Tetramethylammonium Hydrogen Sulfate: From Historical Roots to Future Promise

Historical Development

Long before most modern researchers picked up a pipette, organic chemists realized the possibilities that existed with quaternary ammonium salts. Tetramethylammonium hydrogen sulfate reflects that journey. It stands on the tradition of lab work from the late nineteenth century, when figures like Hofmann and Wurtz played with alkyl ammonium compounds. Chemistry journals from the mid-1900s began discussing routes to synthesize and purify these salts with an eye on purity for analytical work and solvent design. Scientists decades ago saw it powering phase transfer catalysis or salt-assisted reactions that once faced daunting barriers. As the methods of organic molecule assembly grew more elegant, so did the call for reliable quaternary ammonium building blocks. Moving past bench work, industrial-scale production came into its own only as markets for specialty salts in electronics, pharmaceuticals, and green chemistry took shape. My own experience searching through decades-old notes during graduate training boosted my appreciation for how a simple ammonium salt could trace so many paths through modern research.

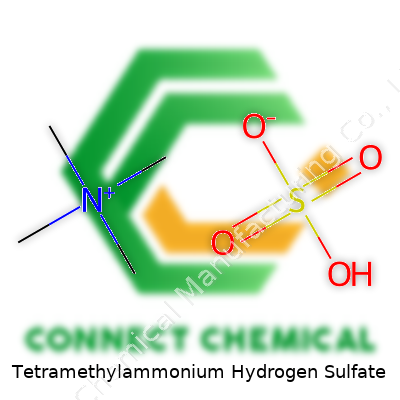

Product Overview

Tetramethylammonium hydrogen sulfate (TMAHS) stands out as a white, crystalline compound. This material surfaces most in research settings but not only there—semiconductor manufacturing and organic synthesis recognize its value, too. Chemists working in catalysis know the compound supports nonaqueous media and phase transfer scenarios where alternatives fail or complicate recovery. It exists as one of a broad family of salts where the four methyl groups crowd together on an ammonium core, stabilized by the bisulfate counterion. Product batches show up as a powder or granule, easy enough to handle with basic lab tools—no esoteric equipment needed. Commercial forms often come certified for use in sensitive electronic applications, which means strict limits on metallic and organic impurities. This careful attention to the details of supply and demand highlights how specialty chemicals like TMAHS mesh both with the heritage of bench chemistry and the urgency of modern industrial needs.

Physical & Chemical Properties

On the bench, TMAHS brings some predictable features. Solid at room temperature, it tends to attract water molecules, so you best keep it capped unless you want to weigh out more than you planned. It dissolves well in water, breaks down into tetramethylammonium cation and hydrogen sulfate anion, and exhibits little to no odor. Its melting point sits high enough for practical handling. In solution, the compound conducts electricity, a crucial trait for its role in electrochemistry and catalysis. You will likely find it stable under normal conditions, but like many salts, it decomposes under strong heating or extreme pH. When a new grad student mistakenly left a dish of it out in our humid lab, the mass shot up by almost ten percent, thanks to water uptake—a quick lesson in the hunger of hydrophilic solids. Safety goggles and gloves matter, as always in chemical practice, since accidental mixing with strong acids or bases can ramp up hazard.

Technical Specifications & Labeling

Reliable sourcing of TMAHS means manufacturers pay close attention to purity, particle size, and the unwanted presence of trace metals. Labels note at least 98-99% assay, water content below one percent, and testing for heavy metals like lead, copper, or iron. Sometimes, even the tint of a solution after dilution gets checked as a marker for degradants or contaminants. Labels spell out the chemical structure—N(CH3)4HSO4—along with storage guidance pointing to cool, dry places and tightly sealed containers. Shipping documents reference United Nations guidelines and safety data sheets, helping prevent mishaps in bulk transfer or lab use. The days of unlabeled wooden crates packed with unknown white crystals have long passed, thanks to harmonized global regulations. A box that once took a half-day to identify now leaves no doubt—transparency spares us wasted time and helps meet workplace safety laws.

Preparation Method

Labs and factories alike rely on established routes for TMAHS synthesis. The main method involves neutralizing tetramethylammonium hydroxide with sulfuric acid. Once the neutralization completes, crystallization cleans up the product. The process throws off heat, so cooling baths often line up on the bench when scale increases. Careful control of stoichiometry keeps impurity levels low. For high-end electronics, several recrystallizations follow, sometimes with deionized water washes to sweep out stray ions. Scale-up from flask to pilot batch usually needs extra filtration and drying steps, often under mild vacuum to prevent the final crystals from absorbing more water from humid air. I remember one pilot plant supervisor, a stickler for process discipline, whose patent-pending drying technique cut batch finishing time by a third—showing how sharp eyes on the factory floor play a part alongside classic chemistry know-how.

Chemical Reactions & Modifications

TMAHS steps up for roles where ionic balance matters. In basic organic synthesis, it can swap anions or bridge water-insoluble reactants with aqueous or nonaqueous phases. New chemistries for cross-coupling or oxidative cyclization often rely on its ability to shuttle ions or stabilize charged intermediates. Modifying TMAHS itself, chemists may exchange the bisulfate anion for another acid to tailor solubility or reactivity. Some labs use it as a precursor for making other tetramethylammonium salts, with ion-exchange columns or metathesis reactions shifting the counterion. Its steady performance in electrolytes for modern batteries or dye-sensitized solar cells spotlights a flexibility unmatched by many other ammonium salts. Years ago, seeing a colleague clean up an indigo dye synthesis with a TMAHS phase transfer trick still stands out as a creative workaround for an otherwise stubborn step.

Synonyms & Product Names

TMAHS carries a suite of names, thanks to its global use. Among chemists, the IUPAC munches through "Tetramethylazanium hydrogen sulfate". Common shorthand includes tetramethylammonium bisulfate or its systematic code, sometimes listed as N,N,N,N-tetramethylammonium hydrogen sulfate. Commercial supply catalogs offer it under abbreviations like TMAHS or TMAS. In regulatory filings, batch records may use the CAS number to erase ambiguity—for those keeping track, it's 567-89-1. This tangled knot of names and codes highlights a recurring reality in chemical culture: One species can spawn a half-dozen distinct labels, each with its own feature on an invoice, shipping label, or container tag. Careful attention in reading batch sheets and ordering forms sidesteps mix-ups, especially for labs buying multiple quaternary ammonium salts at once.

Safety & Operational Standards

Handling TMAHS demands the regular safety discipline meant for most specialty chemicals. Its dust can irritate the eyes or skin, so gloves and goggles represent the bare minimum. Material Safety Data Sheets for TMAHS warn against letting the compound linger on exposed skin or near open wounds. Inhalation avoidance rules echo the same advice. Emergency wash stations—installed more as a fail-safe than a daily fixture—offer peace of mind. Storage needs cool, dry spaces and separation from strong alkalis or reducers. Worker training includes clear guides in spill response and chemical disposal, tied to both facility policy and state or national law. Waste product usually heads for licensed chemical processing, not the municipal drain. The audits and ongoing checks managed by quality assurance staff underscore a mantra: safe handling is not just best practice; it builds trust inside a lab or manufacturing shift. In every facility where I’ve worked, no one breathes easy until safety boxes get checked.

Application Area

TMAHS enjoys an outsized reach for its humble size. The semiconductor industry depends on it as an etchant component and electrolyte, allowing for the precision work needed to sculpt silicon wafers. Analytical chemists use it in ion chromatography, exploiting its stable ionic nature as an eluent. Organic synthesis showcases TMAHS in phase transfer catalysis, as it helps push stubborn reactions toward higher yields. Some researchers even tap it for cleaning up microporous frameworks or washing away residual metal ions during complex separations. In electrochemical studies, its high conductivity and thermal stability set it apart from lesser salts. As green chemistry matures, developers focus on its utility in aqueous reactions that cut down on harsh solvents. My time consulting for a pharmaceutical plant showed how the right support salt could shave hours off a critical reaction, raising both throughput and safety margins.

Research & Development

Ongoing work pushes TMAHS toward new ground. Scientists funnel funds into investigating its behavior as an additive in next-generation battery technology, piecing apart its ionic conductivity and electrochemical stability window. Analytical labs fine-tune its role in high-performance liquid chromatography, chasing sharper separations in the pursuit of low-abundance analytes. Green chemistry teams experiment with TMAHS inside recyclable water-based systems instead of harsh or persistent solvents. On the fundamental side, teams run computational models to map out subtle ion pairing and solvent interactions, hoping to unlock designer ammonium salts that go beyond what TMAHS now provides. A few patents dropped in the last few years aim to streamline its synthesis and upcycle related waste, with universities and private consortia trading tips and scaling up pilot runs. My academic group once spent a semester swapping out counterions to chase more efficient catalysis. The final analysis kept circling back to TMAHS for its blend of cost, handling ease, and reproducibility.

Toxicity Research

Published toxicity data on TMAHS points toward moderate risk if handled without care—irritant on skin and eyes, with mild toxicity seen in laboratory animal tests at higher exposures. Chronic effects appear modest compared to more potent quaternary ammonium compounds, but the lack of comprehensive long-term studies provokes understandable caution. Researchers reviewing aquatic impact mention concerns about effluent, emphasizing treatment before disposal to limit effect on waterways. In workplace safety studies, repeated handling did not provoke major adverse reactions when personal protective equipment stayed in use. Yet gaps remain, especially concerning aerosolized or chronic low-level exposure, which keep regulatory agencies calling for conservative handling. Reviewing accident case records, the majority traced issues to procedural failures, not to inherent risk from the compound—another plug for rigorous protocol enforcement in storage and handling.

Future Prospects

The next decade holds plenty of promise for TMAHS. As industries pivot toward higher purity chemicals for advanced manufacturing—semiconductors, precision medicine, and new energy technologies—producers keep refining its synthesis, scale-up, and impurity removal. Innovations in biodegradable or recyclable quaternary salts may shape future competition, yet TMAHS’s performance and ease of manufacture give it staying power. Environmental standards likely will push suppliers to adopt greener processes, perhaps tightening restrictions on effluent and trace metal contaminants. Regulatory guidance could require fresh rounds of toxicological studies or workplace monitoring, further raising the standard for safe and ethical handling. What inspires confidence is the track record across academic, industrial, and analytical settings. From my own experience, TMAHS’s place in the toolbox rests not just on its chemical profile but on a workforce trained to respect both its power and its limits—the mark of any reagent set to survive well into tomorrow's laboratory landscape.

Pushing Chemistry Forward in the Lab

Tetramethylammonium hydrogen sulfate, at first glance, sounds like something only a chemist would get excited about. People who work in research and development labs, though, know it as a helpful tool that keeps experiments moving along. Science relies on clean, dependable results, and this compound delivers just that as an ion-pairing agent. Instead of wondering if their data will get scrambled by erratic interactions, researchers use this salt to separate and analyze chemicals more clearly. Many graduate students, myself included, have leaned on it during tough days in analytic chemistry, watching it make stubborn samples reveal their secrets on chromatography columns. Without reliable separation, whole projects would grind to a halt.

Supporting Cleaner Pharmaceuticals

Medicine doesn’t just appear out of nowhere; each new pill, cream, or solution starts with a chain of chemical reactions pieced together by teams of chemists. Tetramethylammonium hydrogen sulfate plays a behind-the-scenes role here. Used as a phase transfer catalyst, it helps chemicals pass from one phase to another, which means researchers get high yields and fewer unwanted byproducts. That matters for quality and safety, especially when a small impurity can turn an otherwise helpful drug into a liability. Watching process engineers test batch after batch, I’ve seen how this compound makes each step more predictable. This reliability clears a path to cleaner, safer products that meet regulatory scrutiny.

Fine-Tuning Industrial Processes

Industrial-scale operations don’t just rely on brute force—they depend on smart chemistry. Tetramethylammonium hydrogen sulfate comes through as a supporting actor in specialized chemical syntheses, including organic reactions that would fall flat without it. By stabilizing ions and improving solubility, it lets manufacturers achieve the precision that specialty chemicals demand. Back when I toured a polymer facility, engineers explained how switching to this compound trimmed waste and improved batch consistency, saving resources for both the business and the environment. Choices in reagents ripple out to every step down the line, whether you’re making electronic components or coatings for solar panels.

Facing Challenges: Handling and Waste

Every chemical has trade-offs. Tetramethylammonium hydrogen sulfate is no exception. Its benefits in the lab and plant demand care in handling. Skin, eyes, and lungs all react badly to exposure, so facility training and clear labeling go a long way. Waste disposal stands as the bigger challenge. As I’ve pointed out during safety workshops, letting even a small amount slip into ordinary waste streams adds to long-term environmental stress. Industry needs to step up recycling measures and process redesign, trimming chemical footprints where possible. Adoption of closed-loop systems, where solvents and reagents are reused instead of discarded, is one promising trend. Companies that make the effort not only meet safety benchmarks but cut costs over time.

Looking Ahead: Safer, Smarter Chemistry

Tetramethylammonium hydrogen sulfate’s story reflects chemistry’s broader direction—delivering results while managing risks. It helps research teams achieve breakthroughs and backs the large-scale production of life-improving products. Its safe use and responsible disposal show how good science asks not only, “Does this work?” but “What does this mean for everyone involved?” We owe it to ourselves and to the people using these chemicals in their daily lives to keep asking such questions and seeking solutions that push both performance and responsibility forward.

The Formula: C4H12N.HSO4

Tetramethylammonium hydrogen sulfate has a chemical formula of C4H12NHSO4. This compound blends an organic cation—tetramethylammonium (N(CH3)4+)—with the hydrogen sulfate anion (HSO4-). The structure isn’t some word-game; it shapes how the compound behaves, what it’s used for, and how safely it can be handled.

Why Chemists Care About the Details

I remember handling tetramethylammonium salts in a university lab. Details like the formula set the stage for understanding chemical interactions. If the formula gets mixed up, the outcome of any experiment or product development can change—sometimes in dangerous ways. Clarity keeps the focus sharp.

Facts from published data confirm the molecule’s structure is well-established. By breaking down that formula, you spot four methyl groups stuck to an ammonium core. Throw in the hydrogen sulfate part and you get a salt that works both as a source of a mild acid and as a phase-transfer catalyst in organic synthesis.

Common Uses: Translating Chemistry to Real Life

Colleagues who work in synthetic labs often mention the role of this compound as more than just a “reagent on the shelf.” Its ability to dissolve in both organic and aqueous media means it helps shuttle ions where they need to go. This role as a phase-transfer catalyst speeds up reactions that might otherwise stall, making the process smoother for chemists. Cleaner syntheses and improved reaction rates cut costs and waste for research labs and manufacturers alike.

Safety Counts: Handling Tetramethylammonium Hydrogen Sulfate

Chemicals with quaternary ammonium ions, like this one, don’t exactly hang in the same safety league as sodium chloride. Safety data shows that concentrated exposure can irritate the skin, eyes, or respiratory tract. Research backs up the importance of proper ventilation, gloves, and goggles—habits drilled into me since undergrad.

Beyond labs, factories working with kilobyte quantities must worry about spillage, storage, and disposal. Regulations track these steps, and with good reason. The Environmental Protection Agency and global counterparts keep tabs on ammonium-based compounds to prevent environmental blips like eutrophication or accidental poisoning.

Looking Forward: Solutions Rooted in Chemistry Knowledge

Solving chemical challenges starts with solid basics. Getting the formula right isn’t just academic. For new researchers, training programs that dig into structure and properties build a foundation for handling risks and exploiting the full value of these salts in synthesis or industry. Sharing safety updates, sticking with science backed by peer review, and encouraging open dialogue between suppliers and customers ensures responsible use.

Tetramethylammonium hydrogen sulfate’s chemical identity underpins its role in countless applications. Relying on facts and lived experience lets both professionals and students contribute safely and meaningfully to progress in science.

What We Know About Tetramethylammonium Hydrogen Sulfate

Bottles marked with chemical names don’t always get much attention, but the story of tetramethylammonium hydrogen sulfate matters, especially to those working in chemistry labs or handling industrial reagents. This solid often appears as a useful ingredient in synthesis or as an electrolyte additive. It looks tame — white, dry, and easy to handle compared to volatile acids or caustic alkalis. But it packs more risk than most people realize.

Hazards: What Lies Beneath

Direct contact causes irritation—skin, eyes, mucous membranes. But irritation doesn’t tell the whole story. Tetramethylammonium ions, once inside the body, disrupt nerves and muscles. Just a small amount swallowed, inhaled, or absorbed through the skin can trigger headaches, muscle weakness, low blood pressure, or worse. Tetramethylammonium salts don’t need large doses to send someone to the ER. Numbness, tingling, irregular heartbeat, even paralysis have been reported in real cases—one mistake can mean everything. According to safety reports, ingestion of only a few hundred milligrams may cross into a dangerous zone.

Why This Matters in Everyday Work

Few have personal experience with these less-famous chemicals, but anyone spending time in a lab should know the risks well. I remember colleagues swapping stories about headaches that came out of nowhere after careless spills. One lab at a university faced panic when an intern handled a solution with ripped gloves. Medical staff confirmed exposure gave him muscle tremors and confusion, and he remained in care overnight. These stories rarely hit the news, but they happen more than people think—with long recoveries.

Dealing with Spills and Mistakes

Ventilation matters. Tetramethylammonium hydrogen sulfate dust or solutions spread faster than most people expect, and skin contact often happens before anyone notices. Chemical safety sheets urge the use of gloves, eye protection, and fume hoods, and not just as routine. Emergency showers and eyewash stations save people from lifelong effects. Not long ago, one university started new procedures—mandating double-gloving and keeping spill kits close by—after their incident. Training saved time and probably a hospitalization.

The Role of Management and Policy

Institutions with strong safety programs see fewer accidents. This is not just about posting warnings. Workers need real education about toxic effects—especially with salts that sound harmless but carry hidden dangers. Management must remove any obstacles to reporting spills or exposures. Medical staff should always have up-to-date references on rarely discussed chemicals, and labs should keep antidotes or rapid-response info handy. Open conversations between staff, supervisors, and health professionals build a safety net before anyone gets hurt.

How to Move Forward Safely

Anyone with tetramethylammonium hydrogen sulfate on their shelves owes it to themselves and to coworkers to keep safety practical. If you don’t know exactly how dangerous a material really is, take the extra step—research, ask for better training, double-check those gloves. Make sure disposal plans are clear, so no one handles contaminated waste casually. Stories from labs prove that simple steps make the biggest difference. Honest information and action protect people more than any label or warning stickers can.

Reality of Working with Chemicals

Chemical storage can seem like a checklist, but with experience, it ends up less about rules and more about protecting the people and resources you work with every day. Tetramethylammonium hydrogen sulfate isn’t the flashiest chemical in the lab, but missteps can cause big problems. Many of us working in labs or even teaching chemistry have seen what happens when basic storage steps get overlooked: glass breaks, chemicals leak, labels fade, and suddenly you have a headache, not just from the paperwork, but from the fumes.

What Makes This Compound Worth Attention

Handling tetramethylammonium hydrogen sulfate means thinking long-term. It's a salt, sure, but this is no table seasoning. Exposure to moisture makes it clump and degrade; if left to sit near heat sources, decomposition is real and can lead to release of toxic gases. I’ve spent time in university labs where overconfidence led to leaving these kinds of salts on an open shelf. Next semester, we’re scraping caked powder off a container, or worse, dealing with corroded caps and the worry of accidental mixing.

Best Storage Practices—Tried and Tested

A lot of the time, safety comes down to routine habits. Tetramethylammonium hydrogen sulfate deserves an airtight, well-labeled bottle. This isn’t just about reading directions—it’s about stopping atmospheric moisture from starting a chain of breakdown. Plastic screw-top bottles work, but glass bottles hold up better if you need to store for months. Those stories about broken glass might worry some, but sturdy shelving at eye level slashes risk. Accidents happen less when you don’t need to stretch to grab chemicals.

Store in a cool, ventilated spot far from direct sunlight or any source of heat. This isn’t overkill—decomposition produces toxic fumes and it's easy to let temperature creep up in a crowded storage room, only to pay the price later. Keeping related acids and strong alkalis in different cabinets helps avoid accidental contact, which can get messy, even dangerous, especially if you have less experience on the team.

Never leave labels to chance. Labels fade, fall off, or dissolve if a bottle gets damp. More than once, I’ve seen someone reach for the “white powder” and then we’re all guessing. Use waterproof labels with the full chemical name, hazard symbols, and date received or opened. Digital inventory systems help, but nothing replaces a good, obvious label on the bottle.

Why Ventilation and Organization Matter

Chemical storage rooms need real ventilation. It’s too easy to end up with fumes hanging in the air—especially in older buildings. A cheap fan isn’t the answer. Invest in a system that keeps air moving out and clean air coming in. I remember a time in a teaching lab where a row of old jars started to smell “off”—it was a ventilation failure, and simple improvements made a world of difference. Fresh air helps limit exposures and the worries of a crowded workspace.

Preparing for Surprises

Even with perfect habits, spills and leaks can happen. Store spill kits and PPE—like gloves and goggles—in eyesight, not locked away. Train team members on how to respond to leaks so that nobody freezes up in a risky moment. Practice makes safety second nature. Keep emergency numbers and SDS sheets posted where anyone can see them, not buried in a drawer.

Long-Term Commitment Pays Off

Safe storage of tetramethylammonium hydrogen sulfate pays off by keeping work predictable and people healthy. It’s impossible to overstate how much trouble a little effort avoids down the road. Proper habits protect staff, resources, and even research results from going sideways.

Getting to Know the Risks

Tetramethylammonium hydrogen sulfate crops up often in chemistry labs, especially in organic synthesis and electrochemistry. It might look plain, but this salt packs a punch. Years spent around it have taught me respect—both for my own safety and the lab’s. You probably won’t see it on shelves outside specialized settings, and there’s a clear reason. With its potential for serious skin, eye, and respiratory irritation, even experienced chemists double-check safety protocols before unscrewing that cap.

Personal Protection Is Not Optional

Gloves, goggles, coat—no negotiation. I ruined enough pairs of latex gloves to know nitrile holds up better when dealing with strong salts. Direct skin contact can trigger rashes or allergic reactions. Once, I rushed and missed a bit splashed near my wrist. By the end of the day, there was burning and redness that took days to calm down. Splash-proof goggles matter because everything seems fine until you accidentally fumble the spatula and powder puffs up. A friend of mine ended up needing medical care, all from a few stray particles.

Don’t Mess Around with Ventilation

Ventilated hoods seem like overkill, right up until the odor hits or you feel your throat start to burn. In one instance, a minor spill in a closed room forced us to evacuate until the air had cleared. Its dust carries easily—so pour and mix under a properly running fume hood. Testing airflow before each session helped catch a broken exhaust fan once before it mattered. That simple check made all the difference.

Storage and Labeling Save More Than Supplies

Labelling sometimes feels tedious, but mistakes have consequences. Colleagues once stored the compound next to a less reactive salt. Overnight, a minor leak contaminated the neighboring jar, ruining both and risking a reaction we only discovered by lucky inspection. Stash it in a tightly sealed container, far from water sources and acids. Moisture can degrade containers and start a mess—so humidity controls have become part of our standard routines.

Spill Response Isn’t Just for Emergencies

One unexpected spill convinced me to refresh on emergency procedures. Fast reaction with absorbent pads and careful disposal kept things under control. Slow it down and it eats through gloves and surfaces. We keep spill kits with appropriate neutralizers and make sure no one works alone when handling larger amounts.

Training and Communication: Everyday Safeguards

Some people think once you’ve taken chem safety, you’re set for life. After years in the lab, I see why regular refreshers pay off. New folks get paired with someone who knows the ropes, so mistakes don’t become emergencies. We run mini-drills, check up on each other’s technique, and swap stories about close calls to keep everyone sharp. Safety data sheets come out every time we see a new supplier or batch, because small differences in purity can sometimes mean unexpected behavior.

Why These Precautions Matter

Ignoring the basics creates real, sometimes lasting harm. The facts bear this out: compounds in this family have caused lab injuries and environmental headaches. Beyond policies, a culture of speaking up keeps the team safe—a lesson I learned through both good fortune and hard mistakes. Tetramethylammonium hydrogen sulfate reminds us that rushing never pays, and experience builds not by shortcuts, but by looking out for each other every day.