Tetraethylammonium Hexafluorophosphate: A Deep Dive

Historical Roots of Tetraethylammonium Hexafluorophosphate

Chemists in the mid-20th century started looking for stable, easily handled salts that could support the wave of research into non-aqueous electrochemistry. Tetraethylammonium hexafluorophosphate (TEAPF6) emerged as a standout choice, mainly because the tetraethylammonium cation wouldn’t stir up unwanted side reactions and the PF6- anion would keep things stable across a range of voltages and solvents. Scientists working on early lithium batteries and electrochemical cells leaned into this and helped shape industrial and academic electrochemistry. Over decades, it has helped drive lab breakthroughs, from solvent studies to fine-tuned analytical chemistry, and its influence reaches into commercial labs and specialty manufacturing today.

A Look at Product Characteristics

Physically, TEAPF6 forms as a white crystalline powder, sometimes clumping if left in humid conditions. While it does not carry a strong odor, it calls for proper handling and storage as PF6- can invite subtle hydrolysis in the presence of moisture. Solubility in many polar solvents like acetonitrile, propylene carbonate, and dimethylformamide makes it a go-to salt for chemists who need something both robust and responsive. Its melting point generally hangs around 260°C, though actual behavior in the lab depends on how carefully it was dried and stored. Packagers often label its purity at above 98%, with strict limitations on residual water content, since even a few ppm of water can throw off sensitive experiments.

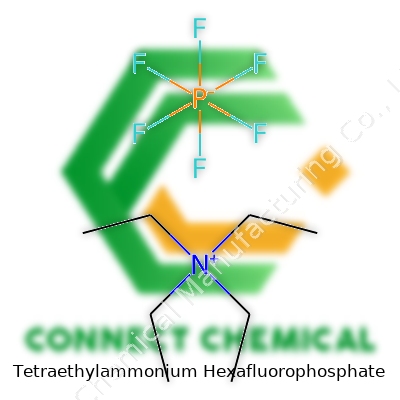

Technical Specifications and Labeling

Product labels typically highlight molecular weight (297.23 g/mol), chemical formula (C8H20NPF6), and the all-important CAS number (5108-97-6). Packaging includes lot numbers and dates to keep track of degradation, with vacuum-sealed pouches or bottles in foil wraps tightly controlling exposure. Suppliers often include data sheets showing tests for metallic impurities, water content (by Karl Fischer titration), and sometimes even chromatograms demonstrating purity. Customers care about all this because single-digit parts-per-million contamination from sodium or lithium can alter high-precision applications, especially in battery research or spectroelectrochemistry. I remember having to reject a lot of reagent for minute traces of iron, which almost ghosted as a background in redox measurements.

Preparation Method: How Chemists Build TEAPF6

To make TEAPF6, a straightforward salt metathesis often starts with tetraethylammonium bromide and silver hexafluorophosphate. Mix the two in anhydrous acetonitrile, filter off silver bromide, and evaporate the solvent. The reaction produces a fine, flowable powder if dried under vacuum. Sometimes purification calls for multiple recrystallizations from ethanol or other polar solvents, chasing the last traces of starting materials or moisture. Clean glassware and dry conditions make all the difference; a careless technician once left a lid off, letting humidity sneak in and throw off conductivity readings for a week. Careful measurement and tidiness preserve the product’s quality and research reproducibility.

Chemical Reactivity and Modifications

TEAPF6 rarely reacts during regular lab use since both its cation and anion remain stable in most solvents. Yet, under harsh acidic or basic conditions, PF6- can break down and produce HF—always a risk when pushing voltages in an electrochemical setup. Modification is generally possible through the cation, swapping tetraethyl for another trialkyl or heterocyclic group. Derivatives expand the salt's utility, with chemists experimenting on conductivity or optimizing for specific ionic liquid formulations. Watching a colleague wrangle PF6- salts taught me that even sturdy compounds have their limits if the wrong glassware or accidental acid addition enters the mix.

Recognized Synonyms and Trade Names

TEAPF6 also appears as NEt4PF6, tetraethylammonium hexafluorophosphoric acid, and sometimes in the shorthand as Et4N+PF6-. Some catalogues show it under brand-specific codes or combine the salt’s name with producer identifiers. For practical work, knowing synonyms guards against duplicate orders or switching suppliers midway through a long-term study.

Staying Safe and Operational Standards

Work with TEAPF6 starts with real safety protocols: nitrile gloves, eye protection, and fume hoods for weighing and transferring. Inhalation risks remain low, but wet TEAPF6 decomposes, emitting small but measurable HF—good ventilation matters. Most producers include MSDS sheets that echo this warning, and labs follow local hazardous waste rules for disposal since PF6- derivatives pose long-term environmental persistence. I’ve always kept spills to a minimum, wiping carefully and sealing all waste for incineration or chemical neutralization.

Applications and Influence

TEAPF6 stays in high demand as an inert electrolyte. Electrochemists count on its ability to create high-conductivity solutions without getting in the way of redox reactions. Researchers in organic synthesis value it for supporting cationic and radical reaction mechanisms. Battery engineers mix it in electrolyte blends, looking for non-reactive, high-voltage stable conductors. This salt also finds work in protein denaturation studies, select types of chromatography, and even in developing ionic liquids for green chemistry projects. In my own work with cyclic voltammetry, a solution of TEAPF6 and acetonitrile provided consistent backgrounds, avoiding the messy baseline noise weaker salts introduce. Product reliability saves hours of troubleshooting—your results hinge on having a predictable, clean support.

Progress in Research and Development

Development efforts now chase even higher purity, with some labs seeking out “ultra dry, battery grade” formulations. Innovations focus on easier handling, safer packaging, and reducing environmental impact by controlling PF6- release during use and disposal. Some startups work on alternatives that mimic the non-coordinating nature of PF6- but with lower persistence or toxicity, betting on regulatory pressure to push for greener chemistries. I’ve seen colleagues stretch standard protocols, introducing TEAPF6 into next-generation analytical techniques, like coupling electrochemistry with mass spectrometry for ultra-trace detection. The salt’s ubiquity anchors it at nearly every electrochemistry bench today, but change rolls along as labs chase lower toxicity and higher performance.

Digging Into Toxicity Research

Toxicological work has shown that TEAPF6 itself offers moderate risk, with low acute toxicity but possible long-term harm if handled carelessly. The chief danger comes from PF6- hydrolyzing, which produces hydrofluoric acid. Chronic exposure worries come up with repeated inhalation or contact, especially over months or years in poorly ventilated spaces. I remember a visiting grad student suffering mild irritation after ignoring glove protocol—lessons stick fast after a scare. Most research institutions train new hires aggressively, and environmental chemists keep questioning the fate of PF6- in groundwater and landfill sites, nudging producers to innovate in recycling or neutralization.

Peering Forward: Future Prospects

TEAPF6 won’t lose its grip on research and industry anytime soon. As batteries grow more essential to everyday life—phones, cars, power grids—reliable, stable electrolytes remain vital. At the same time, the world’s attention turns toward sustainability, driving both regulatory and market pushes for safer, greener alternatives to PF6- chemistry. Labs keep an eye on new salts and clever molecular tweaks, but for now TEAPF6 continues serving as the unspoken backbone of electrochemical science. Its future likely means tighter controls, smarter recycling, and new formulations, but its unmatched track record still lets scientists push the boundaries of analytical and industrial chemistry.

A Chemical With a Real Purpose in Labs

Tetraethylammonium hexafluorophosphate sounds like a mouthful, and it really has a specific place in the worlds of chemistry and engineering. The point isn’t about the name—it’s what this compound brings to the table. I’ve seen how certain chemicals draw a mix of excitement and wariness among researchers, especially the types that are more common in advanced labs than in household products. This salt falls right into that category. It shows up in bottles on chemical shelves where materials for cutting-edge experiments wait, fully labeled and stored behind strict protocols.

Role in Electrochemistry

Inside electrochemistry labs, you notice Tetraethylammonium hexafluorophosphate on the ingredient lists for experiments looking at the movement of ions and electrons. Its real job is to dissolve into a liquid and help conduct electricity, making it a good “supporting electrolyte.” Some salts don’t work as well because they get involved in side reactions or mess up measurements. This one tends to stay out of trouble—important for researchers trying to get accurate results without extra noise.

Researchers studying battery chemistry and supercapacitors lean toward this salt because it allows for clear readings and smoother energy storage experiments. A battery test requires predictable results, so chemists reach for stable choices. This compound’s low reactivity means it’s less likely to skew the findings or damage expensive electrodes.

Organic Synthesis and Beyond

It isn’t just battery nerds who care. Chemists working with organic molecules often need a source of ‘large, non-coordinating ions.’ This salt delivers exactly that. In organic reactions, especially those using electricity for chemical changes, having the right electrolyte can break or seal the deal. The tetraethylammonium part brings a size that helps dissolve both into water and less polar mixtures, opening up options for experiments.

Think about medication research—some syntheses rely on unusual reaction conditions. A chemist might test dozens of approaches before one route works. Tetraethylammonium hexafluorophosphate gets picked because it doesn’t interact too much with sensitive materials but still gets the job done as a conductive ingredient.

Safety and Environmental Talk

Handling Tetraethylammonium hexafluorophosphate takes care. Anyone who’s spent time in a university lab knows safety training isn’t just for show. Gloves, eye protection, clear documentation, and good ventilation come standard. Mishandling any salt—especially ones with fluorine—causes problems ranging from chemical burns to environmental issues if it finds its way into the water supply.

Waste management matters. Most research institutions enforce strict disposal rules. Some countries impose tighter restrictions, aware that byproducts of fluorinated salts can linger. Calls for greener chemistry echo through classrooms and conferences. There’s a push for alternatives that deliver the same outcomes, but with less risk and easier recycling. Sometimes progress happens quietly in back rooms filled with bubbling glass tubes and digital meters. Researchers at all stages now ask: Can we find less hazardous salts for these jobs?

Looking to the Future

As energy storage keeps moving forward, and as chemical reactions get more complex demands, the need for reliable, tested materials like Tetraethylammonium hexafluorophosphate sticks around. But so does the pressure to use safer, cleaner chemistry. Students, professors, and industry workers keep eyes peeled for breakthroughs—hoping to snap up compounds that keep labs moving forward without putting health or nature at greater risk.

Understanding the Real Risks of the Chemical

Tetraethylammonium hexafluorophosphate spins up memories from hours holed up in the lab, always double-checking container labels before even reaching for the gloves. The name packs a punch, and the dangers do, too. This compound shows up a lot in electrochemistry and battery research circles, but comfort with the routine sometimes makes folks drop their guard. I’ve witnessed close calls—people treating it like table salt, then racing for the eyewash. The heart of the matter is: genuine respect for its hazards makes the difference between clean results and a medical emergency.

Personal Protective Gear Comes First

Chemists love to debate protection gear, but not for this compound. The best habit is never skipping gloves—go for heavy-duty nitrile, not the flimsy stuff. Safety goggles are nonnegotiable, with a face shield coming into play if splashing feels even remotely possible. A solid lab coat, long sleeves, and shoe covers stop the powder from hitching rides outside the workspace. Good habits cross disciplines; protective strategies for this material don’t look too different from those for handling strong acids or reactive metals.

Ventilation Isn’t Optional

Plenty of labs still rely on the old chemical fume hood—sometimes with rusted sashes or over-packed with glassware. Working with tetraethylammonium hexafluorophosphate in open air makes little sense. The salt may not have the strong odor of ammonia or the threat of acutely toxic vapors, but dust can linger. Keeping operations under a fume hood means far less chance of inhaling stray particles. Every safety audit I’ve worked involved a quick test of hood airflow with a strip of tissue—higher-tech solutions exist, but you keep your hunches honest with simple checks.

Why Clean Work Surfaces Matter

Many forget how sticky fine powders can be, especially after a spill. I’ve seen white residues creeping onto the edges of notebooks, pipettes, even doorknobs. Treat any spill with seriousness: pick up solids with a dedicated vacuum (HEPA filters only), not by brushing or blowing. Wipe surfaces with wet cloths, never dry. Routine always trumps improvisation—daily cleaning with a mind for contamination keeps the whole space safer for everyone, not just the one running the experiment.

Safe Storage and Waste Disposal

Unlabeled bottles on shelves are a nightmare; a clear label means no questions later. This material deserves a secondary containment box, somewhere cool and low-humidity, away from acids and oxidants. Mixing mistakes can set off hazardous reactions. I learned early to separate chemicals by reactivity, not convenience. Disposing of remnants in the standard trash could land a lab on the evening news. Waste heads to the chemical waste stream, sealed and tagged, no shortcuts. Local regulations guide that process; some places treat fluorinated salts more strictly.

What Training and Team Awareness Achieve

No protocol outperforms a team that looks out for each other. Chemical safety drills seem over the top—right up until the day something goes sideways. Sharing stories and lessons learned from close calls might seem tedious, but it stops new folks from repeating old mistakes. Knowledge needs to walk the halls, not just live on safety posters. Ultimately, you see the best results where people respect the chemistry and each other, making the extra steps part of the everyday routine.

Understanding the Formula and Weight

A name like Tetraethylammonium Hexafluorophosphate sounds overwhelming, but at its core, it’s nothing more than a combination of atoms doing a specific job in labs around the world. Let’s break it down. The chemical formula for Tetraethylammonium Hexafluorophosphate comes out as (C2H5)4N+ PF6-. Some might write it shorter as TEAPF6. The pieces matter: you have four ethyl groups (C2H5), a nitrogen in the center, paired with a phosphate surrounded by six fluorines. The molecular weight checks in at about 259.27 grams per mole. For chemists, this number isn’t arbitrary—it tells you just how much of the stuff you’d need for a reaction or experiment.

Why Bother with the Details?

Knowing the exact structure and weight isn’t just filling out a checklist. My time working in a research lab taught me that a tiny error in interpreting the formula means wasted materials and disappointing results. Tetraethylammonium Hexafluorophosphate helps create the right chemical environment, especially in things like electrochemistry or when separating compounds. If the formula or weight slips your mind—or worse, if you use the wrong version—results get messy fast.

Applications that Matter

Tetraethylammonium Hexafluorophosphate doesn’t only belong on a shelf. You find it helping batteries store energy, enabling electrochemical reactions, and preventing side reactions thanks to its stability. During years working with batteries, I saw how this salt made it possible to test different electrolytes reliably. All that research trickled down to real-world uses—from phones holding a charge longer to research into safer, more efficient energy storage. The stability comes from that hexafluorophosphate part, which keeps reactions under control, while tetraethylammonium provides balance in solution.

Safety and Handling at the Bench

Chemicals like TEAPF6 require respect. In my experience, those new to labs sometimes skip gloves “just to move a bottle.” Inhaling the powder or getting it on skin isn’t just uncomfortable—it can pose risks over time. Safety datasheets recommend careful storage, eye protection, and keeping it dry, since moisture can break it down. In an era with a heightened focus on lab safety, these are habits worth passing down. Proper handling isn’t just about rules—it’s about making sure the science keeps moving without setbacks from careless exposure.

Improving Access and Reducing Waste

Cost and waste become challenges as more research seeks sustainable options. Labs can order bulk TEAPF6, but smaller groups might struggle with high prices or leftover chemicals expiring on shelves. I’ve seen solutions include sharing resources, collaborating across departments, and even reclaiming materials from finished experiments. Focusing on greener processes, suppliers now work to ensure high purity without excess production waste.

Looking Ahead

Chemicals like Tetraethylammonium Hexafluorophosphate keep research humming, but care for detail sets good science apart. With its precise formula and weight, this compound’s role offers a reminder: Chemistry isn’t just theory—it’s the foundation for products and ideas that shape everyday life.

Why Storing Tetraethylammonium Hexafluorophosphate Properly Really Matters

Chemistry isn’t just about mixing things in a lab. Some chemicals come with their own set of unique challenges that you can’t afford to overlook. Tetraethylammonium hexafluorophosphate sounds like a mouthful, but people working with battery research, organic synthesis, and electrochemistry run into it often enough. If you don’t store it right, the stuff can become a headache fast—both for safety and for your research results.

The Risks Are Real

I’ve worked around enough sensitive compounds to know that skipping safety steps never pays off. This compound breaks down in moisture and strong acids. In practical terms, cracking open a jar in a damp storeroom can end with ruined material or a dangerous situation. The PF6- part likes to drop toxic hydrofluoric acid when things go wrong, and that acid won’t simply sting—exposure to HF can cause deep tissue damage and long-term health problems.

Dryness Makes All the Difference

Anyone familiar with storing air-sensitive salts pays close attention to humidity. I’ve kept moisture-sensitive chemicals in desiccators filled with silica gel or in a glove box flushed with nitrogen. For Tetraethylammonium hexafluorophosphate, keep it in a tightly sealed container—glass works well—and stash that in a dry place. Some labs use argon atmospheres for even better protection. Simple hardware store containers don’t cut it, especially for valuable or potentially dangerous chemicals. Resealable glass bottles with PTFE-lined caps earn their keep by keeping moisture out and reducing leaks.

Stay Cool and Away from Light

Temperature swings and light also cause trouble. Most reputable labs keep compounds like this in a refrigerator, 2–8°C. Too cold, and you risk condensation sneaking in when you open the jar. Too warm, and chemical degradation ramps up. Placing the bottle in a dark cupboard or wrapping it in aluminum foil blocks light, which can set off unwanted reactions. Practical experience taught me not to rely on labeling alone—dedicated shelves and clear signage always pay off, especially with less familiar labmates involved.

Common Sense Goes a Long Way

Some habits make everyone safer. Always label containers with the full chemical name, date opened, and hazard warnings. Keep an accurate inventory. Your colleagues depend on solid records, especially if they need to track down why a batch failed or troubleshoot an unexpected reaction. Don’t trust memory—write it down.

Dealing With Spills and Waste

Nobody plans on a spill, but unprepared labs often face them. I learned early on to keep calcium carbonate and spill kits close by. HF neutralizers must stay nearby because standard spill kits won’t do the job. Dispose of this material as hazardous waste—never wash it down the drain. Regional rules may differ, yet all call for strict control and proper labeling.

Learning from the Community

The chemical safety field grows because people share best practices, even when mistakes happen. Joining safety seminars, reading chemical safety sheets, and swapping stories with experienced chemists help keep standards high. Laboratories that encourage open talk about storage and handling don’t just tick regulatory boxes—they keep everyone healthier and the science on track.

Solutions That Work

Secure storage for tetraethylammonium hexafluorophosphate doesn’t take high-tech equipment. Reliable glassware, working refrigerators, desiccators, and good habits do the heavy lifting. Mixing vigilance with a willingness to ask questions makes labs safer. This isn’t just about following rules—it’s about going home healthy at the end of every day.

Real-Life Chemistry: Water vs. Organic Solvents

In labs everywhere, solubility can make or break a day. Tetraethylammonium hexafluorophosphate pops up in many chemical reactions and battery projects, especially for folks trying to get stable, reliable results. Whether it lands in water or an organic solvent matters more than most people outside the lab might guess.

I’ve watched more than one seasoned scientist run into trouble slinging this salt into water. On paper, some quaternary ammonium salts dissolve fine in water. Not this one. Tetraethylammonium hexafluorophosphate looks good in a vial, white and almost fluffy, but toss it in water and you’re left with a cloudy mess. Most of it hangs at the bottom, refusing to budge. Sure, you’ll find a tiny bit dissolves—chemistry never likes black-and-white answers—but nobody sets up an electrochemical cell hoping for “a tiny bit.”

Organic Solvents: The Real Home

Now swing over to organic solvents. Drop this salt into acetonitrile, propylene carbonate, dimethylformamide, even nitromethane, and things change. The solid vanishes and forms a clear solution. For anyone running electrochemistry, that clarity means a lot. No clogging. No weird precipitation. Just reliable conductivity and predictable results. Plenty of published research puts tetraethylammonium hexafluorophosphate into the toolkit for these reasons. In supporting electrolyte roles, especially in non-aqueous environments, it brings sharp performance.

The reason stands behind the structure. The PF6- ion likes organic solvents—it doesn’t make friends with water. It’s all about matching like to like: polar organic solvents draw out the individual ions, helping everything dissolve. In water, the hexafluorophosphate just doesn’t break apart, and you’re left stirring and wishing.

Why It Matters beyond the Lab

People outside the science world might shrug. Why should anyone care if this white powder hates water? In batteries—especially lithium-ion or supercapacitors—the right supporting salt shapes everything from conductivity to long-term safety. One wrong move and you get a slow, clunky battery or one prone to failing before its time. If the salt won’t dissolve in the chosen solvent, that battery won’t deliver, and nobody wants to pay for a phone that dies before lunch or a grid-scale battery bank that fizzles after a year.

I’ve seen younger researchers wrestle with this, dumping time and resources into water-based tests because they assumed all salts act the same. If more training included real stories—spilled acetonitrile, sticky glassware, the frustration of wasted effort—maybe shortcuts wouldn’t be so tempting. It’s not about shaming mistakes. Better awareness avoids surprise setbacks and gets more folks thinking ahead.

Pushing toward Solutions

Switching over to the right solvent early saves headaches. Double-checking solubility data, swapping out water for organic solvents where needed, and thinking through waste disposal plans makes the process smoother. Teams who invest in proper solvent storage and handling make life easier for everyone and cut down on safety issues. Maybe it sounds boring, but avoiding that sticky, useless slurry in the beaker means more progress and less cleanup.

Research keeps searching for alternatives—salts which split the difference between safety, solubility, and conductivity. Greener solvents and friendlier chemicals may eventually edge out the established options. Until then, anyone working with tetraethylammonium hexafluorophosphate learns the lesson: the medium shapes the message, and in chemistry, water isn’t always the answer.