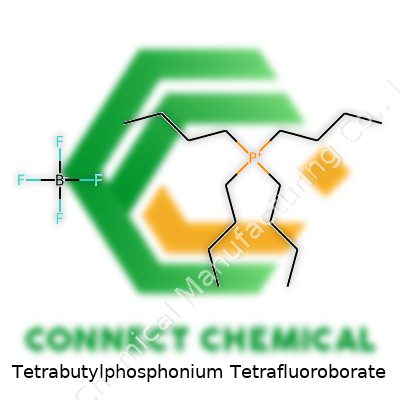

Tetrabutylphosphonium Tetrafluoroborate: An In-Depth Look

Historical Development

Chemists first took a keen interest in ionic liquids like Tetrabutylphosphonium Tetrafluoroborate in the late twentieth century. Unlike water or volatile organic solvents, these salts remain liquid at room temperature. Researchers wanted options with low volatility and high chemical stability. Early work on quaternary phosphonium salts and various borate compounds led to the discovery of substances offering both thermal stability and broad solvency potential. Through this, Tetrabutylphosphonium Tetrafluoroborate carved out a spot for itself, carried by advances in electrochemistry and green chemistry movements over the past few decades.

Product Overview

This compound often comes as a colorless or faintly yellow liquid or a crystalline solid, depending on conditions. Manufacturers package it under tightly sealed, moisture-resistant containers. It finds its way from research labs to manufacturing sites, thanks to its unique mix of properties that scientists and engineers routinely count on for both experimentation and full-scale industrial process optimization.

Physical & Chemical Properties

Tetrabutylphosphonium Tetrafluoroborate, chemical formula [P(C4H9)4][BF4], delivers a solid blend of characteristics. It possesses a melting point typically below 100°C, with some batches sitting near room temperature as thick liquids. The salt doesn’t emit a strong odor, and its density usually floats around 1.0 to 1.1 g/cm³. Its notable thermal stability sets it apart from similar phosphonium salts, resisting decomposition under moderate heat. Its ionic nature makes it highly soluble in polar solvents like water and acetonitrile but shows only modest affinity for non-polar solvents. A big appeal lies in its electrical conductivity and its resistance to vaporizing, which is one reason why safety experts flag this group as less prone to accidental release compared to volatile, flammable analogues.

Technical Specifications & Labeling

Buyers and laboratory managers look for clear quality markers, including assay (usually above 98%), moisture content, and impurity thresholds. Proper product labeling includes the chemical name, batch number, net weight, supplier information, and hazard pictograms. Labels warn about the possibility of eye and skin irritation, and MSDS sheets go further into proper storage, usage, and first aid practices. Accurate mass balance, lot tracking, and traceability have become industry standard as part of safe chemical management, with barcoded containers providing real-time checks in most professional settings.

Preparation Method

Most industrial synthesis of Tetrabutylphosphonium Tetrafluoroborate starts with tetrabutylphosphonium halides, typically chloride or bromide. These salts undergo metathesis, where the halide reacts with sodium or potassium tetrafluoroborate in an aqueous medium. After stirring and phase separation, the ionic liquid tends to reside in the denser bottom layer. Repeated washings with water eliminate leftover starting salts. Final drying happens with vacuum application. This process tends to be scalable and reliable, using common reagents. Careful handling remains crucial, as traces of water or acid can break down the tetrafluoroborate ion or introduce unwanted byproducts.

Chemical Reactions & Modifications

Tetrabutylphosphonium Tetrafluoroborate shows a knack for maintaining stability in the presence of strong acids and bases, though high temperatures and strong nucleophiles can break the BF4⁻ ion, sometimes generating toxic byproducts like boron trifluoride. This phosphonium salt can also serve as a phase-transfer catalyst, helping shuttle ions between immiscible phases. It rarely participates as a nucleophile due to steric bulk around its phosphorus atom, but can sometimes undergo partial alkylation or dealkylation with suitable reagents. Chemists often tweak the phosphonium moiety to adjust solubility or tailor its suitability for a particular reaction system.

Synonyms & Product Names

On product lists, this substance turns up as TBPBF4 or Tetrabutylphosphonium Tetrafluoroborate, sometimes under its CAS number, with trade names set by specialty chemical suppliers. The "quaternary phosphonium ionic liquid" label crops up in technical literature, especially when discussed in comparison to its ammonium or imidazolium peers.

Safety & Operational Standards

Direct contact with Tetrabutylphosphonium Tetrafluoroborate brings risks of skin and eye irritation. Inhalation of vapor or fine particulate should get avoided. Lab safety data sheets recommend working with gloves, goggles, and in ventilated areas. Storage away from strong acids and moisture holds particular weight as hydrolysis creates boron trifluoride and other hazardous gases. Spillage cleanup prioritizes absorption with non-combustible, inert material followed by proper disposal as chemical waste. Handling this salt according to OSHA, REACH, and globally harmonized standards are best practice, proven to reduce workplace incidents.

Application Area

Engineers in electrochemistry use Tetrabutylphosphonium Tetrafluoroborate as an electrolyte in supercapacitor research, benefiting from its thermal stability and wide electrochemical window. Separation scientists lean on it as a solvent for liquid-liquid extraction of rare and precious metals, counting on its low vapour pressure and high selectivity. It features in catalysis as a medium for transition-metal-catalyzed reactions and biotransformations, along with playing supporting roles in polymer processing and pharmaceutical intermediate preparation. In green chemistry circles, its use shows how chemical processes can cut down reliance on VOCs—decreasing environmental footprint and operator exposure.

Research & Development

Academic labs continue mining the properties of Tetrabutylphosphonium Tetrafluoroborate for applications in ionic liquid-based chromatography, batteries, and fuel cells. Industry pilots have tested its role in large-scale organic transformations, water purification, and carbon capture. Over the past decade, publications have pointed toward its solid electrolyte behavior, solvent tunability, and potential for selective extractions. Research dollars flow into customizing the phosphonium group for wider solubility windows, investigating mixed ionic liquid systems, and studying synergistic effects with other classes of room-temperature ionic liquids.

Toxicity Research

Studies seek to nail down environmental and biological toxicity. Early toxicity screens show limited acute toxicity through oral or dermal exposure, but chronic exposure remains poorly characterized. Degradation products, especially under high heat or strong base, may threaten aquatic organisms or human health through boron-based byproducts. Ongoing work with zebrafish and rat models measure bioaccumulation, organ burden, and excretion pathways. To date, industrial exposure cases remain rare due to strict material handling controls, with most incidents traceable to improper waste disposal. Follow-up studies are charting metabolic fates in soil and water, covering the broader implications for widespread adoption.

Future Prospects

The future for Tetrabutylphosphonium Tetrafluoroborate looks promising, especially if green energy and sustainable chemistry trends keep their momentum. Battery development teams are testing ways to use it as part of stable, high-voltage electrolytes—aiming to empower longer-lasting devices. Selective solvent extraction for recycling precious metals from electronic scrap stands ready to scale up as technology matures. Process chemists see more industrial uses if cost and toxicity hurdles get cleared by further research. Continuous tweaks to the bounding phosphonium structure might unlock new application fields, while regulatory scrutiny will spur ongoing improvements in safety data transparency and environmental impact studies. The compound sits in the thick of the conversation on how to modernize chemistry for a lower-carbon, less hazardous world.

The Silent Workhorse in Chemical Applications

Tetrabutylphosphonium tetrafluoroborate rolls off the tongue like a mouthful of marbles, though most chemists just call it a kind of ionic liquid. You won’t bump into it at the hardware store or splash it around in an art studio. This compound sticks close to research labs, manufacturing floors, and places where people shape the future of technology, not just fill a shopping cart.

Ionic liquids, like this one, have knocked open a lot of doors for chemists. They stay liquid at room temperature, don’t catch fire as easily as many solvents, and stand up under tough conditions. That opens several paths for handling tricky reactions, especially when safety plays a part. The biggest impact I’ve seen comes in the field of electrochemistry. Tetrabutylphosphonium tetrafluoroborate helps move electric charge smoothly in batteries and supercapacitors. Many lithium-ion batteries need a medium for ions to travel between terminals. This is where ionic liquids step in—doing the heavy lifting while reducing risks of leaks or catches fire.

Better Reactions, Cleaner Processes

Industrial chemists depend on solvents to run reactions. The trouble with traditional organic solvents comes from their tendency to catch fire, pollute the water, or stink up the whole lab. This compound’s thermal stability and non-volatile nature work in its favor, letting industries clean up processes where possible and cut down on hazardous emissions. It’s not completely green, but it shapes a step toward safer chemical manufacturing.

In organic synthesis, it often acts as a solvent or as a phase-transfer catalyst—a term for helping chemicals mingle that wouldn’t normally mix. Picture a water-oil salad dressing that mixes more easily: the reaction goes faster, wastes drop, and purifying the finished material sees fewer headaches. In my time shadowing chemistry grad students, I witnessed some breakthroughs in reaction yield, all because the solvent knew how to play nice.

Potential Troubles on the Path Ahead

No chemical comes with a free lunch. Handling this substance without care raises questions about toxicity and environmental persistence. While traditional solvents shoot into the atmosphere, some ionic liquids hang around longer, sinking into soil or water if spills go unchecked. Policymakers, especially in Europe, already track the safety profiles of these liquids. Labs who take shortcuts on waste disposal risk bigger headaches down the road—fines, cleanup costs, even tighter regulations.

Researchers constantly size up the tradeoff between function and footprint. That often means designing ionic liquids that break down easier or leave behind fewer worries. Transparency counts. Tech companies and chemical makers benefit from open data about what lands in downstream waste and how much gets recycled. Academic journals now push for details on disposal and reuse. Awareness spreads one publication, one partnership at a time.

Moving Forward with Smarter Choices

Plenty of industries look for performance gains, especially when every drop of solvent counts. Since this phosphonium salt does the trick in batteries, drug synthesis, and even advanced coatings, its footprint in factories probably grows in coming years. Engineers and policy experts need to decide where tradeoffs land. Investing in research that tackles risk and reward means companies won’t find themselves boxed in by future environmental or safety rules.

Down the road, the smartest outfits will choose not just the best performer, but the compound that fits a longer view—safer workers, cleaner streams, and a supply chain that stands up under scrutiny. In chemistry, as in farming or building, being a good neighbor carries weight. That lesson holds true for substances like tetrabutylphosphonium tetrafluoroborate—out of sight for most, but not out of mind for those shaping tomorrow’s technology.

Understanding a Niche Chemical

Tetrabutylphosphonium tetrafluoroborate doesn’t show up in mainstream conversation. You likely won’t see a bottle of it at a grocery store. Its reputation gets built in research labs and the industries dealing with ionic liquids, electrochemistry, and green solvents. Scientists started taking a closer look at it years ago, wanting safer, more efficient alternatives to old-school solvents. People wanted a less volatile, more manageable option. Tetrabutylphosphonium tetrafluoroborate quickly caught their eye.

Stability in the Day-to-Day

Let’s focus on regular room conditions, around 25°C, low humidity, and no wild swings in pressure. Based on published research and some hands-on lab time, this salt holds up well. The molecule resists breakdown unless you expose it to moisture or excessive heat. Air doesn’t bother it immediately. Spills or left-out samples in a dry, cool lab rarely cause headaches the next day.

Ions like these often dodge the risks that come with flammable organic solvents. The tetrafluoroborate anion does react with lots of water over time, giving off corrosive and toxic fumes—hydrofluoric acid lurking as an invisible threat. That’s not a common hazard unless labs get sloppy, though. Through reports like the Safety Data Sheet from Sigma-Aldrich and studies in Green Chemistry and Journal of Physical Chemistry, it’s clear—handled dry and cool, the chemical doesn’t break down or catch fire by itself.

Why Stability Matters

The stability of a chemical shapes how people use it. For ionic liquids, uses keep growing, from batteries to pharmaceuticals. If a substance falls apart or catches fire just because it’s sitting out, no industry wants it. Safe storage means companies cut costs on special containers and can handle bigger amounts without extreme training. It helps drive research without someone worrying about a shelf turning into a danger zone overnight.

Most ionic liquids present low volatility and don’t evaporate quickly, reducing the risks that come from inhalation. From an environmental perspective, stability lessens the chance of accidental contamination and keeps the substance contained. That means less risk inside labs and factories, where spills become rare events rather than regular crises.

Addressing Real-World Risks

No chemical is free from trouble. Over time, storage conditions can shift. Moisture sneaks in through unchecked lids or humid air. That’s when the risk begins—hydrolysis starts, releasing gases that no one wants in their face. That’s why I always made sure desiccators and gloveboxes got sealed tight in my academic days. Even well-behaved salts, left alone, can turn rogue if care slips.

Solutions come down to habits, not high-tech answers. Use airtight bottles, keep workspace dry and ventilated, check for contamination if supplies sit too long, and always keep protective gear close. Training shouldn’t be boring or brushed off—understanding why these protocols exist keeps people motivated. Teaching from personal close-calls and open communication has a stronger impact than just putting posters on a wall. If a substance only poses threats under certain conditions, build a system that never lets those conditions happen.

Final Thoughts

Tetrabutylphosphonium tetrafluoroborate stays stable if kept dry, cool, and away from water. Its reputation isn’t spotless—nothing in a lab is—but real trouble starts with neglect, not the chemical itself. Smart protocols, steady routines, and honest training will keep it in line and let researchers and industries explore its possibilities with peace of mind.

Understanding What’s at Stake

Tetrabutylphosphonium tetrafluoroborate (TBPB) has made a name for itself in the world of ionic liquids and specialty chemicals. Plenty of researchers count on its stability for synthesis, catalysis, and battery research. But real value comes when everyone follows storage basics—because chemical safety at the bench means more than good science; it means watching out for everyone around you. So, how do you treat TBPB with the respect it deserves?

Sensitivity: Don’t Turn a Blind Eye

Anyone who’s spent time with TBPB knows moisture eats away at its performance. Water can cause hydrolysis and generate unwanted byproducts. Speaking from bitter experience, opening a container on a muggy day quickly leads to degraded salt and unpredictable results.

Routine use of desiccators can make a huge difference in keeping this compound ready for action. If you work in a facility without a dry room, desiccant pouches in tightly sealed bottles deliver good results. Use glove boxes or transfer in low-humidity labs whenever possible. That extra care saves money and nerves during experiments.

Temperature: Keep the Heat Down

Heat breaks down phosphonium salts faster than most expect. TBPB sits best at room temperature or cooler, well out of direct sunlight or near hot equipment. I once made the mistake of leaving a bottle near a window in July—by the end of the month, the contents changed color, and yield tanked in synthesis runs. That’s not just annoying, it wastes grant money.

Storage at 2-8°C works well if you have access to a refrigerator or cold room—just be sure the container is tightly closed. Cold helps, but condensation sneaks in if you move materials between temperature extremes, so let bottles warm to room temperature before opening.

Handling and Labelling: Stay Organized, Avoid Surprises

Losing track of what’s in a bottle or how long it’s been open is a frequent cause of lab mishaps. Permanent labelling with a date and source matters more than many admit. Over the years, clear labeling made post-incident reporting easier and kept me out of hot water with health and safety. Always write dates. Write concentrations if you prepare stock solutions.

Spills remain a real hazard. TBPB isn’t friendly to bare skin. Disposable gloves and lab coats, at a minimum, make cleanup smooth. If you ever forget PPE, burns and skin irritation won’t let you forget again.

Ventilation and Containment Matter

TBPB dust and vapor cause discomfort and sometimes lasting harm. Work in a fume hood whenever possible. Airflow and local exhaust remove accidental releases or residues from spills. Store bottles in secondary containment to catch leaks. It’s easy to forget, but a simple plastic tray caught a leak for me once and avoided a bigger headache.

Disposal: Respect the Environment

Never treat TBPB like ordinary trash or drain waste. Collect leftovers or expired stocks for hazardous waste pickup. Many universities and industry sites run chemical waste programs; use them. In the long run, environmental safety builds trust with the public and keeps the lab running without fines or shutdowns.

Rising to the Challenge

Working with chemicals like TBPB always calls for a respect for details and a culture of safety. Talk to co-workers about handling practices. Stay organized. Simple investments in storage bags, desiccants, and better tracking keep TBPB—and the team—reliable and safe.

The Risks Behind the Chemical

Tetrabutylphosphonium tetrafluoroborate can look pretty tame—a clear, oily liquid—but looks don’t tell the full story. Inside research labs or industry setups, I’ve seen folks get a little too casual with it. Somewhere in the rush of running a reaction or making up a solution, it’s easy to forget that even small spills can eat away at your skin or trash that expensive glove you just pulled on. This stuff offers no forgiveness if it finds a cut or scrape.

What the Data Says

There’s enough data from the manufacturers and chemical safety boards: inhalation or skin contact leads to irritation, sometimes even burns. The phosphonium cation used here means it doesn’t stay benign in contact with your skin or mucous membranes. Its tetrafluoroborate anion can break down, leaving behind boron trifluoride, which is even nastier around water—vapor that burns your lungs if you breathe it in, or eyes streaming from just a quick whiff.

Precautions That Actually Matter

What usually helps is building a system by habit, not just ticking items off a lab checklist. Gloves—nitrile or heavy-duty rubber—go on before the bottle comes off the shelf. Lab coats should fit snug at the cuff, and sleeves shouldn’t drag over open vessels. Most folks in the real world skip goggles for glasses, but I learned the hard way after one mishap that a single splash to the eye tops the worst late-night headaches.

Work in a fume hood. This isn’t just about moving air; it protects you if the liquid spits or a flask tips. I have seen fume hoods save more than one person from a ruined shirt, or worse, a trip to the ER. Keeping the hood sash pulled down as far as your arms allow gives you another layer between your face and the chemical.

No Eating, Drinking, or Guessing

The stories I could tell about people sneaking snacks into a lab. Any food around these chemicals ends up risky—residues linger on benches, gloves, notebooks. Hand washing with good soap before touching your face or phone feels basic, but every lab accident report includes that step for a reason.

Label bottles with large, clear writing. Mistakes show up when unlabeled glass looks like ordinary buffer or solvent, but the outcome turns way more serious. Keeping logs of what you opened, poured, or handled cuts down on the “wait, what is this?” panic that flares up when bottles pile up at the end of a long day.

Managing Spills and Disposal

Spill kits don’t help if they’re pushed to the back of the cabinet or hidden by cardboard. Setting up those kits so they’re not just “close” but actually within arm’s reach saves crucial seconds. Pads, neutralizers, and absorbents go a long way if you know where they are and how to use them.

Waste disposal means more than tossing everything in a red bin. Collect all contaminated materials—gloves, pipette tips, towels—then seal them in a labeled waste bag. Local regulations in most places require proper documentation for halide and phosphonium disposal, so finding and following those rules beats scrambling if the inspector drops by or an accident happens.

Reinforcing the Culture of Safety

I’ve seen labs that run routine training sessions—not for show, but to drill in good habits. It’s one thing to hear a safety talk on your first day; it’s another to join monthly refreshers led by people who’ve worked with these liquids for years. Questions flow, real-life examples pop up, and everyone gets a little sharper.

Tetrabutylphosphonium tetrafluoroborate doesn’t give many second chances. The more we rely on habits and honest sharing of risks, the safer the bench—and everyone behind it—stays.

Chemistry Isn’t Just For Scientists

Tetrabutylphosphonium tetrafluoroborate—a tongue-twister, no doubt—does more than just sit on a lab shelf. The people who ask about solubility usually have a reason: research, industry, or maybe just curiosity. See, solubility tells a big story about how a chemical can fit into real-world work. If a substance dissolves in water, it fits with processes used in everything from electrochemistry to materials science. If it shies away from water, folks need new tactics.

Getting Down To The Facts

This compound comes from a family called ionic liquids. Most ionic liquids rebel against water—they’re happier in their own world, away from polar liquids. Tetrabutylphosphonium tetrafluoroborate isn’t an exception. It has large, nonpolar butyl groups making up the “tetrabutylphosphonium” side, and that lowers its desire to mix with water. Published research and chemical databases repeat the same thing: this salt shows poor solubility in water. To get it to dissolve, you’d need strong agitation, high temperatures, and even then you’ll end up with a pretty cloudy mix.

If you really dig into it, the core problem comes down to hydrogen bonding. Water thrives on forming hydrogen bonds. Ionic liquids like tetrabutylphosphonium tetrafluoroborate don’t offer great partnership; their structure only gives up a limited show of polarity. As a lab worker, I once tried to dissolve it in a flask of distilled water—the end result looked more like a snow globe than a true solution. Most of it stayed as chunky white sludge, refusing to blend.

Why Should This Matter Outside The Lab?

It’s easy to brush off questions about specific chemicals as nerdy trivia. In practice, though, these things set the stage for innovation. Take battery research. Scientists love ionic liquids for their stability and low volatility; they want them for next-gen power cells. Water content plays a big role in stability, especially for safety and performance. If the ionic liquid doesn’t blend with water, you avoid water-driven breakdown but give up on simple processing. The same story holds in organic synthesis, catalysis, and even wastewater treatment—each field has to tailor its processes because these salts won’t play ball with water.

From personal experience, people waste hours trying solutions that seem promising on paper. I’ve sat in cold labs watching colleagues grind away, mixing, shaking, and heating these salts. The lesson comes clear: accept their nature, and plan solutions around their quirks.

Looking Beyond Water

Instead of trying to force water solubility, research tends to shift toward finding better solvents or modifying the structure. Organic solvents like acetone, acetonitrile, or even alcohols treat this compound much better. Some researchers tweak the structure—maybe swapping out a butyl group for something smaller or more polar, hoping to squeeze out more solubility. It’s about working with the cards you’re dealt, not fighting the basic rules of chemistry.

Anyone dealing with these chemicals needs real information, supported by experience and trustworthy references. The solubility question might seem small at first glance, but knowing the answer stops wasted time, failed experiments, and even dangerous mishaps. Chemistry rewards the persistent, but it also favors the prepared.