Tetradecyldimethylbenzylammonium Chloride Hydrate: A Close Look

Historical Development

Disinfectants play a crucial role in everyday life, and Tetradecyldimethylbenzylammonium Chloride Hydrate (Benzalkonium Chloride, or BAC) didn’t land in cleaning solutions by accident. Back in the 1930s, scientists started looking into quaternary ammonium compounds as options beyond soaps and ethanol to fight bacteria. BAC sprang from research aimed at combating infectious disease in hospitals and food processing plants, where hygiene stakes are high. Over time, knowledge about microbial resistance pushed chemists to refine BAC’s formulations and combinations, increasing potency for diverse settings. Shifts in public health priorities—like MRSA outbreaks or urgent pandemic responses—pushed this compound further into the spotlight. Generations have learned to trust that bottle of cleaner under the sink, but the development wasn’t just about convenience; it responded directly to urgent health and safety needs.

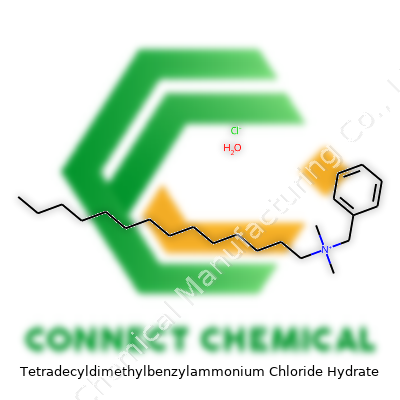

Product Overview

For anyone digging into cleaning supplies or industrial sanitizers, BAC stands out as a staple. It’s a colorless, solid hydrate, usually packaged as a white powder or granules that dissolve easily in water. The market caters mainly to formulators needing steady antimicrobial action, simple handling, and storage. Stability in both commercial and household products has made it a regular go-to for surface wipes, sprays, and even cosmetic preservatives. Healthcare, hospitality, and even agriculture rely on it. Experience in the lab shows that BAC blends well with water and certain alcohols, letting companies turn out a dazzling range of formulations, each designed for real-world scrubbing and sterilizing tasks.

Physical & Chemical Properties

Looking up close, BAC Hydrochloride has a solid character, melting at moderate temperatures, often around 242-245°C (decomposition point). It dissolves easily in water and alcohol, producing solutions that remain clear and odorless—a big advantage compared to pungent alternatives like bleach. The molecule itself, C23H42ClN·xH2O, carries a long, hydrophobic tail joined to a positively charged ammonium head, which lets it cling to bacterial membranes. That makes for aggressive microbial knockdown, but it also means BAC can’t survive strongly oxidizing conditions, limiting certain chemical pairings. Its cationic nature helps it hang onto surfaces, giving longer-lasting protection than basic alcohol wipes.

Technical Specifications & Labeling

Manufacturers post clear guidelines on BAC’s concentration and permissible contaminant levels. For most applications, concentrations fall between 0.05% and 0.2% for use as a disinfectant—strong enough for surface cleaning, diluted enough for safety. Labels specify purity, water content, and batch data for traceability, meeting government and trade guidelines. From a practical standpoint, companies stamp drums and canisters with hazard codes, directions for safe mixing, and disposal advice to keep workers and end users squared away. International transport rules set extra limits, especially for bulk quantities. Labs run frequent assays—chloride titration for identity, IR spectra for impurities—because deviation directly affects performance and safety.

Preparation Method

Synthesis in industry usually starts with long-chain alkyl chlorides, reacting with dimethylbenzylamine under controlled heat and pressure. Water attaches as the hydrate, stabilizing the final product against air and light. Labs insist on high-purity reactants to dodge side reactions, keeping leftover alkylamines or chlorides minimized for safety. Chemists vent excess pressure and purge with nitrogen in closed vessels to control exotherms—heat-ups that can degrade BAC if unchecked. Commercial yields run high if process steps track closely, but scale-up brings its own set of challenges, like waste stream handling and keeping residual solvents below regulatory cutoffs. Ultimately, the recipe walks a fine line between robust chemistry and worker safety.

Chemical Reactions & Modifications

BAC’s structure opens doors for tweaking its antimicrobial spectrum and compatibility. Chemists sometimes swap the alkyl chain for longer or shorter versions, tailoring performance for specific germs—longer tails increase potency but can decrease solubility. Adjusting counterions or blending with other surfactants sharpens performance in hard or soft water. In spill response, BAC breaks down under high heat or in the presence of strong acids, letting firms neutralize residues before environmental discharge. These modifiable features make BAC more adaptable than single-payload molecules, helping users find the right fit across cleaning, preservation, and personal care products.

Synonyms & Product Names

Over the past decades, BAC has picked up a crowded roster of names: Benzalkonium Chloride, BZK, and ADBAC, among others. Even seasoned professionals bump into different trade labels—Zephiran, Quatra, and Roccal show up on datasheets for hospital and industrial brands. Each product reflects minor tweaks: hydrate status, concentration, or blended additives for specific market needs. This can lead to confusion without careful attention to label details. Companies that work across borders often need to check local chemical registries, as some names dominate in North America, others in the EU or Asia. For anyone ordering raw materials, double-checking synonyms keeps mishaps and delivery delays out of the workflow.

Safety & Operational Standards

BAC doesn’t mess around with safety. The compound’s irritation risks for eyes, skin, and lungs put tight boundaries around handling: gloves, goggles, and splash-resistant aprons are the baseline in my lab or any bottling line I’ve visited. Spills can mean more than a ruined shirt; concentrated BAC harms mucous membranes, so emergency eyewashes and quick-access showers stay close. Regulatory agencies like OSHA and ECHA set exposure limits and disposal rules, holding firms to high standards. Labels remind users to avoid mixing BAC with strong oxidants, acids, or cleaning chemicals like bleach—mix-ups can produce toxic fumes. Fire risk usually stays low, but improper disposal turns BAC into a water pollutant, wiping out aquatic life. Training and regular inspection make the real difference between safe operations and costly accidents.

Application Area

BAC’s all over the place if you know where to look: hospitals run it through floors, surgical tools, and patient rooms to cut down infection risk. Swimming pools and spas use it in shock treatments because it beats back mildew and algae growth that regular chlorine leaves behind. In food plants, BAC lines conveyor belts and storage bins, beating out Salmonella and E. coli to keep outbreaks off the news. My years in chemical distribution showed me that BAC’s also a quiet hero in salons—preserving shampoos and conditioners, and keeping hands-off bacteria from multiplying in bottle dispensers. Farms, veterinary practices, and HVAC duct cleanings count on it, too. Since BAC stays active for hours, not minutes, it wins out where quick-drying alcohol sanitizers can’t reach.

Research & Development

Academic work hasn’t let up on BAC, with researchers probing its limits and side effects. Studies now focus on microbial adaptation, as bacterial resistance threatens nearly every disinfectant that’s ever worked. Newer projects explore using BAC in nano-formulations—tiny droplets carried in sprays or wipes that increase surface contact and punch through biofilms bacterial colonies put up to shield themselves. Surveying consumer feedback helps companies fine-tune fragrance, skin feel, and even trigger packaging, so nobody pours too much and spoils a surface. Engineers chase improvements in production yield, solvent recovery, and blending speed, knowing every tweak helps bring safer and more effective products, all while reducing cost and waste.

Toxicity Research

No honest look at BAC can brush aside its health trade-offs. While low levels in consumer products stay safe, concentrated BAC triggers severe toxicity—eye injuries, chemical burns, or even respiratory problems if fumes build up in closed spaces. Studies confirm BAC is more toxic to aquatic life than many common surfactants, raising red flags for wastewater management. Animal studies suggest long-term exposure leads to skin sensitization, and some researchers have linked overuse to rising resistance among hospital pathogens. Disposal rules now require neutralization or high-temperature incineration for bulk BAC, closing off old-school practices that polluted waterways. As a chemist, I trust but never underestimate BAC. Gloves and goggles aren’t optional.

Future Prospects

Disinfectant science rarely stands still; new pathogens, tighter regulations, and sustainability pressures keep BAC reformulation projects on the table. Firms invest in greener versions that break down faster in the environment or pack similar punch at lower doses. Some labs push for hybrid blends—pairing BAC with organic acids or essential oils, stretching its range without hiking toxicity. Digital tracking—from RFID-tagged drums to smartphone app compliance logs—tightens regulatory control. As concerns over bacterial resistance spread, companies back alternative sanitizers or BAC replacements for the sectors at highest risk. Experience suggests BAC won’t vanish soon, but it will shape and reshape itself as demands change, making every bottle a product of science, vigilance, and new ideas.

Behind the Big Name

Most folks run across cleaning products with some tough-sounding ingredients printed in tiny letters on the back label. One of those long names, tetradecyldimethylbenzylammonium chloride hydrate, finds its way into hospitals, restaurants, and, lately, home disinfectants. Reading that name doesn’t give away much, but people trust the results. Turns out, that faith is not misplaced.

Where It’s Found and Why It’s Used

I remember walking through a hospital corridor, catching a faint whiff of bleach and something sharper—one step into the janitor’s closet, and you’d see canisters with this compound’s long name on them. This ingredient pulls a lot of weight in infection control. It kills a range of bacteria, viruses, and fungi better than plain soap and water. It works by breaking down the walls of microorganisms, so germs don’t stand a chance of survival. It works fast, on counters, doorknobs, and even floors crowded with shoes every day.

Restaurants use it for the same reason. I used to help in a café where cutting boards and knives had to get cleaned every two hours. We’d soak everything in a solution that packed this compound—no corner cutting, since health inspectors paid surprise visits. More recently, during the COVID-19 pandemic, a lot of homes added quaternary ammonium compounds, like this one, to their cleaning routines, hoping to stop the spread of illness.

Trusting in Safety and Effectiveness

People want things to work, but also expect to stay safe. The Environmental Protection Agency keeps a close watch here. This compound appears on lists of registered antimicrobial pesticides, which tells buyers it went through reliability checks. New research from the Centers for Disease Control and Prevention notes these quats break down pathogens within just a few minutes—if people follow label instructions. That is a key point. If cleaning staff or homeowners mix too strong a solution, health risks can show up—skin irritation, eye redness, or, in rare cases, respiratory trouble. I learned early on to wear gloves and never mix cleaning products, since mistakes make things worse, not better.

Many cleaning experts encourage reading product labels closely. Wipes and sprays with tetradecyldimethylbenzylammonium chloride hydrate do a great job on hard, non-porous surfaces, but not every product works the same way on every germ. Some viruses need heavier artillery; some bacteria develop resistance. Proper usage makes all the difference. Overuse could contribute to resistant strains of bacteria, a growing concern according to reports in journals like Infection Control & Hospital Epidemiology.

Looking Toward Healthier Balance

Better safety comes from several angles. Staying up to date with research helps families and businesses make smart choices. Manufacturers can offer safer delivery methods—dilution systems, better packaging, clear labeling—so workers don’t get exposed unnecessarily. Organizations can rotate disinfectants, use physical cleaning along with chemicals, and build routines that don’t just rely on one solution.

Lessons from everyday use show how much responsibility sits with the person holding the cloth or mop. Using products like tetradecyldimethylbenzylammonium chloride hydrate makes spaces safer, but smart handling keeps both people and the environment out of harm’s way. Cleaning for health means paying attention, using just enough, and leaving things better than we found them.

Looking Beyond the Label

Tetradecyldimethylbenzylammonium chloride hydrate shows up in plenty of household disinfectants and industrial cleaners. It sounds complicated, but it’s no stranger to anyone using wipes or sprays promising to kill bacteria and viruses. These products make life cleaner, especially in homes with kids and pets, but the long words on the back of the bottle leave people a bit uneasy. So, how safe is this chemical around people and animals?

Human Exposure: Real Risks and Everyday Choices

Working in a veterinary clinic and growing up with pets meant keeping things sanitized. The products under the sink have ingredients like this all the time. Government agencies like the Environmental Protection Agency have called this compound a “quaternary ammonium disinfectant.” That’s a mouthful, but the science community usually shortens it to a “quat.” Quats kill microorganisms fast. Hospitals use them, schools spray them, and grocery stores rely on them too.

Short-term skin contact doesn’t always cause problems for most people. After years of cleaning cages or washing tables, skin occasionally turned red if I didn’t wear gloves, but actual burns or severe irritation were rare. Eyes, nose, and mouth tell a different story. Getting cleaning spray mist in the eyes stings sharply. People with asthma feel their chest tighten with heavy exposure. The Material Safety Data Sheet warns not to breathe in fumes or let the chemical touch sensitive skin for too long. Overusing these cleaners or skipping safety instructions increases risk. Spills on food prep surfaces that don't get rinsed off may leave a residue not meant to be swallowed.

Doctors warn about possible allergic reactions and even chemical burns if the liquid stays too long on the skin. Long-term impacts remain unclear for many “quats,” though some studies point to respiratory problems in workers using them all day. The key here lies in ventilation and limiting unnecessary exposure. Gloves, goggles, and basic common sense go a long way. Good handwashing matters after using any chemical cleaner.

Pets at Home: Special Precautions Matter

Pets tend to lick floors, paws, or anything that smells interesting. Dogs crawl through spots that just got mopped. Cats lick their fur after walking on a sprayed surface. I’ve seen animals at clinics with inflamed paws or upset stomachs after cleaners haven’t dried fully. Tetradecyldimethylbenzylammonium chloride hydrate shouldn’t go into pet bowls or bedding, and instructions often recommend keeping pets away from just-cleaned spots until everything is dry.

Veterinary toxicologists and the ASPCA remind everyone that “quats” commonly cause mild to moderate irritation. Swallowing higher concentrations leads to vomiting, oral ulcers, or more serious issues. Pet owners need to read the fine print, wait for surfaces to dry fully, and store bottles out of reach. If pets run through wet areas, rinse paws with plain water before they start grooming.

Cleaner, but Not Carefree

The modern obsession with disinfecting everything makes these chemicals a daily reality, but safety isn’t something to sweep under the rug. Use what you need, suit up for heavy cleaning, check that pets don’t stroll through sticky floors, and keep an eye out for any odd reactions—humans and animals alike. Companies could help by improving labels so anyone can get the picture without squinting at jargon. More research into long-term exposure might guide upstream changes in formulations too. Until then, keep it real by mixing cleaning with caution and don’t hesitate to ask your vet or doctor for guidance when in doubt.

Why Storage Matters

Many folks working in cleaning services, hospitals, or food processing have seen containers labeled with long, complex chemical names like Tetradecyldimethylbenzylammonium Chloride Hydrate. This compound, called a “quat” for short, helps to kill germs and fungus. Getting storage right isn’t just a bureaucratic exercise. Safe and smart storage protects people, safeguards the environment, and keeps the product effective.

Keeping the Chemical Stable

Moisture, heat, and sunlight break down many chemicals. Tetradecyldimethylbenzylammonium Chloride Hydrate falls into that category. I’ve seen what happens when bottles get left too close to a window or in a steamy supply closet. The liquid sometimes turns cloudy, and the product becomes less reliable. Manufacturers warn against storing it above room temperature, so a cool, dry, and shaded place makes sense.

Direct sun or warmth from pipes, radiators, or even heated warehouse floors can speed up degradation. In my experience, a straightforward shelving unit in a ventilated, interior space works much better than storing in a garage or near an outside wall.

Safe Containers and Labeling

Original manufacturer containers—think tightly sealed plastic bottles—usually keep out unwanted moisture and air. Some folks try transferring to glass jars or unlabeled tubs, but I’ve learned that this almost always causes more trouble. The lid might not seal well. People in the workplace forget what’s inside or how to mix it. Professional practice and basic OSHA rules point to this: leave Tetradecyldimethylbenzylammonium Chloride Hydrate in its original bottle, keep the label clear and visible, and tape a copy of the safety sheet nearby.

Avoiding Accidents and Mixing

Mixing up chemicals can go wrong pretty fast. A friend working maintenance once stored a quart of cleaner beside an ammonia solution. Someone looking for a quick fix grabbed both, and the fumes sent two coworkers to the emergency room. Never store quats beside bleach, ammonia, or acids. Separate shelves and bright hazard labels stop dangerous mix-ups.

If kids or untrained staff can reach storage areas, use locked cabinets. Chemical burns or inhaled fumes can cause lasting harm. Proper storage keeps everyone on site safer and cuts emergency calls.

Spill Control and Inventory

Leaks from cracked lids or bottles sometimes run across shelves or stain the floor. I’ve handled more than one sticky mop-up from forgotten containers. Place a plastic tray or shallow tub under bottles. If a leak occurs, the mess stays confined, and cleanup takes minutes, not hours.

Inventory management goes hand in hand with storage. Regular checks on condition, expiry dates, and bottle seals prevent surprises. Rotate stock so the oldest is used first, and dispose of anything past its use-by date.

Responsible Disposal

Unwanted Tetradecyldimethylbenzylammonium Chloride Hydrate shouldn’t go down the drain or into the trash. Local waste stations or chemical collection programs—often free—dispose of it properly. This keeps harmful runoff out of waterways and off fields. Following these disposal practices shows respect for both staff and the surrounding community.

Building Safer Habits

Simple habits form the cornerstone of good chemical storage. A spot away from heat and sun, sealed containers, separation from incompatible chemicals, and routine checks: these reduce accidents and waste. Staff training and clear guidelines do most of the heavy lifting. I’ve seen strong habits save property, health, and money, again and again.

About the author:This commentary draws on years of hands-on experience in facility maintenance and safety compliance, blending expert advice with lessons from real workplaces.

Understanding Product Directions

Grabbing a cleaner off the store shelf and wiping down the kitchen counter seems straightforward, but a lot hinges on using it at the right strength. Plenty of people, including me, have glanced at the back label, puzzled by technical terms and ratios like “dilute 1:10” or “use at 0.5%.” These numbers matter. They decide how well the product knocks out the germs lingering on that countertop.

Why Getting the Mix Right Truly Matters

Surface disinfectants usually use chemicals like sodium hypochlorite, hydrogen peroxide, or quaternary ammonium compounds. Taking household bleach as an example, the U.S. Centers for Disease Control and Prevention often recommends a 1:10 dilution, which means adding about one part bleach to nine parts water. That works out to a roughly 0.5% active chlorine concentration—enough for cleaning up after someone is sick or for combating outbreaks. Less-concentrated solutions—around one tablespoon in a quart of water, or 0.1% chlorine—work for routine maintenance like wiping down doorknobs and sinks.

Getting the numbers wrong can lead to two problems. Too weak a mix leaves bacteria and viruses behind. Too strong, and now the product could damage surfaces, cause eye or skin irritation, or leave behind strong odors. I've seen ruined tabletops and faded fabrics when folks used straight-from-the-bottle bleach on things that called for a gentler touch.

Trusting the Science

The science is simple. Higher germ loads need stronger mixes. Outbreaks in hospitals call for something robust, and recommendations often rise to 0.5% active chlorine or comparable concentrations for other disinfectants. For home and community settings, routines can stick to weaker solutions. The Environmental Protection Agency keeps lists of products that meet their standards, so checking there can save second-guessing.

Reading and Understanding Labels

Before pouring anything out, looking closely at directions is key. Disinfectant bottles list “contact time” and recommended dilution. Surfaces need to stay wet for a certain number of minutes—some require up to ten—to completely kill off pathogens. Skipping this step wastes effort and leaves infections on the table, literally. From my own cleaning habits, I learned early that quick wipe-downs do not always finish the job. A little patience pays dividends in reducing risk.

Supporting Good Habits With Information

Reliable product labeling and public health messaging help people get things right. Clearer instructions printed in plain language—not chemical jargon—make a difference. Schools, restaurants, and hospitals already use written protocols, but homes benefit from easier to understand guidance, too. Some companies have started adding dilution diagrams or visual infographics to their labels, which helps, especially for those not used to reading measurement units or chemicals.

Moving Toward Better Practices

Encouraging manufacturers to keep instructions user-friendly, and requiring clear labels from regulators, arms everyone with the tools for safer surface disinfection. Knowledge means fewer illnesses picked up from door handles and kitchen tables. In my experience, staying healthy sometimes boils down to reading a product’s fine print and following directions closely.

Why Handling This Chemical Takes Real Care

Working in labs and facilities where disinfectants and cleaning agents line the shelves, many folks run into chemicals most people can’t pronounce. Tetradecyldimethylbenzylammonium chloride hydrate, known in some circles as a “quat,” shows up in everything from hospital disinfectants to industrial cleaners. At first glance, it seems safe—no clouds of fumes, no strong burn on the nostrils. Still, I learned quickly that trusting looks can land you in trouble.

This compound carries a meaningful punch when it touches skin, eyes, or lungs. It pulls down bacteria and viruses like a champ, but it doesn’t care all that much about flesh and bone either. Once, during my early days cleaning animal labs, I found out that dry, irritated hands and cracked knuckles came from more than just too much washing. That telltale sting? It came from a careless splash.

Skin and Eye Contact: A Real Risk

Quats like this one can chew up the oils and natural protection our skin provides. When handling solutions or concentrates, gloves are not an option—they’re a necessity. The typical latex or nitrile options do the job. Chemical-resistant gloves stop the compound from soaking through. Goggles matter too. Liquid sprays and splashes go for the eyes. Redness, pain, or more serious injuries stack up fast if you miss this step. Once, a distracted colleague brushed his hand across his eye after wiping a spill and chased soreness for days.

Breathing It In: Not Just a Worry for Chemists

If you think you’re safe just because the stuff isn’t a fuming acid, think again. Fine droplets hang in the air when people spray or mist the solution, and those droplets can get sucked into the lungs. Irritation and coughing can catch up with you, especially after long cleaning sessions in rooms without airflow. Masking up with a basic surgical mask gives some shield, but for heavy use or poorly ventilated spots, respirators with multi-purpose cartridges cut down the risk.

Clothes and Spills: Don’t Shrug Off Safety

This chemical doesn’t stop at skin and eyes. Covered arms and legs prevent spills from sitting on skin. Lab coats or smocks aren’t just for nurses and scientists in movies—they’re practical gear. If you spill any solution, relying on paper towels won’t cut it. Soap and water flush the stuff off your skin. Washing your hands before you touch your phone, face, or lunch may feel repetitive, but it pays off.

Personal Experience and Hard Lessons

I have watched too many new hires rush right in, thinking a little chemical can’t do much. Then skin trouble and sore eyes teach the lesson the hard way. Training helps, but real habits—like reaching for gloves and not touching your face—stick with you after you see what a single careless moment can cost.

Fixing Gaps and Building Better Habits

Reading safety sheets and company rules puts you on the right path, though it’s easy to skim those pages. Regular checks on personal protective equipment, refilling gloves, and keeping goggles where people need them beat buying first-aid cream later. Ventilation upgrades and labeling help too, cutting down confusion about which products carry real bite. Building a safety-first mindset means seeing every bottle of this quat as a serious chemical with real impact—not just another name in the janitor’s closet. Those habits keep folks healthy and working day after day.