Octyltributylphosphonium Tetrafluoroborate: A Closer Look

Historical Development

Octyltributylphosphonium tetrafluoroborate first entered the scientific scene as researchers around the early 2000s sought out new classes of ionic liquids with low volatility and the ability to dissolve a wide array of materials. Before then, most labs prioritized imidazolium- and pyridinium-based ionic liquids. The introduction of phosphonium-based compounds marked a shift; they withstood higher temperatures and resisted many chemical breakdown pathways. In the last two decades, these traits have made them stand out as modern chemistry’s “problem-solvers” in everything from catalysis to electrochemistry. Manufacturers initially stuck to small-scale batches for research, but scaling up production opened pathways for more industry-focused applications, and new safety and labeling rules took shape as usage broadened.

Product Overview

Octyltributylphosphonium tetrafluoroborate belongs to a special group of ionic liquids defined by their phosphonium cation and tetrafluoroborate anion. This unique combination produces a material that flows as a liquid at room temperature. The octyl and tributyl groups contribute flexibility and hydrophobicity, making this ionic liquid particularly robust under a range of reaction conditions. Most bottles of this chemical arrive clear to slightly yellow, packaged in tight-sealed amber glass to defend against moisture. Businesses use it for more than just its straightforward liquid form; the substance can act both as a reaction medium and as a stabilizer for sensitive intermediates, setting it apart from more traditional options.

Physical & Chemical Properties

Octyltributylphosphonium tetrafluoroborate typically presents itself as a viscous liquid that resists evaporation and remains stable up to at least 200°C. Its density usually sits between 0.95 to 1.05 g/cm3 depending on the exact formulation and grade. The substance dissolves organic materials and salts, even those notorious for low solubility elsewhere. Water and humid air pose a bigger challenge; the compound’s hydrophobic structure helps, but exposure to moisture can cause hydrolysis of the tetrafluoroborate ion, creating potential safety hazards. Thermal decomposition generates corrosive and toxic byproducts including hydrogen fluoride, so keeping it below its critical decomposition temperature is more than a matter of good housekeeping—it’s essential. The liquid only faintly smells, mostly from trace phosphines or residual solvent.

Technical Specifications & Labeling

Technical data sheets list purities of 97% and higher, with water content usually less than 0.1%. Many suppliers specify chloride levels below 1 ppm and total heavy metals lower than 10 ppm. Labels carry GHS hazard pictograms, warning of irritation risks or aquatic toxicity if spilled. Key identifiers like CAS number, lot code, and recommended storage temperatures (15–25°C, keep dry) are mandatory. Some labs color-code phosphonium salts for easier tracking, though amber-tinted bottles remain the norm to guard against UV light degradation. Clear handling protocols and first-aid instructions hang next to every storage site—rules drawn from real incidents, not just regulatory codes.

Preparation Method

Octyltributylphosphonium tetrafluoroborate production often starts in small reactor vessels, with tributylphosphine ready for nucleophilic attack on an alkyl halide (like octyl bromide). The resulting phosphonium salt is then exchanged with sodium tetrafluoroborate in an aqueous or organic solvent system, forming the desired ionic liquid after filtration and vacuum drying. Water must get stripped away meticulously to avoid hydrolysis that can ruin whole batches. After thorough drying, final purification steps remove coloring agents and unreacted starting material traces. Manufacturers often let each lot rest before analysis, since the substance can “breathe”—absorbing trace air moisture or microscopic contaminants from the production line.

Chemical Reactions & Modifications

The phosphonium center resists most bases and acids that would degrade other ionic liquids; that gives it an edge in difficult environments. It can serve as a solvent for catalytic transformations, particularly processes that run at high temperatures. The tetrafluoroborate anion sometimes swaps out with other anions in metathesis reactions to tune the properties for specific tasks—an approach that’s fueled decades of patents. Some work has explored attaching functional groups to the octyl or butyl arms, creating task-specific ionic liquids for niche chemical separations, but these modifications rarely see commercial-scale volumes due to cost.

Synonyms & Product Names

Chemists sometimes refer to this material as [P4448][BF4] or simply as octyltributylphosphonium borofluoride. Suppliers use their own product names, adding catalog numbers or suffixes for special purities, but customers care more about the lot’s consistency than about branding. Common references in journals stick to the shorter [P4448][BF4] shorthand to keep reactions concise.

Safety & Operational Standards

Facilities set up standard operating procedures based on first-hand handling experience and published toxicological data. Eye contact demands immediate irrigation, and staff keep hydrofluoric acid antidotes on hand due to decomposition risks. Typical PPE includes nitrile gloves, polycarbonate eye protection, and splash-resistant lab coats. Fume hoods remain the favored workspace, especially for transfers and high-temperature operations—clean-ups happen before residue dries to a sticky mess on benchtops. Users rely on spill kits designed to treat both organic and inorganic hazards, since this compound bridges both chemical domains.

Application Area

Octyltributylphosphonium tetrafluoroborate proved itself as more than just a “designer solvent” for green chemistry. Electrochemists choose it for its wide electrochemical window and resistance to breakdown, making it a strong candidate for new types of batteries and electroplating processes. Catalysis benefits from its ability to stabilize reactive intermediates, while extraction specialists turn to this fluid for separating rare metals or pollutants from complex mixtures. Pharmaceutical researchers keep it in the toolbox for phase-transfer catalysis and the separation of chirally pure drugs. Even in academic research, its use has inspired dozens of new applications, pushing projects beyond the scope of standard solvents.

Research & Development

Scientists have shifted from basic physical property mapping toward exploring how this ionic liquid can fine-tune selectivity in complex chemical systems. Some of the most promising discoveries lie in coupling the phosphonium liquid with renewable raw materials, aiming for more sustainable manufacturing. Academic groups now test its performance in next-gen batteries, hoping to extend device life while reducing fire risk compared to flammable organics. Collaborative efforts between industry and public labs focus on recycling and recovery, as expense and environmental impact drive the search for circular life cycles. Real-world feedback from plant technicians still shapes development—telling researchers what fails on the floor matters as much as what works on paper.

Toxicity Research

Toxicology teams have flagged both acute and chronic risks, mostly tied to the tetrafluoroborate ion and the potential release of phosphines or fluoride on degradation. Skin absorption stays low, but ingestion or inhalation can lead to serious side effects, including organ damage from fluoride ions. Ecotoxicity studies report harm to aquatic organisms, giving regulatory agencies reason to monitor wastewater streams where this compound is present. Long-term exposure effects on humans sit under ongoing investigation as more industries adopt ionic liquids in bulk. Waste processors have begun treating effluents as hazardous material, relying on chemical breakdown and adsorptive removal before discharge.

Future Prospects

Future directions steer toward both broader usage and tighter safety controls. Researchers look for ways to enhance biodegradability without losing thermal stability—a tough challenge that pushes against today’s understanding of ionic liquid design. More sectors want reliable, non-flammable solvents, whether in battery tech, specialized separations, or greener synthesis pathways. Regulatory authorities draft newer frameworks to anticipate the next wave of ionic liquid adoption, demanding cradle-to-grave safety assessments. If engineers succeed in scaling up low-toxicity production and improving recyclability, octyltributylphosphonium tetrafluoroborate could anchor a new era of industrial chemistry—driven as much by practical lessons from the shop floor as by the latest breakthroughs in the lab.

Where It Shows Up in Daily Life

Octyltributylphosphonium tetrafluoroborate isn't the sort of chemical most folks recognize from their household cleaning cupboard or the back of a shampoo bottle. The name alone throws off even experienced chemists. Yet, this compound has become a go-to player in a few specialized fields, particularly where innovation meets practicality.

The Hidden Power in Green Chemistry

In my time visiting university labs, I've watched the slow march toward greener chemistry take root. Students spend late nights searching for solvents that don’t force everyone to wear face shields or install expensive venting. That’s where chemicals like octyltributylphosphonium tetrafluoroborate come into play. This substance, part of a class called ionic liquids, gets attention for replacing more dangerous solvents in synthesis and extraction work. It brings low vapor pressure and thermal stability, which means fewer toxic fumes escape into the air and the risk of fire drops way down. I’ve seen researchers breathe easier—both literally and figuratively—knowing their lab routines put less stress on their lungs and the environment.

Role in Electrochemistry and Energy Storage

Batteries and supercapacitors seem like they sit a world away from the questions most people face in their daily grind, but as remote work, electric vehicles, and renewable energy spread, everyone cares about safer, longer-lasting power. This chemical pops up in high-tech batteries as an electrolyte. Not only does it help improve charge capacity and lifespan, it allows these storage devices to handle higher temperatures and rougher conditions. I once witnessed a battery demonstration using ionic liquid electrolytes at a trade show—no nasty chemical odor, even after a meltdown test on stage. It left no doubt that these new materials deserve real-world attention.

Catalysis and Chemical Processing

Octyltributylphosphonium tetrafluoroborate carves out a role as a catalyst as well. In the plastics and pharmaceuticals industry, traditional acids or organic solvents complicate things: they pollute and cost time and money to handle safely. This chemical acts as a phase transfer catalyst, shifting substances between water and oil phases without the need for harsh reactants. It opens the door for more precise reactions, better product yield, and fewer headaches from environmental regulators. After speaking with a friend who manages a specialty chemical plant, I learned how switching to ionic liquids knocked out several steps in their waste treatment process.

Challenges and Responsible Use

No new chemical arrives without issues. Toxicity data around ionic liquids, including octyltributylphosphonium tetrafluoroborate, still needs expanding. Researchers keep an eye on how these substances break down in water and soil, watching for possible long-term effects. They're not magic bullets for every problem, and safety rules must keep pace with industrial growth. I believe regulations should evolve with science, updating workplace exposure limits and mandating better labeling on containers. It’s not enough to cheer for new technology—people and the planet both deserve respect as innovation advances.

Understanding the Real Risks

Octyltributylphosphonium tetrafluoroborate sounds technical, but real-world handling puts the focus on safety practices, not just chemical names. Working around specialty chemicals means more than tossing on gloves. This compound has properties that can mess with skin or eyes, and careless mistakes often spark bigger issues in labs or workplaces.

Direct Exposure: What Actual Lab Life Teaches

My experience in university chemistry labs taught me one clear lesson: prevention beats reaction every time. Getting careless or assuming "nothing will happen this time" usually lands someone in a bad spot. Many chemicals, this phosphonium salt included, bring irritation risks through skin or eye contact. Chemical burns don’t show up instantly, which fools newcomers. A stray splash leads to redness, stinging, or even longer-lasting problems if left alone.

Vapor is another quieter enemy. Strong ventilation in any workspace isn't negotiable; a cheap extractor fan often pays for itself in accidents avoided. Breathing in fine solvent vapors or decomposition products leads to sore throats and headaches faster than most realize. The best techs I know always check the Material Safety Data Sheet (MSDS) for every substance, even if they’ve worked with similar chemicals before.

Preventing Spills and Accidents

Every spill creates a mess multiplied by panic if workers aren’t trained. Ready access to absorbent materials and a clear plan for disposing of contaminated cleanup lowers the stakes dramatically. My old supervisor insisted we each practice spill drills, and the habit stuck with me: gloves on, goggles fitted tight, and never work alone during unfamiliar procedures. Keeping emergency showers and eyewash stations within 10 seconds' reach makes the difference when seconds count.

Storage: Little Choices Add Up

Proper storage prevents most workplace headaches, and small lapses turn minor hazards into disasters. This chemical doesn’t get along with water or strong oxidizers. I remember someone ignoring that rule—hello, ruined sample, wasted hours, and major frustration. Keeping containers tightly sealed, labeling everything clearly, and storing away from high heat saves a lot of grief.

Personal habit matters here. I’ve seen too many containers left uncapped. Even routine sloppiness like that allows dust, moisture, or other chemicals to spoil expensive stock and cause unplanned reactions. People forget, but chemicals don’t give out friendly reminders.

PPE Isn’t Optional

Some colleagues reached for basic latex gloves thinking it covers everything. Wrong move. This kind of compound calls for nitrile or neoprene gloves, splash-proof goggles, and lab coats that fully cover skin. Those who skip full PPE tend to regret it sooner or later, most often during clean-up or quick transfers. Everyone shares stories about the veteran who skipped gloves “just this once” and spent days bandaged up.

Solutions: Training, Culture, and Design

Safety sticks when everyone owns the process. Up-to-date training, easy-to-read signs, and hands-on demos reduce accidents across all levels. Involving everyone in a lab safety talk builds a front-line defense stronger than any written policy. Reporting near-misses openly, instead of hiding them, helps teams fix problems before they blow up. Effective leaders model good habits and recognize those who do things right, not just those who chime in on paperwork.

Safe handling of octyltributylphosphonium tetrafluoroborate relies on personal responsibility, strong teamwork, and learning from every mistake—yours or someone else’s. That’s how real-world safety culture grows, one careful step at a time.

What Stands Behind the Name?

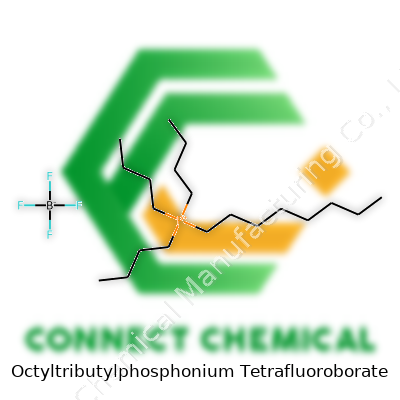

Chemists run into some pretty jaw-dropping names for salts, and Octyltributylphosphonium Tetrafluoroborate definitely grabs attention. Behind the tongue-twister, you’ll find a unique ionic compound made by pairing an organic phosphonium cation and a stable fluorinated anion.

The octyltributylphosphonium ion forms the backbone. Chemically, the cation’s core is a phosphorus atom bonded to a long octyl chain and three butyl groups. Each butyl moiety forms a straightforward four-carbon chain, while the octyl group runs a full eight carbons long. This gives the cation the formula [P(C4H9)3(C8H17)]+. Imagine a tetrahedral phosphorus atom in the middle, wrangling those bulky carbon tails.

On the other side, the counterion comes in as tetrafluoroborate (BF4−). Made up of a single boron atom surrounded by four fluorines, this anion is both robust and highly symmetrical.

String all these parts together and the official chemical formula for octyltributylphosphonium tetrafluoroborate lands as C20H44BF4P. The CAS Registry Number, which serves as an international reference, is 244108-85-0. The CAS number isn’t just a bureaucratic detail. Scientists rely on it to cut through confusion when ordering, researching, or patenting chemicals.

Why This Compound Matters in the Lab

Personal experience in electrochemistry brings to light how many ionic liquids have unlocked new ways of dissolving solutes and approaching green chemistry. Octyltributylphosphonium tetrafluoroborate fits squarely in this family. This salt shows strong resilience to air and moisture, a rare trait in many ionic conductors. That resilience lets researchers experiment without dealing with the usual headaches from humidity.

The real advantage comes through its low melting point and high thermal stability. Unlike traditional salts, these features allow it to exist as a liquid at room temperature or close to it. I’ve seen it substitute volatile organic solvents in battery research, reducing the risks associated with fires and chemical exposure. That kind of safety improvement matters for anyone in a teaching lab or scaling up to industry.

Stumbling Blocks and Potential Solutions

Widespread adoption isn’t smooth sailing. Sourcing high-purity octyltributylphosphonium tetrafluoroborate is a pain point. Prices climb fast because multi-step synthesis demands stringent moisture control and high-quality starting materials. Chemists often find themselves chasing down contaminants, which threatens the reliability of results. When impurities sneak in, performance drops and experiment reproducibility takes a hit.

Some labs have started developing greener, higher-yield routes that cut back on the need for exotic reagents. One promising approach swaps expensive organic solvents with greener, bio-based alternatives during synthesis. Besides shrinking the environmental footprint, this can also reduce operational budgets over time. In early pilot trials, switching to continuous flow reactors helped control reaction conditions more tightly, which made it easier to limit by-products and boost consistency in batch quality.

Paving the Way Forward

Adopting these innovations could lower market barriers and put high-grade ionic liquids like octyltributylphosphonium tetrafluoroborate in more hands. As research teams and manufacturers share best practices, reproducibility could improve, and novel applications in energy storage, catalysis, and green chemistry will follow. A more collaborative approach to troubleshooting synthesis challenges seems to hold more promise than relying on a handful of suppliers and academic labs pulling in different directions.

Why Storage Guidelines Matter

Octyltributylphosphonium tetrafluoroborate, a mouthful to say but a workhorse in ionic liquid labs, isn’t just another compound on a shelf. Store it the wrong way and small mistakes can spiral, turning an otherwise stable material into a headache or, worse, a hazard. Over the years, I’ve seen a wide range of storage habits, from the meticulous to the lackadaisical, and the results stick with you — especially when a leaky cap ruins a week’s work. Handling storage properly keeps your experiments on track and your lab colleagues safe.

The Core Risks: Moisture, Light, and Heat

Octyltributylphosphonium tetrafluoroborate holds up well against air for short periods, but long-term exposure to water in the atmosphere or even just sitting open during humid weather will eventually break it down. I remember pulling a sticky, half-caked bottle from a forgotten bench — the chemical had drawn in enough moisture to start decomposing. The product’s performance drops sharply after that, and disposal costs add up.

Sunlight and high temperatures don’t do this salt any favors. Over time, bright light or heat can trigger reactions you won’t notice until you’re troubleshooting failed syntheses. Direct sunlight coming through a window turned a clear sample cloudy in less than a week for one of my students, and the puzzle took hours to solve. That day convinced me to shift expensive compounds out of open windowsills for good.

Best Practices: Keeping the Compound Responsive and Safe

I always recommend finding a cool, dry spot for storage. Think about a temperature-controlled cabinet or, at the very least, a shaded section of the lab far from radiators or lab ovens. At my last workplace, the team repurposed an old medical fridge for ionic liquids, and many tricky issues disappeared overnight. This chemical doesn’t require freezing, but it holds up best at stable room temperature — so no more intermittent swings as HVAC cycles up and down.

Moisture-blocking caps and thick-walled bottles stop most outside air from creeping in. Silica gel packets tucked alongside bottles do wonders, especially if the compound needs to stay in storage for months. Some colleagues go further by purging the air above the chemical with nitrogen, which cuts out almost all water and oxygen.

Labeling, Housekeeping, and Safety

There’s nothing more frustrating than an unmarked or half-finished bottle. Every few weeks, I make a round through storage checking labels, marking purchase dates, and reminding folks to finish older batches first. This isn’t just busywork — it keeps contaminants and unknowns out of new experiments. Accidents tend to pile up where open containers mingle with waste bottles and mystery liquids.

Any spill, even a small one, needs a quick wipe-up and disposal in a chemical waste container with the right label. Heavy-duty gloves and goggles work best during transfer and cleanup. I’ve watched new lab members ignore this step, only to spend the morning stinging from splash-back. Respecting those small rules around this chemical pays off in time and reduced medical visits.

Staying Ready for Audits and Scaling Up

Regulatory inspections get easier with good storage habits. Clear documentation, tight sealing, and dry, stable shelving keep everyone on the right side of safety reviews. Lines between personal diligence and regulatory compliance blur fast; strong habits support both.

Octyltributylphosphonium tetrafluoroborate isn’t rare, but it isn’t cheap either. A bit of planning goes a long way. Locking down these storage details isn’t just about following instructions — it protects investments and keeps your science moving forward.

The Practical Side of Chemical Sourcing

Chemists in labs, engineers on the shop floor, and purchasing teams all have different priorities. These differences sharpen the focus on details that often go unnoticed, like the purity grade or packaging type. Working in several labs, I have witnessed the headaches that stem from a chemical arriving in the wrong grade or an awkward container, especially with specialty compounds such as octyltributylphosphonium tetrafluoroborate.

Pursuing the Right Purity

In research and process work, purity is not just a technicality; contaminated or inconsistent batches push projects off track. For this ionic liquid, suppliers typically offer a range of purities. Most researchers gravitate toward high-purity material—99% and up—because trace contaminants sabotage experiments where sensitive reactions matter. On the industrial side, some processes accept lower grades if cost savings outweigh the risks. Sulfur, water content, and trace metals are constant concerns. In one synthesis project, colleagues lost weeks chasing the cause of erratic yields, only to track it down to a lower-purity batch filled with unpredictable side products. Transparent certificates of analysis, independent quality audits, and direct conversations with vendors have always helped weed out the risky suppliers from the reliable ones.

Packaging Matters—More Than Most Think

Packaging decisions impact safety, convenience, and cost. Large-scale operations might need the compound in drums or kegs—sometimes warehouses want to avoid the clutter of opening multiple small containers. On the other end, university labs stick with small glass or plastic bottles, often 10 or 25 grams at a time, to cut waste and minimize exposure. Some suppliers only offer fixed sizes, but the more established ones let customers specify custom fills. Smart packaging also prevents degradation; a poorly sealed bottle picks up moisture from the air, ruining months of planning. Over the years, I have seen dozens of labs forced to discard thousands’ worth of chemicals because the supplied container lacked proper seals or labeling.

Why the Options Exist

Having options matters because not every user faces the same risk or scale. In regulated industries—think pharma or semiconductors—customers expect full documentation, barcodes, and tamper-proof seals. Strong E-E-A-T (experience, expertise, authority, and trustworthiness) from suppliers adds peace of mind, which is worth much more than a one-size-fits-all approach. Smaller outfits, teaching labs, and startups pay close attention to minimum order sizes. Stretching tight budgets, they avoid buying excess material that will expire on a shelf, especially with substances that demand careful handling.

Supporting Better Practices

Suppliers who actually care about end users—those who send along stability data and suggest compatible storage—stand out. It is worth recognizing that simply offering different purities and packaging does not guarantee quality, but refusing to listen to a lab’s needs usually signals problems elsewhere. Dialogue between user and supplier builds real trust. On the customer side, tracking shelf life and organizing a central chemical inventory avoids costly mistakes. Many research groups now swap notes on preferred vendors and share blacklists of companies with opaque sourcing.

Paths Forward

A more responsive supply chain, where buyers can specify exactly what purity and form they need, does not just lower frustration. It cuts down waste, saves money, and lets everyone—from students to seasoned chemists—focus on real science instead of logistics. Good relationships with trusted suppliers, diligence in reviewing documentation, and a steady flow of honest feedback go a long way toward building a stronger, safer research environment.