Tetramethyl Ammonium Dihydrogen Phosphate: A Closer Look

Historical Development

The story of Tetramethyl Ammonium Dihydrogen Phosphate weaves through the broader evolution of organophosphorus chemistry that defined much of the twentieth century. Early on, researchers sought out ways to create stable, water-soluble compounds for use in both laboratory and industrial applications. Quaternary ammonium salts stood out because people recognized their unique ionic structure and potential as effective buffers and catalysts. By the 1960s, scientists had motivation to extend this chemistry, mixing tetramethylammonium with phosphate sources. Laboratories used simple acid-base reactions, marking a new era where organics and inorganics came together. Over the years, improvements in purification and synthesis kept pushing this compound from academic curiosity into roles with more industrial weight.

Product Overview

Tetramethyl Ammonium Dihydrogen Phosphate (TMDHP) turns up as a crystalline solid that dissolves easily in water, which makes it a comfortable fit for use as a catalyst, buffer, and intermediate in various chemical processes. In my work with analytical chemistry, this chemical helped researchers run experiments where tight pH control matters. Its presence is clear in specialized buffer solutions and niche industrial applications. Chemists choose TMDHP when they want the stable, non-volatile behavior of a quaternary ammonium ion alongside reliable phosphate reactivity. This compound balances those two needs without the graininess or hassle sometimes found in older inorganic phosphates.

Physical & Chemical Properties

TMDHP presents itself as a white to off-white crystalline or powdery substance. It carries the solid, slightly slippery texture often found in ammonium salts. The strong ionic nature explains why it dissolves quickly in water, forming clear solutions that work well in controlled experiments or productions. Melting points often land above 235°C, and its decomposition can release toxic fumes including methylamine and phosphorous oxides. From personal handling, this compound reminds chemists to respect its pH influence. It usually has neutral or slightly acidic values, pegged to the nature of the dihydrogen phosphate ion. Chemically, TMDHP shows stability at room temperature, but does not play well with strong oxidizers or strong acids for extended periods. With a molecular formula of C4H16NO4P, its molar mass reaches about 173.2 g/mol.

Technical Specifications & Labeling

Manufacturers deliver TMDHP with purity grades often reaching 98% or higher, supporting even high-precision industries. Labels mention typical moisture content below 1%, and heavy metal limits usually under 10 ppm. Packaging comes in tightly sealed, sturdy bottles to cut down on contamination and accidental moisture uptake. Chemical suppliers highlight the CAS number 1112-87-0 and batch-specific data, giving end-users the confidence they need to trace quality back through every shipment. All containers get hazard warnings, disposal instructions, and exposure guidelines, reflecting the handling regulations that surround modern industrial chemicals.

Preparation Method

Lab-scale synthesis starts with precisely measured tetramethyl ammonium hydroxide and phosphoric acid. Adding the hydroxide slowly to the acid, under constant cooling and stirring, forms TMDHP along with water as a side product. Careful evaporation or vacuum drying yields pure crystals. For larger operations, batch reactors and continuous crystallization streamline the process. Filtration and drying handle the final product, with further purification needed if the processing environment introduces any detectable impurities. Safety protocols call for full ventilation, gloves, and eye protection to prevent unwanted exposure to the vapors and dust that can rise during synthesis or handling.

Chemical Reactions & Modifications

TMDHP acts as a mild proton donor through its dihydrogen phosphate ion, which makes it valuable in acid-base reactions that require buffering around a slightly acidic environment. Reacting with strong bases pushes the equilibrium toward tetramethylammonium phosphate, a less acidic relative. Under thermal stress or continued heating, methyl groups may break loose, producing methylamine gases familiar to those who have worked with quaternary ammonium derivatives. In organic synthesis, researchers tap this phosphate as a catalyst or reactant in methylation reactions, leveraging both its ammonium backbone and phosphorous content for improved selectivity and yield. Any modification to the molecule involves careful planning, because the stable ammonium four-methyl structure resists easy transformation.

Synonyms & Product Names

Over time, naming conventions have shifted. Some supply catalogs list “Tetramethylammonium Dihydrogen Phosphate,” others use “N,N,N,N-Tetramethylammonium Dihydrogen Phosphate,” and a few go with “TMA-dihydrogen phosphate.” A quick glance through scientific literature may pick up names like “Tetramethylammonium biphosphate” or the shorthand TMDHP. The differences reveal the compound's migration from chemistry labs into broader commercial use, each name hinting at the chemical’s dual roles as both an organic ion (tetramethylammonium) and a phosphate salt.

Safety & Operational Standards

In handling TMDHP, safety always takes center stage. Even though it doesn’t fly off as a volatile organic, it brings moderate toxicity risks—especially from ingestion or inhalation. The dust irritates mucous membranes, a lesson shared by anybody who worked in a busy lab without a fume hood. Proper ventilation and dust masks cut down on exposure. Spills clean up easily with water and standard absorbents, but workers avoid using incompatible cleaning agents and never mix with strong acids or oxidizers. Disposal runs by professional hazardous waste channels, since local drainage would violate environmental codes. Data sheets recommend protective clothing and eye protection, especially during preparation or bulk weighing.

Application Area

TMDHP doesn’t turn up at every turn, but in the corners of specialty applications it makes a real impact. Buffer systems for analytical instrumentation rely on it for precise, repeatable calibration of pH meters or ion-selective electrodes. I’ve seen it used to maintain exact acidity in chromatography and titration protocols, shaving margin for error in pharmaceutical development. Some surface treatment industries choose quaternary ammonium phosphates as anti-static or flame-retardant additives, where the balance of organic bulk and phosphate backbone tampers with conductivity or thermal breakdown properties. Material science researchers study TMDHP for potential roles in polymer synthesis, seeing if it changes cure rates or chain formation. It doesn’t usually show up in food or consumer goods, a reflection of both safety considerations and cost.

Research & Development

Academic and industrial researchers keep an eye on TMDHP for novel roles in catalysis or as a designer ionic liquid component. Recent published work examined its effect on phosphoric acid fuel cell membranes, where stability and conductivity both matter. Some teams probe ion-pairing between TMDHP ions and transition metal catalysts, believing that the unique structure can tune reactivity in ways unavailable using conventional inorganic phosphates. Analytical method development benefits from the compound’s well-understood behavior, with labs refining quantification in complex matrices or controlling ionic drift in sensitive electrochemical setups. Experienced chemists see the true value in easy handling and adaptability, especially as new applications in green chemistry call for non-volatile, recyclable reagents.

Toxicity Research

TMDHP’s toxicity profile ranks as moderate. Acute exposure studies in rodents set LD50 values in the hundreds of milligrams per kilogram range, with symptoms tied to nervous system disruption and mild cholinergic effects. Chronic exposure increases risk, especially as methylammonium compounds may carry a low but measurable risk of developmental toxicity. This scientific understanding supports today’s workplace guidelines: no tasting, inhaling, or long-term skin exposure—all rules backed up by both data and experience. Environmental research has raised questions around runoff and aquatic toxicity, pushing researchers to recommend stringent discharge controls in factories or large campuses. Regulation leans on the precautionary principle, as gaps remain in long-term epidemiology and ecological fate.

Future Prospects

As green chemistry presses for safer, less wasteful reagents, TMDHP stands at the boundary of traditional chemical know-how and current demand for greater safety and control. Researchers see opportunity in fuel cell technology, battery electrolytes, and new composite materials, where quaternary ammonium phosphates can change conductivity or flame retardancy. Toxicity concerns keep regulatory agencies alert, which in turn guides how new production and applications develop. The future might not kick this compound into mainstream bulk chemistry, but in the focused world of specialty buffers and catalytic research, Tetramethyl Ammonium Dihydrogen Phosphate remains a toolkit staple, shaped by decades of careful study and cautious application.

Unlocking Hidden Roles in Science and Industry

Few people outside of labs think about compounds like tetramethyl ammonium dihydrogen phosphate (TMADP). Without a catchy nickname or flashy color, TMADP stays tucked away on shelves in research facilities and manufacturing plants. Still, this chemical plays a key part in plenty of behind-the-scenes work, making life a little easier for engineers, chemists, and even tech developers.

TMADP’s Niche in Electronics

TMADP matters a lot in the electronics industry. Its main appeal comes from its ability to work as a source of both phosphorus and nitrogen. These elements are crucial in chip fabrication, especially during processes that etch patterns into silicon wafers. Phosphorus compounds move electrons in the right direction, carving out the tiny highways that carry signal across computer chips. Since TMADP dissolves in water, process engineers can mix it right into cleaning and etching baths. Wet-etching and surface preparation are where the chemical gets put to the test, stripping away unwanted layers and prepping wafers for the next step. Without reliable chemicals like TMADP, the multi-billion dollar chip industry would stumble and grind to a halt.

Trust and Quality Under the Microscope

Not every compound with a complex name earns trust by default. Precise measurements matter. Any contamination can cost hours of work. Scientists choose TMADP for its reliable purity. Teams behind the scenes test every batch closely, since one slip can throw an entire product line off track. This standard of quality is not a luxury—it's essential in places like semiconductor fabs where a single mistake means redoing work that took days or weeks.

Supporting Analytical Chemistry and Research

Labs lean on TMADP as more than just an ingredient. It’s a part of many buffer solutions and titration mixtures, key for testing new materials or diagnosing industrial trouble. When researchers hunt for tiny changes in a solution’s acidity (pH) or check reaction consistency, they trust chemicals like TMADP to stay stable and not skew results. College chemistry students—and their professors—often introduce this reagent in experiments where precision wins the day. It’s easy to take this reliability for granted, until a reaction runs wild or a reading goes off the charts.

Sustainability and Handling

TMADP presents fewer health hazards compared to some older phosphorus reagents. Still, exposure at high concentrations poses risks, and proper protective gear belongs in every workplace where it’s handled. Safety training doesn’t always grab headlines, but there’s no shortcut for it. Modern facilities set protocols based on how these chemicals behave and what’s known from years of experience and assessment.

Forging the Path Ahead

The world keeps calling for faster chips, cleaner water, and more efficient batteries. Each of these demands trickles down to the quality of the chemicals at every stage. TMADP forms a small but vital link in that chain. As environmental regulations tighten and manufacturing targets shift, the search for safer, greener, and more cost-effective alternatives never stops. Partnerships between chemists, regulatory bodies, and industry groups help keep this progress on track, ensuring chemicals like TMADP remain both useful and safe for years to come.

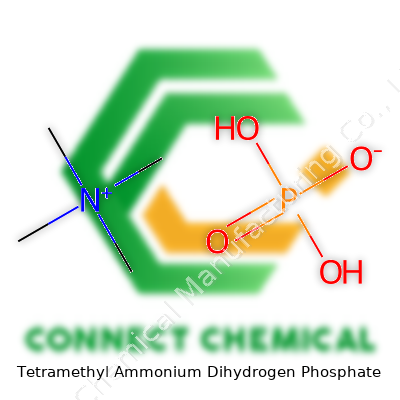

A Closer Look at the Chemistry

Tetramethyl ammonium dihydrogen phosphate carries a chemical formula of (CH3)4N H2PO4. In labs, this formula comes up often during research on ionic compounds and organophosphates. The molecule features a tetramethyl ammonium cation linked with a dihydrogen phosphate anion. In simpler terms, you get four methyl groups attached to an ammonium core on one side and an acid phosphate group on the other. This combination leads to a salt prized for its usefulness in experiments that need a clear, reliable buffer or a precise source of phosphate.

Value in the Real World

I spent more than one afternoon in university chemistry labs tracking down stable chemicals for electrolysis reactions. Tetramethyl ammonium dihydrogen phosphate quickly became a favorite. It dissolves in water without leaving behind a cloudy residue, and you can depend on its purity. This salt seems low-profile compared to more popular reagents like potassium phosphate, but when high-purity, non-metallic buffers are required, it stands out for reliability and ease of handling.

This isn’t just lab nostalgia. Digital device makers and pharmaceutical firms rely on reagents with clearly defined structures and predictable behaviors. One impure or unstable sample can cost days or lead to data nobody can trust. With a well-established formula like (CH3)4N H2PO4, manufacturers and researchers get fewer surprises. They know exactly what to expect, whether they’re working on next-generation batteries, designing specialty polymers, or producing medicines.

Staying Safe With a Potent Compound

There’s no room for carelessness in chemical stewardship. Tetramethyl ammonium compounds, while generally less toxic than some heavy metal salts, still demand respect. Inhalation or inadvertent contact can irritate skin, eyes, or the respiratory system. Using gloves, eye protection, and effective ventilation, even during transfers or dilutions, has kept chemists like me from unwanted trips to the eyewash station. It’s vital that everyone who works with this compound reviews the latest safety data, not just for personal protection but to safeguard colleagues and the environment. Thankfully, most standards in academic and industrial settings enforce regular training on chemical handling and disposal.

What the Future Holds

Interest in compounds like tetramethyl ammonium dihydrogen phosphate has grown with green chemistry. Scientists search for new processes that cut down on waste and avoid toxic byproducts, and this relatively simple and stable salt often fits that bill. Its clean decomposition, paired with good water solubility, means fewer headaches during cleanup or waste treatment. That matters a lot as regulations continue to get stricter across the globe.

Greater demand for sustainable electric devices and medical treatments points to a rising need for compounds with clearly defined chemistries. Reliable materials won’t fix every lab disaster, but getting a handle on exactly what’s going into a reaction always leads to smarter results. In my experience, the best moments in science come from having confidence in every ingredient — and knowing the chemical formula down to each atom counts for a lot.

A Closer Look at Chemical Safety

Tetramethyl ammonium dihydrogen phosphate doesn’t jump out at most people from daily headlines. For chemists, manufacturers, or folks who deal with electronics, this compound occasionally turns up in laboratories or production lines. It forms a white crystalline solid, easy to overlook if you’re not tuned into its specifics. But behind that simple appearance, anyone handling chemicals owes it to themselves and their colleagues to treat every substance with informed caution.

Most household products echo warnings with good reason—imagine strong cleaners under the kitchen sink. This chemical’s hazards line up more with those you’d see in a research setting, not something you'd find at a grocery store. Evidence from safety datasheets and chemical suppliers marks tetramethyl ammonium dihydrogen phosphate as toxic in specific circumstances. It’s no cyanide or mercury, but the risks are real—just delivered differently.

Health Risks and Routes of Exposure

Direct contact with skin, inhalation of dust, or swallowing even small amounts can trigger harm. Reports show it can irritate eyes and respiratory passages almost immediately. Swallowing or vaping up enough of it may land someone in the hospital with headaches, nausea, or nerve-related symptoms. The tetramethyl ammonium group isn’t something the body can break down quickly. Since it affects the nervous system, symptoms might take a few hours to show, and by then, reversing damage gets tougher.

I’ve worked with quaternary ammonium compounds over the years. In one mishap, a powdered sample became airborne while a researcher was mixing solutions. Coughing and burning eyes followed, even though the initial contact lasted only seconds. That day, the ventilation hood did more than protect—the awareness among our team made everyone double-check protective gear. No one expects trouble, but proper lab habits make all the difference.

Environmental Considerations

Labs generate waste—leftover chemicals often wind up in drums awaiting disposal. Compounds containing phosphorus or quaternary ammonium ions don’t just sit harmlessly in the trash. If poured down drains, they become pollution concerns for treatment plants. Aquatic organisms react poorly to trace contaminants from specialty chemicals, sometimes leading to toxic buildup in local water sources. Even if one batch doesn’t cause visible harm, repeated carelessness stacks up for communities and ecosystems.

Regulation and Best Practices

In most places, tetramethyl ammonium dihydrogen phosphate works under restriction, not a ban. That means researchers and industry must follow protocols for storage, labeling, and disposal. Gloves, goggles, and fume hoods aren’t suggestions—they are the bare minimum. In my experience, clear procedures and emergency drills help drive home the routines. Newcomers quickly learn that safe handling isn’t about paranoia but about respect for a tool’s double edge.

Some labs set up training guides and regular audits to keep people sharp. Sharing accident reports, and reviewing what worked, builds real-world sense. Keeping MSDS sheets within reach—rather than buried in file cabinets—turns “just in case” into “just prepared.” If a spill occurs, neutralizing powders, eyewash stations, and good communication stop a small problem from turning into a disaster.

Paving a Safer Path Forward

Technological advances can offer alternatives. For instance, searching for less toxic chemicals with similar properties sometimes works—even if it takes longer or costs more. Consultants with green chemistry backgrounds now help universities and companies tweak protocols to cut unnecessary exposure risks. The broader lesson remains: every bottle of chemical deserves respect and informed caution. No shortcut matches good habits, clear information, and a healthy dose of respect for the tools we use every day.

The Reality of Handling a Specialty Chemical

Anyone who has worked in a laboratory or a facility storing specialty chemicals learns that sometimes, what’s written on safety data sheets doesn’t always fit cleanly with day-to-day routines. Tetramethyl ammonium dihydrogen phosphate stands out as one of those substances where the storage details can affect both workplace safety and product quality. More than a long-winded chemical name, it commands a careful approach because of its unique mix of chemical properties and reactivity.

Why This Compound Demands Respect

Tetramethyl ammonium dihydrogen phosphate doesn’t carry the explosive risk you’ll see with some peroxides or the fire hazard of peracetic acid, but people using it shouldn’t let their guard down. There are two straightforward risks: toxicity from exposure and chemical instability with the wrong environment. Inhalation or skin contact may cause irritation, and dust control matters. If it mixes with acids, the result can be unpredictable, sometimes producing harmful vapors. There’s also its tendency to take up moisture from the air, which may affect purity over time.

The Direct Approach to Storage

Nothing beats keeping a chemical dry and sealed up. Tetramethyl ammonium dihydrogen phosphate handles moisture poorly, and exposure to humidity turns it clumpy, which can lead to difficulty in accurate measurement or application. Employers owe it to their workers and their bottom line to use well-sealed containers, preferably those built from high-density polyethylene or glass with chemical-resistant closures. This quaternary ammonium compound breaks down faster if left to sit in open air or in a flimsy jar. Every chemist I know has stories of ruined batches from a poorly screwed cap.

Temperature swings play a quieter but bigger role than some realize. Store this salt in a steady, cool spot out of direct sunlight. Consistent temperature preserves stability longer; leaving it near vents, heaters, or sunny shelves speeds up decomposition even if the effects aren’t obvious the first month. Don’t overlook labeling. Clear, large-font labeling, accurate date of receipt, and hazard classification help avoid mix-ups, especially in busy or shared storage rooms.

Human Factors and Solutions

Even with written policies in place, accidents still happen because shortcuts seem harmless. It’s easy to tell yourself, “I’ll move it in five minutes,” and never circle back. I’ve seen labs where liquids seeped under unsealed lids because nobody wanted to clean sticky residue off their gloves. Staff training works best when it’s regular and hands-on. Bringing people together once a year to review the material hazards and demonstrate basic storage techniques builds habits. Posters around storage rooms listing reminders (keep container dry, check seals, avoid acids) go further than long binders tucked in drawers.

Spill kits should sit close by, not hidden down the hall. A simple dustpan, gloves, and proper disposal bags cover most small spills, but big issues need chemical-absorbent materials. Ventilation deserves attention too. Even with the best storage, accidents put vapors in the air. Installing local exhaust hoods keeps the air clean and protects everyone—especially in older buildings where circulation lags.

It’s About Respect, Not Fear

Tetramethyl ammonium dihydrogen phosphate doesn’t call for panic, just informed respect. Store it somewhere dry, cool, well-marked, and always sealed up. Dedicate a little space on the shelf, train your team, and keep supplies ready for mistakes. Over the years, these basic habits have shielded both health and investments from unnecessary risk. That simple approach always beats scrambling to fix things after the fact.

Why This Chemical Calls for Respect

Tetramethyl Ammonium Dihydrogen Phosphate doesn’t get mentioned in most household safety manuals, but those working with chemicals or conducting laboratory research know it’s not something to take lightly. A handful of academic facilities and high-tech industries rely on it in specialized processing, from microelectronics to surface treatments. My years around chemical storage have shown that getting casual with these compounds opens the door for careless mistakes—and in this game, mistakes carry consequences.

Understanding the Hazards

This compound holds a spot on hazard lists for several reasons. Skin and eye irritation show up quickly if gloves, goggles, and lab coats fall out of use. Mistakes with inhalation or accidental ingestion can lead to deeper issues, ranging from respiratory discomfort to nervous system effects. Stories stick with me—an old lab tech sharing how one careless splash led to days off due to skin burns, and a facility coordinator warning me that even vapors unsettle the lungs during extended exposure.

Essential Personal Protective Equipment

Stepping into any lab where Tetramethyl Ammonium Dihydrogen Phosphate shows up means putting on full personal protective equipment (PPE). Nitrile gloves perform better against chemical penetration than latex, and chemical splash goggles protect from stray droplets that find exposed faces. In settings with poor ventilation, a fume hood becomes non-negotiable. Relying only on an open window or a ceiling fan just doesn’t cut it. Covering up doesn’t make anyone a hero, but rushing a job without protection brings regret.

Storage and Labeling Cut Down on Risk

Some mishaps stem from small things—an unlabeled jar or a cracked container. Chemicals belong in sturdy, tightly sealed containers, set away from direct light or moisture. Access restricted to trained staff means newcomers don’t wind up taking risks out of ignorance. In one university lab I visited, a simple checklist on the door—confirming containers were sealed and labeled—proved more effective than an entire wall of printed safety posters.

Emergency Prep Isn’t Just a Formality

Too often, safety showers and eyewash stations gather dust, but an incident transforms them from background objects to frontline defenses. During drills, staff get familiar with the locations and how to use these stations. Hydrofluoric acid taught us to treat every chemical as capable of surprise. Spill kits stocked with absorbent pads, neutralizers, and disposal bags save time when something goes wrong. In every workplace that handled Tetramethyl Ammonium Dihydrogen Phosphate, spill response drills marked the difference between panic and quick containment.

Training and Open Communication Save Lives

Training sessions and walk-through demonstrations help new team members move from theory to careful handling. Shortcuts multiply risk. Everyone, from interns to senior chemists, owes it to themselves and coworkers to speak up if something feels off—if a procedure seems rushed, if a label looks faded, or if PPE supplies run short.

Finding Solutions

No safety system replaces vigilance, but straightforward steps go a long way—regular reviews of storage protocols, updating safety data sheets for ready reference, encouraging open conversations about near-misses, and ensuring management backs a culture where safety trumps speed. Accidents might not make the evening news, but avoiding them means everyone finishes the shift healthy and able to return home to their families. That’s a goal every workplace should aim for, not just the ones handling notorious chemicals.