Tetradecyltrimethylammonium Bromide: A Closer Look at a Functional Surfactant

Historical Development

People started working with quaternary ammonium compounds a century ago, shifting away from older soaps that couldn't handle hard water very well. Early researchers noticed the strong surface-active qualities of alkylammonium salts and their promising use in cleaning, textile processing, and other technical applications. Tetradecyltrimethylammonium bromide—sometimes called TTAB—gained ground as a key surfactant in the 1940s as chemists learned more about tailoring molecular structures for specific physical properties, such as foaming power and anti-static effect. Laboratories and factories adapted recipes over time, moving from laboratory bench to ton-scale. Regulatory bodies stepped in around the 1970s, as the environmental and health impact of such compounds drew attention, bringing in more rigorous handling and labeling requirements.

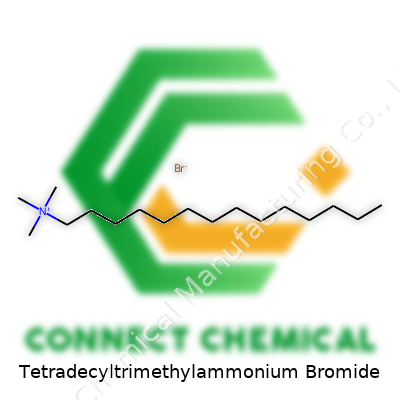

Product Overview

TTAB shows up in labs and industry settings as a reliable cationic surfactant. Its molecule carries a fourteenth-carbon hydrocarbon tail and a charged ammonium head matched with a bromide counterion. The structure allows it to anchor at interfaces, reduce water surface tension, and change how water interacts with oils or particles—it’s hard to overstate the difference this responsibility brings compared to conventional soaps or nonionic surfactants. From cleaning up oil spills to prepping DNA samples in a research lab, TTAB remains a preferred pick.

Physical & Chemical Properties

Handling TTAB, you find a white, sometimes slightly off-white powder, sometimes sold in crystalline or granular form. Its characteristic melting point sits near 240°C, indicating solid thermal stability compared to shorter-chain analogues. TTAB dissolves in both water and alcohol, and once dissolved, the solution feels slippery, much like other surfactants. The key performance lies in its surfactant behavior; it lowers surface tension at concentrations as low as 0.02%, and forms micelles above its critical micelle concentration, which for TTAB typically falls between 2 and 5 mM depending on water purity and temperature. The positive charge on its nitrogen atom gives it an edge in applications like emulsification, antimicrobial formulations, and analytical chemistry, where interactions with negatively charged surfaces and molecules matter.

Technical Specifications & Labeling

Suppliers usually present TTAB with purity between 98% and 99%, confirmed by titration or chromatographic analysis. Labels specify the product’s UN number (UN 2811 for toxic solids), CAS number 1119-97-7, recommended storage in tightly sealed containers, and a clear warning about its corrosive nature. Most shipments follow guidelines under US OSHA and European CLP standards. Enterprises purchasing TTAB for industrial or research uses must comply with labeling requirements, including signal words, hazard pictograms, and statements covering both acute toxicity and chronic exposure risks.

Preparation Method

TTAB production runs by reacting trimethylamine with 1-bromotetradecane. The process usually involves mixing the two reactants under inert conditions, often in a closed, temperature-controlled vessel to prevent escape of the volatile amine and minimize exposure to concentrated alkyl halides. Manufacturers commonly rinse and recrystallize the crude product from organic solvents to meet stringent chemical purity, ensuring consistent surfactant performance during end use.

Chemical Reactions & Modifications

Once made, TTAB can be further modified to suit application-specific challenges. The quaternary ammonium head group remains relatively stable under most reaction conditions but can be swapped with different alkyl or aryl chains for altered solubility or surface activity. Some specialty derivatives emerge from exchanging the bromide ion with others like chloride or iodide, delivering slight shifts in solubility and charge-transfer properties. In organic synthesis and research, TTAB occasionally becomes a phase-transfer catalyst or a template ion in self-assembling systems. I’ve witnessed the versatility of TTAB firsthand during colloid preparation—its ionic head drives the formation of well-defined nanoparticle dispersions, crucial for modern drug delivery research.

Synonyms & Product Names

Besides TTAB, this surfactant appears on labels or in catalogs as myristyltrimethylammonium bromide, TMTAB, or by trade names that combine company initials with the alkyl chain length. The variety of names reflects a range of sources—some from old chemical registries, others by specialty chemical manufacturers. Researchers can run into confusion here, especially chasing down synonyms in older literature, but the unambiguous CAS number clears up most identification issues.

Safety & Operational Standards

Handling TTAB falls under high-risk chemical protocols. The powder irritates skin and eyes upon contact and creates respiratory issues if inhaled. Operators need gloves, goggles, and lab coats. Dust control—via fume hood or closed handling systems—cuts down on accidental inhalation. Cleanup requires attention as solutions and powders both disrupt aquatic life and persist in the environment. Disposing of TTAB waste involves following local hazardous waste protocols, neutralizing remaining chemical in coordination with environmental safety officers. Responses to accidental exposure call for immediate flushing with water and medical evaluation.

Application Area

Most use cases group into cleaning and disinfection, analytical research, and sometimes fine chemical manufacturing. TTAB’s antimicrobial punch makes it effective in hospital cleaning supplies and surgical scrubs, where surface activity and germ-killing power must combine. Laboratories apply TTAB for DNA extraction and protein assays, where lysing cell membranes without breaking down the delicate biomolecules inside matters a lot. Research into drug delivery systems often leverages TTAB micelles as vehicles to stabilize and carry hydrophobic drugs. Water treatment plants sometimes use TTAB-based formulations to knock out algae and bacteria that resist other controls.

Research & Development

Current research often explores TTAB’s self-assembly behavior—how its molecules flock together to form micelles, vesicles, or layered structures in solution. These properties have relevance for new types of catalysts, responsive coatings, and nanomaterial synthesis. Another hot area involves combining TTAB with other surfactants or polymers to tweak its charge, solubility, or interactions with biological membranes. Environmental chemistry labs keep investigating TTAB breakdown pathways, eyeing ways to reduce its persistence in water or soil after use. Not long ago, I worked alongside a team looking to replace non-biodegradable surfactants with TTAB analogues displaying faster breakdown in real-world conditions, but with similar performance in surface chemistry.

Toxicity Research

TTAB triggers toxic effects for aquatic life at low concentrations due to its membrane-disrupting qualities. Studies have tracked lethal thresholds in water fleas, fish, and some amphibians, pointing to a real environmental burden if manufacturers or end users flush TTAB out unchecked. Mammalian studies note irritant properties and, in high doses, can record neurological effects or organ damage, prompting strict controls in consumer and laboratory settings. Regulations demand detailed environmental risk assessments before large-scale use, especially where water bodies could see runoff or treated-waste discharge. Researchers actively seek ways to soften TTAB’s impact by working on faster biodegradation routes and developing guidelines for safer handling.

Future Prospects

The outlook for TTAB ties deeply to how society balances performance with environmental responsibility. As new legislation forces chemical suppliers and users to rethink toxicity and waste, TTAB’s status may shift, either toward modified forms that retain the benefits and shed some of the hazardous baggage, or toward greener replacements derived from plant-based hydrocarbons. Meanwhile, the research world keeps finding spin-off uses for TTAB in advanced materials, diagnostics, and even data storage technologies relying on controlled nanoparticle arrays. If practical chemistry can marry performance with safety, TTAB and its relatives might hold their ground or even expand, although the pressure to minimize environmental harm never really lets up.

Why Tetradecyltrimethylammonium Bromide Matters in Research and Industry

Tetradecyltrimethylammonium bromide, often called TTAB, might sound like a mouthful, but this compound finds a steady home in many labs and manufacturing floors. Its main strength comes from being a cationic surfactant. If you've ever washed greasy pans or tried to clean up an oil spill in a science class lab, the struggle comes down to getting two things that don't mix—oil and water—to cooperate. Surfactants help bridge that gap.

In my university days, professors used to stress the subtle art of picking the right surfactant. TTAB’s long alkyl chain lets it break up tough grime and help other ingredients blend together. This property turns out to be valuable in places ranging from chemistry classrooms to pharmaceutical plants.

TTAB in Science Shelves

Chemistry students get introduced to TTAB as a staple for preparing micelles—tiny bubbles that can trap oils or drugs in their core. This is more than a visual trick. Researchers use TTAB as a model system for studying biological membranes and drug delivery. Many studies cite its efficiency in solubilizing proteins and testing how molecules cross cell-like barriers. In one recent paper, researchers looked at how TTAB helps shuttle drugs across skin layers, making treatments more effective for conditions like eczema and psoriasis.

Another clear strength of TTAB shows up in analytical chemistry. Color-changing chemical reactions often need a surfactant to work properly. TTAB is chosen for these experiments because its ionic nature ensures that certain reactions go to completion, which keeps data consistent and reliable. I remember using TTAB in titration labs—it saved hours for the whole class, especially when working with hard-to-dissolve powders.

Stepping into Industrial Uses

Industries aiming for smooth cosmetics and stable cleaning products use TTAB for its thickening and stabilizing kicks. In personal care, its ability to break up oils helps create gentle shampoos and facial cleansers that actually rinse away daily dirt. Some toothpaste brands sneak TTAB into their formulas because it kicks up the foaming and helps spread the flavor around your mouth evenly. It keeps ingredients from separating, which means a smoother product from tube squeeze to final rinse.

The textile and paper sectors put TTAB to work for different reasons. Factories use TTAB to help dyes bond evenly onto fibers, which results in brighter colors that last longer through washing. Suspension of color is a recurring challenge in papermaking, and TTAB addresses that head-on by dispersing particles and reducing unwanted clumping. In electroplating, TTAB acts as a stabilizer, delivering shiny finishes to metals and electronics parts that need both function and a sharp look.

Concerns and Safer Handling

Just because TTAB works well doesn’t mean it’s risk-free. Direct exposure can irritate skin or eyes, and high concentrations threaten fish and other aquatic life. I’ve seen enough safety data sheets to know workers need proper gloves, goggles, and ventilation around this stuff. Disposal routines require careful planning to keep it out of streams and rivers. Some companies look for biodegradable alternatives, but replacing TTAB outright brings its own mix of technical and cost challenges.

As we use more household products and medical creams, the need to balance effective chemical helpers like TTAB with health and environmental impacts only grows. Smart innovation focuses on reworking product formulas to use less surfactant, recovering and recycling waste, and venturing into plant-based surfactants where possible.

The Real Story on Lab Safety and Chemical Risks

Tetradecyltrimethylammonium bromide sounds like something out of a chemistry textbook, but it shows up in a surprising number of places. From labs to cleaning agents and even personal care products, the odds are good that someone working in science or certain industries has run across it. The question people ask is blunt: Is it safe to handle? My years in chemical research labs and sharing bench space with eager undergrads saw this question bounce around during every safety briefing.

Skin Contact and Inhalation – Why PPE Isn’t Optional

No getting around it: this compound can irritate skin, eyes, and the respiratory system. Spend enough time reading safety data sheets, and you realize this isn’t just legalese. I’ve seen firsthand what ignoring gloves does. Even a small spill can cause redness and itching in minutes. Lab techs who skip goggles sometimes walk away with burning eyes or a trip to the eyewash station. Inhalation can hit you with throat irritation or a coughing fit. Chronic exposure brings a higher risk of lasting effects that nobody wants.

Facts Behind the Warnings

Studies show that direct contact can impact the skin’s protective barrier. Researchers have documented cases of dermatitis in workers around similar quaternary ammonium compounds. The Centers for Disease Control and Prevention lists skin and eye irritation among top warnings. The European Chemicals Agency also classifies it as hazardous for both skin and eyes, pushing for strict handling rules. If someone gets a strong enough whiff of dust or vapor, they may feel respiratory discomfort right away.

Why Proper Training and Ventilation Matter

Emergency rooms don’t fill up with chemical accidents because people are careless. The root of these incidents often traces back to rushed work or lack of training. Every student I’ve trained learns to respect these hazards. Ventilated hoods are standard for a reason. Good ventilation keeps vapor and dust from building up. Proper training means knowing not only what to wear but also what to do if a spill happens.

Making Labs and Workplaces Safer: Easy Steps

Simple fixes make a big difference. Gloves, goggles, and lab coats cut down the risk. A splash of compound that hits bare skin is much easier to clean from a glove. Eye protection acts as the last line of defense during an unexpected splash. Keeping food and drinks away from workspaces also keeps accidental ingestion off the table. Shower and eyewash stations close at hand mean quick responses when things go wrong.

Looking Beyond the Lab: Environmental and Health Awareness

Tetradecyltrimethylammonium bromide isn’t just a workplace hazard. Runoff from manufacturing or spills can harm aquatic life. For those who live near industrial sites, properly managed waste means a safer community. The Environmental Protection Agency monitors these chemicals for a reason—long-term buildup in soil or water could have ripple effects nobody can predict.

Practical Solutions: From Policy to Personal Habits

Clear labels, up-to-date training, and accessible safety gear protect workers better than any warning sign. Businesses owe it to their employees to invest in proper ventilation and spill clean-up kits. On a personal level, a habit of washing hands after handling anything chemical pays long-term dividends. Staying curious and reading updated guidelines keeps surprises to a minimum.

Understanding the Chemical

Tetradecyltrimethylammonium bromide stands out in research labs and industry due to its strong surfactant abilities. It often shows up in chemistry labs, helping separate solutions or improving detergents. This chemical looks like a white powder, almost odorless, but its safety demands attention.

The Risks Involved

Anytime I’ve handled chemicals like this, breathing space and spill control come right to mind. Tetradecyltrimethylammonium bromide can irritate skin, eyes, and your respiratory pathway. If left in an open jar or storage area, it draws moisture from the air and can clump together or dissolve where you don’t want it. Worse, it might react with strong oxidizers and kick up toxic fumes at high temperatures.

Building Smart Storage Habits

A dry, cool spot keeps it safest. Humidity triggers caking, which makes accurate weighing tricky and can even spark reactions. Pharmacies and labs prefer airtight containers that foolproof the seal. Screw-top bottles with gasket seals work, but I’ve also seen simple but clear “dry cabinets” that do the trick—just a plastic tub lined with silica packs.

This chemical doesn’t enjoy sunlight. Direct exposure can tinker with purity, so cabinets or dark glass bottles extend its shelf-life. My old supervisor backed up every new jar with taped temperature and date information, because stock rotation matters. If the material dries out or changes texture, it’s time to recheck safety data.

Temperature and Placement

Room temperature fits the bill unless your setup swings to extremes. No need for a fridge, but avoid heat sources—storing near a radiator or under a lab bench vent could tip the scale on safety. Toxic dust in the air is nobody’s friend, and vapor release lines up with higher temperatures.

Physical separation plays a bigger role than people expect. Any strong acids, oxidizers, or reactive powders sit on different shelves. Back in training days, mixing the wrong substances caused near misses more than once. Clear, labeled shelves and logs cut down on accidents.

Security and Access Control

Not everyone who walks through a lab or storage room identifies risks at a glance. Lockable storage cabinets block curious hands or those not trained in chemical handling. Keeping the room well-ventilated matters as a backup if dust or fumes do sneak past the container seal.

Handling Disposal and Accidents

Nobody likes thinking about emergencies, but spills do happen. Tight lids and secondary trays under jars help contain leaks. I once watched a teammate drop a half-full bottle—a quick-acting spill kit with absorbent pads stopped the mess before it spread. Waste or leftover material should always head to chemical waste containers, not the drain. Following regulations keeps trouble away from your colleagues, your plumbing, and the environment.

Room for Improvement

Even with good practices, reviews make the difference. Weekly checks for cracked lids or moisture build-up can stop a small problem from turning into a big loss. Training others and keeping up with local guidelines means no one stays in the dark. Every chemical, even one as common as tetradecyltrimethylammonium bromide, brings responsibility. Simple steps today protect everyone for weeks, months, or years down the road.

Digging into the Chemistry

Tetradecyltrimethylammonium bromide goes by the formula C17H38BrN. In simple terms, this compound contains a long alkyl chain with fourteen carbons attached to a trimethylammonium group, balanced by a bromide ion. That formula doesn't just provide a name—it reveals the way molecules line up, lock together, and interact with water or oils.

Why the Formula Matters

A molecular formula like C17H38BrN does a lot more than sit on a label. It shines a light on the behaviors and uses of this compound. The long carbon chain gives the molecule a hydrophobic tail, while the trimethylammonium head carries a strong positive charge. Pairing this charge with the negative bromide sets up the compound as a quaternary ammonium salt—popular in labs as a surfactant.

Knowing the exact formula helps workers in countless industries handle the substance safely. My time in the lab proved to me that having a firm grip on chemical structures prevents mix-ups and lets everyone keep results consistent. It doesn't sound glamorous, listing atoms in a formula, but there's no clearer way to know what goes on in a bottle.

Real-world Uses Drive Safety Concerns

Surfactants like tetradecyltrimethylammonium bromide help keep mixtures stable, break up dirt, and carry out chemical reactions. The formula reveals that the molecule can wedge itself into the border between water and grease. In water, the charged head plays nice with molecules that dissolve fast; the carbon tail dives into oily phases. This dual nature lets it spread out, lower surface tension, and scrub at stubborn stains.

But the formula isn't just information for chemists—it carries important clues for health and safety. Some quaternary ammonium compounds can irritate skin, breathing passages, or even disrupt cells at the microscopic level. Recognizing a bromide salt like this means handlers think twice about gloves, masks, and disposal. My work in research projects reinforced that lesson. Even a slight miscalculation—maybe from confusing similar-looking salts—raises accident risks. Tiny structural differences in the formula can change toxicity or how a material reacts in the body. So a clear written formula keeps the risks in sight from day one.

Improving Practices through Better Chemistry

Manufacturers, educators, and regulators all benefit when the formula makes it into the paperwork and training. For instance, the U.S. National Institutes of Health and European Chemicals Agency rely on accurate formulas to guide recommendations and identify hazardous reactions. Scientists referencing C17H38BrN get precise matches in databases and avoid costly mistakes.

Better chemistry starts with a strong understanding of what's in the bottle. Spelling out the formula sets the stage for smart choices from raw material handling straight through to waste management. In classrooms and factories, no one should have to guess. All it takes is one slip to cause a spill or harm someone’s health. Sharing and repeating the correct chemical formula may not sound thrilling, but it saves time, money, and keeps people safe.

Facts Support Better Decision-making

A molecular formula is more than trivia—it gives clear ground for risk assessment, experiment design, and environmental safety. Practicing good habits with formulas worked for my projects, and it holds up in industrial and educational labs everywhere. By prioritizing the right formula, we get better outcomes and protect communities—at work and beyond.

Understanding What’s at Stake

Tetradecyltrimethylammonium Bromide (TTAB) can show up in a surprising range of places. Most often, it finds use in industrial cleaning, cosmetics, and the laboratory. People who work with surfactants or research chemicals might recognize the name. The average person, though, rarely thinks about TTAB—unless something goes wrong.

Reactions in Real Life

Exposure to TTAB doesn’t just mean a minor irritant. On human skin, the compound can actually cause redness, burning, or even blistering. Eyes get it worse—one splash could mean severe irritation and vision problems. Stories from laboratory workers highlight immediate stinging and discomfort if they brush against a contaminated surface. Consumers who use certain cleaning products are sometimes surprised by a mild rash after heavy scrubbing. That’s not a coincidence; it’s the chemical at work.

Breathing in TTAB powder or vapors at a factory or in an unventilated lab has been linked with coughing, wheezing, or trouble catching a breath. Repeated exposure brings heightened risks—workers in production lines can develop chronic respiratory issues. In animal studies, chronic exposure produced nagging lung inflammation. It’s best not to ignore early warning signs like sore throat or chest tightness during projects involving this compound.

The Real Problem: Lack of Awareness

Many people think industrial chemicals only belong in factories. Yet, TTAB appears in shampoos or soaps for its cleaning ability. Cosmetic makers sometimes use it for its preservative effects. Without strict oversight, this creates an environment where workers and consumers get surprised by allergic reactions or skin problems. Casual users aren’t likely to flip a bottle over and Google each ingredient. Some brands rely on consumers simply trusting that products have been safely formulated.

Environmental Concerns Creep In

Wastewater with TTAB winds up moving downstream. Fish and aquatic life show signs of toxicity after even minimal exposure. This isn’t easily solved. Regulatory bodies often scramble to keep up with new studies about chemicals like TTAB seeping into rivers and lakes. Once it reaches the environment, clean-up grows expensive and slow. Current research from several universities paints a clear picture: aquatic ecosystems take a long time to recover from these pollutants. Someone fishing in a small stream might notice fewer fish, but they’re not handed a chemical analysis of the water.

What Action Looks Like

It’s too simple to blame this risk on manufacturers or regulators alone. Safer work environments can start with better training and clear labeling—no excuses. Lab managers who invest in high-quality gloves and proper ventilation cut the risk for their teams. For home use, pushing companies to use transparent ingredient lists ups accountability. If something causes skin irritation, customers need to know what they’re reacting to and which products to avoid next time.

Standing on the consumer’s side, advocacy groups can press for stronger regulations on the use of TTAB in beauty and hygiene items. This might take time, but change starts with public awareness. Companies that commit to safer alternatives show that business success doesn’t have to come at the cost of public health.

If you work around TTAB or use products with it at home, don’t trust luck. Knowledge and caution lower the odds of an emergency. Whether it starts with a protective glove or a closer look at an ingredient label, small steps can shift the story toward safety.