Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide: An In-Depth Commentary

Historical Development

Chemists always look for salts that bring a mix of stability and reactivity to the table, and Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide—often referred to as TEATFSI—stands out in this quest. Curious minds in the late twentieth century saw the need for stronger electrolytes and efficient phase transfer catalysts. It wasn’t enough anymore to rely on old-fashioned quaternary ammonium salts or single-anion electrolytes. Much of the real progress for TEATFSI happened as ionic liquids started to pick up steam in the 1990s. Scientific publications and patent filings—many coming from Japan and Europe—systematically broke ground, showing the world that combining a tetraethylammonium cation with the iconic bis(trifluoromethylsulfonyl)imide anion delivered a molecule with much lower melting point, far-reaching solubility in polar and nonpolar solvents, and high electrochemical stability. As big grants flowed toward better batteries and advanced organic syntheses, backward-looking chemists started to see what a unique role these newer salts played.

Product Overview

TEATFSI can look unremarkable on the shelf, a colorless to off-white powder that dissolves in water, methanol, and most high-dielectric solvents. At first glance, it doesn’t break the visual mold compared to simple tetraalkylammonium halides, but the story gets interesting once you bring it to the lab bench. Many companies, including Sigma-Aldrich, Tokyo Chemical Industry, and local Chinese producers, market TEATFSI for research and industrial use. It ships in high-purity bottles labeled for laboratory handling or bulk containers for pilot-scale projects, often in crystal or fine powder form. Many researchers notice its promise in preparing low-viscosity ionic liquids or advanced organic electrolytes. TEATFSI’s price point reflects purification challenges, particularly the need for an anhydrous and halide-free product, which pushes producers to filter out even trace impurities that ruin sensitive reactions.

Physical & Chemical Properties

TEATFSI weighs in with a molecular mass near 396 g/mol. Its melting point hovers well below room temperature for many preparations, rendering it a key player in ionic liquid research. The bis(trifluoromethyl)sulfonyl)imide anion ensures that it resists hydrolysis and oxidation, unlike more notorious halide analogs. That anion also imparts hydrophobic characteristics, so the salt doesn’t stay long in water without a fight. Its ionic conductivity remains competitive, attracting those who want more mobile ions and stable interfaces, especially under heat or electrical load. Any laboratory that measures conductivity, viscosity, or phase transitions of salts will come away impressed by TEATFSI’s reliable performance. Its low lattice energy and large, weakly coordinating anion lead to the wide liquid range prized in electrochemistry and synthetic work.

Technical Specifications & Labeling

Manufacturers typically guarantee TEATFSI purity above 98%, with moisture content below 0.5%. Chemists who handle glovebox work, lithium battery research, or catalytic studies appreciate this attention to low water and halide levels. Product labels list batch number, date of manufacture, and recommended storage conditions—usually desiccators and dry nitrogen. Transport containers include hazard statements—such as irritant to eyes and mucous membranes—though the salt doesn’t rise to the level of a UN-regulated dangerous good. Technical data sheets also point out standard analytical methods to confirm identity (NMR, FT-IR, ion chromatography), ensuring users maintain reproducibility and proper recordkeeping for regulatory reporting.

Preparation Method

Synthesizing TEATFSI isn’t as daunting as one might expect, provided access to the right precursors. The starting tetraethylammonium bromide usually reacts in a metathesis with lithium or potassium bis(trifluoromethyl)sulfonyl)imide. Dissolving both salts in water or acetonitrile, followed by filtration and solvent removal, yields the product. Chemists often repeat recrystallization to drive away the last traces of bromide, because even minute impurities can sabotage further applications in electronics or catalysis. Inefficiencies in filtration can lead to colored byproducts, so many scale-up facilities add activated charcoal purification steps. Large-scale plants use counter-current extraction with non-solvents to push yields, while researchers stick to rotary evaporation and gentle vacuum drying.

Chemical Reactions & Modifications

TEATFSI performs well in salt metathesis reactions, helping swap in the bis(trifluoromethyl)sulfonyl)imide anion wherever the tetraethylammonium family goes. This light touch has opened new paths for preparing supported catalysts and designer ionic liquids. The compound demonstrates thermal endurance above 200°C, which pushes it into new chemical windows for battery development. Its weakly coordinating anion allows transition metal or lanthanide complexes to form without much fuss—this quality matters for homogeneous and phase-transfer catalysis. Organic chemists see TEATFSI as an efficient phase separator, since it won’t quench reaction intermediates or bind cations too tightly.

Synonyms & Product Names

Names for TEATFSI include tetraethylammonium bis(trifluoromethanesulfonyl)imide, tetraethylammonium TFSI, and in some catalogs, N,N,N,N-tetraethylammonium bis(trifluoromethylsulfonyl)azanide. Some manufacturers simply abbreviate to TEA-TFSI. These variations matter when comparing literature, since a paper from Tokyo or Munich may swap between synonyms, confusing newcomers. Registries like the Chemical Abstracts Service assign a unique number, but field chemists and process engineers spend more time confirming purity via spectroscopy than worrying over the paperwork.

Safety & Operational Standards

TEATFSI falls into the low-to-moderate hazard tier, but routine lab practice keeps everyone honest. Skin and eye contact guarantee local irritation, thanks to the salt’s hygroscopic nature and the presence of fluorinated groups. Researchers and technicians don gloves, goggles, and lab coats. High-efficiency fume extraction and closed transfer systems prevent inhalation of fine particles. Companies shipping larger quantities comply with standard chemical logistics protocols, even if the compound escapes the tightest UN classification. Spills clean up with dry absorbents, never water, because of slippery, hard-to-contain surfaces. Those who work on scaling up production sites keep meticulous incident logs and workplace monitoring data, demanded by global regulatory bodies.

Application Area

Electrochemistry labs value TEATFSI for its reliable performance as a supporting electrolyte in nonaqueous solvents. Its high ionic conductivity and low viscosity enhance studies on organometallic and transition metal complexes. Battery researchers, searching for safer, longer-lasting lithium-ion cells, favor TEATFSI-derived ionic liquids because of wide electrochemical stability window, suppressing dendrite growth and raising thermal runaway thresholds. Organic synthetic chemists reach for TEATFSI when they need to drive phase transfer reactions or promote challenging couplings. Industrial catalysis, membrane research, and even pharmaceuticals see the salt playing a key role—anywhere researchers want low nucleophilicity, chemical stability, or flexible solvent compatibility. Even pilot-scale energy storage start-ups tap TEATFSI for advanced prototypes, citing its role in suppressing side reactions and providing consistent cycling behavior.

Research & Development

University and private R&D centers keep TEATFSI on their shortlist for ionic liquid engineering and next-generation electrolytes. Several research teams in the United States and Germany examine how changing the cation from tetraethylammonium to bulkier designs tunes physical properties, hoping for more selective catalysis. Some projects focus on blending TEATFSI with renewable solvents or biodegradable matrixes to minimize environmental impact, especially as regulators push for greener tech. Direct industrial collaborations have busied themselves with lithium salts for safer battery cells, showing that the bis(trifluoromethyl)sulfonyl)imide anion survives grueling thermal and electrochemical cycling better than old-school PF6- or BF4- anions. Patent literature shows an uptick in new hybrid electrolytes containing a TEATFSI backbone, particularly for grid-level storage and flexible electronics.

Toxicity Research

Toxicology groups approach TEATFSI as both a laboratory irritant and a topic of emerging concern for environmental persistence. Rat and mouse studies have revealed that exposure at high doses produces mild hepatic changes and transient neurological symptoms, which pushed safety committees to keep chronic exposure well below occupational thresholds. TEATFSI resists rapid biodegradation—the same property that makes it stable in a battery keeps it around in aquatic samples—so chemists remain conscious of waste disposal. Ecotoxicity screens with Daphnia and zebrafish have led process engineers to add catchment systems and in-line neutralization before sending effluents offsite. The substance belongs to a class whose long-term effects in the environment aren’t yet fully mapped, demanding further study before full-throated industrial adoption.

Future Prospects

The next decade will likely bring more demand for TEATFSI, particularly as the world doubles down on efficient, reliable batteries and ultra-stable ionic liquids. I see chemists nudging the formula in new directions—tweaking the tetraethylammonium backbone, merging green chemistry principles, all aiming for both performance and sustainability. Expect to see emerging publications and pilot projects that focus on closing the loop for environmental release, improving synthesis routes, and finding biodegradable analogs. With the right regulatory oversight and proactive laboratory practices, TEATFSI can keep playing a central role in high-performance science, provided researchers and industry don’t ignore end-of-life and environmental impact. Companies and universities have already begun threading the needle between safety, cost, and innovation, showing that responsible stewardship and creative laboratory work continue to matter in the world of advanced materials.

Digging Into Its Role in Electrolytes

Sometimes chemistry delivers a mouthful like Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide—think TEATFSI for short—and it’s easy to see why most folks don’t bump into it unless they’re deep into lab coats and voltage meters. The real story with TEATFSI unfolds in high-performance batteries and supercapacitors. I’ve seen growing demand for rechargeable tech, from electric rides to backup power banks, where safe and stable electrolytes make a serious difference. TEATFSI offers low viscosity and doesn’t easily catch fire, which puts it ahead of regular lithium salts or more volatile solutions. If you’ve ever worried about gadgets overheating or batteries swelling up, the choice of salt matters. A stable electrolyte helps keep these issues in check and increases the number of charge cycles the device can handle.

What Sets It Apart for Science and Engineering

Chemists and engineers love materials like TEATFSI because they pair well with ionic liquids. This salt can withstand some rough chemical treatment and stays solid even at higher voltages—crucial as devices get smaller and more powerful at the same time. Researchers chase after substances with a wide electrochemical window, and TEATFSI delivers. It doesn’t break down when voltages shift. Plus, its large anion helps improve the dissociation of ions, which boosts current flow in most setups.

My own background tinkering with home electronics gave me a taste for how tricky reliable power can be. TEATFSI isn’t playing a headline role in consumer goods yet, but labs rely on it for prototypes, performance tests, and research into future batteries. Reports show it enables higher safety margins in high-voltage testing, which industry watchers consider a win, especially as everyone wants longer battery life without safety trade-offs.

Environmental and Safety Considerations

No chemical comes without trade-offs. Fluorinated compounds like TEATFSI require careful production and waste management. Manufacturing can produce persistent waste products, and not every lab has the strictest standards for handling them. Watchdogs and regulators have flagged the need for tighter control here. On the consumer side, though, less risky electrolytes help avoid fires and cut down on hazardous leaks.

A key step is pushing manufacturers to improve waste cleanup. Green chemistry asks companies to invest in recovery systems and new purification steps. Upgrading facilities costs money, but better safeguards at the start could save on fines and environmental cleanup bills later. Evidence from the EU reports points to companies benefiting by cutting waste and drawing up recycling routes for recovered chemicals.

Supporting Modern Tech Growth

Most of us carry mobile devices that depend on lithium-based power. Growth in grid storage and electric cars brings higher demand for more stable and high-performing salts. TEATFSI fits into this story by helping researchers fine-tune prototype cells and batteries. Investment in such advanced materials works only if paired with safe handling from the beginning to the end of the product’s life. Watching the news reveals why this matters—images of smoking phones or burning electric scooters drive home the point.

Room for More Progress

Switching to less hazardous salts can keep dangerous accidents down and boost public trust in new technologies. TEATFSI shows what’s possible when chemistry labs focus on performance and resilience. The push now is not just toward stronger batteries, but also more responsible ways to build, recycle, and handle every component inside them.

Understanding the Substance

Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide, often called TEATFSI in lab circles, doesn’t roll off the tongue easily. This chemical pops up in research labs working with advanced batteries, electrolytes, and sometimes ionic liquids. It brings unique properties to electrochemistry, mainly due to its stability and how well it dissolves in certain solvents.

Risks Lurking on the Bench

Researchers may know the basics—wear gloves, put on goggles, don’t get stuff on your skin. TEATFSI doesn’t immediately burn through gloves or explode on contact with air, so it might trick some into thinking it’s just another harmless salt. Trouble begins when that attitude sticks around. Every chemical carries its own risks, even if the hazards aren’t as dramatic as sulfuric acid or sodium.

In my own grad student days, I handled similar compounds. White powders with impressive names would arrive in glass vials, with safety datasheets sometimes ignored at first. TEATFSI isn’t volatile, but fine powders and laboratory haste often mix. Breathing in any dust, including this one, can irritate airways. Getting a few milligrams on your hands tends to go unnoticed until an hour later when skin starts to itch. I learned quickly to never eat lunch in the lab and to double-wash my hands.

Hazard Breakdown

The datasheet for TEATFSI flags a few points: it can irritate eyes and skin, and nobody has tested it thoroughly for chronic or environmental toxicity. Those fluorine atoms bring persistence; what washes down the drain probably stays around a long time. No dramatic acute effects, but long-term buildup could harm aquatic life. The industry can’t claim innocence just because no big accident has made headlines—almost every lab accident I’ve seen comes from skipping a simple step.

Why Safety Culture Matters

Labs have come a long way. Most now store TEATFSI in well-labeled containers, away from acids and open flames. Shelves stay organized so powders can’t mix, and personal protective gear has improved. Still, no rule works if people shrug off risk. Lab veterans tell horror stories for a reason. People learn from seeing small mistakes become big messes.

Good safety practice comes down to personal discipline. Don’t move powders outside the fume hood. Wear real gloves, not the cheapest box from the storeroom. If a spill happens, use suction instead of brushes—nobody wants to stir up a chemical cloud. Even post-experiment cleanup asks for care. Waste containers for fluorinated salts get labeled, sealed, and tracked. Staff get reminders on proper disposal, even if regulations lag behind new synthetic salts.

Smarter Solutions for Safer Handling

Training pays off. I once saw a new lab member set up a vacuum filtration with no splash guard—the result covered the benchtop with a fine dusting of white, and a stern safety lecture followed. After that, hands-on instruction covered all the small details: how to weigh powder without scattering, how to unstop vials without sending crystals flying.

Industry-wide, greener alternatives slowly enter the market. Some labs have started swapping in less persistent anions for research projects, though TEATFSI still holds advantages in thermal stability for certain batteries. Sharing good habits—like never working alone, logging hazards, and using electronic lab notebooks—helps the next group avoid repeating mistakes.

People shape the true safety of these chemicals. Respect for the unknowns and care in the routine keep researchers safe and stop small problems from growing into real disasters.The Importance of Chemical Clarity

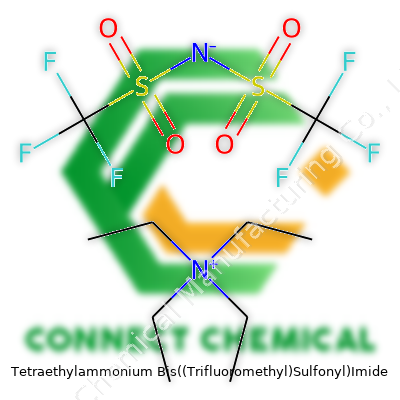

People often take for granted how vital clear naming and formulas remain in chemistry. In the world of research and industry, mixing up compounds isn’t just a minor error—it could cost money, time, or even pose a hazard in a lab. The chemical formula for Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide is C8H20N+•[(CF3SO2)2N]–, and understanding this formula offers more than just trivia for a test. It opens up a window into how we work with modern materials.

Why This Formula Matters in Science

This mouthful of a compound isn’t just a jumble of letters and numbers. The tetraethylammonium cation, represented as C8H20N+, teams up with a complex and powerful anion, bis(trifluoromethylsulfonyl)imide, which chemists often write as (CF3SO2)2N–. That pairing brings a unique set of physical and chemical properties to the table. Chemists crave these properties because they open pathways to advanced materials, especially in electrochemical devices. From batteries in electric vehicles to safer electrolytes in supercapacitors, the actual impact stretches far beyond the beaker.

Why Naming Sometimes Clouds the Picture

Clarity breaks down if shortcuts or casual terms creep in. In a job I had mixing specialty oils, an incorrectly written formula on a label forced a factory shutdown. The confusion cost a whole day of scrambling and checking, all due to careless notation. For students and professionals, clarity protects health, keeps the work running, and reduces risk.

Supporting Science with Accurate Formulas

Getting this formula right supports not just safe storage but also better research. Electrolytes based on (CF3SO2)2N– anions improve ionic conductivity and stability under tough conditions. Researchers report that this type of anion is less reactive with lithium and other metals, helping batteries last longer and run safer. The tetraethylammonium part gives enough size for the salt to dissolve in organic solvents, enabling more experiments in different setups. It’s no surprise top journals require authors to provide correct chemical details—they’re not gatekeeping, they’re making sure results can be trusted.

Focusing on Solutions and Moving Forward

A good step lies in building habits—write out every formula, double-check before publishing, and encourage questions. Science classrooms push “show your work” for good reason. Chemical supply companies can also do more by making sure their product labels and safety sheets highlight the accepted chemical notation, reducing language errors. People who design software and databases can develop smarter tools to auto-check names and formulas for common errors, catching mistakes before they become a problem for someone in a hurry.

Daily Takeaways for Science and Industry

Chemistry advances on details. The precise formula for Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide—C8H20N+•[(CF3SO2)2N]–—contains decades of progress, from new battery tech to safer industrial practices. Sticking to proven names supports a safer workplace and better discoveries. The real lesson isn’t just memorizing a formula, it’s respecting the tools that keep science both inventive and dependable.

Getting Real About Chemical Storage

Most laboratory settings teem with chemicals that demand a careful eye, and Tetraethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide—usually called TEATFSI—owns a deserved spot on that list. Folks in research and industry know storage isn’t only about finding a shelf and shutting the door. It’s about avoiding mishaps that risk safety, waste research funds, and put long-term projects in jeopardy.

The Core Storage Concerns

TEATFSI doesn’t act like table salt. It reacts with moisture. Left in a humid spot, it draws in water. That means anyone who lets this compound spend long hours in open air risks contamination. Water messes with its purity, weakens performance, and sometimes edges the compound toward unpredictable reactions.

I’ve seen what happens when a lab overlooks the drying steps for similar salts. Solvents pick up water fast, and equipment starts to corrode or clog. Rushing storage often leads to compromised data or, in industrial settings, faulty products.

Environmental Conditions Matter

Researchers keep TEATFSI in tightly sealed containers. Glass or specialized plastic jars—the kind that resist corrosion—stand up well. Ordinary screw caps struggle to keep out water vapor over time, so labs use PTFE-lined closures. Silica gel packets sometimes go in the container, soaking up what little moisture still seeps through.

Low temperatures help. A household fridge runs too wet and provides inconsistent conditions, so climate-controlled dry storage wins. Professional chemical refrigerators with humidity controls deliver better results. But not every site can spring for fancy fridges, so a dry room with steady cool air often does the trick. Shelf placement also counts. Direct sunlight speeds up chemical breakdown, so a shaded, cool corner serves much better than a spot near a window or radiator.

Why Safety Protocols Can’t Slip

Spill management in the storage area needs to be clear. TEATFSI won’t erupt in flames if splashed with water, but wet spills get sticky and tough to clean, and they linger, inviting more drops of moisture to ruin everything nearby.

Labeling every bottle with handling dates, storage location, and user initials seems simple—until someone skips it. Misplaced compounds or mystery bottles waste time and threaten safety. Every lab accident I’ve seen traces back to a moment of inattention, a skipped label, or a forgotten protocol. I’ve learned to double-check labels and storage logs each shift. It pays off in fewer headaches.

Managing Disposal and Future Risks

Every storage arrangement should allow for safe chemical disposal. Used or contaminated TEATFSI never goes in household trash or down the sink. Chemical waste protocols vary by country, but approved chemical waste bins with tight lids offer a reliable choice. Regular disposal schedules—checked by a team, not just one person—keep things running smoothly.

Supporting Teams with Training and Communication

New researchers need hands-on training, not just a checklist. Walking newcomers through the storage workflow builds safer routines and steers people away from risky shortcuts. I’ve found that regular discussions about storage mistakes open up a healthy team culture. People feel comfortable flagging issues before problems escalate.

High-quality storage keeps TEATFSI stable and safe. With consistent attention and real teamwork, most problems stay small, and the compound keeps delivering reliable results for research and industry alike.

Let’s Talk Chemistry That Actually Matters

Tetraethylammonium bis((trifluoromethyl)sulfonyl)imide doesn’t usually pop up in dinner table talk, but it’s become a staple in labs and tech companies chasing safer batteries and advanced materials. The buzz around ionic liquids, especially this one, comes down to how they behave in real-life conditions—and solubility in water tops that list.

Throwing It in Water—What Happens

Anyone who’s dealt with tetraethylammonium salts can tell you, water solubility changes everything. On paper, tetraethylammonium bis((trifluoromethyl)sulfonyl)imide should dissolve just fine. The tetraethylammonium piece usually brings good solubility. The (trifluoromethyl)sulfonyl imide part, though, makes things trickier. With its bulky structure and strong fluorinated parts, the salt drifts toward hydrophobic behavior—that is, it prefers not to mix with water.

Lab tests spell it out: in pure water at room temperature, only tiny amounts of this compound dissolve. Solubility reports land in the ballpark of a few grams per liter, far less than something like table salt. For chemists and engineers, this isn’t just a trivia question. The limited water solubility nudges designers toward mixed solvents or straight up non-aqueous systems when developing new materials or electrolytes.

Experience in the Lab: Expectations vs. Reality

A few years back, I joined a team working to develop fast-charging batteries. The plan looked simple—use this ionic salt to bump up energy performance. The roadblock came quick: while mixing with water, a cloudy layer formed instead of the clear solution we expected. The salt simply didn’t dissolve enough for our needs, forcing us to trade water-based design for acetonitrile and other organic solvents. That move raised both costs and safety concerns, since non-water mixes need extra handling care and come with new environmental headaches.

Why People Still Want Water-Soluble Salts

Solubility means options. Water-based electrolytes bring lower toxicity, easier cleanup, and safer working conditions. It also cuts production costs and sidesteps waste disposal issues tied to hazardous organics. With stricter environmental regulations coming fast, a material that blends happily with water gives companies a leg up in both compliance and marketing claims. Right now, tetraethylammonium bis((trifluoromethyl)sulfonyl)imide doesn’t fit the bill.

Better Chemistry—Possible Solutions

Some chemists have tried to tweak the salt’s structure, hoping small changes might boost water compatibility. Swapping out the tetraethylammonium group for shorter or more hydrophilic alkyl chains sometimes gets better results. Another route involves mixing in co-solvents—add a bit of ethanol or propylene carbonate, and suddenly more salt dissolves.

Industry doesn’t stand still. Companies now test similar alternatives with more “green” cred—think sulfonate-based or quaternary ammonium salts that handle water better. Academic labs share results openly these days, filling preprint servers with new recipes that dissolve more, work safer, and cut toxicity. So the push is strong to find a sweet spot: high ionic conductivity, low volatility, and enough water solubility that companies don’t need to fall back on old, messy solvents.

The Bottom Line

People in research and production keep a close eye on the solubility story because it can make or break the switch to more sustainable chemistry. Today, tetraethylammonium bis((trifluoromethyl)sulfonyl)imide sits on the fence, offering great electrochemical properties but barely mixing with water on its own. For safer and greener products, the search continues—driven by fresh ideas from the lab and tough questions from regulators.