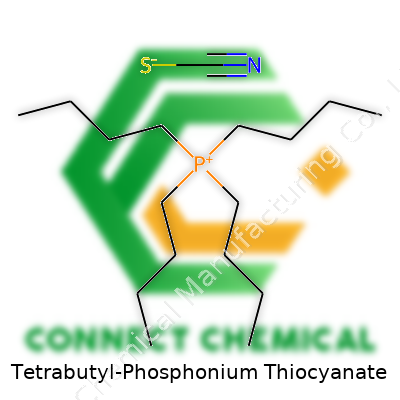

Tetrabutyl-Phosphonium Thiocyanate: A Commentary on its Development and Use

Historical Development

Tetrabutyl-phosphonium thiocyanate has its roots tangled in decades of work on quaternary phosphonium salts. Researchers in the late twentieth century started experimenting with phosphonium compounds, chasing after stronger ionic liquids and improved phase transfer catalysts. Back then, folks looking for better solvents and safer alternatives to harsh chemicals gave this class of compounds a closer look. Phosphonium-based salts, including tetrabutyl-phosphonium thiocyanate, became known for their stability and versatility, especially compared to their ammonium cousins. I remember reading early reports in the chemical literature where scientists highlighted its unique combination of low volatility with robust solvation properties, which spurred a fresh wave of experimentation across chemical engineering and material science labs.

Product Overview

Tetrabutyl-phosphonium thiocyanate brings together an organic phosphonium cation and a thiocyanate anion, breathing life into diverse chemical processes. It landed on the market as both a technical reagent and a specialty solution component. Anyone who’s worked with this salt knows it shows up as a white to off-white powder, sometimes picking up moisture if you leave it uncapped. I’ve run across suppliers who offer it in high purity grades, tailored for research or industrial settings. It always pays to check the label, as purity and water content can swing performance on the bench.

Physical & Chemical Properties

The salt’s melting point sits around 70-80°C, which means you can handle it as a solid at room temperature and then work with its solutions easily when you need it. Its solubility stands out in polar solvents like water, acetonitrile, and even DMSO. Unlike ammonium compounds, tetrabutyl-phosphonium thiocyanate resists thermal breakdown and stays chemically stable under many reaction conditions. The strong ion-dipole interactions make it a go-to for processes requiring high ionic strength or salt-based stabilization. The distinctive, faintly sulfurous smell sometimes catches folks off guard—always reminds me to keep my fume hood on and double-check the seals on storage bottles.

Technical Specifications & Labeling

Walk into a chemical storeroom, and you’ll see bottles with careful labeling: product name, supplier, batch number, percent purity, and warnings tied to its moderate toxicity. Chemical safety sheets for this compound warn about potential eye, skin, and respiratory irritation, echoing general phosphonium salt guidance. Specifications usually require water content below 0.5%, and common available grades run from 97-99% pure, though trace impurities can mean headaches in sensitive applications. In my own use, meticulous logging of material certificates helped avoid costly rework on projects involving rigorous controls.

Preparation Method

Labs prepare tetrabutyl-phosphonium thiocyanate by reacting tetrabutyl-phosphonium chloride with potassium or sodium thiocyanate. The process often calls for a fight with moisture, since water loves to tag along. I’ve seen better yields and cleaner product from using anhydrous conditions and quick filtration to remove byproducts. After drying, purification steps like recrystallization or vacuum drying can polish up the result. Quality rides on factors like reagent grade, thorough washing, and timely separation of solids from the mother liquor. Taking shortcuts in any step almost always kicks off trouble downstream—clogged filters, stubborn emulsions, or lower active content in the final test.

Chemical Reactions & Modifications

Anybody who handles organophosphorus chemistry notices the flexibility this salt gives. It serves as a phase transfer agent in nucleophilic substitution and fits in some ionic liquid syntheses. The thiocyanate group opens the door to addition reactions, sulfur transfer, and even mild oxidations. Cross-coupling work in organic synthesis often leans on the salt’s high reactivity, and I’ve watched researchers harness it to tailor surface chemistry of advanced materials. Derivatives pop up from straightforward modifications: swapping out alkyl chains on the phosphonium, or introducing isotopically labeled thiocyanate for tracing studies. Each tweak brings its own quirks, so careful method development saves time and resources.

Synonyms & Product Names

This compound doesn’t hide behind many aliases. Most suppliers and researchers call it Tetrabutyl-phosphonium thiocyanate or simply TBPT. Some technical catalogs add product codes or language like “quaternary phosphonium SCN salt.” Bilingual and international suppliers may toss in translations for clarity, but across the literature, the standard name prevails, making life easier for anyone searching or cross-referencing studies.

Safety & Operational Standards

Every bottle ships with thorough handling instructions. Safety goggles and gloves stand as basic requirements, especially since exposure to skin or inhalation can lead to irritation. Emergency showers and eyewash stations should stay within arm’s reach. Even though large-scale industrial incidents with phosphonium salts turn up rarely in the news, anyone running scale-up batches gets regular reminders on spill response, neutralization, and proper waste segregation. Plenty of companies lean on standard operating procedures and frequent refresher training to catch mistakes before they multiply. Regulatory frameworks in the US and EU ask for documentation at every stage—nobody wants regulators or auditors catching lapses from missing SDS sheets.

Application Area

The versatility of tetrabutyl-phosphonium thiocyanate cuts across fields. In materials chemistry, it helps control particle size and porosity for zeolites, silicas, and novel organic frameworks. Industrially, you’ll find it smoothing out some extraction processes, especially where selective solubility offers an edge. Catalysts based on this compound push forward green chemistry approaches, dropping the need for harsher or less recyclable options. In analytical labs, professionals employ it to stabilize ions and sharpen sensitivity in certain detection methods. As someone who’s juggled separation sciences and catalysis research, I’ve found that even a pinch can swing yields or selectivities, giving projects an advantage without resorting to exotic or prohibitively expensive agents.

Research & Development

From the early days of bench chemistry to today’s data-driven labs, R&D on tetrabutyl-phosphonium thiocyanate sticks to the hunt for improved safety, efficiency, and sustainability. Researchers aim to create better catalysts by tweaking the salt structure or combining it with other functional materials. There’s a strong push to lower costs through greener synthetic routes as traditional phosphorus sources grow scarcer and regulations tighten. The big leap I keep seeing centers on design of safer ionic liquids: researchers blend TBPT into these formulations because it stabilizes reaction mixtures and reduces environmental risks by avoiding volatile organics. Universities and companies report new findings every year, chasing down performance metrics from conductivity to thermal window, knowing that one breakthrough can catch the eye of process engineers looking to future-proof their operations.

Toxicity Research

Toxicological studies on tetrabutyl-phosphonium thiocyanate haven’t gone as deep as with older industrial chemicals, but scientists know to avoid complacency. Short-term studies show limited acute toxicity at realistic exposure levels, but not enough reassurance to skip proper protection. Animal models reveal mild irritation at moderate doses and some lingering bioaccumulation concerns. The big questions for environmental chemists hang on whether these salts degrade safely or stick around, which matters especially near waterways or agricultural runoff. Workers need education, not just paperwork, since even low-toxicity labels can breed carelessness. It takes collective effort to fill data gaps—for example, international consortia exchanging findings on metabolic breakdown and long-term chronic effects before regulators step up restrictions.

Future Prospects

Looking ahead, tetrabutyl-phosphonium thiocyanate promises to play a role in shaping sustainable chemistry. Industry and academia see it as a stepping stone to safer, non-volatile ionic liquids and tunable solvents that outperform long-standing hydrocarbons. Demand ties into the rise of green chemistry, where every new step forward means fewer emissions and lower waste. Researchers are also examining it for batteries, separation membranes, and biomedical uses, betting on the unique balance of stability and reactivity. Still, no chemical stands isolated from broader changes in regulation or public perception. Weighing health, safety, and sustainability, stakeholders keep searching for improvements in synthesis, product stewardship, and safe disposal. From what I’ve seen in the lab and followed in industry trends, its story is only just picking up speed, with plenty of room for breakthroughs that couple science, policy, and real-world benefit.

Unpacking the Role of Tetrabutyl-Phosphonium Thiocyanate

Tetrabutyl-phosphonium thiocyanate turns up in labs where chemists need a reliable ionic liquid. This compound steps up in research settings, especially when someone is looking for a material that dissolves a wide range of substances and works at room temperature. Industry likes it for some of these same reasons—its stability and low volatility keep things safer and more predictable. Think of settings with strict conditions, like battery development and organic synthesis. It's not just about coming up with new technology; it’s about fine-tuning processes so scientists and engineers stay ahead in efficiency and sustainability.

Key Uses in Industry and Science

In the real world, large-scale chemical manufacturing demands materials that won’t unexpectedly react or break down. Tetrabutyl-phosphonium thiocyanate fits into this pattern. It’s not as widely known as sodium chloride or sulfuric acid, but it supports important advances, particularly in the field of electrochemistry. If you ever picked up a lithium-ion battery, work like this was behind the scenes. Researchers use this compound while building better electrolytes—substances that move electric charge inside a battery—with more reliable charging cycles and less heat buildup. Factories working to scale up these materials find tetrabutyl-phosphonium thiocyanate useful as a supporting player. Instead of worrying about dangerous fumes or runaway reactions, they use this compound and focus on getting the performance just right.

Analytical chemists trust it in scenarios that call for extracting certain metals or for separating substances during sample preparation. Some environmental clean-up operations require chemicals that can “grab” pollutants and keep them steady for later removal. This compound fits into these roles, acting a bit like a targeted filter. That sounds small, but those kinds of steps shape how efficiently hazardous materials get removed from water or soil.

Why Its Use Matters Today

There’s a growing need in the world to manage chemical waste and energy smarter. Tetrabutyl-phosphonium thiocyanate aligns with these trends. Its performance in non-aqueous phase extraction and specialty catalysis helps to lower the amount of hazardous solvents used in labs and industry. Less solvent means less pollution, and better selectivity means fewer byproducts end up in the waste stream. People in the field of green chemistry keep searching for ways to swap out old, polluting chemicals with cleaner substitutes. This compound, because of how it blends a strong ionic liquid with a flexible thiocyanate group, offers a promising alternative.

Solving the Challenges—Safety, Cost, Innovation

Costs and safe handling can slow down adoption of new chemicals. Tetrabutyl-phosphonium thiocyanate isn't as cheap as legacy salts, and large-scale production requires careful logistical planning. Staff need solid training, and engineers must pay attention to possible toxic effects if the compound escapes into the environment. Solutions start with standardizing handling procedures at both the supplier and the end user’s workplace. Clear labeling, tightly controlled transfer systems, and up-to-date Material Safety Data Sheets (MSDS) help lower risks.

Chemists and companies always look for ways to make better, more affordable ionic liquids. Continued research into synthetic routes and recycling methods for phosphonium-based ionic liquids can drive down costs. As demand builds for greener technology, investment in safer manufacturing and scale-up will increase. This fits a pattern I’ve watched across other classes of specialty chemicals: with visibility, scrutiny, and targeted investment, future researchers will refine and expand the benefits.

Understanding the Basics

Diving into the formula for Tetrabutyl-Phosphonium Thiocyanate uncovers a striking mix of chemistry and practicality. The formula stands as C17H36PSCN. Here, the “tetrabutyl” part signals four butyl groups clinging to a phosphonium core, showing up as C4H9 chains. The “thiocyanate” references the SCN unit attached to that phosphonium.

At a glance, this compound’s name might throw some off, but any industrial chemist recognizes the relevance of its structure. The four butyl arms hanging off one phosphorus atom produce not only a charge but a shape and bulk that affect everything from how this chemical dissolves to how it interacts in synthesis.

The Phosphonium Edge

Over the years, phosphonium-based salts have seen steady demand in both research and industry. This particular compound separates itself by offering both a large organic cation (tetrabutyl-phosphonium) and an active anion (thiocyanate). The balance between the bulky organic portion and the nimble thiocyanate changes how the salt works. For instance, its solubility in a range of solvents beats what you find with traditional inorganic salts.

In the lab, swapping out traditional sodium or potassium thiocyanate for the tetrabutyl-phosphonium cousin can lead to surprising turns. Solubility jumps, and organic reactions run cleaner with less unwanted residue. For anyone searching for greener chemistry or safer alternatives, this salt cuts out some of the complications brought by metal-based ions, plus it opens new doors for customization in synthesis.

Why the Formula Deserves Attention

The chemical formula is more than just numbers and symbols. Each piece tells a story about behavior and possibility. In my experience, working with compounds like C17H36PSCN means fewer headaches around residue during work-up stages. The absence of small, reactive metal ions changes reaction pathways, reduces side reactions, and can even upgrade product quality.

Looking through published research, it’s clear the presence of the phosphonium group gives it unique properties. Ionic liquids, for example, become more stable and tunable with that same phosphonium backbone. As sustainable chemistry gains traction, interest in these types of compounds is only growing. Academic labs led the way by using this salt in phase-transfer catalysis, but now companies invest in tailoring these formulas for larger scale use, especially where toxicity and environmental impact become sticking points.

Potential Solutions and Next Steps

Despite its clear advantages, accessibility and cost sometimes restrict the wider use of tetrabutyl-phosphonium thiocyanate. While synthesis has gotten more economical, scale-up remains tough due to the specialized starting materials. Open collaboration between research institutions and chemical suppliers can help close the gap. Shared best practices and transparent supply chains would cut both cost and time, letting more chemists tap into the benefits this compound brings.

At the end of the day, the chemical formula C17H36PSCN isn’t just a string of elements, it’s a recipe packed with energy for change. In applications ranging from organic synthesis to materials science, fully understanding such compounds helps raise standards for safety, efficiency, and sustainability across the board.

Real Risks in the Lab and Beyond

Tetrabutyl-Phosphonium Thiocyanate lives in chemical supply catalogs, research labs, and sometimes in manufacturing setups. Some folks see only a chemical name on the label. Those who handle these compounds daily know there’s more to the story.

Let’s be clear: this isn’t something for backyard experiments. Handling it without respect for safety brings real hazards. Anyone who’s accidentally splashed a solvent or missed a safety step remembers the sting, sometimes for years. This compound, like so many strong organic salts, can irritate skin, burn eyes, and release fumes that leave throats raw. It isn’t as easy to brush off as table salt, and the body knows it right away.

What Science Says About Hazards

Published safety data lists Tetrabutyl-Phosphonium Thiocyanate as hazardous by standard criteria. Direct contact invites chemical burns and serious irritation. Breathing in dust doesn’t end well, especially over time. Years spent around these chemicals teach a person to double-check fume hoods and seals. The thiocyanate part carries risks for the thyroid, a lesson learned through decades of toxicology studies. Exposure over a long haul can quietly stress the thyroid until health problems finally appear.

There’s also the fire hazard. While not explosive, this compound won’t just sit quietly if fire breaks out. Plenty of chemical fires started when something like this caught a stray spark. The fumes, when burned, spread more toxins. Housekeeping in chemical spaces means respect for this risk, learned through trial, error, and sometimes frightening close calls.

Hard Lessons and Responsible Handling

During my years in shared labs, the best lessons came after small mistakes. A friend once put off cleanup for coffee, only to find his gloves dissolving minutes later. Every safety plan suggests gloves, goggles, and lab coats for a reason. Secondary measures like proper storage and labeled containers matter just as much as personal helmets and jackets on a job site.

I remember hearing about a transfer job gone wrong: someone moved a similar compound under a regular office vent, not under the hood. The result—airborne dust and three people sent home with headaches. Training helps, but daily reminders from peers and plain old habit make the real difference.

Building a Safer Approach

Reliable controls start with treating every chemical with a little skepticism. Routine never guarantees safety, so keeping up-to-date safety data sheets always within arm’s reach saves time and nerves. More companies invest in real hands-on training, not just digital modules. In my experience, nothing beats a quick walk-through with new hires to build awareness.

Safe disposal still causes headaches for many organizations. Partnering with chemical waste professionals, not cutting corners, protects workers and neighbors. Even on a tight budget, investing in proper spills kits and routine air monitoring brings down risks. Open conversations about near-misses build up collective memory and help prevent repeats.

A Matter of Respect, Not Fear

Nobody needs to treat Tetrabutyl-Phosphonium Thiocyanate like some lurking monster. Managing risk takes serious attention, not panic. It stands as one more reminder that behind every long, odd chemical name lies real potential for harm. Use knowledge, care, and the lessons of those who came before, and this compound becomes just another tool—not a threat waiting in the dark.

Why Storage Matters for Tetrabutyl-Phosphonium Thiocyanate

Working with special chemicals like Tetrabutyl-Phosphonium Thiocyanate means paying close attention to storage. Anybody who’s spent time in a lab knows this: one bad storage choice can turn a routine day into a mess filled with hazards, unexpected reactions, or damage to equipment. Sometimes I think back to my early days in research — one bottle, set on the wrong shelf, created fumes that ruined a whole week’s worth of samples. That’s why storage isn’t some dry guideline. It keeps work running, and people safe.

Keeping the Chemical Stable

Let’s start with temperature. This compound won’t keep its cool if left near a heat source, direct sunlight, or in an overly warm storeroom. Warmth speeds up unwanted changes, and nobody wants to peel a crusted cap off a bottle that’s just reacted with thin air. Cool, dry places do the trick. Aim for well below 30°C and far from any radiators or sunny windows.

Humidity turns into its own silent culprit. Moisture in the air gets into bottles, builds up inside caps, and stirs up a whole host of problems — from clumping to slow decomposition. Running a dehumidifier in the storage area can make a difference, especially in humid climates. Even during rainy seasons, a desiccator for opened containers blocks out the damp. Keep things bone-dry, and the chemical stays as it should.

What Interacts and What Doesn’t Belong Nearby

Nobody likes to play guessing games with chemical compatibility. Tetrabutyl-Phosphonium Thiocyanate must never share shelf space with oxidizers or strong acids. Mixing storage, especially on a crowded shelf, guarantees spills turn serious. Separate storage means you never worry about accidentally grabbing the wrong bottle or dealing with fumes that drift from a cracked seal. Flammable liquids, oxidizers, and strong acids belong far away, preferably in their own locked cabinets.

Container and Label Decisions That Matter

A sealed container, made of chemical-resistant material, isn't just a preference — it’s the difference between smooth work and searching for leaks. Glass or HDPE often hold up best. Make sure every bottle carries a clear label. I’ve seen cases where an unlabeled sample led to confusion, doubled handling time, and even wrong experiments ruined by cross-contamination. Updates matter, too. Change the label if the contents get transferred.

Access and Security for Middle-Sized Labs

Labs vary: solo researchers, teaching spaces, or industrial stockrooms. No matter the context, only trained folks should walk in and handle this material. Posting a logbook, and locking the storage area, stops accidents before they start. In my experience, clear rules about who collects and returns bottles reduce lost containers and risky improvisation. Spare a minute for training every new set of hands — it pays off in routine lab safety.

Disposal Plans and Emergency Prep

No storage plan is complete without a backup for spills. Emergency containment kits, spill neutralizers, and simple instructions next to the shelving save time in a pinch. Disposal bins, labeled specifically for this category, mean nobody guesses what goes where when something’s expired. Working with local disposal services, even if it takes a call or two to sort it out, keeps the storage area from piling up with outdated chemicals.

Final Thoughts on Getting It Right

People sometimes think of chemical storage as a checklist: shelf, label, done. Real safety and longevity come from everyday habits. Watch the temperature, separate the incompatible, lock up the area, and always plan for cleanup. Tetrabutyl-Phosphonium Thiocyanate might not make headlines, but the details of how you store it shape every step that follows in research, teaching, or industrial work.

Understanding the Risks

Tetrabutyl-phosphonium thiocyanate isn’t a household chemical you find under the kitchen sink. It stands in a group of specialty substances used in advanced chemistry and industry, and it doesn’t take much reading before you find caution labels begging for respect. In a lab or manufacturing area, it’s the job of every worker to treat this compound with something beyond routine caution. Every container, label, and data sheet reminds us that poor handling bites back hard, sometimes without warning.

Personal Experience: Stories from the Lab

In my early years working with specialty chemicals, I watched a seasoned colleague develop a nasty chemical burn across his palm from skipping gloves “just for a second.” The pain lingered for days, longer than his regret. Tetrabutyl-phosphonium thiocyanate can irritate the skin and eyes on contact, and breathing its dust or vapors causes respiratory distress fast. You can’t see it or smell it before it starts to hurt. Stories like this become warning signs that stick in your mind: respect for gloves, goggles, coats, and fume hoods turns from advice into habit.

Safe Storage and Handling

This chemical gets stored in tightly closed, labeled containers in cool, well-ventilated spaces. Moisture, heat, or open flames don’t mix with tetrabutyl-phosphonium thiocyanate—fire risk is real, and a spill can ruin equipment or cause health emergencies. From the start of every shift, inspecting gloves, lab coats, and goggles brings peace of mind. Only nitrile or neoprene gloves keep exposure down. Anyone handling the compound wears safety goggles with side shields, not regular glasses or open lenses.

Spill and Exposure Response

Nobody plans for a spill—yet these moments become the most telling in a workplace. All workers need to know where the spill kits, showers, and eyewash stations sit, because seconds matter. Neutral absorbent, carefully scooped up and sealed in a proper waste container, cleans up solids. Trained personnel don’t sweep or vacuum fine powder without a certified HEPA-equipped vacuum, since dust stirs up quickly and floats into the air or onto skin. Clothing hit by the compound heads straight for containment or disposal, never home in a laundry basket.

Training and Ongoing Vigilance

New lab techs learn quickly that every chemical has a story, and every exposure leaves a mark. Regular safety drills, quick-reference sheets, and clear labels cut down on “close calls” and build a culture of responsibility. Managers tie safety protocol reviews into every routine meeting. Workers speak up when supplies run low or procedures drift off course. Complacency never rewards; people stay sharp with gentle reminders and open communication.

Responsible Disposal

Byproduct or leftover tetrabutyl-phosphonium thiocyanate doesn’t land in a regular trash can or down a sink. Companies contract licensed hazardous-waste haulers or train in-house teams for compliant disposal. Records of every transfer and sign-off travel with the waste, keeping both personnel and regulators satisfied. Tracking these materials helps spot leaks, losses, or unexpected risks, leading to quicker responses and better planning the next time.

The Heart of Safe Chemistry

No shortcuts exist in handling compounds of this type. Lives stay safer through habits learned from experience, teamwork, and respect for the hidden power of what seems like ordinary bottles or powders. Real safety isn’t just a policy; it’s a commitment owned by every hand that opens a container.