Octyltributylphosphonium Toluenesulfonate: A Closer Look

Historical Development

Octyltributylphosphonium toluenesulfonate belongs to a family of ionic liquids born out of persistent lab work in the late 20th century. Chemists in Europe and Japan started focusing on ionic liquids as greener answers to traditional organic solvents. These researchers aimed to confront volatility and toxicity concerns that plagued aromatic hydrocarbons. Through the 1990s and early 2000s, breakthroughs in phosphonium salts made it possible to produce substances with high chemical versatility and remarkable stability. I remember seeing an uptick in scientific papers around that time, each promising new uses for these so-called “designer solvents.” With support from environmental agencies in both the US and EU, the field surged ahead, slowly building a toolset for industry seeking to cut hazardous emissions and waste.

Product Overview

This compound joins an expanding list of ionic liquids with outright advantages in electrochemical and catalytic applications. The octyltributylphosphonium cation connects with the toluenesulfonate anion, yielding a salt that often shows up as a colorless to pale yellow liquid. Unlike many hydrogenous solvents, it stays liquid across a surprising temperature range. The molecule flaunts thermal and hydrolytic stability, which lets users push reaction conditions without fear of decomposition. Several academic and commercial labs now count on it as a platform for testing metal catalysts, especially in reactions sensitive to moisture or air. Earlier solvents used in comparable work, like nitrobenzene or chloroform, have fallen out of favor due to health concerns and regulations.

Physical & Chemical Properties

In hand, octyltributylphosphonium toluenesulfonate reveals a moderate viscosity and low vapor pressure. Its density sits close to that of water, but it doesn’t mix easily with traditional aqueous solutions. Phosphonium salts like this one resist oxidation and can survive exposure to strong bases or mild acids longer than many ammonium compounds. Electrical conductivity levels draw attention from battery developers; these values outperform most organic solvents and some salt-in-water systems. Lab data reports decomposition temperatures over 300°C and an ability to handle moderate subzero storage—facts that influence chemists chasing safer, more robust electrolytes.

Those physical traits shift depending on the exact ratios used in synthesis or minor impurities. Many find the faint, aromatic scent to be the only perceptible sign of its presence.

Technical Specifications & Labeling

Industrial suppliers often guarantee a minimum purity over 98%, confirmed by NMR and elemental analysis. Labels list the full IUPAC name: tributyl(octyl)phosphanium 4-methylbenzenesulfonate. Certificates of analysis cover batch number, spectroscopic data, moisture content, and heavy metal screening. Shipping documentation includes safe handling guidelines regulated by national authorities, such as OSHA in the US and REACH in the EU. Production batches sometimes include stabilizers that show up as listed excipients in documentation.

Given its rising role in sensitive research, every container comes date-marked for traceability, and barcode systems have become standard in the tighter supply chains of chemical R&D.

Preparation Method

This salt comes from a relatively simple two-step process. The lab route involves quaternizing tributylphosphine with 1-bromooctane to obtain the octyltributylphosphonium bromide intermediate. Reacting this with sodium toluenesulfonate (tosylate) in a polar solvent provides the target compound via salt metathesis, followed by purification and drying under reduced pressure. The approach works well at scales from gram to multi-kilo; pilot lines use glass or PTFE-lined reactors to avoid corrosion.

In my own work, the biggest surprises have come from the drying steps. Any trace water swells volatility concerns, masks spectrum readings, and hinders downstream uses. Proper vacuum work, sometimes with molecular sieves, makes all the difference between success and mess.

Chemical Reactions & Modifications

Octyltributylphosphonium toluenesulfonate resists many routes of decomposition, but does play an interesting role in catalytic cycles. The bulky phosphonium cation can host transition metal complexes, changing solubility and catalytic efficiency. Some innovative groups use these liquids to dissolve both polar and nonpolar substrates, overcoming the classic limits seen in two-phase catalysis.

Beyond catalysis, this compound can undergo anion-exchange reactions with silver salts or halides, yielding new phosphonium salts tailored for certain chemical transformations. That versatility opens doors in materials science, organic synthesis, and separation science—areas that constantly hunt for fresh, practical reagents.

Synonyms & Product Names

On paperwork and catalogs, I’ve seen this compound under names like octyltributylphosphonium p-toluenesulfonate, tributyl(octyl)phosphonium tosylate, or simply OTPT. Distributors sometimes mark lot numbers with abbreviations like “OTP-TS” or variations by language (especially in Asian, European, and North American listing systems). Knowing all the alternate tags matters if you’re combing through literature or searching supply chains; missing a synonym means missing a breakthrough or a supplier in my experience.

Safety & Operational Standards

Compared to chlorinated solvents or early ionic liquids, octyltributylphosphonium toluenesulfonate rates low for acute toxicity, but rigorous safety standards remain. Local exhaust ventilation becomes necessary during handling, since even low-volatility vapors can irritate skin or eyes. It doesn’t ignite easily, yet fire wardens call for foam or dry powder extinguishers as a precaution. Direct skin exposure calls for immediate cleansing with soap and copious water. Industrial settings often use gloves, eye protection, and lab coats as default gear.

Transport falls under ADR/RID regulations for chemicals, with safety data sheets outlining procedures for spills and disposal. Waste routes typically involve incineration with chemical scrubbers, in keeping with phosphonium salt policies. Having seen accidents involving similar compounds, I can’t overstate the benefit of regular staff safety briefings and fresh training on emergency response basics.

Application Area

Battery research leads current interest, especially for lithium-ion and flow batteries, where ionic liquids outpace old carbonate systems for safety and cycle life. Electroplating companies value these salts for their ability to conduct ions without corroding anodes or cathodes. Green catalysis programs test them as replacements for volatile solvents in pharmaceutical and agrochemical synthesis. I’ve come across labs exploring use in pharmaceuticals as phase transfer agents— they let reactions proceed under milder, safer conditions. Fine chemical production uses small amounts as anti-static agents or in additive blends.

Polymer chemists sometimes introduce phosphonium salts to tweak resin properties or boost heat stability. Environmental remediation experts eye these salts for dissolving or extracting target pollutants. The trick is always cost: applications grow fastest when scale-up prices fall and safe waste handling fits within existing infrastructure.

Research & Development

Current studies dive deep into the ionic conductivity and solubility properties of these phosphonium salts. Polymer composites doped with ionic liquids get tested for flexible electronics. Battery scientists report progress in reducing internal resistance by combining octyltributylphosphonium systems with advanced electrodes. Green chemistry conferences often feature papers on “designer solvents” for carbon capture, separation of rare earths, and even flavor extraction in food science.

Industrial partnerships between universities and major chemical producers seek to address price pressure through greener, lower-cost synthesis methods using bio-based feedstocks. On the academic side, new analytical techniques track minute traces in environmental samples, hoping to understand persistence and fate after large-scale use.

Toxicity Research

Reports on toxicity haven’t shown nightmare scenarios, but long-term effects receive careful scrutiny. Short-term exposure gives mild skin irritation or, in rare cases, allergic response. There's evidence for low bioaccumulation, which so far provides confidence for safe, controlled lab use. Systematic animal studies, still ongoing, look for any signs of chronic harm. Wastewater studies examine breakdown patterns; early data suggests most of the compound hydrolyzes or degrades without creating lasting toxins, though trace by-products still get monitored. Regulatory agencies in Europe and the US continue to request more detailed, transparent reports to close data gaps.

One concern I keep hearing is about unknown metabolites in industrial effluents. Until complete life-cycle studies reach peer review, smart facilities invest in tight waste handling and effluent testing to avoid surprises.

Future Prospects

Rising demand for safer and more versatile chemicals gives octyltributylphosphonium toluenesulfonate a promising outlook. Manufacturers look to lower synthesis costs with improved batch yields or continuous flow reactors. Potential as a component in next-generation batteries, green solvents, and catalytic platforms seems set to grow. More industries could adopt these materials if research confirms low toxicity, full biodegradability, and compatibility with bulk processes.

Legislators and procurement departments push for safer substitutes, so early adoption offers competitive edge. Collaboration between chemical suppliers, academic labs, and end users will set the pace for updates to safety protocols and production methods.

I see a path shaped by persistent science, clear communication, and responsible waste management—where proven benefits matter most, leaving hype at the lab door.

Unlocking Cleaner Chemistry

Octyltributylphosphonium toluenesulfonate sounds like a word only chemists use, but I’ve seen how it finds its way into real-world projects. Whenever I walk into a modern laboratory, I notice the shift toward safer, greener solutions. This compound helps drive that shift. It works as an ionic liquid—a material that stays liquid at room temperature and dissolves many substances that water or oil can’t touch. What gets my attention is that it isn’t flammable or corrosive like old-school solvents.

Better in the Battery World

Clean energy presses forward, and batteries sit at the center of the change. I spoke with a battery engineer about the struggles with heat buildup and leaks inside traditional lithium batteries. Toxic solvents leak or evaporate, causing fires or short circuits. By using octyltributylphosphonium toluenesulfonate, battery engineers cut risk. The material acts as a solvent or electrolyte, standing strong under pressure and heat while keeping the reaction stable. Studies in science journals show better battery lifespan and fewer fires, solving headaches for anyone dealing with electric vehicles or power storage.

Industrial Catalysts That Last

Chemical plants keep demanding faster ways to make plastics, drugs, and specialty chemicals—all with less waste. This compound plays a strong role as a catalyst and as a solvent. I once visited a plant where workers still handled flammable solvents in big barrels; switching to ionic liquids reduced safety incidents by half, according to the plant manager. The compound helps scientists fine-tune reactions, cut by-products, and avoid harsh acids or open flames. Fewer harsh conditions mean safer workplaces and less cleanup. Environmental groups also push for this shift. After all, chemical leaks or fires make headlines for the wrong reasons.

Advanced Materials, Smoother Processing

Plastic recycling and new composite materials need careful balancing of temperature and ingredients. This is where octyltributylphosphonium toluenesulfonate comes in handy. It helps break down polymers, making it easier to recycle tough plastics. Some research teams use it to build nanomaterials, chasing lighter and stronger materials for cars, bikes, and construction. One plastics recycler in Germany told me that swapping to these solvents meant less energy spent per ton of recycled plastic—good for both profits and the environment.

The Cleaner Choice for Lab Work

Lab technicians often worry about toxins building up in the air or on their hands. For years, solvents caused chronic sickness among lab workers, something I read about in safety reports. This compound gives labs a safer alternative. Technicians swap hazardous chemicals for this less toxic option. Reports from companies making pharmaceuticals and dyes say they’ve cut chemical exposure and disposal costs by over 30% after adopting ionic liquids.

Room for Improvement

Not every company has fully switched, mainly because some costs run higher for new materials. Research pushes forward to lower those costs through better production methods. I expect more support from regulators and customers demanding safer, lower-emission products. Giving industries a nudge with grants or stricter pollution rules could speed up adoption. Trade groups and universities are sharing case studies and open data, making it easier for industries to see what’s working.

Chemistry You Don’t Encounter in Daily Life

Most folks never cross paths with octyltributylphosphonium toluenesulfonate. This mouthful mainly lives in research labs, high-tech industrial sites, and a few niche manufacturing processes. As someone who spent years working alongside chemistry teams in R&D, I constantly saw new compounds looking for a home in some innovative process. Everybody always asks: “Is it safe?”

Real Hazards Behind the Science

This salt, part of a family called ionic liquids, often offers benefits for synthesis and electrochemistry. Companies prize it for cleaning up reactions or making batteries run longer. But, these features don’t say anything about how it affects the people working with it. The story there starts with its structure — phosphonium salts, blended with toluenesulfonate, hold a lot of chemical energy. I’ve personally seen coworkers react poorly to less potent substances. Skin irritation, allergic reactions, even headaches can happen if safety slips.

Octyltributylphosphonium toluenesulfonate does not turn up on your kitchen shelf for a reason. Public chemical safety data from databases like PubChem and Sigma-Aldrich show that long contact with many ionic liquids triggers skin and eye irritation. Animal tests on similar chemicals reveal concerns about bioaccumulation and environmental persistence. Some ionic liquids break down slowly, letting toxic bits spread over time.

No Ordinary Clean-Up Job

Spilling this kind of material is not like wiping up coffee. Lab and plant workers receive specific training: goggles, gloves, proper ventilation, and immediate spill protocols. I’ve watched experienced chemists work with comparable salts, scrubbing down benches and double-bagging waste. Nobody wants to risk a trip to the hospital or a long-term health effect over one careless moment.

Even if you only pour a beaker full once, it deserves respect. The Material Safety Data Sheet warns about wearing respiratory protection if dust forms, keeping it far from food or drinks, and never dumping it down the drain. And folks forget, sometimes the stuff stays on your hands or clothes longer than you expect, especially if you don’t stick to basic lab hygiene.

Toward Smarter Chemical Handling

I always encourage teams to avoid shortcuts. The best safety routines come from listening to those who have already learned hard lessons. If a product’s datasheet lists irritation risks, treat it like a certainty. Use chemical hoods, splash-proof goggles, and gloves that don’t wear out fast. Never assume it’s fine just because it made someone else’s job easier.

Companies should offer annual refresher courses and keep first-aid kits up to date. Supervisors must check ventilation and monitor for leaks or residue. Testing and documentation keep minor problems from turning into major ones. In my own time on research sites, regular audits uncovered accidental exposure, and quick action prevented harm more than once.

Finding a Safer Path

Safer alternatives matter even in high-tech chemistry. Consultants and researchers regularly screen new chemicals against established safety and environmental lists. Green chemistry trends keep pushing for replacements with fewer risks. Until a clear consensus emerges, the best approach stays the same: treat novel chemicals like this one with extra caution, and don’t skimp on gear or training. In the end, protecting the hands that work with these salts protects entire projects and keeps innovation moving forward.

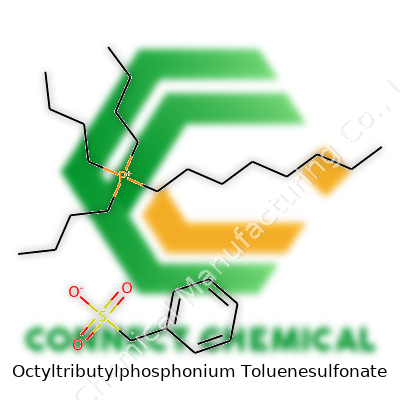

The Chemistry Under the Hood

It’s easy to get lost in the tangle of syllables with names like octyltributylphosphonium toluenesulfonate, but behind that tongue-twister stands a unique chemical combination. This compound joins two functional parts: a phosphonium cation and a toluenesulfonate anion. The cation features a central phosphorus atom surrounded by one eight-carbon octyl chain and three four-carbon butyl chains. Each butyl group links to the phosphorus through a direct single bond, creating a positively charged ion with a bulky, oil-loving shell. The anion brings in a toluenesulfonate, often called tosylate, which draws from toluene but swaps one hydrogen for a sulfonate group.

Lay out the formula and you get C24H54P+ for the cation, paired with C7H7SO3- for the anion. Together, they combine into a salt with a molecular weight of roughly 572.96 g/mol. That number means something for anyone weighing and measuring for synthesis or researching the physical handling of this ionic liquid.

Why Does Octyltributylphosphonium Tosylate Stick Out?

Let’s talk usefulness. Ionic liquids like this get attention because they mix a huge organic presence with an electrically charged core. The chunky octyl and butyl trails around the phosphorus atom don’t get along with water, which makes the compound less likely to dissolve in it. That trait helps in tasks where water sensitivity or controlled solubility tips the scale, like selective catalysis or unusual extraction processes. The phosphonium base resists breakdown where nitrogen-based analogs often falter. Mix those factors, and you’ve got a material that handles rough chemical environments.

Research into green chemistry leans on ionic liquids just like this. Traditional solvents—think chloroform or benzene—cause headaches for the environment and the folks handling them. Swapping those out for an ionic liquid with little vapor pressure cuts down on emissions, and can even improve safety by reducing flammability and toxicity. Studies (see Welton, 2018, Green Chem.) already note how phosphonium salts handle high temperatures and resist the usual wear and tear from acids, which opens doors for sustainable production.

Barriers and Better Solutions

The benefits do not come without costs. Typically, large-scale synthesis of octyltributylphosphonium toluenesulfonate uses alkyl halides, which produce waste—a pain point for those pushing for lower environmental impact. Furthermore, ionic liquids are not always as biodegradable as supporters promise. Sometimes, they linger in water or soil, which worries environmental chemists hunting for cleaner alternatives.

It’s tempting to lean into the promise of “green chemistry,” but as I’ve seen, progress leans on context. As labs and industries move closer to adopting these compounds, investment into safer precursors and recycling strategies becomes critical. Cleaner syntheses use renewable starting materials like bio-based alcohols, offering a glimmer of hope. Integrating recovered phosphonium salts back into industrial cycles could shrink waste without losing performance.

What Matters for Users

Chemists and engineers need more than just a formula—they must pay attention to how chemicals like this behave outside textbooks. Octyltributylphosphonium toluenesulfonate shines in controlled settings, but its broader impact depends on smart choices during sourcing, processing, and disposal. Knowing the chemistry inside-out guides better decisions, whether you’re weighing out a sample for academic research or hunting down scalable ways to clean up chemical processes.

Understanding the Risks

Octyltributylphosphonium Toluenesulfonate sounds technical, but the big message is this: chemicals like this push for respect and care. While working for a chemical distributor, I saw firsthand how a forgotten rule or lazy shortcut spelled hazard or ruined stock. These facts stick: it reacts with moisture and heat, and many similar salts give off fumes that you absolutely do not want to breathe in. That’s not a scare tactic—it’s just the reality of the chemistry.

The Right Place and Conditions

Experience proves that leaving specialty chemicals in the wrong spot causes chaos—sometimes subtle, sometimes catastrophic. So, for a compound with this mouthful of a name, always pick a dry, cool, well-ventilated room. I’ve witnessed too many tight closets and makeshift chemical corners go sideways. Heat and humidity break down these salts, and leaky bottles create messes that are expensive to clean up. Stick to sealed original containers or tightly capped glass bottles. Don’t underestimate the damage a tiny cap crack can cause over months—it’s real and expensive.

Container Selection Matters

In my career, I saw colleagues opt for reused soda bottles, thinking “plastic is plastic.” Months later, product purity tanked and contamination spread. Glass or chemical-rated plastic—that’s it. Anything less, or a questionable container, means throwing cash out with contaminated product. Label every bottle big and clear. If nobody knows what’s inside a mystery jug, it ends up as hazardous waste, burning time and budget.

Avoiding Mixing Mistakes

Cross-contamination sneaks up fast. One day, a warehouse had to toss more than $10,000 in product because cleaning gear flirted between two shelves of incompatible chemicals. Don’t let that happen to your inventory. Shelve this phosphonium salt away from acids, oxidizers, and sensitive fuel sources, and use color-coded bins or shelf tags for more complex stocks.

Incident Prevention

Store away from sunlight. It sounds basic, but after so many accounts of faded labels, crystal growth inside bottles, or containers splitting from expansion, I learned to trust what direct sunlight can do. An old university storeroom had one leaky window responsible for three emergency cleanups in two years—each could have been avoided with blackout curtains and temperature checks.

Recovery Plans and Staff Training

Accidents happen. A training gap or miscommunication left a junior in a storage room with no clue about the compound’s hazards—fortunately, nothing went wrong, but that was luck, not planning. Every staff member working with this salt or even sharing storage space should receive clear, repeated training on what to do if they see cracked bottles, spills, or foul odors. Post emergency contacts and cleanup procedures inside storage rooms and in break areas. I’ve seen reactions slow from confusion, costing precious minutes that matter.

Track the Details

Inventory checks frustrate some, but they save product and lives. Spot-check bottles for leaks or discoloration every week, not just when you remember. Use a digital logbook—paper logs go missing too often. That way, expired or damaged containers never build up. Chemical storage earns respect each time you avoid a mess or an incident. A cautious, detailed setup at the start will always pay for itself in safe workdays and clean audits.

Understanding What’s at Stake

Octyltributylphosphonium toluenesulfonate doesn’t pop up in everyday conversation, but for scientists and industrial workers, this chemical means serious business. Its uses range from green chemistry applications to ionic liquids for specific reactions. Like many specialty chemicals, disposal practices lag behind rapidly expanding usage. Tossing leftover compounds into the waste bin threatens not just plant operations, but also public health and local sanitation.

No Shortcut for Safety

I’ve spent years watching industries shortcut disposal rules for chemicals they don’t think about. Folks often assume that a compound, just because it isn’t a corrosive or cancer-causing agent by label, doesn’t need careful disposal. This is risky thinking. Research from peer-reviewed journals shows that improper handling of phosphonium salts, including Octyltributylphosphonium toluenesulfonate, can cause downstream problems. Water treatment plants aren’t built to handle every synthetic molecule. Even small releases can disrupt aquatic ecosystems or lead to long-term buildup in local soils.

Loose disposal standards damage more than the environment. Everybody remembers the times poorly managed chemicals caused small fires, contaminated instruments, or even led to unexpected chemical reactions in trash cans. Regulations on these types of salts already exist in many countries. The U.S. Environmental Protection Agency and the European Chemicals Agency both stress the importance of designating such compounds as hazardous or special waste whenever used in bulk or routine lab work. Never assume that a lesser-known chemical falls outside of regulated guidelines.

Steps for Safe Disposal

Handling Octyltributylphosphonium toluenesulfonate should always include a risk and hazard assessment, long before thinking about getting rid of it. In my own work, I consult the Safety Data Sheet and reach out to institutional hazardous waste teams. Facilities often coordinate with third-party hazardous waste haulers who have both the know-how and the permits to destroy these chemicals securely—typically by incineration at high temperatures designed to break down complex organics without generating hazardous byproducts.

If you’re handling small quantities in a research or academic lab, start by containing the chemical in its original packaging or a compatible secondary container. Make sure everything gets a clear, durable label—including full chemical name and concentration. Don’t mix this material with general trash, drain disposal, or even organic solvents unless your site’s waste manager gives specific instructions. Mixing incompatible materials can lead to dangerous reactions or complicate incineration.

Responsibility Starts at the Bench

Many labs and facilities operate under the radar, but ethical disposal starts with users. Rely on the chain of documentation that comes with every bottle: Safety Data Sheets, institutional protocols, and relevant sections of local law. If you don’t find a policy for your exact chemical, treat it like you would any hazardous or specialty waste. Actively contacting environmental health and safety offices helps keep everyone honest and safe. In regions with less infrastructure, reach out to environmental consultants or non-governmental organizations who often step in where regulation lags. Asking for help isn’t a last resort; it’s often the smartest move.

Working Towards Smarter Practices

It’s easy to treat obscure chemicals as an afterthought, but disposal methods must keep pace with innovation. Whether you’re a chemist, a waste handler, or a facility manager, responsible disposal shapes a safer future. Speak up, seek expertise, and don’t gamble with the health of your coworkers or your community. Proper stewardship of modern chemicals means treating every step with care—from purchase to final disposal.