, the story of octadecyltrimethylammonium bromide, often called OTAB or STAB, shows how industrial chemistry evolved out of necessity. The demand for surface-active agents in the mid-1900s pushed researchers to explore long-chain quaternary ammonium compounds. Discoveries came from labs that stayed up late hoping to get the right mixture for detergency, textile processing, and emulsion stabilization. The surfactant revolution wasn't driven by one breakthrough; it took a mix of creative minds pooling together ideas. Chemical companies began to realize quaternary ammonium salts offered stable options in a world previously dominated by unpredictable natural soaps. This period marked a shift toward reliable industrial chemicals with known properties, making life easier for generations of product developers.

Product Overview

OTAB serves as a cationic surfactant. Its main value sits in its strong ability to form micelles, which assist in emulsifying oils, dispersing solids, and even disrupting biological membranes. This doesn't mean OTAB belongs only in arcane industrial settings; its role popped up in basic research and even in household cleaning products for a while. In the lab, bottles labeled with the OTAB name rarely gather dust—students and seasoned chemists both reach for it to test its performance in extracting DNA or to control the morphology of nanoparticles. Every time I worked with it, I sensed its versatility. Despite having alternatives, industries and small research outfits still rely on its dependable characteristics.

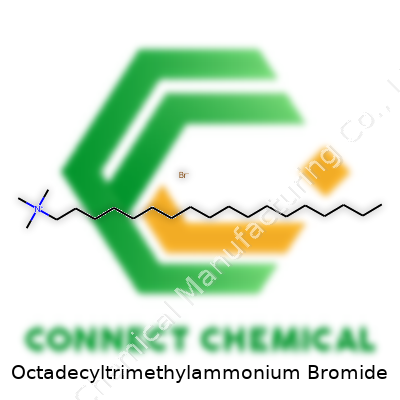

Physical & Chemical Properties

If you pour out a sample, OTAB appears as a white, waxy solid at room temperature. You can spot the typical faint, fatty-amine odor. The molecule packs an 18-carbon chain attached to a quaternary ammonium head, giving it a strong cationic charge and hydrophobic tail. Its melting point hovers near 60°C, and it's highly soluble in alcohols but struggles in water, especially at lower temperatures. Chemically, OTAB won’t react violently under normal use, but keep it away from strong reducing agents and oxidizers. Structurally, its amphiphilic character draws interest for both its ability to disrupt lipid layers and to coat particles with a dense, hydrophobic brush. The product sometimes leaves a slippery feel, reminding people of its use in materials that need lubricity or water repellency.

Technical Specifications & Labeling

Commercial OTAB usually arrives in tightly sealed, labeled containers, where manufacturers highlight purity—often above 98%. Labels show its CAS number (112-03-8), chemical formula (C21H46BrN), and precise weight. Shipping documents flag its hazardous classification, because cationic surfactants tend to irritate skin and eyes. Good supply chains will guarantee batch-to-batch consistency, offering detailed certificates of analysis that display moisture content, color, and melting range. In my experience, batch variation rarely becomes a problem unless the product sits poorly stored or exposed to humidity for months.

Preparation Method

Chemists in industry commonly synthesize OTAB through a simple alkylation reaction. They mix trimethylamine with 1-bromooctadecane in a solvent like acetonitrile or ethanol, let the solution stir under reflux, and collect the quaternary ammonium product. The process isn't flashy, but it gets the job done, allowing for kilogram-scale production at manageable costs. Washing and recrystallization usually produce a product that looks as pure and bright as what you find in catalogs. The ease of manufacture, in my view, is one reason why OTAB became a go-to option in so many sectors.

Chemical Reactions & Modifications

OTAB’s structure offers several modification points for folks who want to tune surface activity or biological function. Substituting alternative halides for bromide, for instance, tweaks solubility and counterion behavior. Researchers also graft the long alkyl chain onto silica or polymer matrices, creating stationary phases for chromatography or anti-fouling materials. The ammonium group accepts a range of organic cations, making OTAB a springboard for novel surfactants or antimicrobial agents. My first exposure to its power came in dispersing metallic nanoparticles—without it, particle agglomeration made measurement nearly impossible.

Synonyms & Product Names

OTAB might pop up under names like Stearyltrimethylammonium Bromide or STAB in product catalogs. Vendors use shorthand because the full name takes too long to squeeze onto bottles. Don't let the different labels fool you; most of these refer to the same base chemical. The range of trade names can confuse those new to the field, but the chemical formula always shines through the marketing jargon.

Safety & Operational Standards

Handling OTAB requires respect for its irritating tendencies. Inhalation or direct skin contact often leads to itching or minor inflammation. Labs and factories stick to gloves, goggles, and proper ventilation. Disposal isn't a trivial matter—limiting release into waterways is a rule, given quaternary ammonium compounds’ toxicity toward aquatic life. In my own work, accidental spills on stainless steel benches needed immediate cleanup to avoid staining or etching. Product labels, material safety data sheets, and training sessions reinforce the right way to work with OTAB.

Application Area

People across research and industry turn to OTAB for various reasons. Water treatment plants use it as a coagulant and biocide. Textile and paper processors deploy OTAB for fiber conditioning and static control. Analytical chemists value it for controlling nanoparticle growth and size in synthesis, while cell biologists test its properties as a membrane disruptor. Cosmetic chemists sometimes use it in formulations to deliver antimicrobial benefits to hair and skin products. Over the years, I’ve seen it included in migration studies looking at surfactant behavior in gels and colloids. Its ability to alter surface interactions without major toxicity at low concentrations carved a unique space among specialty chemicals.

Research & Development

Innovation rarely stands still, especially not in surface science. Labs tweak OTAB derivatives to boost antimicrobial activity or reduce environmental impact. Recent work looks at biodegradable alternatives that keep cationic performance but break down easier in nature. Teams study OTAB-based coatings that resist fouling on marine equipment or prevent biofilm formation in hospital settings. The push for greener chemistry led some groups to replace the long alkyl chain with sustainably sourced fatty acids. From my own projects, projects where the simple addition of OTAB increased the dispersion of gold nanorods gave clear proof that basic chemical tweaks enable new application spaces.

Toxicity Research

Concerns about health and environmental exposure persist. OTAB and similar compounds often bioaccumulate in aquatic systems and can disrupt cell membranes in non-target species. In people, trace exposure usually causes little harm, but prolonged or high-concentration contact increases the risk of dermatitis or respiratory distress. Regulatory scrutiny tightened as research kept showing that residual OTAB in wastewater slows down microorganism growth in treatment plants. Recent toxicity studies aim to understand how to limit harmful outcomes without sacrificing positive functional benefits. Keeping OTAB out of food or water systems became standard not just out of regulation, but out of repeated demonstration of its impact. I remember eye-opening trial results showing how even parts-per-million quantities can knock back algae and small aquatic life.

Future Prospects

OTAB will probably remain in demand—even if safer alternatives slowly eat away at its market share. Surface-active molecules that perform as well, cost less, and don’t disrupt ecosystems stand to take over niches where environmental pressure runs high. For now, research continues on greener syntheses and on modifications making OTAB easier to remove after use. Demand for nanoparticle synthesis, medical diagnostics, and next-generation coatings keeps OTAB relevant. Seeing new students pick up a bottle and ask about how it all works shows the lesson isn’t just chemical; it’s about learning where tools fit best and how to adjust as science marches forward.

What Makes This Compound Useful?

The name “Octadecyltrimethylammonium Bromide” rarely shows up outside chemistry labs, yet it has found a place in dozens of industries. Over my years tinkering with lab setups, I’ve seen that the biggest draw comes down to its surfactant qualities. Surfactants let oil and water mix in ways that make everyday products from glossy hair conditioners to high-grade industrial cleaners work better. Its long hydrophobic tail and positively charged head let it organize molecules, clean surfaces, and run interference in complicated processes. For anyone mixing stubborn ingredients, this property removes headaches and saves time.

Making Materials Behave

I’ve learned a lot talking to folks in the nanotechnology space. Here, this chemical controls how tiny particles stick together or push apart. In laboratories, it helps shape nanoparticles, keeping their size consistent and preventing random clumping. Scientists rely on predictable particle sizes for electronic screens and even some cancer diagnostics—real-world proof that little things can improve big outcomes.

Textile factories value the chemical’s ability to coat fibers evenly, keeping dyes attached so colors resist fading. Dye runs cost time and money, both in giant textile mills and in small home workshops. From my visits to factories, I’ve noticed that switches to better surfactants translate to longer-lasting clothing, less water waste, and lower dye usage.

Personal Products and Cleaners

Look at the ingredient list of some conditioners or lotions and you might spot this mouthful of a name. In the personal care world, it helps blend oil and water so creams feel smooth, not greasy. That soft, silky spread comes straight from chemicals like this one. For manufacturers, predictable results mean fewer recalls and happier customers. If you’ve ever left a conditioner in your hair and felt your hair softer without feeling weighed down, this behind-the-scenes actor did its part.

Big industrial cleaning operations include this compound in detergents that need to break down sticky gunk or greasy messes. It plays nice with both water and oils, scrubbing surfaces without damaging the stuff underneath.

Safety and Environmental Questions

A growing number of people are concerned about where chemicals end up after use. Some reports have shown that big doses of octadecyltrimethylammonium bromide don’t break down easily in nature. Over time, this can harm aquatic life by messing with how fish and plants absorb nutrients. Personal experience reminds me of hearing from environmental scientists who watch for these compounds in wastewater, pushing for better filtration or alternative substances. Some companies work with greener surfactants made from plants—these break down faster and cost only a little more.

What Can Improve the Situation?

It helps to support changes at every level. Labs can develop versions that work just as well but cause less long-term pollution. Consumers have a role too, by favoring products that list eco-friendly surfactants. Even small swaps, like using less product, shrink the load on water systems.

Regulators need fresh data. For real progress, oversight teams must track where these chemicals go after leaving factories and homes and set smart limits as new findings come in. With transparent reporting and steady research, the positive uses can stay in place while side effects get cut down.

Why Octadecyltrimethylammonium Bromide Matters

Octadecyltrimethylammonium bromide isn’t a household name, yet it pops up all over science and industry. Most people don’t realize how much this molecule does behind the scenes. It’s valuable in labs, with a molecular formula of C21H46BrN. This single piece of information—a string of elements and numbers—carries weight. Knowing the formula ties directly to understanding the molecule itself, how it works, and what risks or benefits it brings.

Looking Deeper Into the Formula

The name might sound intimidating, but everything becomes clearer step by step. At a basic level, the formula tells us the molecule contains 21 carbon atoms, 46 hydrogens, a single bromine, and a nitrogen atom. This grouping shapes how it behaves in water, oil, or contact with other chemicals. Anyone who’s handled it in a lab knows it forms an interesting balance between a long, greasy “tail” from the octadecyl group and a charged “head” thanks to the ammonium nitrogen. The bromide sits alongside, managing the overall charge.

I’ve had my own share of experience preparing solutions with this compound. Stability can be finicky. Given its large structure, clumping and cloudiness sometimes occur unless conditions are right. It’s that blend of hydrophobic and hydrophilic parts that makes it useful in separating or modifying surfaces, be it in research or manufacturing.

Applications Drive Safety and Innovation

The formula shows why such a compound acts as a surfactant. Anyone running experiments on dispersing nanoparticles or separating cells knows this molecule can help break up clumps and get better results. It’s also found in antimicrobial coatings, making hospital equipment less likely to harbor dangerous bacteria. Its track record in fabric softeners and hair products proves its flexibility. The formula’s unique arrangement gives it these valuable traits.

But this utility comes with responsibility. The presence of bromine hints at possible hazards. Bromine compounds sometimes trigger skin or eye irritation, and there’s a risk when large amounts get into waterways. I’ve always found it necessary to check protocols twice, especially in busy labs. Reading the formula isn’t just for show; it’s a crucial part of making sure everyone is safe on the job. Proper ventilation, gloves, and storage—these aren’t just good practice but absolute musts with this compound.

Steps Forward: Making Chemistry Safer and Smarter

Solutions don’t come only from better safety goggles or labels. Chemistry needs more accessible information—plain facts, not just scientific language. Everyone handling complex molecules like Octadecyltrimethylammonium bromide benefits from knowing what makes up these substances, not just what they do. Teachers should introduce students to formulas alongside safety concerns. In my own classes, connecting formulas to real-world risks kept students more engaged and prepared.

Sharing knowledge openly, from makers to users, reduces mistakes. There’s room for better tracking how much of this substance enters the environment and what happens next. Regulations must lean on solid facts: formulas, toxicology, proven uses. The more people understand each ingredient, the more responsibly society acts. That’s a change worth pursuing, in any setting where chemicals touch lives.

Everyday Contact and Chemical Footprints

Octadecyltrimethylammonium bromide, with a name that twists the tongue, finds its way into many products. Folks in the lab recognize it as a quaternary ammonium compound, the kind that grabs hold of dirt and oils. Over the years, chemists have tossed it into solutions as an emulsifier or a cleaning agent. Tabletop experiments at home or in university sometimes bring out a small vial labeled OTAB. Not many stop to think: Could this chemical cause harm?

Handling Hazards and Observed Toxicity

During research, some scientists report that OTAB irritates skin and eyes. Anyone who has spilled a small amount probably remembers a burning or stinging sensation. Inhaling dust or vapors brings coughing or shortness of breath. Studies in animal models show that repeated exposure—especially in high doses—sometimes damages organs or disrupts breathing. The U.S. National Institutes of Health points out that OTAB gets labeled “harmful if swallowed” and “toxic to aquatic life.” Pouring leftovers down the drain isn’t just careless—it causes real impact if those tiny fish and micro-organisms in rivers find themselves surrounded by it.

Real-World Exposure and Environmental Impact

Talking with colleagues in environmental science, you hear stories about runoff from manufacturing plants. Wastewater packed with OTAB drifts downstream, and aquatic bugs either struggle or disappear. This is no small problem. Even in trace amounts, studies tie OTAB to changes in the way algae and invertebrates survive and reproduce. The result: food chains take a hit, and ecosystems lose balance.

People in cities usually won’t pick up acute poisoning from this chemical. Yet, a factory worker or someone working in agricultural labs using surfactants gets exposed more often. At that point, workplace safety matters most. Gloves and goggles in the lab are the rule, not the exception. Safety data sheets call out these risks for good reason.

Steps Toward Safer Use

It’s easy for companies and researchers to focus on utility, forgetting that chemicals follow their own rules outside controlled settings. While college courses teach lab safety early, folks in processing plants and cleaning services also benefit from clear training. Ventilated workspaces, regular safety checks, and spill management practices make a real difference. Teaching workers how to handle, store, and dispose of OTAB goes a long way in keeping hands, lungs, and waterways safe.

There’s another layer: regulation. Some countries push for stricter limits on emissions and workplace exposure. Steps like installing filtered drains and switching to safer alternatives move the dial. Surfactants come in many shapes—bio-based options sometimes fill the need without the same toxicity profile.

Making Responsible Choices

Personal experience tells me: respect for chemistry keeps accidents at bay. OTAB delivers strong cleaning power and emulsification, but, like bleach or ammonia, deserves caution. People make decisions every day about what gets dumped or recycled. Not all chemicals belong in household drains. Industry, education, and households can cooperate by following safety guidelines and exploring less hazardous substitutes. That approach stands out as both practical and responsible.

Looking Beyond the Label

Octadecyltrimethylammonium bromide, often known by its mouthful abbreviation OTAB, pops up in a range of research and industrial settings. Many folks see chemicals as little more than plastic bottles on dusty shelves, but this compound carries risks and quirks that ask for real attention. A lack of care in storage—maybe a cabinet that gets too warm or a bottle with a loose cap—could spell health hazards, wasted product, or worse. That alone puts the spotlight on safe, smart storage.

Treat It with Respect

I’ve seen more than one lab where materials like OTAB get shoved onto whatever shelf has space. Sometimes researchers forget that simple mistakes, like leaving a cap half-twisted, can let moisture seep in. OTAB loves to grab water from the air, making it form sticky lumps and lose reliability. Anyone who has watched a reagent cake up right before a key experiment will know that frustration. Safety data sheets highlight this reactivity, so ignoring it sets up both safety and scientific projects for failure.

The Risks Are Real

While OTAB may not look dangerous at first glance, exposure can irritate eyes and skin, sometimes causing more severe reactions with repeated contact or inhalation. I remember one incident in a shared storage room: someone spilled a little, didn’t clean it up properly, and by next week, half the labels in the area had curled up from reactions with the vapor. No one wants to chase extra safety audits because of avoidable mistakes.

Conditions That Count

A couple rules consistently prove their worth here. Keep OTAB in airtight containers—glass with tight lids usually works well. If moisture seeps in, the product clumps, sometimes permanently. Meaning, you throw out expensive chemicals for no reason other than being careless. Give each container its own clear label and store it away from acids or oxidizers, as these can start unwanted chemical reactions if a leak occurs.

Space matters, too. OTAB fares best at room temperature, tucked away from direct light and heat sources. Many chemical storage rooms still have sun-exposed shelves or pipes that run hot water just behind them, sometimes raising shelf temperatures above safe limits. It’s simple—look for cool, dry areas, double check for drafty vents, and keep fire hazards in mind. Storing flammables together with this compound doesn’t make sense.

Solid Management Makes All the Difference

Taking care with storage means every person in the lab or warehouse understands the stakes. Keep a log sheet near OTAB zones so users sign in and out. This isn’t just about bureaucracy—if something goes wrong, traceability matters. I like to see visible rules posted, not buried in binders. This way, new team members catch on fast.

Chemical safety sometimes feels like a chore—until it isn’t, and then it feels urgent. By putting a few deliberate steps in place, accidents shrink, costs go down, and nobody scrambles to replace ruined chemicals. That care, day in and day out, creates a safer space for everyone while keeping projects on track.

The Quirks of a Surfactant with a Long Chain

Octadecyltrimethylammonium bromide—sometimes called Stearyltrimethylammonium bromide or simply STAB—catches the eye in chemistry for a reason. Picture a molecule with a long, waxy tail made up of 18 carbon atoms and a charged ammonium head. That’s a setup you find in many surfactants. In practical terms, STAB brings together oil-loving and water-loving properties, but its heavy hydrocarbon tail puts serious limits on its solubility in water.

What Happens in Water?

Only a little bit dissolves when you dump STAB into cold water. Studies and reference texts put its solubility near 1.0 gram per liter at 25°C. For a substance with a long hydrocarbon chain, that number already sounds pretty reasonable. You see much higher solubilities with shorter-chain quaternary ammonium salts, where the balance tips more toward water compatibility. As carbon chains get longer, the water gets less interested in helping out.

Why Should We Care about This Number?

Solubility shapes how chemists and product developers use STAB. Too much insoluble material causes cloudiness and even clumping, which matters in fields like hair care and textiles. Folks want clear, stable solutions. In the lab, I’ve watched frustrated students try to make a solution for a surfactant experiment, swirling their flasks to stubborn white floaters that take forever to disappear. They usually learn quickly: gentle warming or adding a bit more time helps, but there’s only so much that can dissolve before hitting a ceiling.

The solubility number also guides dosing in antimicrobial testing or when improving surface coatings. For example, in water treatment, adding too much might mean wasted material and inconsistent performance. Getting it just right means understanding more than just the basic chemistry textbook line about “like dissolves like.” The shape of the molecule and its interaction with both water and whatever else is in the mix are at play. Practical experience with these mixtures makes all the difference. The smell, feel, and appearance of the solution can tell you if too much powder was added. Rookies overload and learn to scale back—a little patience goes a long way.

Cracking the Solubility Challenge

Some companies work around this by prepping concentrated stock solutions using alcohols or by slowly warming the mixture. Heating works by loosening up the dense water structure, letting hydrophobic chains squeeze in, sometimes forming micelles in the background. The flip side is that special handling adds cost and complexity, which isn’t always practical for end users who expect simplicity. In my time tinkering with home cleaning products, trying to overdo it with surfactants like this just led to gloppy mixtures that separated overnight—no one wants to return to a product separated into layers.

Potential Workarounds and Takeaways

Mixing Octadecyltrimethylammonium bromide slowly, using warm water, and respecting its solubility limit all matter. Solutions shouldn’t look hazy or leave residue, whether in the lab or in industrial settings. Understanding this balance helps avoid costly mistakes, from failing quality control to producing ineffective products. Most importantly, it keeps people from reinventing the wheel every time they use this versatile but stubborn molecule.