Tert-Butyl 6-Bromohexanoate: A Down-to-Earth Look at a Versatile Chemical

Historical Development

Chemists started paying attention to tert-butyl 6-bromohexanoate decades ago, looking for new tools in the ever-evolving world of organic synthesis. Laboratories in the late 20th century pushed to find ways to introduce halogens like bromine into fatty acid derivatives, searching for compounds flexible enough for both research and industrial jobs. Before long, the structure’s blend of a bulky tert-butyl ester and a reactive bromo group gave chemists shape-shifting abilities. They could insert it, break it down, or swap the halide depending on the demands of the experiment. Today, this molecule rides on improvements in halogenation chemistry and esterification methods pioneered over generations, echoing progress made in synthetic methods across Europe, North America, and East Asia as new researchers leaned on the experience and mistakes of the past.

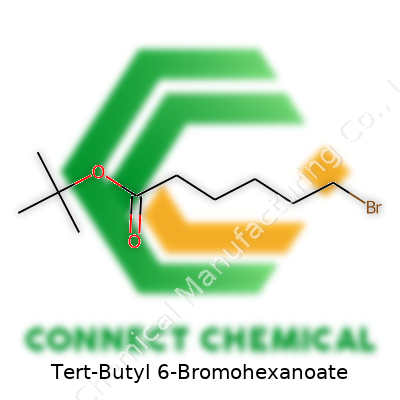

Product Overview

Tert-butyl 6-bromohexanoate offers something unique – stability from its tert-butyl ester, and reactivity from the bromo sitting at the end of a flexible six-carbon chain. The molecule often comes to life as a pale liquid or light solid, hinting at its moderate molecular heft and chemical versatility. Commercial suppliers pitch it as a fine chemical for research, but those who have spent time with this compound in the lab know its potential across several branches of chemistry. You don’t need a fancy degree to appreciate its ability: it can step in as a building block or fork in the road for more complex molecules.

Physical & Chemical Properties

Looking at tert-butyl 6-bromohexanoate’s structure, you find a carbon chain six units long, tethered to a bromine atom at one end and a tert-butyl ester at the other. This setup gives it both hydrophobic properties and a handle for chemical transformations. Expect a boiling point that climbs over 250°C (at atmospheric pressure), with a melting point low enough for it to remain liquid under basic lab conditions. It dissolves in organic solvents such as dichloromethane, chloroform, and slightly less well in ethers. Its moderate polarity means it usually floats above water, but you’ll want to keep it away from moisture, as long periods in humid air can lead to slow hydrolysis.

Technical Specifications & Labeling

High-purity tert-butyl 6-bromohexanoate usually ships with a certificate stating over 98% purity, often checked by NMR, GC-MS, and HPLC. Storage advice discourages sunlight, with sealed amber bottles found in fridges in well-run chemistry departments. Labels need to show hazard statements about skin and eye irritation, and to give the correct UN number for hazardous shipping, since the bromo group brings potential. Most bottles carry both European and US regulatory labeling, put together for quick reading to cut down confusion.

Preparation Method

A reliable synthesis begins with 6-bromohexanoic acid or its anhydride. A blend of tert-butanol and a mineral acid or acid chloride sets up the formation of the ester, a reaction that takes some patience for completion. More streamlined approaches call for Steglich esterification using DCC and DMAP, common in research labs looking to avoid strong acids. Purification steps often involve quick washes and column chromatography. For those who don’t have the time or budget, solid-phase variants exist, saving steps and solvents in some cases.

Chemical Reactions & Modifications

The beauty of tert-butyl 6-bromohexanoate lies in its readiness for change. The bromo group at the end of the chain acts like a flag – strong enough to swap for an amine, a thiol, or a hydrogen, depending on what tool you use. Nucleophilic substitution dominates, and it doesn’t take fancy equipment to carry out these tweaks. You can also hydrolyze the tert-butyl ester, revealing a carboxylic acid ready for coupling steps or further transformation. Despite its ease of reaction, the backbone remains tough enough for use in multi-step syntheses where stability and reactivity need to work together.

Synonyms & Product Names

Across labs and catalogs, tert-butyl 6-bromohexanoate often shows up under names like 6-bromohexanoic acid tert-butyl ester, tert-butyl 6-bromohexanoate, and tert-butyl 6-bromohexanoate ester. Some suppliers use abbreviations like t-Bu 6-Bromohexanoate. In my experience, keeping track of these variations saves time when searching for stock or ordering for a new project, especially when switching between American and European catalogs.

Safety & Operational Standards

Bromo compounds carry known risks, and even one careless moment without gloves or goggles can lead to trouble. Long experience in shared labs pushes me to keep spill kits and ventilation running. Direct contact brings skin and eye irritation. Vapors can cause headaches or dizziness with poor air flow. The tert-butyl ester doesn’t exactly scream danger, but the reactive bromo end demands respect. Institutions insist on closed shoes, long sleeves, and safety showers within arm’s reach. Waste must go in halogenated organic solvent bins—local environmental health officers don’t let brominated waste slide by. Regular training makes the difference between close calls and injury-free shifts.

Application Area

Over the years, I’ve seen tert-butyl 6-bromohexanoate pulled from storage drawers for jobs in pharmaceuticals, agrochemicals, and polymer science. Medicinal chemists use it to build up carbon chains between functional groups, feeding into big drug molecules. Polymer researchers use the ester and bromo handle to control grafting, crosslinking, or to start polymerization chains. Peptide chemistry benefits from its flexibility as a linker, and I’ve watched it help in labeling or modifying surfactants and specialty lubricants. Its ability to take on new forms without extra fuss pulled it into bioconjugation experiments and surface modification work on silica and glass as well.

Research & Development

Innovation keeps this molecule relevant. Research groups push for greener ways of making tert-butyl 6-bromohexanoate, turning to bio-based starting points or switching to solvent-free reactions. Analytical labs in the pharmaceutical world run tests to see how subtle changes in the synthesis route shift the impurity profile, often chasing higher selectivity and yield. Teams involved in scalable flow chemistry look for ways to run bromoalkanoate reactions with as little waste as possible. In my network, a few materials scientists even tweak the chain length or bromo group position, hoping to unlock new surface or bulk properties. Chemical suppliers respond by launching high-purity versions and pre-mixed reagents for faster uptake in academic and startup settings.

Toxicity Research

Toxicologists never take brominated compounds lightly. Test data shows that ingestion or extended skin contact can trigger acute irritation, and rodent studies point towards organ toxicity with chronic exposure. There’s little excuse for not respecting the safety data sheet, which spells out both acute and delayed risks. While sterically hindered esters like tert-butyl 6-bromohexanoate carry less acute hazard than low-mass bromides, the precautionary principle still guides use, with gloves, goggles, and hoods as a minimum. Environmental toxicity isn’t ignored, either—authorities like ECHA flag halogenated esters for careful handling in waste streams and continuous tracking in groundwater studies.

Future Prospects

The push towards greener and safer chemistry sets the stage for future developments around tert-butyl 6-bromohexanoate. Chemists work to reduce bromine use, but the usefulness of the bromo handle keeps demand steady. Companies invest in cleaner halogenation processes and biodegradable esters that break down gently after use. Advances in flow and microwave chemistry could shrink reaction times, improve yields, and lower costs. On the research front, new medical and material science challenges offer more doors for this six-carbon linker—for me, that keeps it exciting to see just how far a simple bromoester can go. Regulations shape its future as well, nudging users toward more responsible waste management and downstream monitoring. The compound stands as a witness to the give-and-take between creativity and caution in the chemical world.

Digging Into Purity: Why It Matters

Tert-Butyl 6-Bromohexanoate shows up a lot in research labs and chemical manufacturing. Folks working in synthesis or pharmaceutical development keep a close eye on purity, since sloppy batches can throw off whole projects. In my own time in a synthetic lab, running an NMR after each reaction, I learned pretty fast to check the purity of every intermediate, not just the end product. If there’s a hitch in the middle, you pay for it twice over — in wasted time and materials. That’s why purity can’t just be an afterthought, especially with specialty esters like this one.

Understanding Typical Purity Values

From what I’ve seen, and conversations with colleagues, Tert-Butyl 6-Bromohexanoate usually arrives from reputable suppliers with purity claims between 95% and 99%. These numbers come straight from analytical techniques like gas chromatography and NMR. Labs working toward fine chemical synthesis usually shoot for the high end, above 98%. Once you open a fresh bottle, you notice how strict storage and handling play a role. Any moisture or cross-contamination can bump those numbers down fast.

Third-party labs often provide certificates of analysis. In practice, those results match up with in-house checks maybe 90% of the time, but it pays to trust and verify. An off-spec impurity—say, leftover 6-Bromohexanoic acid or unreacted alcohol—throws a wrench into downstream reactions, especially when aiming for clean coupling or protecting group strategies. Impurities don’t always announce themselves, so regular checks keep projects on track.

Why These Numbers Matter to Real People

People doing medicinal chemistry appreciate every percentage point. I remember an antiviral project where we tracked an intermediate’s purity, only to spend days troubleshooting a dirty batch. It all traced back to a shipment of tert-butyl bromoester that never even hit 96%. Cost-cutting on raw materials led directly to extra cleanup work, more solvent waste, and missed timelines. It’s a domino effect that you only avoid by sticking to high-purity lots.

For commercial applications, customers aren’t just paying for chemicals; they’re buying reliability and safety. A lower-purity batch can trigger side reactions, dull biological studies, or make scale-up unpredictable. Those headaches don’t hit the datasheet, but they hit the bottom line in labor and delays.

Steps to Keep Purity Levels High

In practice, maintaining high quality throughout storage and handling makes a clear difference. Dry, sealed containers and a consistent supply chain help. Many researchers run a quick TLC or NMR before using a new batch, especially for sensitive work. Where budgets allow, working with ISO-certified suppliers lowers the risk of mystery impurities.

Digital tracking of lot numbers, results, and any observed problems gives everyone in the lab better insight. Sharing data with colleagues can flag recurring problems that wouldn’t show up in just one experiment. For small-scale users, group purchases or buying from established distributors offers some extra security compared to untraceable online sources.

Looking Forward

To get reliable results from Tert-Butyl 6-Bromohexanoate, especially in R&D or scale-up, careful attention to purity always pays back. Lab experience teaches that shortcuts with purity rarely save money in the end. The best bet combines regular analysis, solid supplier relationships, and learning from every batch, good or bad. That’s what lets new ideas move off the bench and into the real world.

Getting Real About Chemical Safety

Anyone dealing with organic chemicals like Tert-Butyl 6-Bromohexanoate faces a real balancing act between research convenience and safety. You shouldn’t just throw this stuff on a shelf and call it a day. I’ve spent time in labs where cutting corners has led to ruined compounds or even more serious problems, so I take storage seriously—and for good reason. This compound carries more risk than a bottle of acetone or some extra salt.

The Essential Storage Conditions

Tert-Butyl 6-Bromohexanoate has a way of causing trouble if left exposed to the wrong elements. Heat, moisture, and light don’t mix well with its shelf life. It likes being left alone, well away from sunlight and open air. Heat speeds up chemical decay and invites reactions you won't want happening in your storage cabinet. Temperatures under 25°C are far safer—ideally, a fridge dedicated to chemical storage seems like the best compromise between accessibility and longevity. I’ve seen bottles wrapped in foil to block out light, and, while basic, this method gets the job done if you don’t have an amber bottle handy.

Moisture’s the real villain here. Most esters—including Tert-Butyl 6-Bromohexanoate—break down when water sneaks in. Humidity inside a regular cabinet can lead to hydrolysis, making your compound useless just when you need it. Dry boxes with desiccant packs go a long way, and regular checks ensure these packs still do their job. Seal the bottle tightly after each use and avoid using the same spatula for different chemicals, since even small contamination can cause slow breakdown over time.

Chemical Compatibility and Safety Mindset

Labs work better with clear separation of chemicals. You don’t want oxidizers or acids sitting next to organics like this one, not just to prevent unwanted reactions, but because regulations demand it. Mixing mistakes cause spills and even fires. If there’s one lesson I learned early—label every container with clear dates and contents, not just a code number scribbled with a Sharpie.

The Material Safety Data Sheet for Tert-Butyl 6-Bromohexanoate gives the lowdown on fire risks, inhalation hazards, and exactly why you need gloves when handling it. I’ve seen people skip reading the MSDS and regret it after one unexpected spill. Familiarity with its precautions could spare you a lot of pain, and it’s non-negotiable in any responsible lab.

Why It Matters More Than Just Paperwork

Sloppy storage doesn’t just put your project at risk—it stacks up wasted money, ruined timelines, and even the health of the people in your lab. Beyond personal headaches, chemical mishandling impacts the credibility of research. Regulators in Europe and the United States pay close attention to chemical management, especially for substances with toxic or hazardous byproducts.

Addressing these concerns calls for more than checklists. It’s about building habits—always recapping, documenting, double-checking temperatures, and making sure moisture stays out. If your team spends some time upfront training on these practices, you save effort, protect long-term projects, and create a safer lab for everyone. In the end, protecting your investment starts with how you store it, not just how you use it.

The Value of CAS Numbers in Chemical Identification

Chemists work with thousands of different compounds, and accurate identification helps science stay organized and safe. A CAS number acts like a fingerprint for a chemical. It all comes down to precision. The CAS number for Tert-Butyl 6-Bromohexanoate is 309956-78-3. This isn’t just trivia—without a correct identifier, researchers can end up with the wrong bottle, a misplaced resource, or worse, a safety mishap.

My Experience Searching for Chemical Data

Anyone who’s worked in a research lab knows the pain of hunting for an obscure reagent or cross-referencing similar-sounding chemicals. There’s nothing worse than having a supplier send a bottle with a slightly different label because the name looked similar, but the CAS number was off. Having the right CAS number fixes half the headaches and cuts wasted time. Once, a colleague of mine prepped hours of experiments before realizing the compound delivered had a mismatched CAS number on the certificate—the reagents even looked the same on the surface. Cleaning up afterward took more time than the experiment itself.

Why Accuracy Matters in Research

The consequences of mix-ups go beyond inconvenience. In organic synthesis, purity and structure matter. Tert-Butyl 6-Bromohexanoate, identified as 309956-78-3, often finds use in the preparation of specialized intermediates for pharmaceuticals. A small misstep could mean a failed batch or a potential hazard. In regulated industries, paperwork for audits or compliance relies on that unique identifier. Imagine carrying out months of research, only to find regulatory paperwork rejected because a wrong CAS number appeared in the records.

Bridging the Gap: Best Practices for Safe Chemical Handling

Using CAS numbers prevents miscommunications between collaborators, suppliers, and even regulators. Consistency starts with good cataloging. I’ve always made a habit of labeling everything in the stockroom with both the compound’s common name and its CAS number. It makes ordering and inventory straightforward and helps everyone from the newest intern to the most experienced scientist stay on the same page.

Building solid habits in how chemicals are stored and tracked can prevent major problems down the road. Cross-check every order, read certificates of analysis, and always double-check the CAS number, especially when preparing shipments or making purchases on international websites. This is essential both for keeping lab members safe and for successful experiments.

Moving Toward Better Transparency

Suppliers and academic institutions should maintain updated chemical registries, integrating CAS numbers into digital inventory systems. I’ve noticed some of the best labs run quick orientations about these systems for newcomers. It’s worth encouraging more transparency in chemical supply chains by demanding manufacturers provide robust documentation tied to each unique CAS number.

A CAS number—like 309956-78-3 for Tert-Butyl 6-Bromohexanoate—serves as a promise: what’s on the label matches what’s in the bottle. This approach supports science and keeps people safer, one precise identifier at a time.

Looking for Bulk Quantities: More Than a Lab Inquiry

Anyone who’s run a project needing chemicals like Tert-Butyl 6-Bromohexanoate understands the challenge of sourcing in scale. Sometimes it means burning hours on supplier websites, shooting out emails, waiting for quotes that may never land. In research and manufacturing, this compound comes up for its role in organic synthesis—especially for building blocks in pharmaceuticals, agrochemicals, or specialty materials. So, is it easy to get your hands on barrels of the stuff, or are you stuck with a few grams?

Sourcing: Plenty of Listings, Fewer Real Options

Type the compound name into any chemical supplier aggregator and you’ll find dozens of labs and companies claiming to offer it. Most listings top out at a few grams—a far cry from the kilograms needed for pilot or production runs. Based on vendor catalogs, companies like Sigma-Aldrich or Thermo Fisher typically treat this molecule as a specialty reagent rather than a bulk commodity. I’ve personally tried sourcing chemicals at this scale for startup research, and stock often disappeared once we asked about higher volumes.

Some Chinese suppliers advertise metric ton volumes, showing that—at least on paper—there’s no shortage for those with the right contacts and purchasing power. Yet, those buying in the West often face questions around documentation, lead times, and purity standards. Regulatory and quality headaches turn up quickly when the product arrives without a certificate of analysis or consistent supply chain assurance.

Market Reality: Niche Demand and Supply Relationships

Bulk demand mainly comes from contract manufacturers or pharma companies running established syntheses. It’s not the same as ordering solvents or acids. Tert-Butyl 6-Bromohexanoate acts as an intermediate; real industrial buyers set up long-term supply agreements and vet vendors to secure lot-to-lot consistency. The unpredictability of spot buys in specialty chemicals means market price swings and unreliable deals.

A large part of reliable supply comes down to relationships. Trustworthy suppliers respond to custom requests, can ship documents, and know the compliance landscape. In my own search for rare intermediates, Eastern European and Indian producers could scale, but vetting those partners took weeks, sometimes months. The FDA and EMA maintain watch lists for good reason—cut corners can wreck an entire production batch.

Supply Solutions: What Works and What Breaks

For labs scaling up, one solution is to partner with contract research organizations that handle procurement, QA and reliability screening. Another route is working with third-party brokers who understand global sources and can trace impurities back to the drums they shipped from. In-house synthesis still makes sense for some, but only if you have access to skilled chemists and solid safety infrastructure. I’ve seen several cases where building the intermediate became more expensive than hunting down a supplier—especially when raw material prices jumped.

A key fix for small and mid-size buyers lies in more transparent digital marketplaces linking certified suppliers with buyers. Some startups focus on traceability, but wider adoption takes time due to risk aversion and the high costs of failed runs. Keeping regulatory paperwork in order and pushing suppliers for complete documentation pays off in the long run. A lesson learned the hard way: bulk purchases work best with advance planning and a paper trail you can audit.

Chemical Building Blocks Open New Doors

Tert-Butyl 6-Bromohexanoate isn't something you hear about outside a chemistry lab, yet its presence has ripple effects across many industries. This chemical belongs to a class called brominated esters. In daily life, you rarely see such compounds in their raw form, but their applications feed into hundreds of products and techniques. My early interest in chemistry started with the satisfaction of piecing together a complex puzzle molecule-by-molecule, and compounds like this showcase how that behind-the-scenes process changes what ends up on shelves.

The Role in Pharmaceutical Discovery

Drug researchers rely on intermediate chemicals to create medicines. Tert-Butyl 6-Bromohexanoate serves as one such stepping stone. Its bromine atom makes it easy to tweak, swap for other groups, and shape the kind of molecule drug makers need when inventing new treatments. That flexibility gives researchers power to experiment with countless structures. When working in synthesis, I’ve seen how using a versatile intermediate can shave weeks—or even months—off development timelines.

Peer-reviewed research catalogs many examples of using bromo-hexanoates in exploring anticonvulsant drugs, muscle relaxants, and experimental cancer therapies. The cost and time savings translate into real progress—pharmaceuticals that arrive sooner and fail less often in late-stage trials.

Pushing Ahead in Materials Science

The influence of tert-butyl 6-bromohexanoate stretches into polymers and specialty chemicals. Chemists use it to add reactive “handles” to a base structure, making it possible to link, assemble, or anchor new functions onto long plastic chains. These subtle tweaks can change how a plastic behaves—its stickiness, durability, or how it resists water. Contributions like this help deliver better coatings, adhesives, or components that last longer and perform smarter. Industries building everything from touchscreens to lightweight car parts rely on these advances.

Shaping Research in Organic Synthesis

The compound makes life easier when building complex molecules from scratch. I recall helping undergraduate researchers work with similar brominated esters in undergraduate labs, introducing students to the “art” of transforming raw materials step-by-step. Chemicals like this teach how one small change—a hook here, a protective group there—opens different synthetic pathways, preventing mistakes and producing clean results. Academic and industrial teams use this flexibility to develop flavors, fragrances, and next-gen fine chemicals.

Safety and Responsible Handling

Handling any brominated organic demands strict control. It’s not just a matter of ticking boxes—these compounds pose hazards if used without training or respect for proper safety measures. Gloves, goggles, and fume hoods all matter, not just for the one using them, but for everyone in the workspace. Experienced chemists pass on these habits because one slipup leads to more problems than anyone wants to remember. Waste management also figures in, since regulatory agencies keep sharp eyes on how halogenated chemicals get disposed of. Cutting corners with toxic or persistent compounds doesn’t pay off—it always comes back, in fines or environmental messes.

Better Science, Better Products

Good chemical building blocks help shape possibilities across sectors. By providing a practical, customizable option, tert-butyl 6-bromohexanoate enables breakthroughs in medicine, new material design, and applied chemistry. The value doesn't only come from what this molecule brings alone; it’s all about how it fits into bigger workflows, speeding up ideas and delivering real results. Real responsibility also follows—people working with it know care, training, and oversight keep progress safe. That combination lets science offer better products year after year.