Tetramethylammonium Sulfate: A Comprehensive Commentary

Historical Development

Tetramethylammonium sulfate stands out among quaternary ammonium compounds for its diverse uses across fields. About a century back, researchers looking to expand the catalog of ammonium salts prepared this compound through straightforward alkylation reactions. Early chemical literature shows scientists chased new ionic structures, curious about the physical and chemical stability of these nitrogen-rich salts. By the mid-20th century, the substance made its way from university labs into industrial settings, supporting processes from synthesizing specialty chemicals to refining medicinal agents. Chemical manufacturers, scientists, and engineers have benefited from this evolution. As a chemist working in academic research, availability has improved dramatically over the past two decades, making it feasible for smaller labs and educational purposes instead of keeping it strictly “behind locked cabinets.”

Product Overview

Chemical suppliers describe tetramethylammonium sulfate as a white, crystalline, non-volatile solid. Its molecular formula, (CH3)4N2SO4, highlights its highly charged structure with four methyl groups attached to a central nitrogen. The compound meets multiple technical specifications for purity, desired particle size, and absence of coloration, as customers put an emphasis on minimizing impurities for both analytical and industrial needs. On my own bench, the solid appears uniform and handles well under standard laboratory conditions, showing remarkable resistance to decomposition at room temperature yet dissolving rapidly in water—a property technicians leverage to prepare precise concentration solutions.

Physical & Chemical Properties

Tetramethylammonium sulfate is colorless, odorless, and exhibits high solubility in water, which is a clear advantage in aqueous chemistry and catalyst systems. The melting point typically falls around 270°C, which points to thermal stability up to those temperatures. As a hygroscopic material, it absorbs moisture from air, so closed storage with desiccant reduces risk of clumping, especially in humid environments. Its ionic nature, with a positively charged tetralkylammonium group balanced by the doubly charged sulfate, lends itself to the role as a phase-transfer agent, facilitating reactions between substances that normally resist mixing. This trait, paired with its high degree of purity, sets the standard for repeatable outcomes in chemical syntheses.

Technical Specifications & Labeling

Producers keep a close eye on industry standards and regulatory requirements, making sure labeling includes CAS numbers, purity percentages (frequently exceeding 98%), lot numbers for traceability, and hazard information per international guidelines. Labels mention precautions like avoiding contact with eyes and skin, storing at ambient temperatures away from incompatible reagents, and using suitable protective equipment. My experience with suppliers shows that reputable companies list analytical results — like residual solvents, heavy metals, and trace organic content — directly on certificates of analysis. This attention to detail carries over to shipping; packaging in moisture-proof bottles or sealed bags preserves quality from factory to laboratory shelf.

Preparation Method

Preparation starts with tetramethylammonium hydroxide, which reacts with sulfuric acid under controlled conditions. The neutralization yields tetramethylammonium sulfate and water, a relatively straightforward reaction for most trained chemists. Laboratories control addition rates to manage the exothermic release of heat. In commercial practice, manufacturers scale up by using automated mixing tanks, in-line pH monitoring, and drying processes (such as vacuum evaporation) to isolate pure crystalline material. Companies operating on a larger scale manage waste by capturing and neutralizing acidic vapors, emphasizing both yield and environmental compliance. Years ago, preparation at university scale sometimes came with unpredictable byproducts, but new control methods have reduced that headache.

Chemical Reactions & Modifications

Tetramethylammonium sulfate reacts as both an ion-pairing agent and phase-transfer catalyst. In organic synthesis, chemists add it to nonpolar solvents to shuttle ionic species across boundaries that otherwise block reaction. It participates in metathesis reactions, exchanging sulfate with other anions, broadening its utility to include custom salt preparations. Modification of the methyl groups—while theoretically possible—isn’t common due to the chemical stability of the quaternary nitrogen. In my hands, using this compound sped up several challenging nucleophilic substitutions, especially during early-stage pharmaceutical research. On the analytical side, using it in chromatographic buffers can boost separation of charged molecules, enhancing signal detection and resolution.

Synonyms & Product Names

In catalogs, tetramethylammonium sulfate often appears under alternative names like “N,N,N,N-Tetramethylammonium sulfate,” “TMA Sulfate,” or “Quaternium-5 sulfate.” For regulatory submissions and standardized reporting, chemical abstracts list it under CAS 4961-62-4. The synonym “TMA2SO4” pops up in shorthand technical documentation or research logs, although precision in naming proves vital when ordering or writing protocols to avoid confusion with other quaternary ammonium salts.

Safety & Operational Standards

Industrywide, companies and laboratories stick to best practices. Wearing gloves, goggles, and lab coats shields users from accidental exposure. Safety data sheets point out that while tetramethylammonium sulfate does not fit the “acutely hazardous” label, ingestion or long-term inhalation can produce systemic effects. Washing hands, not eating or drinking near the workspace, and storing the material in secure, labeled containers keeps risk low. From personal practice, I warn newcomers about its hygroscopic tendencies; rapid resealing after use prevents clumping and potential contamination. In larger operations, spill response guidelines help teams clean up quickly, using absorbent material and disposing of it through proper chemical waste channels.

Application Area

Tetramethylammonium sulfate serves multiple industries. Analytical chemists rely on it to prepare buffer solutions in ion chromatography, boosting separation of amino acids, organic acids, and nucleotides. In environmental labs, it acts as an eluent for testing water and soil samples. Synthetic chemists gravitate toward its phase-transfer qualities during difficult substitutions or rearrangements. Producers of specialty polymers and resins sometimes employ the compound for its ionic compatibility with both organic and inorganic monomers. Pharmaceutical R&D groups use it to modify solvent properties, controlling the selectivity and rate of drug synthesis. Having worked in several of these labs, I’ve seen firsthand how it supports innovation and shortens development timelines.

Research & Development

Ongoing research tackles both novel uses and environmental impact. Scientists explore its potential in electrochemical devices, including fuel cells and batteries, hoping to leverage its ionic conductivity. Work at the intersection of materials science and green chemistry looks at using tetramethylammonium sulfate as a template for nanostructured materials, like zeolites and mesoporous catalysts, which drive cleaner chemical processes. Peer-reviewed journals report varied successes in genetic and biochemical assays using the compound to maintain stable pH and ionic strength. Manufacturers respond by developing high-purity and custom-formulation grades, based on feedback from academic and industrial clients, aiming for both performance and sustainability. I have seen research grants increasingly require attention to the life cycle of chemicals, pushing teams to scrutinize sourcing and disposal just as closely as core functionality.

Toxicity Research

Current literature suggests tetramethylammonium compounds can cross biological membranes and disrupt neurotransmission at significant doses, a concern mostly for environmental and occupational exposure. Short-term skin or eye contact usually produces mild irritation, but chronic exposures linked in animal studies caused neuromuscular effects. Regulatory reviews tend to rank the sulfate salt as less hazardous than its chloride or hydroxide siblings; still, researchers investigate long-term residues in water systems, especially as popularity rises in chemical industry. Modern analytical techniques, including mass spectrometry and high-performance chromatography, allow teams to spot minuscule quantities in complex samples, guiding safe limits and informing policy. My own lab committed to local hazardous waste programs, recognizing that what leaves the sink can eventually come back in drinking water.

Future Prospects

Looking ahead, the future for tetramethylammonium sulfate centers on reducing environmental footprint while supporting next-generation technology. Companies pursue greener synthesis routes, perhaps harnessing renewable methanol for the methyl groups or reusing sulfuric acid from recycled sources. In the field of sustainable chemistry, integrating the compound into closed-loop processes aims to minimize emissions and waste. New roles will appear as demand for precise ionic manipulation rises, especially in green energy storage, pharmaceutical innovation, and high-throughput analytics. Research partnerships between academia, industry, and regulatory agencies help ensure both utility and responsibility. As someone working both at the lab bench and in collaborative projects, I see a direct line connecting chemical ingenuity to everyday products, provided development keeps pace with safety and environmental considerations.

How Tetramethylammonium Sulfate Finds Its Way to the Lab Bench

Walking into any busy chemical lab, you always notice a few workhorse chemicals tucked away among the racks. Tetramethylammonium sulfate stands out as one of those steady, unglamorous compounds that fuels not just basic science but also big industrial operations. Chemists reach for it all the time, mostly because they trust its stability and reliability. From my own experience, it plays well in those tightly controlled environments where accuracy matters more than flash.

What People Actually Do With Tetramethylammonium Sulfate

Most folks in the lab know this salt by its nickname, TMAS. On the surface, it looks plain — just a white, crystalline solid. The story gets deeper once you start using it. In analytical chemistry, TMAS allows for high-purity separations. Take ion chromatography, for example. It helps buffer solutions, sets up the right pH, and makes sure other ions don’t wander where they shouldn’t go. Scientists genuinely want precision in their readings, and TMAS helps cut down on background noise so the real chemical signals shine through.

Synthetics labs prize it during organic reactions, particularly those where stronger, less selective bases could ruin a delicate new molecule. TMAS brings a milder approach, acting almost like a referee in a rough game: keeps everyone honest, avoids brawls between competing reactants, and makes sure you reach the final product without too many detours.

Better Results for Research and Technology

Research doesn’t stop at the academic doorstep. Tech companies need TMAS when they prep semiconductor surfaces. Any particles or stray ions can mess up a wafer at the sub-micron scale, and TMAS helps clear the way during cleaning or etching steps. Its high purity and water solubility make it a real asset here. From microchips in smartphones to sensors in cars, this chemical makes sure technology keeps advancing.

Pharmaceutical companies tap into TMAS for more reasons. Many active drug molecules contain bulky nitrogen groups, and TMAS can spark transformations that are hard to achieve with other reagents. As a result, new drug candidates arrive at the testing stage faster. That means more chances to tackle stubborn diseases and improve patient outcomes.

Health, Safety, and Oversight

Any tool this versatile also deserves respect. TMAS boasts low volatility and a manageable toxicity profile when compared to old-school organic solvents. Regulatory bodies like OSHA and the EPA track its use, encouraging industry to handle spills quickly and prevent environmental release. In my time working with chemical inventories, clear labeling and training cut down on mistakes. Regular audits keep everyone alert, and using protective gear takes away much of the small risk.

Waste gets neutralized before disposal, typically by dilution and chemical treatment under controlled conditions. This approach keeps TMAS out of waterways and landfill leachate, staying in line with current best practices. Investing in safe, reusable containers cuts losses and reduces waste, too.

Looking Ahead

As analytical techniques grow sharper and semiconductors shrink smaller, TMAS probably stays on stage. R&D could one day find greener ways to make it, possibly from biosourced feedstocks. Sharing safety data and strengthening lab habits give everyone more confidence, whether they’re working with grams or tons.

TMAS doesn’t grab headlines. Yet, its quiet role behind breakthroughs in science, medicine, and technology underscores the impact of small, well-chosen tools on real-world progress.

What is Tetramethylammonium Sulfate?

Tetramethylammonium sulfate often finds a spot on lab benches and reagent shelves. Its formula—C8H24N2O4S—tells part of the story. Each molecule carries two tetramethylammonium cations and one sulfate anion. This makes it a salt, and those with hands-on experience know it dissolves well in water, which stands out during preparation and measurement.

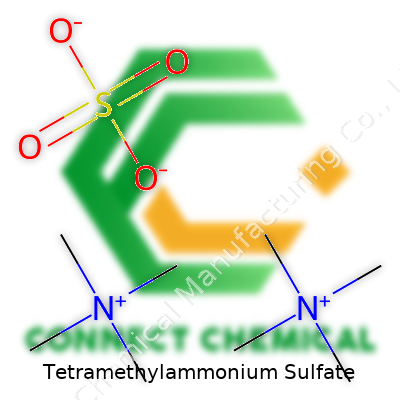

Chemical Structure from the Ground Up

The tetramethylammonium cation shows up as (CH3)4N+. Picture a nitrogen atom in the center, flanked by four methyl groups. These methyls shape a symmetrical, almost cross-like setup. The nitrogen sits with a positive charge, balanced by the strong symmetry of those four methyl attachments. The sulfate anion (SO4)2– delivers a tetrahedral framework—one sulfur in the middle and four oxygen atoms at each corner, sharing two electrons between the oxygens and sulfur.

Put the parts together, and you have two tetramethylammonium cations pairing up with one sulfate anion, writing it out as [(CH3)4N]2SO4. This 2:1 ratio balances all the charges, forming a stable ionic compound.

Why the Structure Matters

A structure like this finds more than shelf life in the chemistry world. In my work running buffers, the clear and highly soluble nature of this salt means quick, predictable results. No hiccups, no clumping, and no residue after mixing. This comes from its simple, symmetric ion pairing and readiness to mix with water. In analytical labs, the lack of color and clean dissolution make it ideal for calibration standards or ionic strength adjustments.

Working with different quaternary ammonium compounds, I noticed tetramethylammonium sulfate brings less contamination compared to organic salts with longer chains. Each methyl group keeps the chemical streamlined and predictable, minimizing random interactions. There’s less interference in tests—a major bonus if precision matters to your results.

Beyond the Lab: Handling and Safety

Experience shows that safety isn’t just about the label; it’s about the habits you form. Even though tetramethylammonium sulfate remains less toxic than its cousins with longer alkyl chains, gloves and basic ventilation still count. Accidental exposure, though rare, can upset the skin or eyes. Chemical knowledge pays off: this compound breaks down easily in water and doesn't stick to surfaces, making clean-up less of a headache.

With chemical salts, long shelf life often means stable storage in dry, room temperature settings. Containers with tight lids shut out humidity, preventing clumping over time. Following material safety data sheets keeps everyone in the lab ready for any mix-ups or spills.

Potential Issues and Solutions

Not every salt gets along with every procedure. Tetramethylammonium sulfate can upset certain organic syntheses if you rely on delicate reactive intermediates. If reactivity pops up, swapping to another quaternary ammonium compound or switching to inorganic salts solves most compatibility issues. Lab teams who share chemical inventories should keep clear labels and proper handling instructions. A bit of organization prevents accidents and mix-ups, especially for those unfamiliar with the compound’s straightforward but essential features.

Getting to Know the Chemical

Tetramethylammonium sulfate shows up in labs and certain industrial processes, often playing a role in chemical analysis or organic synthesis. Most people rarely hear about it, unless they work in science or safety. I remember handling bottles labeled with complicated names in a college chemistry lab. Most of us trusted the warnings printed on these labels, but knowing the facts about chemicals like tetramethylammonium sulfate gives you more than just peace of mind— it provides a healthier respect for what you're working with.

Health Impacts: Taking the Warnings Seriously

The hazards linked to tetramethylammonium sulfate can't be ignored. The chemical has a reputation for affecting the nervous system if it enters the bloodstream. Even small amounts—if absorbed through the skin, ingested, or inhaled—have caused toxic reactions in some cases. From what I’ve read and seen, shortness of breath, muscular twitching, and, worst-case scenario, convulsions or heart irregularities, have all shown up in the toxicology reports. The fact that health incidents have happened even with such specialized chemicals drives home how protective equipment is more than just a rule—it's a must.

Science backs up the worry. Tetramethylammonium compounds act as nerve toxins, which puts them into a higher risk category compared to many plain salts. Animal studies and scattered workplace accidents both point to real danger when safe handling guidelines slip. I’ve seen safety posters in many university labs highlighting how these substances can pass through the skin fairly fast, putting anyone who gets a splash or spill at risk. Once in the bloodstream, the risk goes up, especially because antidotes for these kinds of exposures aren't as simple as something you'd keep in a regular first-aid kit.

Environmental Concerns and Disposal

There’s another issue—what happens after the job is done. Tetramethylammonium sulfate doesn’t just disappear once you pour it down the drain. Water systems can’t break it down right away, so it may persist in the environment. Research suggests it breaks down under certain conditions, but toxic effects on aquatic life still stand out in reports. Environmental toxicity makes the argument for proper collection and disposal stronger. In my experience, dedicated waste streams and labeling help, but it takes ongoing attention to keep chemicals from slipping through the cracks, especially in busier facilities.

Reducing Risk: What Works in Practice

Safety starts with training. Any chemical can turn dangerous in careless hands, but tetramethylammonium sulfate sits higher on the risk ladder. Proper fume hoods, gloves that actually block chemical permeation, and direct access to safety showers matter. I've seen some skip these steps, hoping for the best, but the stories of close calls—and worse—get around fast.

Lab leaders and safety officers need to champion ongoing reviews. Re-evaluating storage strategies and sticking to chemical inventories does more than check legal boxes; it limits exposure possibilities. Communication helps too. Every time I worked somewhere that encouraged sharing near-misses and lessons learned, the rate of real accidents dropped.

Moving Toward Better Practices

Part of handling hazardous chemicals involves questioning their necessity. Substitution with less toxic compounds deserves continued research. For now, as long as tetramethylammonium sulfate appears in labs and industry, direct education and strict procedures keep the worst risks at bay. Along with personal stories, evidence points to a common theme—respect for the chemical, backed by solid facts and practiced know-how, makes the difference between safe science and a crisis nobody wants.

The Real Risks of a Common Lab Salt

Tetramethylammonium sulfate shows up often in chemistry labs, mostly because it fits into organic synthesis work and analytical testing. Chemistry texts might make it look harmless, just another white powder to weigh and toss in a flask. That’s not the full picture. This compound can bring real danger if folks cut corners on storage and handling. Small mistakes don’t just spoil a project; they hurt people. Stories from a few university labs prove how easy it gets for researchers, especially new ones, to underestimate the risks.

Understanding What You’re Dealing With

This chemical pulls water from the air and won’t play nice with skin or eyes. Exposure rarely means a quick sting and then you move on. Burns and real health impacts show up after direct contact. Splash it on a workbench or leave a jar open in a humid storeroom and you’re setting up headaches for days—sticky cupboards, slipping scales, ruined samples, and unexpected irritation.

Safe Storage Isn’t an Afterthought

Keep it dry and keep it away from any sort of heat. Too much moisture brings on clumping, and heat encourages breakdown, sometimes giving off fumes you’d rather not breathe. A sturdy, sealed container stands as the first line of defense. Shift it off open shelves and put it where only trained staff will go looking—a locked chemical storage cabinet with clear labels for all to see. I’ve seen junior students grab the wrong material more than once when old jars lost handwritten labels.

Protection and Training Pay Off

Lab coats don’t cover all risks. Only chemical splash goggles and decent gloves—a simple pair of nitrile types—will shield your skin and eyes from mistakes. I once watched a colleague ignore gloves for just “a quick weigh-in.” That ended with a trip to the health clinic after a small spill set off itching and redness. Safety sheets hang next to the main door in reputable facilities for good reason. Without clear written procedures and regular training refreshers, teams get sloppy and things slide. Everybody in the room must know what to do if something spills or splashes—wash right away, don’t just hope any risk will vanish.

Waste Doesn’t Belong Down the Drain

Disposal seems like a back-end issue, but it matters as much as safe handling. Used gloves, paper towels, and any solution waste all require hazardous waste bins. Pouring leftovers down the sink or tossing them with regular trash pollutes water systems and violates university or municipal rules. Every lab manager I’ve worked with regrets the day an inspector found trace residues behind old packages or in drains because no one wanted to do an extra walk to the hazmat bin.

Solutions Start With Respect

Tetramethylammonium sulfate doesn’t show its danger upfront, which tricks people into measuring it without care. People need strong reminders not to rush safety checks, skip labeling containers, or keep extra packages stuffed in the wrong corners. Modern labs add inventory logs, restricted access storage, full training, and incident drills. Shared responsibility keeps everyone in check—someone’s always watching for others’ short-cuts. This team approach builds a culture where these risks won’t cause harm, and tight storage protocols become second nature for any chemical, not just this one.

How Chemists Work With Tetramethylammonium Sulfate

You probably won’t see tetramethylammonium sulfate on a grocery store shelf, but walk into a research chemistry lab, and there’s a good chance it’s somewhere in the storage cabinets. People use this substance to create special solutions that scientists call ionic liquids. These aren’t just science buzzwords. Ionic liquids open up new ways to separate tough mixtures, which means more effective experiments and cleaner results in analytical chemistry.

In a lab environment, accurate results matter. I’ve watched colleagues depend on this compound for ion chromatography, a delicate process that sorts out the tiny charged molecules hiding in water samples or drug formulas. Its presence improves the performance of the equipment and helps detect even the faintest traces of pollutants, pharmaceutical leftovers, or nutrients like nitrates. That’s pretty important if you care about what’s in your drinking water or need to certify pharmaceutical purity.

Industrial Uses

Big industrial players also get mileage out of tetramethylammonium sulfate. Take the electronics world. Silicon wafers aren’t born clean. Their surfaces face dust, oils, and other kinds of grime before they get etched into microchips. Special cleaning solutions made with this chemical help wipe away electrical and chemical debris. Tiny flaws on a chip can wipe out performance or trigger costly recalls, so quality control teams at semiconductor factories count on the reliability of their cleaning formulas.

Pulp and paper mills see some benefit, too. Processing wood into simple paper sounds easy, but there’s a fine balance—chemical treatments must break down the right components without making a mess of the fibers. Blends containing tetramethylammonium sulfate sometimes support this step, offering selective action and sparing the useful plant fibers. That results in paper with fewer blemishes, which matters if you rely on high standards for packaging or publishing.

Ongoing Research—And Potential Risks

Researchers like to push boundaries. I’ve seen creative chemists explore tetramethylammonium sulfate in fields like catalysis and advanced battery development. This compound can change how ions move around, and those tweaks sometimes lead to better, longer-lasting batteries. For people working on greener technologies and energy solutions, small tweaks like this drive major breakthroughs.

Of course, there are concerns, too. Substances like this do not belong in groundwater or rivers. They don’t break down too fast, and their impact on aquatic life is still under review. Responsible scientists keep a close eye on waste management plans, aiming to avoid spills and stick with closed-loop recycling wherever possible. Good lab practices and industrial hygiene protect workers and the environment.

Potential Solutions and Safer Practices

People expect safer products and a lighter footprint on the environment. Chemistry is full of surprises, but it’s clear that stronger rules around waste handling and spillage will help both industries and researchers use tetramethylammonium sulfate with fewer negative side effects. Continued investment in green chemistry can also produce alternatives that deliver similar performance without sticking around in the ecosystem. As a chemist, I’ve seen how routine retraining and a little innovation reduce the risks, so that the benefits—better products, efficient manufacturing, and reliable experiments—reach society without the baggage of unwanted pollution.