Tetramethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide: A Closer Look

Historical Development

For those working in synthetic chemistry, ionic liquids have changed a lot over the past fifty years. Tetramethylammonium Bis((trifluoromethyl)sulfonyl)imide grew in popularity during the late 20th century, especially as researchers dug into alternatives to volatile organic solvents. Early on, ammonium salts with large anions drew attention thanks to their thermal stability and unique solubility. Research directions shifted radically with the introduction of the bis(trifluoromethylsulfonyl)imide anion —NTf2—which set a new standard for hydrophobicity and electrochemical windows in ionic liquids. Across labs, the drive to generate safer, more customizable solvents pushed the development of these salts, and their industrial importance keeps growing.

Product Overview

Tetramethylammonium Bis((trifluoromethyl)sulfonyl)imide brings together the compact, symmetrical tetramethylammonium cation and the highly delocalized NTf2 anion. This produces a salt with high chemical and thermal stability. Many chemists value how it hardly absorbs water, resists decomposition, and dissolves well in many organic solvents. Standard grades appear as colorless to off-white solids. In my work with energy storage and organometallic processes, nothing beats this salt for cutting down volatility and managing conductivity. Its place among electrolytes, phase transfer catalysts, and advanced separation media keeps expanding.

Physical & Chemical Properties

Physical appearance usually ranges from a crystalline powder to a waxy solid. The melting point stays above room temperature, often around 100–150°C, which keeps the material practical under moderate laboratory conditions. The NTf2 anion, with its bulky, fluorinated structure, makes this salt notably lipophilic. Solubility in acetonitrile, dichloromethane, and other polar aprotic solvents proves excellent, while water solubility stays low. The compound stays thermally stable well above 200°C, which matters a lot for electrodeposition and high-temperature battery applications. Chemically, it resists both strong acids and bases, and doesn’t break down in the presence of light or air. For folks running reactions that demolish weaker salts, this option stands up to harsh reagents with impressive resilience.

Technical Specifications & Labeling

Commercial products list a purity, usually above 98%. Moisture content remains particularly important, since water can degrade the ionic character and impact downstream chemistry. Typical bottles include the full chemical name, CAS number (e.g., 64903-17-7), structural formula, storage instructions, and recommended use intervals. For large quantities, batch numbers trace manufacturing history so any irregularity gets caught early. In my lab, I always check for proper double-sealing and use desiccators to prevent contamination, especially if running moisture-sensitive reactions or storing for months on end.

Preparation Method

The main synthesis begins with the tetramethylammonium halide, most commonly the chloride, which reacts with an excess of lithium bis(trifluoromethyl)sulfonylimide in water or acetonitrile. The metathesis reaction forms the product, as the lithium chloride byproduct gets filtered or extracted away. After washing and drying, the remaining salt undergoes repeated recrystallizations if high purity is required. Efficiency jumps when reagents are dry, oxygen exposure is minimized, and all glassware is scrupulously clean. This allows for consistent product batches for industrial use. In academic settings, fine-tuning the synthesis by varying solvent ratios or temperatures lets chemists adapt the process for scale or special purity needs.

Chemical Reactions & Modifications

Chemical stability is the calling card of the NTf2 anion. That makes Tetramethylammonium Bis((trifluoromethyl)sulfonyl)imide a reliable, nearly inert electrolyte or phase transfer agent in difficult separations. Modifications tend not to happen directly on this molecule, but researchers do use it as a benchmark—for example, testing its performance against other ionic liquids in catalysis, batteries, and extraction. The cation-anion pairing can be swapped: switching to larger organic cations lets chemists alter melting point and viscosity in search of novel ionic liquids. In my work with electrochemistry, this salt never interfered with redox pairs, even at high voltages.

Synonyms & Product Names

You might see this compound labeled as Tetramethylammonium NTf2, TMA-NTf2, or Tetramethylammonium bistriflimide. Suppliers sometimes use names like Tetramethylammonium bis(trifluoromethanesulfonyl)imide, or simply “TMA TFSI Salt.” Accuracy in naming prevents ordering mishaps, especially when similar salts differ only in cation or anion structure. I’ve run into confusion myself over ambiguous catalog abbreviations, so keeping track of supplier codes alongside the full IUPAC name saves hassle in busy labs.

Safety & Operational Standards

While many see ionic liquids as “green” alternatives, these compounds still demand care. Always use gloves, goggles, and proper ventilation, since long-term effects of inhalation or skin exposure remain under debate. Safety data sheets warn against ingestion and advise immediate cleanup of spills, since NTf2 salts leave residues that resist water rinses. Avoiding open flames and storing away from acids or bases stretches the shelf life and reduces risk. Disposal poses challenges: many facilities classify these fluorinated compounds as hazardous waste, due to potential toxicity and poor environmental degradability. I’ve seen research groups routinely evaluate waste processing protocols before scaling up reactions, to avoid costly compliance surprises.

Application Area

This salt excels in battery electrolytes, supercapacitors, and electroplating as a non-volatile, stable ion carrier. In catalysis, the compound helps phase transfer and boosts selectivity for alkylation or metalation reactions where less robust salts would decompose. Separation science has seen big advances using this salt: for extraction of rare earths, removal of metal impurities, and even as a stationary phase in chromatography. In my own projects, I’ve used TMA-NTf2 to tune ionic strength and minimize unwanted side reactions. Imaging, mass spectrometry, fuel cells, and green chemistry all draw benefit from its resilience and non-nucleophilicity.

Research & Development

Academic labs keep digging into new uses for NTf2-based salts, aiming to lower viscosity, boost conductivity, and design task-specific ionic liquids. Much attention zeroes in on recycling, regeneration, and environmental persistence of fluorinated anions. Ongoing collaborations between academia and industry drive cleaner synthesis routes with fewer byproducts and improved waste management. Additive blending and co-solvent exploration keep expanding the range of viable applications. In the field of organometallic catalysis, these salts let chemists stabilize difficult intermediates, running reactions that would fizzle with classic solvents.

Toxicity Research

Current evidence shows NTf2-based salts have lower acute toxicity compared to traditional solvents, but debate continues about their impact on ecosystems and chronic exposure. While short-term contact may cause mild irritation or discomfort, long-term risks have not been fully studied. Animal studies suggest possible bioaccumulation of the anion, raising questions around wastewater handling and downstream effects. Some reports point to the persistence of fluorinated species in the environment, especially if waste slips through standard treatment plants. Proper labeling, containment, and training make a big difference reducing occupational exposure. I favor periodic reviews of published toxicology, as understanding develops rapidly.

Future Prospects

With energy storage, miniaturized electronics, and green synthesis on the horizon, attention on advanced ionic liquids keeps ramping up. Customizing cation–anion combinations aims to tailor conductivity, viscosity, and performance for next-generation devices. Scaling up sustainable production without fluorinated waste stands as a key challenge. New analytical techniques may let researchers spot subtle reactivity or degradation long before scale-up. In terms of safety, regulatory bodies continue weighing the element of uncertainty regarding persistence and toxicity. Finding routes for full lifecycle management of these compounds looks essential. Growth in advanced manufacturing stands to benefit, and ongoing work in labs worldwide keeps refining the strengths and exposing the limitations of Tetramethylammonium Bis((trifluoromethyl)sulfonyl)imide and its peers.

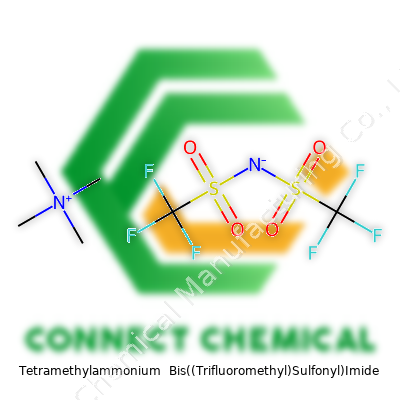

Chemical Formula and Structure

Tetramethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide carries the chemical formula (CH3)4N+[(CF3SO2)2N]-. Some folks in research call it TMA-TFSI. At its heart, you have a tetramethylammonium ion with four methyl groups stemming from a central nitrogen: (CH3)4N+. The anion, bis((trifluoromethyl)sulfonyl)imide, brings together two trifluoromethylsulfonyl groups linked to a nitrogen via a -N(SO2CF3)2 backbone. The 3D shape turns out less obvious on paper but keeping that double sulfonyl armature with electron-rich fluorine atoms helps this compound stay stable and soluble in challenging solvents.

Why the Structure Matters

Chemistry in practice isn’t just about knowing a formula. This compound’s unique balance between the lipophilic trifluoromethyl tails and the ionic core allows it to dissolve in both non-polar and polar media. Ionic liquids built around the TFSI anion catch eyes in electrochemistry circles because of low viscosity, high stability, and wide electrochemical windows. They're not volatile. No stinging odors jump out when bottles open. My own slip with leaky, foul-smelling electrolytes made me appreciate the “dry” handle this salt gives to experiments in new battery or capacitor setups.

Real Applications Driving Demand

In labs and industries where folks chase safe, long-life batteries or capacitors, TMA-TFSI turns up often. The salt forms clear, stable molten mixtures—ionic liquids—at room temperature. These are valuable for next-gen lithium batteries, dye-sensitized solar cells, supercapacitors, and as antistatic agents in manufacturing environments. Reports highlight that systems using TFSI anions outlast traditional ones, especially under high-voltage cycling or in humid air. Even basic handling improves; the salt resists absorbing water as aggressively as some classmates do, cutting down on unwanted side reactions.

Concerns and Solutions Beyond the Lab Bench

Every material with promise brings its own baggage. Commercial-scale synthesis of TFSI-based compounds often involves expensive reagents and high energy use, which can push up environmental and financial costs. The breakdown of TFSI salts can generate persistent trifluorinated byproducts. Some studies already suggest these molecules resist natural degradation, leading to worries about water or soil contamination if disposal slips through the cracks.

Green chemistry has stepped in, showing interest in designing safer fluorinated sulfonimides with similar performance but greater biodegradability. Switching to renewable feedstocks and closed-loop manufacturing can also reduce both emissions and waste. Academic and industry research groups now publish life-cycle assessments alongside traditional data. This shifts attention away from exclusive focus on lab performance toward responsible production, recycling, and disposal.

Room for Practical Innovation

The science community thrives when curiosity couples with accountability. Chemists can’t dodge the need for more robust testing on decomposition and environmental fate. Industry voices should jump into these discussions, not just regulatory agencies and NGOs. Research funding could reward those who tackle not only how well TMA-TFSI works, but also how it behaves after use. Folks working in labs, pilot plants, or manufacturing floors shoulder a shared responsibility to look at both the benefits and baggage packed into every new chemical recipe.

The Backbone of Many Modern Electrolytes

Electrochemistry has solved plenty of problems that older generation chemists only dreamed about fixing. One of the lesser-known but vital compounds in the field is Tetramethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide. Scientists tend to shorten its name to TMA-TFSI, which already tells a lot about its day-to-day application—it shows up most in places where precision, safety, and efficiency really count, but where the public eye rarely looks.

Energy Storage: Not Just Lithium

People talk about lithium batteries as if they run the world—and in some ways, they do. TMA-TFSI plays right into that story, but it exists in the supporting cast, often involved in specialized battery chemistries from research labs to niche commercial markets. Researchers like how this salt delivers both high ionic conductivity and impressive chemical stability. If you’ve followed the challenges with high-performance lithium-ion and flow batteries, you know how moisture and decomposition present risks. This is where TMA-TFSI steps up: its structure shrugs off water and resists breakdown even under strong voltages. That reduces danger and extends the lifespan of batteries trying to manage high energy densities. In flow batteries, which store renewable electricity, additives like this make the storage process more reliable by cutting out unwanted reactions at the electrode.

Greener Chemical Syntheses

Modern labs don’t simply want results—they want cleaner processes. TMA-TFSI supports this move. It acts as a cornerstone in many ionic liquids, giving chemists solvent options that offer low volatility, broad liquid temperature windows, and strong stability. In my experience, shifting single-step reactions from traditional organic solvents to TMA-TFSI-based ionic liquids often lets labs avoid harsh conditions and cut back on hazardous waste. Whether a team produces pharmaceuticals or specialty polymers, the ability to recycle or reuse solvents means fewer headaches about compliance and environmental impact. A study published in the Journal of the American Chemical Society reported 70% reduction in solvent waste for certain alkylation reactions just by switching to these ionic liquids.

Electroplating and Advanced Surface Treatments

The clean, glassy finish on your phone or laptop often owes its durability to electroplating baths. TMA-TFSI’s high solubility and low reactivity help technologists deposit uniform layers of precious and semi-precious metals, including gold and platinum, without unexpected side effects. Old recipes for electroplating baths sometimes relied on harsh acids or volatile organics; newer TMA-TFSI-based blends let companies avoid those hazards. Reports from the European Surface Science Consortium point to measurable improvements in plating speed and consistency when including this compound in treatment solutions.

Semiconductor Manufacturing

Cleanroom engineers fight a constant battle with contamination and instability in the quest for more compact chips. In specialty etching and doping steps, the stability of TMA-TFSI’s anion and its resistance to moisture offer improved process control. Application engineers have used TMA-TFSI in formulations for photoresist removal and as a platform for delivering ions in precision etching. The compound’s consistency means tighter process windows and fewer yield losses. My conversations with colleagues at semiconductor suppliers confirm a slow shift toward these salts, which might not steal headlines, but quietly keep supply lines humming by cutting back on defects.

Meeting Industry Needs with a Trustworthy Tool

Tetramethylammonium Bis((Trifluoromethyl)Sulfonyl)Imide reflects a broader effort to make the foundational steps of chemistry safer, cleaner, and more reliable. Whether powering a car or improving a solar storage array, its presence threads through modern technology in ways that don’t attract much limelight—but end up shaping outcomes all the same.

Reality Check: Why Safe Chemical Handling Matters

Anyone who’s spent time around labs, workshops, or even a high school chemistry class understands that proper chemical storage is more than a checklist—it’s a lifeline. I’ve watched a poorly-stored bottle of sodium hydroxide eat through a shelf in my early lab days, and that memory hasn’t faded. Respect for chemicals begins with accepting they don’t care if you make mistakes; gravity, heat, moisture—these things all play against you once a mistake happens. So let’s get into what really matters for keeping everyone safe.

Respecting Labels and SDS Sheets

No scientist or technician has ever looked cooler by ignoring a Safety Data Sheet. Labels and these sheets tell you plainly: eye protection, glove type, ventilation, spill procedure, and what temperature turns an innocent bottle into a ticking hazard. Manufacturers often send out updated guidance, so treating that as background noise risks everyone’s safety.

Staying Cool—and Dry

Temperature and humidity make or break chemical stability. Strong acids or bases often react to moisture in the air. If you store hydrochloric acid near a vent or in a steamy room, corrosion creeps up on metal fixtures and an invisible cloud of fumes hangs around. Keeping chemicals in a well-marked, dry, and cool storage area not only protects the shelf life but keeps your equipment breathing easy too.

No Chemistry Roulette: Segregation Means Safety

Space costs money in any work area, but squeezing bottles of oxidizers next to organic solvents turns the shelf into a powder keg. Segregating chemicals keeps nasty surprises off the menu. Schools drill that lesson into students early, but grown-ups mess it up too. My first real gig in industry saw a shelf collapse just because someone wanted to put “all the acids together.” Segregation by hazard class—acids, bases, flammables, toxics—reduces risk right down the line. Steel cabinets for flammables, polyethylene bins for acids; it’s not rocket science, it’s self-preservation.

Original Containers Win Every Time

Rebottling chemicals to save space or grab a clean label backfires. Manufacturers design bottles to handle the chemical’s quirks—pressure build-up, photoreactivity, you name it. Homemade labels fade, and coffee jars can never replace UN-rated packaging. Keeping chemicals in their original containers preserves both vital information and safety features.

Ventilation: Don’t Let Invisible Hazards Pile Up

Fresh air helps, but not every room pulls its weight. Fume hoods exist for a reason: even sealed bottles can leak trace vapors. In my experience, opening a bottle of phenol in a windowless closet marked “storage” turns a minor job into an evacuation. Chemical storage areas need real circulation and, in some cases, active ventilation systems to keep vapors from concentrating.

Checks, Double-Checks, and the Buddy System

Regular audits catch small leaks and aging containers. I once found a forgotten bottle of ether—top crusted with crystals, cap sweating danger. Scheduled checks and team-based walkthroughs spot things one person alone might overlook. It’s easy to get lax when things seem fine, but diligence beats band-aids and apologies.

Tough Talk on Waste

Disposing of chemicals by pouring them down the sink risks both pipes and people. Following local waste codes protects the community and ecosystem. Teams need training, not shortcuts. Chemical waste should go straight into labeled containers, stored in a lockable spot until disposal.

Real Accountability Protects Everyone

Safety isn’t about red tape. It’s about walking out the door the same shape you walked in—every day. It means accountability, common sense, and respect for substances that don’t play nice when ignored.

Understanding the Chemical

Getting to know a compound starts with respecting its potential risks. Tetramethylammonium bis((trifluoromethyl)sulfonyl)imide belongs to a group of chemicals that don’t mess around. Its long name signals a level of complexity where high reactivity and possible toxicity often mix together. The presence of fluorine, especially in a sulfonyl group, hints at chemical stability but also environmental persistence and risk for the person handling it. I remember early in my career, underestimating a new ionic liquid only to learn from a team member that strong gloves prevented a rash no one wanted. That stuck with me.

Personal Safety: Kit and Precautions

Goggles and nitrile gloves should be your companions. Splash-resistant lab coats that close at the neck and wrists keep contamination away from clothing and skin. Never skip the gloves—my own experience cleaning out a workspace showed me just how easy it is to pick up traces of hazardous materials, and this one doesn’t wash off with soap and water alone. Face protection, such as a splash shield, becomes necessary if transferring the compound from one container to another.

Ventilation in the workspace matters as much as your personal kit. Fume hoods equipped with proper filters help because the chemical can give off toxic fumes if heated or mishandled. I’ve worked in labs where the absence of a functioning hood led to headaches for the team. In places where the air moves freely, accidents stay contained, and you keep your lungs healthy.

Storage and Handling

Keep this chemical dry and away from heat. Many organofluorine compounds break down into toxic gases if exposed to high temperatures, and water can start reactions you won’t want. Use only containers certified for aggressive chemicals—HDPE or PTFE work best. I’ve seen cardboard near liquid chemicals; that is just asking for leaks and burns.

Label every container clearly. No one likes coming into a lab to see unlabeled flasks. Mistakes happen, but clear marking keeps them from turning into emergencies. Spills must be cleaned right away with appropriate absorbent materials and neutralizers. A good practice: Have a spill kit nearby that covers corrosive and fluoride-containing chemicals. I’ve had to improvise with paper towels—never a good sign.

Environmental and Health Impact

Disposal shouldn’t go down the drain or into regular trash. Licensed chemical waste handlers know how to deal with substances that stick around in the environment and poison water supplies. Inhaling vapors or letting them touch your skin increases toxic exposure, and no one really knows the long-term effects of some byproducts. Full-face shields and long sleeves help limit exposure and remind everyone that respect for chemicals means fewer regrets later. Using a buddy system ensures someone’s there if things go wrong, and regular safety checks help too.

Training and Documentation

Written procedures and training sessions for the team keep standards consistent. Even the most experienced chemists benefit from a quick rehearsal of emergency procedures. Posters in the lab, from proper glove disposal to eyewash instructions, serve as silent guides. I once responded to a splash with a well-practiced fifteen-minute eyewash thanks to having those instructions nearby. That type of preparation makes all the difference.

Smart Steps Forward

Better engineering controls—local exhaust, advanced filtration, and automated handling—cut down on close contact. Real safety comes from a culture that values checking twice and never cutting corners, something I’ve learned through both close calls and careful work. Reducing unnecessary exposure, double-checking labels, and keeping spill response equipment close all go a long way in making sure everyone gets home safely.

People Want Clean Products

Ask anyone who works in a lab or in manufacturing: purity in chemicals isn’t just a fancy technical measure—it shapes whole processes. A product with 99.9% purity means fewer headaches sorting out unexpected byproducts, tighter safety controls, and more predictable reactions. My own first experience with “off the shelf” chemicals included a supposedly pure sample that turned out to be speckled with colored flecks. It failed the experiment and cost my team a week of troubleshooting. Visual cues can set alarm bells ringing long before a purity certificate ever gets checked.

What Does Purity Mean for the User?

Most suppliers state purity as a percentage. For industrial-grade sodium chloride, for example, you’ll often see numbers like “min. 99.5%.” In small-scale pharmaceutical production, that number might climb above 99.9%. What’s left in that remaining fraction isn’t just an idle curiosity. Sometimes it’s water or dust, but almost always, users chase down specific contaminants that could ruin a reaction or spoil a product’s shelf life. In over-the-counter medications, purity lets pharmacies guarantee both safety and effectiveness.

Looks Matter More Than People Think

Appearance keeps buyers honest. A white crystalline powder shows up as exactly that—free-flowing, no clumping or discoloration. If something meant to be clear arrives cloudy, or if a powder clumps when it should pour, people worry about moisture and possible contamination. During my time in water treatment, fine, dense powders never performed as advertised if they came damp or with unusual smells. Even a minor change in how something looks can signal a shipment stored wrong, or a chemical with way too many impurities.

The Documentation Side of Purity

With every technical purchase, suppliers provide a certificate of analysis—breaking down not just the main ingredient, but also trace components. For paints or food additives, this transparency stops surprises in the supply chain. I will never forget finding a batch of citric acid with too much iron—our lemonade batches in that plant turned a rusty brown overnight. Testing and documentation save money and reputation alike.

Dealing with Purity Problems: Practical Steps

What’s the best way forward when a shipment looks “off” or falls short on its numbers? Don’t just toss it—start with a side-by-side comparison to a reliable sample. Reach out to the supplier for another test or a replacement. In my experience, early and honest communication works better than hoping a small difference won’t matter. Make regular spot checks part of the job, just as important as equipment maintenance or safety drills. Consistency rewards businesses with trust and fewer surprise failures.

Solutions Start with Communication and Vigilance

Many issues around chemical purity vanish with routine quality checks and honest supplier relationships. Teams that invest in robust incoming inspection processes spend less overall than those who cut corners. Involving both quality control and end users builds a shared understanding of what to expect. That’s the real value: purity and product appearance become signals of reliability—key to keeping operations smooth and customers happy.