Tetradecyldimethylethylammonium Bromide: Past Paths, Current Practices, and Looking Ahead

Historical Development

Tetradecyldimethylethylammonium bromide didn’t just appear in a lab on a whim. Folks in chemical research circles have tinkered with quaternary ammonium compounds for over a century, driven by the demand for reliable antiseptics, surfactants, and specialty chemicals. The ammonium salt family, with those signature long hydrophobic chains, has attracted industrial interest since early efforts in controlling microbes and boosting formulation performance. Over decades, its structure–one long tetradecyl group, a couple of methyl sides, and a not-so-showy ethyl–came together based on both need and results, especially in those stretches where scientists needed both oil and water compatibility. These choices weren’t accidents, but results of trial, error, and pure necessity within an expanding chemical landscape. As the surfactant industry grew after the Second World War, demand for compounds like this one surged, and it became a familiar name in both lab notebooks and commercial catalogs.

Product Overview

You find Tetradecyldimethylethylammonium bromide in powdered or crystalline forms, generally showing up white or off-white thanks to high-purity manufacture. It doesn’t just sit on a shelf–it earns its keep in places where you need a tough, stable surfactant or a strong antistatic agent. Manufacturers focus on purity, hydration state, and shelf stability to meet varied application demands. Some formulations prefer granular consistency for easier handling, while other industries switch up packaging and concentrations. The real edge comes from its versatility—being friendly both to oil and water, it stretches its reach across many industrial uses, from cleaning agents to specialized research chemicals.

Physical & Chemical Properties

Take a closer look, and its physical personality sets it apart. You notice a melting point generally in the neighborhood of 145-155°C, which means it holds up fine in standard lab and industrial temps. Tetradecyldimethylethylammonium bromide dissolves easily in water and some alcohols, blending into clear solutions that work for both lab and process settings. The hefty tetradecyl tail keeps things hydrophobic, useful if you’re keeping things separated or building up surfaces. Yet, its positively charged ammonium head has an affinity for water, so it binds liquids on one end and oils or dirt on the other, a classic recipe for an effective surfactant. Chemically, this compound stands up to most acids and bases at reasonable concentrations and gives little trouble with common metals or container materials.

Technical Specifications & Labeling

Regulatory labeling doesn’t leave much to chance. Labels spell out not only the chemical’s name but its percentage purity, batch number, manufacture and expiration dates, as well as possible contaminant warnings. You catch hazard pictograms—irritant or environmental hazard icons—crop up in transport and storage documentation. Suppliers include recommended storage instructions—dry, cool, away from incompatible materials. For industry use, technical sheets back up the label, laying out purity specifications, particle sizing (for powders), and solubility ranges. All these details tick off both safety and performance boxes for regulatory auditors and bench chemists, laying the groundwork for consistent handling and legal traceability.

Preparation Method

Synthesizing Tetradecyldimethylethylammonium bromide isn’t much of a mystery to industrial chemists. It takes a specific alkylation sequence–introducing tetradecyl chloride or a similar linear alkyl halide to a base dimethylethylamine solution. The reaction pushes forward in organic solvents under gentle heating, sometimes with a catalyst for efficiency. After the quaternization hits completion, the new quaternary ammonium compound precipitates out, and purification starts: repeated filtrations, washing out any unreacted raw materials, and careful crystallization. Larger plants scale up with more controls, making sure byproducts stay out of the final product. Waste handling stands front and center–wash waters and solvent residues need treatment, another piece of the manufacturing puzzle.

Chemical Reactions & Modifications

The quaternary ammonium group resists most hydrolysis and oxidation, so Tetradecyldimethylethylammonium bromide handles a tough work environment. Chemical tinkerers sometimes alter the alkyl tails to tweak surfactant properties, like lengthening or branching chains to finesse surface tension, solubility, or foaming. Its bromide counterion swaps easily–putting other halides in place or even jumping to other anions for specialty effects. Strong alkalis break down the molecule if misused, but it doesn’t flinch in acidic or neutral solutions during regular use. In some research labs, the compound’s structure accepts fluorescent tags or binding agents, helping study membranes or transport proteins, thanks to its strongly amphiphilic character. These branches form the backbone of innovation, driving both products and papers.

Synonyms & Product Names

No shortage of alternate names: Tetradecyl(dimethyl)ethylammonium bromide, TDDEAB, and a few brand-specific codes pop up in industry catalogs. Some suppliers jump to stylized trademarks, while others stick close to the IUPAC convention. Researchers usually abbreviate names to avoid tongue-twisters in daily logs. Regulatory filings tend to use the most systematic names, but common trade reference checks keep synonyms easy to spot, avoiding supply mix-ups in high-stress settings.

Safety & Operational Standards

You don’t take safety for granted with quaternary ammonium compounds. Proper training covers both dust inhalation and skin contact, since exposure can irritate and sometimes sensitize. Standard operating procedures require gloves, goggles, and fume extraction—especially when handling powders or mixing in bulk. Spills mean immediate cleanup, not just for worker safety but also to avoid any slip hazards in damp conditions. Storage regs follow both fire codes and environmental rules, keeping incompatible chemicals at bay. Waste needs careful neutralization; you can’t pour residues down the drain without treatment, since the molecule’s environmental persistence raises alarms in water systems. Regular audits and training updates make sure handling doesn’t slip into backburner territory, especially in busy plants.

Application Area

Tetradecyldimethylethylammonium bromide pops up across industries, pulling its weight as an antimicrobial, a surfactant, and a specialty intermediate. The cleaning and sanitation sector banks on its power to break up grime and control bacterial growth—surface disinfectants, hospital cleaners, and personal care all draw on its abilities. Textile processes need antistatic agents during fiber processing, while oil recovery teams call up its surfactant profile to squeeze out hard-to-reach petroleum from stubborn rock beds. In laboratories, the compound finds new jobs as a solubilizing agent for biological samples, where balancing hydrophobic and hydrophilic tendencies pays off. Specialty coatings and adhesives also show interest where controlled surface properties matter, giving another niche to fill beyond everyday cleaning chemicals.

Research & Development

Whole swathes of research keep uncovering new uses and risks. Academic labs probe at Tetradecyldimethylethylammonium bromide’s potential in cell membrane studies, protein structure analysis, and controlled drug release, focusing on its amphiphilic character. Engineers tinker with modified derivatives for next-gen wipes, textiles, and coatings, looking to boost performance without raising toxicity. Environmental scientists flag persistence and bioaccumulation as growing concerns, which can drive research toward biodegradable alternatives or more easily reclaimable derivatives. Computational chemists model molecular interactions, while bench chemists synthesize new variants and run antimicrobial efficiency trials. Internally, companies invest in process improvements to squeeze waste and energy savings, partly out of profit motive and partly as regulatory pressure mounts. Every iteration adds fresh data, broadening both the knowledge and the critical feedback.

Toxicity Research

Data from toxicity studies carry real weight with regulators and industry. Acute exposure in concentrated form harms skin and mucous membranes, a risk seen in industrial mishandling and accidental releases. Chronic or repeated exposure may sensitize some individuals, and there’s growing attention on aquatic toxicity given the compound’s persistence and potency at low doses. Wildlife studies have pointed out harm to invertebrates and fish, further fueling restrictions in some regions. Human epidemiology stays limited because of controlled workplace conditions, but responsible operators take no shortcuts—closed transfer systems, engineer controls, and comprehensive PPE keep risks in line. Researchers work on fine-tuning both detection technologies and remediation protocols as part of ongoing risk management efforts.

Future Prospects

Future directions mix high hopes with grounded concerns. Regulations around environmental persistence and aquatic toxicity tighten as more data hits the table, and new legislative moves shape market access. The push for greener, more biodegradable alternatives forces both manufacturers and users to reckon not only with convenience but with real ecological trade-offs. On the technical front, optimized synthesis pathways, better recovery and recycling, and continued molecular modifications stand as clear targets for both economic and environmental reasons. Synthetic biology might someday offer greener routes to such compounds, sidestepping harsh chemicals. At the end of the day, balancing performance, safety, and environmental impact stays the driving force—each breakthrough reflecting lessons learned from both history and current research.

The Role of Tetradecyldimethylethylammonium Bromide in Cleanliness

Tetradecyldimethylethylammonium bromide ends up in plenty of cleaning products. It’s a quaternary ammonium compound—folks in the chemistry world just call these “quats.” In my time scrubbing out labs and hospital floors, I’ve noticed that quats like this one pop up as powerful disinfectants. This chemical attacks the cell membranes of bacteria and some viruses, making it hard for germs to stick around. During the pandemic, demand for strong disinfectants jumped, so quats became almost standard in everything from wipes to surface sprays. A lab-tested fact: quats knock out both gram-positive and gram-negative bacteria, which means they cover a lot of ground. Hospitals use this stuff in regular cleaning rotations for high-touch surfaces like bed rails and door handles, cutting down the risk of healthcare-associated infections.

Chemicals in Everyday Products: Out of Sight, Not Out of Mind

I once worked in a textile plant, and that's where I learned quats get added to fabrics as anti-static agents. Tetradecyldimethylethylammonium bromide stops static from building up, which matters for things like medical gowns, where a sudden zap of static electricity isn’t just annoying—it could be dangerous. It also helps as a softener, lending towels and sheets that plush feeling straight from the package. Home laundries use similar ingredients in dryer sheets. Many consumers have no idea they’re handling these chemicals every day.

Industrial Uses Shape How We Live

Factories use Tetradecyldimethylethylammonium bromide for water treatment and as an emulsifier in pesticides and paints. It helps oil and water mix long enough for paints or sprays to go on smoothly. These chemical helpers keep paint from separating in the can, so anyone can open a tin months after it leaves the factory and still get a usable product. On wastewater treatment sites, adding this compound can control bacterial growth in the system pipes and tanks. I’ve talked with engineers who swear by these additives to keep their systems running longer.

Safety Questions and the Push for Alternatives

Quats, including our topic chemical, don’t just vanish after use. Scientists keep an eye on their impact on waterways, especially since water treatment plants can’t always catch every molecule. Studies in the past decade point to possible toxic effects on aquatic life, including fish and tiny crustaceans. Some healthcare workers and custodians, after years of exposure, develop skin or respiratory illnesses. The problems point to a growing call for safer substitutes, especially in products used every day by regular folks.

The best path forward means balancing the cleaning power of quats with a responsibility toward health and the environment. People deserve to know what’s inside the bottles and packaging they touch all day. Labels need to share that info in plain language, and manufacturers should invest in research for chemicals that get the job done without building up in people or wildlife. Letting users make informed choices starts with clear facts.

Everyday Risks in the Lab and Workplace

Ask anyone working with chemicals, and they’ll tell you: safety doesn’t come from fancy protocols alone. It comes from knowing what you’re handling. Tetradecyldimethylethylammonium bromide goes by a long name, but it shows up quietly in research labs and sometimes in specialty disinfectants. Most folks outside of chemistry circles haven’t heard of it, but if you pour, mix, or measure compounds, this one stands out due to its surfactant and disinfectant abilities. The real question lingering is, can you just scoop it like sugar or does it demand respect? My experience veers toward respect.

What Science Says About Hazards

Scientists describe quaternary ammonium compounds (the family this chemical belongs to) as effective for killing bacteria and viruses. They’ve earned a spot in some cleaning products and industrial labs. Tetradecyldimethylethylammonium bromide brings that same punch, but risks come with the territory. Peer-reviewed studies and safety data sheets report it can cause irritation on contact with skin or eyes. Breathe its dust or vapor, and nose or throat irritation often follows. Long exposure multiplies that risk, and if someone accidentally ingests it, symptoms intensify—think nausea, vomiting, or worse.

Look through toxicological data, and the conclusion is clear: respect the chemical, and accidental problems drop way down. I once spilled a related compound on my hands. Even with a quick rinse, my skin went red and itchy for hours. Working with gloves isn’t paranoia; it’s just a lesson learned.

Safety Comes from Smart Habits

Lab safety isn’t a luxury. Gloves, goggles, and lab coats keep problems at bay. Ventilated spaces prevent particles from hanging in the air, reducing risk of inhalation. Experience says that skipping goggles to “save time” often backfires. Accidental splashes find eyes and skin at the worst times. Wash stations and eye showers shouldn’t gather dust; they exist because accidents happen.

The most reliable safety data comes from published research and regulatory guides like the Globally Harmonized System (GHS). According to those sources, using personal protective equipment (PPE) and practicing good hygiene guard against accidental exposure. Wash hands before breaks, never eat near workstations, label containers clearly—these aren’t just rules, they’re essentials.

Public Awareness and Worker Rights

Some workplaces treat chemical exposure as a fact of life. Workers, from custodians to research staff, trust their employers to follow safety standards. Laws require clear labeling and training, and honesty goes a long way. Skipping the safety review or storing chemicals improperly opens doors to health risks—sometimes with long-term consequences.

Health organizations and reputable sources recognize the need for balance. Avoiding unnecessary risks protects workers and the public, supporting trust in science and manufacturing. Building a safety culture relies on education, transparency, and real discussion. Accidents decline when people feel safe asking questions and reporting spills or reactions.

Practical Solutions for Safer Handling

Storing Tetradecyldimethylethylammonium bromide in tightly sealed containers, away from food or drink, makes sense. Frequent training—offered in clear language—helps everyone remember what’s at stake. Regular checks of ventilation and PPE supplies prevent complacency.

At the end of the day, science rewards curiosity but punishes neglect. If you don’t know what a chemical will do, read the data and ask questions. Handling this compound safely isn’t hard, but it takes attention, memory, and teamwork—three things no modern workplace should skip.

Understanding Why Proper Storage Matters

Storing chemicals like Tetradecyldimethylethylammonium Bromide never feels routine to anyone who has seen the kind of trouble that can pop up from a little bit of carelessness. This compound, found in plenty of labs, often sits in a container for months before use. A quick nod to storage protocol can mean the difference between a batch staying stable or breaking down into something unusable—or worse, hazardous. Years working around quaternary ammonium compounds taught me that heat, light, and moisture become your biggest enemies if you want clean, reliable results.

Simple Steps Make a Big Difference

Moisture loves to sneak into containers, ruining even the most straightforward chemistry work. Once clumping or caking starts, you can forget accuracy. Tetradecyldimethylethylammonium Bromide, like most salts of this family, starts to pick up water from the air if left exposed. Each time a jar sits open on a bench, the risk increases. Storing this compound in a tightly sealed bottle, with as little headspace as possible, cuts down on contamination. Glass or specialized plastic containers with gasket-lined caps work well.

A dry cabinet never feels like an extravagance for those who care about repeatable results. Silica gel packets tossed alongside the reagent give you an extra cushion of protection. Dropping the habit of setting bottles near sinks or water sources saves money and safety headaches down the line.

Keep Temperature in Check

Letting stored chemistry get too warm or cold often spells unnecessary trouble. Middle ground always proves reliable. At room temperature, between 20 to 25 degrees Celsius, most batches remain stable for long stretches. Labs with unpredictable heating or cooling should lean on temperature-logged storage areas.

Direct sunlight tends to heat up bottles and nukes sensitive compounds, including some quaternary ammonium salts. I’ve seen yellowing or outright spoilage from bottles left in sunny windows. Simple fixes like opaque storage bins or cabinets shield against those UV rays. Even cheap tinfoil wraps can extend shelf life if options run thin.

Labeling and Keeping Track

A clear, honest label saves more than one late-night experiment. Write the date you pulled the material from main stock; mark any special storage precautions right on the label. More than once, I’ve opened a bottle and discovered some bright spark swapped chemicals, risking cross-contamination—and an accident. Track batch numbers and suppliers too, since chemicals from different lots sometimes behave a little differently.

Sloppy recordkeeping turns even the most robust storage system into a guessing game pretty fast. Digital inventories make tracking changes simple. Double-check expiration dates at the start of each month.

Responsible Handling Builds Trust

Safe, predictable chemical storage builds trust across the entire research team. A smart approach avoids the headaches caused by spoiled reagents, contaminated reactions, or even health risks. Keeping Tetradecyldimethylethylammonium Bromide stable supports not just one lab but everyone downstream relying on solid, consistent work.

Learning from mistakes shapes a culture that values diligence over shortcuts. The best labs build small checks—tight seals, dry environments, proper labeling—into their daily habits without making a fuss about it. For anyone serious about quality chemistry, this extra attention always pays back.

Understanding What We’re Handling

Tetradecyldimethylethylammonium bromide doesn’t sound catchy, but it commonly pops up in industrial disinfectants, sanitizing sprays, and some specialty cleaning solutions. This compound works well for killing bacteria and viruses, which is exactly why it calls for a careful approach in disposal. Runoff or careless dumping puts both the environment and human health at risk. Water treatment plants aren’t equipped to filter out compounds like these efficiently, so pouring unused product down the drain can create toxic byproducts. Wildlife and aquatic organisms, sensitive to chemical residues, can suffer from exposure even at surprisingly low concentrations.

My Own Experience Around Chemical Waste

In college, a professor led our chemistry lab with firm rules for handling and discarding chemicals. One time, a classmate poured leftover quaternary ammonium compound, not unlike this one, into the communal sink. The professor halted the class. He showed us a stack of reports on groundwater contamination in local neighborhoods, linked back to improper lab disposal over the years. That stuck with me. Even a single bottle improperly dumped can contribute to bigger problems down the line—disinfectants like this persist beyond just the classroom.

Risks That Come with Poor Disposal

Domestic plumbing and public wastewater systems just aren’t built for specialty chemicals. Side effects range from damage to sewer infrastructure, up to poisoning of aquatic ecosystems. These compounds break down slowly, which means fish and frogs stand little chance if the wrong stuff moves through their water. Plus, improper handling can expose people to hazardous vapors or skin reactions. Each step of the way, risks ripple outward and don’t stop at your home or lab.

Practical Steps: Getting Rid of It the Right Way

If you find yourself with leftovers, reach out to your community’s hazardous waste facility. These centers know how to neutralize or safely store substances like these, keeping them out of landfills and waterways. Check state or city government websites; they often run household hazardous waste events. You can bring chemicals in their original containers, tightly closed, and staff takes care of the rest. At work, safety officers or environmental health contacts oversee chemical disposals. Letting them know about your stash helps everyone breathe easier.

If you’re not near a collection site, some specialty waste handlers offer pick-up services. I’ve seen businesses pool together for disposal days, sharing the cost and keeping compliant with local regulations. Before tossing anything out, always check the product’s Safety Data Sheet for details. The SDS lays out proper disposal methods and what not to do. Ignoring these guidelines can land people in legal or financial trouble—fines for improper waste handling add up fast.

Looking at Long-Term Solutions

Many manufacturers have started recognizing the environmental cost of their products, offering take-back programs or switching to less persistent chemicals wherever possible. Even municipalities are working to expand hazardous waste collection programs, making it less of a hassle for regular folks to do the right thing. Lobbying for better funding and public education strengthens these systems.

Safe disposal of something as specific as tetradecyldimethylethylammonium bromide means paying attention—reading the fine print on containers, asking local facilities, and never treating it like standard trash. The road to responsible chemical management runs through everyday choices and local action.

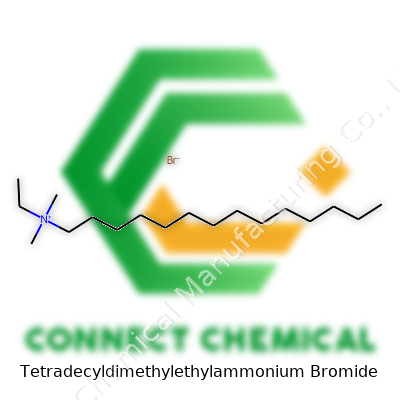

The Chemical Formula

Tetradecyldimethylethylammonium bromide sports the formula C16H36BrN. Looking at those numbers, you spot sixteen carbon atoms, thirty-six hydrogens, one bromine and a nitrogen. It’s a mouthful — but each part points to exactly what this compound does and why chemists use it all over the world.

The Structure Behind the Name

If you’re into chemistry, the name does half the work. “Tetradecyl” signals a fourteen-carbon tail, which is long and greasy, while the “dimethylethylammonium” part means two methyl and one ethyl group attached to nitrogen, tying into its role as a quarternary ammonium compound. Bromide tags on at the end as the counterion. This structure gives it both hydrophobic (fat-loving) and hydrophilic (water-loving) properties, making it a powerful surfactant.

The Surfactant World

From a practical stance, surfactants like this one help keep oil and water from going their separate ways. I’ve met plenty of people who never realized how much their daily routine relies on compounds like this, from that shampoo lather to hospital surface cleaners. Blame—or thank—this chemical family for that squeaky clean feel. Tetradecyldimethylethylammonium bromide sits in disinfectants, fabric softeners, and antiseptics because it takes care of germs and grime efficiently.

Why the Formula Matters in Real Life

In healthcare, fights against bacteria and viruses never quit. Disinfectants based on this compound can punch holes in microbial membranes and wreck pathogens that spread disease. It’s no coincidence that you’ll find quarternary ammonium compounds everywhere you look in hospitals. I remember following strict cleaning protocols far before the COVID-19 pandemic, but demand for strong, broad-spectrum surface cleaners hasn’t slowed since then.

The food industry and water treatment plants count on this molecule for similar reasons. The chemical formula isn’t just a string of letters and numbers on a label—each atom determines exactly how this chemical disrupts cell membranes and carries away grease. The long hydrocarbon tail drills into fat and dirt, and the charged nitrogen grabs onto water, dragging the mess away.

Safety and Environmental Impact

But every powerful tool comes with responsibility. Evidence points out that overuse of quarternary ammonium compounds can drive resistance in microbes, similar to how some bacteria resist antibiotics. Environmental studies suggest this class of chemicals can linger in wastewater and harm aquatic life. Wastewater treatment doesn’t always grab every trace of these compounds. The formula that makes them sticky in stains also makes them stubborn floaters in the environment.

Balancing benefits with risks calls for careful measures. Switching to the lowest effective concentrations for routine cleaning, improving disposal practices, and researching biodegradable alternatives can lower the footprint. Leading scientists have flagged the need for stricter monitoring and education, especially in hospitals and the food industry, since misuse can do more harm than good later down the road.

Looking Ahead

The legacy of tetradecyldimethylethylammonium bromide grows with every bottle of sanitizer and bulk drum of industrial cleaner sold. At the same time, the industry faces mounting evidence about long-term ecological effects. Engineers and researchers keep pushing for greener, less persistent alternatives to strike a new balance between cleanliness and caution. For now, every drop that hits a surface proves how closely chemistry ties to healthy living—and how every formula tells a bigger story than the name on its label.