Tetrabutylphosphonium Hexafluorophosphate: A Comprehensive Perspective

Historical Development

Stories about quaternary phosphonium salts seldom make front-page news, but among chemists, Tetrabutylphosphonium Hexafluorophosphate has a legacy worth noting. Its origins reach into the era when labs sought ionic liquids and versatile electrolytes for safer, more efficient industrial processes. By the late twentieth century, a few persistent researchers started swapping the usual ammonium or imidazolium cations for phosphonium ones, looking for better stability and wider liquid temperature ranges. The hexafluorophosphate anion caught attention early due to its robust, non-coordinating nature. Combining it with tetrabutylphosphonium produced a compound that handled extreme conditions, which soon led to its inclusion in electrochemical studies and organic synthesis. Progress accelerated once scientists in Japan and Europe explored it as an alternative to more hazardous salts, ultimately anchoring its role in both academic and commercial labs.

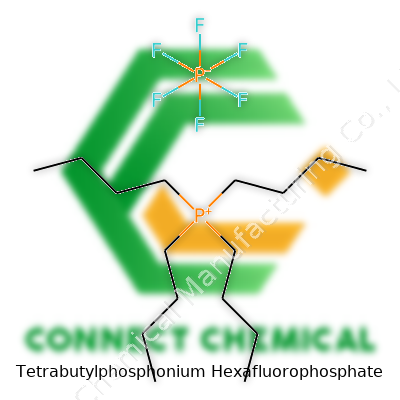

Product Overview

Ask anyone with experience in synthesizing ionic liquids and they’ll likely mention tetrabutylphosphonium hexafluorophosphate. Its clear to off-white crystalline powder stands out from more common ionic compounds, holding firm in environments that deter most salts. A straightforward synthesis, involving the reaction of tetrabutylphosphonium bromide with potassium hexafluorophosphate, yields a compound ideal for controlling ion exchange, salt metathesis, and phase transfer. Its broad utility as a supporting electrolyte in nonaqueous electrochemical studies makes it a go-to for those faced with solvents that chew through less sturdy salts. Many industrial catalogs list it as TBPFP or [P(C4H9)4][PF6], but older literature sometimes calls it tetrabutylphosphonium hexafluorophosphate(V), hinting at the anion’s oxidation state.

Physical & Chemical Properties

Anyone handling TBPFP will notice its high melting point, often above 180°C, which means it rarely melts in ordinary lab conditions. This stability arises from the bulky phosphonium cation and the nearly inert PF6- anion. TBPFP dissolves in polar organic solvents like acetonitrile or acetone, revealing its value as an electrolyte in nonaqueous media. It resists degradation by air and moisture, though long exposure to water eventually leads to slow hydrolysis, giving up hydrofluoric acid and phosphoric acid derivatives. Density hovers near 1.2 g/cm³, and the salt resists major color changes even after repeated heating and cooling cycles, so long as it’s kept dry. Its non-flammability and limited volatility further encourage its use in sensitive or high-temperature applications.

Technical Specifications & Labeling

Suppliers usually ship TBPFP in airtight, amber glass vessels or sealed polymer pouches to prevent hydrolysis or contamination. Lot numbers and purity levels, often above 98%, appear directly on the label, along with storage instructions: keep in a cool, dry place, away from acidic vapors or moisture. Reputable vendors provide a full certificate of analysis—detailing melting point, moisture content (usually less than 0.5%), and an IR or NMR spectral fingerprint for authenticity. Many labs demand trace metal and halide levels below 100 ppm, a bar that reputable suppliers meet with rigorous in-process testing. Labels also highlight the GHS signal word ‘Warning,’, and include pictograms warning about environmental hazards.

Preparation Method

Crafting TBPFP starts with tetrabutylphosphonium bromide, commercially available or prepared by reacting tributylphosphine with butyl bromide. Adding this to a cold, saturated solution of potassium hexafluorophosphate causes immediate precipitation of potassium bromide while TBPFP stays dissolved. Extraction with dichloromethane pulls the hexafluorophosphate salt into the organic layer. After drying and solvent removal under low pressure, a crystalline residue forms. Recrystallization from ethanol or acetonitrile helps purify the product, which then heads for vacuum drying. This hands-on process eliminates bromide traces and removes stubborn water, leaving a salt that performs right out of the jar.

Chemical Reactions & Modifications

TBPFP behaves with remarkable reliability during ion exchange processes. Swap its cation for a sodium, potassium, or another organic cation, and the reaction often goes to completion under mild agitation. The hexafluorophosphate anion rarely leaves its post unless subjected to strong acid, heat, or attack by fluoride sources. In rare cases, TBPFP can transfer its phosphonium moiety in organic transformations, especially in phase-transfer catalysis of alkylation and silylation reactions. Intrepid chemists sometimes exploit its compatibility with strong nucleophiles to remove PF6-, replacing it with tetrafluoroborate or perchlorate depending on desired final properties. Side reactions, especially hydrolysis, must be controlled to prevent release of HF, a safety concern in scale-up.

Synonyms & Product Names

Among professionals, the common acronyms include TBPFP, [P4444][PF6], and sometimes TBPPF6. Catalogs sometimes also cite the compound as tetrabutylphosphonium PF6, or designate it with its full systematic name, Tetrabutylphosphonium hexafluorophosphate. Some manufacturers add trade dress or code numbers, but the molecular formula (C16H36F6P2) quickly resolves ambiguity. Academic work leans toward the elegant bracketed notation, easing publication and database indexing.

Safety & Operational Standards

Safety officers recognize TBPFP’s relatively low acute toxicity, but nobody in the lab drops their guard; Fume hoods remain standard for transfers and weighing, protecting staff from accidental inhalation. TBPFP poses minimal fire risk but demands vigilance due to the potential for hydrolysis-generated hydrofluoric acid, especially during waste disposal. Spills call for gloves, goggles, and non-metal scoops, and must head straight to hazardous chemical bins. Facilities set airborne exposure limits lower than those for standard organic solvents, erring on the side of caution due to the persistent nature of PF6-. Cleanup follows strict protocols to avoid trace contamination, especially before any high-purity application. Documentation and adherence to OSHA and REACH standards drive good practice, keeping staff and downstream users safe.

Application Area

Electrochemists find themselves reaching for TBPFP when constructing nonaqueous batteries or running precise voltammetric measurements. It sets the standard in supercapacitor electrolyte mixes, offering high ionic mobility while resisting thermal breakdown. Organic chemists appreciate its role as a phase transfer catalyst, helping stubborn reagents react across immiscible boundaries or drive alkylations and Michael additions to completion. Fluorine chemists often rely on TBPFP as a template for anion exchange experiments, searching for new materials with advanced magnetic, electronic, or optical properties. Some environmental engineers investigate its capacity to stabilize hazardous metal ions, capturing them before they escape into water supplies. Even in pharmaceutical labs, its salt-forming ability with basic drugs can tailor solubility or absorption profiles, although more studies are still needed before widespread adoption.

Research & Development

Labs worldwide continue to tweak the TBPFP recipe, searching for ways to lower production costs, increase purity, and minimize waste. Electrochemical researchers experiment with cation chain length, investigating whether switching butyl to longer or branched groups improves conductivity or reduces toxicity. Others mix TBPFP with different anions, hunting for the perfect combination of solubility, ionic strength, and environmental profile. Some teams are testing immobilized TBPFP derivatives on polymer backbones, aiming to make “solid” ionic conductors for flexible sensors and microelectronics. Computational chemists have taken a turn, modeling structure-activity relationships to guide new synthesis strategies or predict reactions with emerging contaminants. Collaboration with industrial partners remains strong, since the need for scalable, sustainable electrolytes only increases by the year.

Toxicity Research

Toxicologists approach TBPFP with appropriate caution. Animal studies reveal low oral and dermal toxicity at the concentrations normally encountered in industrial and lab settings, but longer term chronic data remain sparse. Ecotoxicity profiles show slow breakdown in aquatic environments; the PF6- anion resists microbial attack, raising concerns about bioaccumulation in water bodies. Ozone depletion and greenhouse gas release are not major issues, but persistent residues in soil or groundwater drive demand for careful containment and disposal. Some recent work investigates whether TBPFP or its hydrolysis products disrupt endocrine pathways in aquatic invertebrates, prompting new risk assessments before municipal or environmental-scale applications move forward. Personal experience in chemical safety training reinforces how important it is to anticipate not just obvious acute hazards, but subtle, chronic ones that might emerge with heavier use.

Future Prospects

Prospects for TBPFP look bright compared to some legacy chemicals facing stricter regulation. As the push for safer electrolytes and high-performance ionic liquids accelerates, TBPFP stands ready to play a larger part, especially in next-generation batteries or as part of novel catalysis platforms. Researchers remain on the hunt for modifications that improve its environmental break-down without sacrificing stability. Advances in green chemistry could soon allow for TBPFP synthesis with less waste, fewer hazardous reagents, and greater atom economy. Startups exploring recyclable electronics and flexible sensors see value in robust, non-volatile salts like this one. With a strong track record in diverse applications and ongoing support from both industry and academia, TBPFP's story continues to unfold, inspiring both curiosity and caution from the growing community of chemists and engineers.

The Role of Ionic Liquids in Modern Chemistry

Tetrabutylphosphonium hexafluorophosphate often appears in the world of chemistry as an ionic liquid salt that stands out for its flexibility and unique properties. In my own work in research labs, the excitement surrounding ionic liquids comes from their ability to dissolve a wide range of substances and operate at temperatures that don’t destroy delicate compounds. Traditional solvents struggle with this task. Chemists like to work with materials that bring efficiency to reactions and keep things as safe as possible, and this compound does both. Instead of giving off harmful vapors or catching fire easily, this salt can keep a low-key profile while handling heavy-duty tasks.

Electrochemistry’s Reliable Partner

Electrochemical devices and experiments depend on reliable electrolytes. Tetrabutylphosphonium hexafluorophosphate steps into this role for batteries, capacitors, and even advanced sensors. In these applications, the goal is to move ions quickly and stably, without the risks that come from more volatile chemicals. I’ve seen firsthand how researchers prefer these salts in lithium-ion and supercapacitor labs. They’re drawn to their ability to hold up through many charging cycles, making devices safer and lasting longer.

Supporting Green Chemistry Initiatives

A big movement in academic and industrial labs focuses on cutting down hazardous waste. Tetrabutylphosphonium hexafluorophosphate helps because it doesn’t evaporate easily and can be reused in some cases. These qualities fit perfectly into green chemistry goals. Nobody wants to fiddle with dangerous solvents if there’s a cleaner route – especially with stricter safety rules in place. This salt can carry the load as a dissolver or supporting agent in catalyst systems, often making reactions cleaner and easier to separate from products.

Catalysis and Organic Synthesis

Synthesis chemists lean on tetrabutylphosphonium hexafluorophosphate to run tricky reactions that might fail in water or common solvents. Its unusual ion setup can stabilize charged reaction partners, shifting chemical reactions in directions not possible otherwise. Over the last decade, researchers have published studies where the molecule jumpstarts couplings, oxidations, or reductions that unlock better yields. My colleagues and I talk about how useful these “designer” salts have become for finding new synthetic shortcuts.

Challenges and Safer Strategies

Not every story with an exotic chemical ends in triumph. Supply chain hiccups, rising costs, and safe disposal headaches can complicate work with specialty salts. Phosphonium-based salts sometimes carry concerns about toxicity if mishandled. In the lab, I’ve learned the importance of glove use and careful disposal, since hexafluorophosphate ions can pose environmental risks if poured down the drain. To address this, some labs have shifted toward biodegradable or less hazardous alternatives, and researchers keep hunting for replacements that work just as well.

Steps Toward a Balanced Approach

On one hand, tetrabutylphosphonium hexafluorophosphate opens doors in high-performance batteries and eco-friendly chemistry. On the other, it reminds everyone that better chemicals bring new safety questions. Strong guidelines, clear labeling, and thorough training must go hand in hand with technical innovation. As industries turn to more specialized molecules, everyone wins by keeping a close eye on both the benefits and the risks.

Understanding the Hazards

Tetrabutylphosphonium hexafluorophosphate sounds intimidating—and it should. Anyone who has mixed chemicals in a lab or spent time in research knows not every compound deserves equal respect, but this one asks for caution. Working with phosphonium salts teaches a quick lesson in chemical safety because the risks aren’t just stories we read about in textbooks—they play out in labs every year. Handling this compound without preparation can lead to skin burns, eye irritation, and—if fumes are inhaled during a spill—a coughing fit that doesn’t fade quickly.

Personal Protection Means Everything

Start with gear. Lab coats don’t just keep the principal happy; they help shield your skin. Nitrile gloves hold up better than latex when working with organic salts like this. I’ve worked with dozens of gloves over the years, and nitrile stands up longer before breaking down. Face shields or tight-fitting safety goggles matter too. Eyewash stations matter most when you hope you never use them—just knowing they’re nearby builds confidence.

Keeping the Lab Air Clean

Labs without proper fume hoods spell trouble. Years spent in university basements and postdoc labs drives home the point: letting this phosphonium salt vaporize means inhaling something you’d rather not. Pouring, mixing, and transferring always happen under a running hood. It’s loud, and sometimes it gets warm, but at least breathing stays safe. Spills still carry risk, but working under extraction keeps the worst out of your lungs.

Storage Is More Than Stacking Bottles

Never store this compound near strong acids or open flames. A shelf set aside for volatile salts, far from common acids and flammables, keeps things tidy and safe. Uncleared clutter once led my bench mate to bump a bottle and nearly tip it—tight storage shelves and clear labeling can prevent a dozen headaches down the road. Close and label containers every time; it beats searching for a mystery powder.

Dealing with Spills and Waste

If the salt escapes, don’t scramble. Absorb small spills with inert material—vermiculite works best—then scoop into a sealed bag for disposal. Large spills? Leave and call trained staff for help. For waste, flag it for the hazardous pickup crew. Don’t pour it down the drain or leave it by regular trash; traces in municipal water cause problems beyond your lab.

Training and Mindset

Lab safety doesn’t start with rules—it grows from experience. I’ve seen a grad student pour a liquid too quickly and splash his gloves, hear him curse, then shuffle to the sink. Training drills aren’t just hoop-jumping. Practicing a spill response, knowing where every shower or eyewash sits, or timing yourself getting from one end of the lab to the door—all that makes a difference when adrenaline hits.

Focusing on Solutions

Labs do better by updating chemical inventories and reviewing procedures every semester. Fact sheets, posted in plain sight, help jog memories. Promoting a culture where people feel comfortable reminding each other about PPE and safe practices leads to fewer accidents and a friendlier workplace. It’s not about being paranoid—it’s about building trust, staying healthy, and getting the real work done without needless risk.

What Brings People to Tetrabutylphosphonium Hexafluorophosphate?

Folks deep into chemical research bump into names like Tetrabutylphosphonium Hexafluorophosphate. The name sounds like a mouthful, but break it down, and you see a chemical shaping industries, labs, and experiments around the world. Anyone wading into ionic liquids, electrolytes for batteries, or specialty syntheses runs across this compound.

The Formula That Sets It Apart

Dive into its roots: its chemical formula reads C16H36PF6. Picture four butyl chains locked to a phosphorus atom, all facing off against a tough and stable hexafluorophosphate anion. This blend creates a salt that resists water but loves nonpolar solvents, which is why so many chemists reach for it.

The molecular weight stands at 372.43 g/mol. That number matters in the lab, since every milligram drives calculations for reactions, yields, and purity checks. In practice, a mistake on this number can throw off a whole batch.

Why This Compound Sits at the Center of Innovation

Anyone working in modern chemistry knows not every salt works for every job. Try running a lithium-ion battery, and ordinary salt falls short. Use Tetrabutylphosphonium Hexafluorophosphate, and you find something against shoddy conductivity and limited temperature range. Its ionic liquid roots drop the freezing point, cut volatility, and open doors to stable, safe batteries and capacitors.

Pharmaceutical chemists use it to separate tricky compounds. Its structure lets it outcompete lots of weaker, old-school salts. In the green chemistry world, people value that it swaps out hazardous solvents for something friendlier, ticking a big box for safety and sustainability.

Handling Challenges and Risks Head-On

Chemicals worth using come with risks that can’t be ignored. For Tetrabutylphosphonium Hexafluorophosphate, one big caution hides in its handling. Like many fluorinated salts, mixing moisture and this salt can trigger hydrolysis or kick up corrosive byproducts. A pair of gloves and a dry-box turn from luxuries to must-haves. Most labs stick strict protocols whenever someone cracks open a container.

On top of that, waste management calls for paying attention. Fluorinated byproducts spark questions about long-term exposure and environmental buildup. These concerns have pushed researchers to hunt for ways to recycle or recover used materials, aiming for a cleaner, safer workflow.

Making Smarter Choices in the Lab

Responsible chemists weigh benefits against real-world drawbacks. Shifting to Tetrabutylphosphonium Hexafluorophosphate in a synthesis means balancing performance with health and safety. Training and real experience beat out abstract warnings. Student chemists, especially, learn fast when they actually run the numbers, check the scales, and spend time testing for purity.

Good practices start simple: proper labeling, solid personal protection, sealing up bottles, watching waste—these habits matter. Paired with more research, including support from trusted peers and up-to-date science literature, anyone working with this salt can get strong results without trading off health or workplace safety.

Looking Forward

Chemicals like Tetrabutylphosphonium Hexafluorophosphate show the need for a thoughtful approach—using what works, tossing what harms, and never forgetting the reasons behind each choice. The molecular weight and formula lay out the facts, but real experience and honest care drive progress.

A Chemical With Unmistakable Risks

Tetrabutylphosphonium hexafluorophosphate, often called TBPPF, brings value to research and industrial labs. This salt plays a role in synthesis work, catalysis, and battery projects. If you keep this chemical on the shelf, real risks follow. The hexafluorophosphate anion carries potential for releasing toxic fluorides, especially when it runs into moisture or strong acids. My familiarity with handling specialty reagents in chemistry labs guides every point in this advice.

Store Dry, Store Cool

Water and TBPPF never mix well. Exposure to humidity or a stray water droplet triggers slow hydrolysis, breaking the stuff down and liberating hydrogen fluoride gas. HF gas attacks glassware, gloves, and skin with little warning. A tightly-sealed bottle remains vital, preferably under dry nitrogen or argon, inside a desiccator. Anyone who’s cracked open a bottle left in the air too long has noticed the stinging odor and sometimes a lumpy mass instead of free-flowing powder. Rigid habit saves you: return the container to an airtight, labeled spot without delay.

Temperature Influences Safety

Heat shortens the lifespan of many ionic salts. I smell trouble if TBPPF finds its way to a shelf near a hot reactor or windowsill. Temperatures above room level accelerate decomposition and sometimes cause the bottle to bulge if gas builds up inside. Safe storage means keeping the chemical in a temperature-controlled cupboard, often at 2–8°C. Revelations from lab incidents have shown even a summer heatwave threatens if the air conditioner conks out. Refrigerators, purpose-built for chemicals, pay for themselves with the reassurance they provide—though keep food well away for safety and regulatory reasons.

Material, Labeling, and Isolation

Not every container works. Plastic types like HDPE earn a nod, since glass reacts with HF if hydrolysis happens. I always trusted polypropylene vials for small stocks. Clear, tough labels, resistant to solvents and smudging, prevent mix-ups. It’s too easy to grab the wrong bottle in a rush, so bold labels listing hazard codes, opening date, and contents protect everyone. TBPPF never belongs next to strong acids, bases, or oxidizers. Spend two minutes thinking about shelving order, and crisis often stays away. Segregate by hazard, not just alphabet.

Vigilance Beats Complacency

Years in chemistry taught me that emergencies start the moment routines fade. Inspect containers for cracks, hardened caps, or pressure build-up before use. A leak shows up as a white crust or odd odor—get that sorted as soon as possible, using gloves and a fume hood. Dispose of old or degraded material in line with hazardous waste rules; flushing anything with hexafluorophosphate down the drain is reckless and illegal.

Caring For People and Places

Good chemical storage stands as an act of respect: for your health, the safety of colleagues, and the integrity of your lab or workplace. High-stakes materials like TBPPF demand routines and habits, not casual shortcuts. Information on the safety data sheet stays right at the bench, easily grabbed if questions arise. Storing TBPPF with mindfulness limits the chance of nasty surprises—everyone goes home in better spirits, and the science continues without regrets.

Digging Into the Basics

Tetrabutylphosphonium hexafluorophosphate, with a tongue-twisting name and an impressive set of uses, regularly pops up in labs and industries working on advanced chemical syntheses. The buzz around this compound often circles back to one basic question: where does it dissolve, and why should anyone care?

Solubility seems like a dry detail, but it sets the stage for an entire experiment or industrial process. I’ve watched promising ideas stall just because the chemistry didn’t check out in the solvent that was available or allowed. So, knowing if a substance like tetrabutylphosphonium hexafluorophosphate dissolves in water or sticks to organics isn’t academic; it’s practical, and it has real economic consequences.

Water vs. Organic: The Choice Shapes Results

This compound doesn’t play nice with water. The hexafluorophosphate anion, paired with the bulky tetrabutylphosphonium cation, means it just won’t mix in an aqueous environment. Sticking some of this salt in water leads to a cloudy mess or a layer that hovers on top, not the clean solution most scientists want. Try to force it, and valuable time goes down the drain.

Things turn around in organic solvents. Drop tetrabutylphosphonium hexafluorophosphate into something like acetonitrile or dichloromethane, and it goes right in. The solution clears up fast. That match between the hydrophobic nature of the tetrabutylphosphonium cation and organic solvents helps create a stable environment for the compound to do its job. I’ve watched colleagues get frustrated with water solubility for other salts, but here, organic chemistry gives a clear advantage.

Why Solubility Sets the Rules

Being soluble in organics and not in water determines where and how researchers or industry can use tetrabutylphosphonium hexafluorophosphate. In the lab, this property guides every step: from planning electrolytes for batteries, to making ionic liquids, to running certain types of separations. Chemical engineers working on renewable energy storage or specialty reactions often choose tetrabutylphosphonium hexafluorophosphate because of this very solubility profile.

Pick the wrong solvent and you can get clumping, poor yields, or reactions that plain won’t go. I’ve been there, swapping solvent after solvent, wasting hours waiting for something to dissolve. It gets expensive, both in material and time. Beyond the lab, industrial settings care, too. Moving to a new process might mean rewriting safety protocols or investing in solvent recovery, which can change profit margins fast.

Beyond the Beaker: Environmental and Safety Issues

The push for “green chemistry” brings up other questions. Using organic solvents often raises concerns about flammability, toxicity, and disposal. Some old-school solvents work well, but handling them safely takes a solid plan backed by training and strong oversight. Water, by comparison, seems safer, but in this case, it won’t do the job. That means looking for organic solvents with low toxicity and high recoverability, and keeping up with regulations that keep changing in response to new research and public pressure.

Lab directors and industrial chemists can’t ignore the rules. They track exposure levels, set up ventilation, and push for solvent recycling. It’s not just about doing the job, but doing it right. That responsibility falls on everyone from the bench scientist to the floor manager.

Looking for Smarter Solutions

Researchers search for new solvents or tweak existing molecules, aiming for high performance and lower environmental impact. Solvent selection charts, team meetings, and pilot runs all play a part in finding a suitable match. Sometimes I’ve seen the answer in unlikely places, like ionic liquids or hybrid systems designed to improve both safety and efficiency. Keeping up with new solvents, including those with better recovery rates and lower hazards, helps balance good science with smart environmental decisions.