Tetramethylguanidine Acetate: A Deep-Dive Into Its Past, Present, and Future

Historical Development

Tetramethylguanidine Acetate (TMGA) emerged from decades of exploration into guanidine derivatives. Chemists in the post-war era relentlessly sought stable organic bases that could push reactions without many drawbacks. The rise of TMGA came from those needs, especially as petrochemical industries expanded and synthetic methods demanded stronger, more selective basic catalysts. Early reports from Eastern European research groups in the mid-20th century shone a spotlight on tetramethylguanidine’s potential as a strong, non-nucleophilic base. As laboratories everywhere searched for tissue-friendly acetates, combining tetramethylguanidine with acetic acid looked like a sensible option for delivering a mild, useful salt with broad utility in both research and industry.

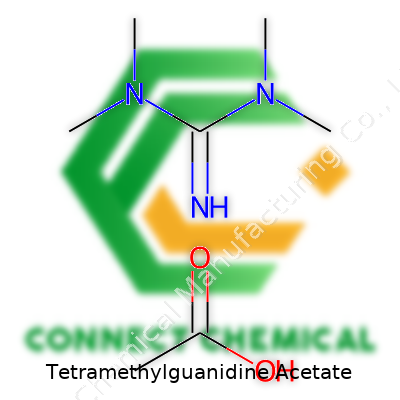

Product Overview

TMGA stands out as a white to off-white crystalline solid with an acetate anion stabilizing the organic base cation. Many chemical suppliers stock it for a range of uses, from pharmaceutical intermediates to polymerization reactions. Those working in organic synthesis recognize the appeal: the guanidine portion offers high basicity, while the acetate keeps handling straightforward. Its shelf life, ease of dissolution in polar solvents, and relative stability in air have guaranteed steady demand. I’ve seen colleagues rely on it for protecting group chemistry, often reaching for TMGA to keep their workflow simple and reliable.

Physical & Chemical Properties

TMGA has a molecular formula of C6H15N3•C2H4O2 and a molar mass of about 191.24 g/mol. The salt crystallizes easily from a variety of solvents, showing good solubility in water, alcohols, and acetonitrile. Its melting point lands in the range of 120-130°C, higher than standard guanidine salts thanks to the acetate counterion. With a pKa of about 13 for the conjugate acid, the tetramethylguanidine moiety is highly basic. In the lab, dry TMGA appears odorless and doesn’t fume, which lowers risk during use. Its stability under mild heat and light protects its activity for routine reactions. These properties arise from the delocalization in the guanidine core and the modulating effect of four methyl groups shielding the nitrogen atoms.

Technical Specifications & Labeling

Specifications from suppliers usually guarantee purity upwards of 98%, with water content and residual solvent levels specified in the low percentage range. Labels highlight batch, production and expiry dates, recommended storage conditions, and hazard precautions—primarily addressing skin and eye contact risks. From my own ordering experiences, clear batch traceability gives reassurance during repeat synthesis. Poor labeling can lead to dangerous mix-ups, especially for those working with a range of guanidine salts. Some manufacturers provide detailed SDS documents outlining reactivity, incompatibilities, and emergency measures, which schools and companies need for regulatory compliance.

Preparation Method

Chemists often use straightforward acid-base neutralization to prepare TMGA. The process starts by mixing tetramethylguanidine base and glacial acetic acid in equimolar amounts in a proper solvent like ethanol or acetonitrile. After gentle agitation, the mixture cools, prompting the acetate salt’s crystallization. Filtration and drying under reduced pressure follow, yielding material ready for direct bench use. Yields top 90% if stoichiometry and solvent are properly chosen. Laboratories scaling up for industrial use sometimes switch to continuous stirred-tank reactors, maintaining product quality while ramping up output. The simplicity of this synthesis means researchers everywhere, even in smaller labs, can prepare their own TMGA if commercial stocks run low.

Chemical Reactions & Modifications

TMGA reacts vigorously with acids and electrophiles, quickly forming guanidinium salts or facilitating alkylation reactions. It acts as a superb base for esterifications, Michael additions, and elimination reactions—pushing conversions without side reactions common to stronger, less selective bases. Modifications focus around the guanidine portion, with chemists introducing longer alkyl chains to alter solubility and reactivity. Adding hydrophobic groups opens doors in polymer chemistry, especially for tunable catalytic systems. While I have mostly seen TMGA as a stand-alone reagent, some colleagues report success pairing it with phase-transfer catalysts for greener solutions in water-sensitive reactions.

Synonyms & Product Names

Researchers sometimes encounter TMGA under alternate names such as N,N,N',N'-tetramethylguanidinium acetate, TMG acetate, or Tetramethylguanidinium ethanoate. Suppliers like Sigma-Aldrich, TCI, and Alfa Aesar each brand it with differing catalog entries, but most stick to these core names so that sourcing remains manageable. Confusing synonyms occasionally arise in less formal trade, so cross-checking CAS numbers—typically 150-391-5 for the base and 926-25-6 for the acetate form—remains standard practice for accurate identification.

Safety & Operational Standards

Safe handling of TMGA starts with understanding its strong alkalinity. Accidental contact with eyes or skin can trigger irritation, and inhalation of fine dust could provoke respiratory discomfort. In our lab, I insist on goggles, gloves, and scrupulous bench hygiene. TMGA’s reactivity toward acids calls for clear waste sorting procedures, with neutralization steps spelled out for any spills. National and international regulations don’t label TMGA as toxic by ingestion, but prudent chemists keep all guanidine derivatives away from food preparation surfaces. Proper storage in cool, sealed containers extends usable shelf life and avoids accidental hydration or decomposition. Clear standard operating procedures for weighing and transfer protect both new and experienced lab staff.

Application Area

TMGA has taken root in analytical, organic, and pharmaceutical chemistry. In small molecule synthesis, it drives methylation, protection and deprotection stages, and select condensation routes. Polymer chemists use TMGA to initiate ring-opening polymerizations of lactones and carbonates, producing biodegradable plastics and specialty elastomers. It’s found utility in peptide coupling, taking over from older, harsher bases that risked racemization. I’ve seen industrial chemists favor TMGA when working at scale—it combines reactivity and manageable hazard levels, so plant operators feel more comfortable during production shifts. In analytical work, it sometimes functions as an ion-pairing agent or as part of buffer systems for advanced separations.

Research & Development

The ongoing push for new catalysts, greener processes, and more selective syntheses keeps TMGA in the sights of chemical researchers. Development efforts revolve around refining the salt’s role in asymmetric catalysis or combining it with tailored acids to achieve novel reactivity. Researchers at leading universities have designed TMGA derivatives that participate in switchable solvents and recyclable reaction media, answering some of industry’s sustainability challenges. Academic interest meets industrial need in the search for cheaper, safer reagents to streamline pharmaceutical intermediates and agricultural active ingredients. The real-world impact comes down to bench chemists who adapt findings into their daily routines, discovering new compatibility points or workarounds with complex substrates.

Toxicity Research

Existing toxicity database entries for TMGA remain limited but reassuring compared to many related compounds. Acute effects come mostly from local irritation, with little evidence showing chronic toxic, carcinogenic, or mutagenic impact under typical handling. Animal studies, performed using responsible dosing, suggest low oral and dermal toxicity. Still, the compound’s high alkalinity means accidental ingestion or eye exposure should prompt urgent flushing and medical attention. Regulatory agencies do not set specific occupational exposure limits for TMGA, mostly because industry usage volumes and volatility remain low. Continued stakeholder vigilance, through periodic review of MSDS updates and broader guanidine chemistry literature, closes knowledge gaps and prepares users for unforeseen hazards.

Future Prospects

TMGA's future points toward broader adoption in sustainable synthesis, where chemists cut waste and harsh reagents without giving up yield. As pressure mounts to replace hazardous substances in both research and manufacturing, demand rises for reliable, moderately hazardous bases that stand up to tough conditions. Custom-modified TMGA derivatives could underpin new recyclable ionic liquid systems or green catalysis, especially if supply chains strengthen and pricing stays competitive. Emerging fields in data-driven synthesis optimization and high-throughput screening will harness TMGA and its cousins for automated, miniaturized chemistry. The more the research community shares results and practical lessons, the more chemists unlock hidden versatility from compounds that, like TMGA, have quietly backed progress in labs for decades.

Looking at Its Main Uses

People working with chemistry often run into tongue-twisters like tetramethylguanidine acetate. Behind this complicated name sits a real backbone of many lab processes. Tetramethylguanidine acetate shows up in organic synthesis, often helping researchers build new molecules for medicine, material science, and even environmental testing.

This compound acts as a strong organic base. In simple terms, chemists use it to kickstart, speed up, or control chemical reactions. Building pharmaceuticals often involves piecing together tricky molecular structures. With tetramethylguanidine acetate, researchers can get those reactions to move along, making synthesis cleaner and more predictable.

Why Industries Need It

Everyday folks don’t see the work tetramethylguanidine acetate performs, but it influences a surprising number of products. Pharmaceutical companies rely on this base when crafting drugs that might someday wind up in a local pharmacy. Take antiviral drugs, which lean on streamlined, reliable reactions for their backbone structures.

Specialty chemicals, like those running in electronics or coatings, also benefit. A small batch manufacturer making an advanced material—maybe a new plastic or coating—looks to this compound for its steady reactivity. It’s not something used by the ton, but its impact on yields and purity can turn the tide between a successful batch and hours lost chasing bad results.

A Personal Look at Reliability and Safety

Spending time in an organic lab taught me the importance of dependable reagents. A good chemical base turns chaos into order, especially during complex steps like esterification or amidation. Tetramethylguanidine acetate keeps side reactions down, which saves time, cuts waste, and even makes cleanup easier. Labs trying to run greener, safer operations have more options than ever, and this compound often fits into efforts to avoid harsher bases or less predictable alternatives.

Safety always matters. Strong bases pose real risks if handled carelessly. Thankfully, chemists can find robust safety data from trusted sources. The literature recommends gloves, goggles, and sometimes even working in a hood, depending on scale. Having this information from independent testing organizations, and not just manufacturers, builds confidence. Following protocols, as I learned and practiced, makes sure no one pays the price for rushing through a prep. Open conversations about handling and risk make for smarter teams and safer labs.

Environmental Impact and Looking Forward

Companies and universities pay attention to the waste their processes create. Traditional strong bases sometimes produce harsh byproducts that demand costly cleanup steps before disposal. Tetramethylguanidine acetate, with its defined byproducts and predictable behavior, helps researchers map out safer routes to their targets. Academic studies and industrial reports both recognize that shifting toward well-characterized reagents, along with modern treatment strategies, lowers the environmental footprint.

Some challenges linger. Price remains a real factor, especially for startups or academic labs with tight budgets. More sustainable synthesis methods for making this compound could level the playing field. Sharing best practices and real-world results in open forums would go a long way toward keeping both costs and hazards manageable for everyone involved.

Final Thoughts on Its Value

Tetramethylguanidine acetate may never win a popularity contest outside research and manufacturing circles, but its contributions ripple out into many fields. By supporting more efficient and targeted chemical work, it pushes industry and science forward. In my own experience, reliable and well-documented reagents shorten the road from bench to breakthrough, and every thoughtful improvement matters.

Getting Down to the Compound

The name Tetramethylguanidine Acetate sounds like something out of a chemistry textbook, but its formula tells a practical story. Tetramethylguanidine—C5H13N3—ties with an acetate ion—C2H3O2−. The pairing comes out as C7H16N3O2. This isn't just trivia. Knowing this formula means you see exactly what's being handled in a flask or written into a reaction scheme.

Why This Formula Actually Matters

Years ago, I worked in a lab that juggled “unknowns” for days. Misreading a compound meant wasted hours and rising costs. The acetate salt form pops up for good reason—it’s more pleasant to handle than the pure, strong, fishy-smelling base.

Clarity in chemical formulas matters for safety. Tetramethylguanidine by itself ranks as a strong organic base, favored in pharma and fine chemicals. Mixed with acetic acid, you get a solid or concentrated salt, easier to weigh and control. This swap makes measuring, mixing, and transporting much easier and safer—especially at scale. CSB reports on lab incidents again and again reinforce a similar point: errors grow when the details get skipped.

Tetramethylguanidine Acetate in the Lab

Research and industry rely on this salt for reactions needing precise basic conditions without adding water or strong mineral bases. I’ve talked to colleagues who leaned on this salt for alkylation reactions. The acetate part brings predictability to mixes—no surprise moisture jumping into an anhydrous procedure. The base part supplies a kick without bringing in corrosive properties you’d see with something like sodium hydroxide.

Proper formula knowledge feeds into ordering, labeling, and training. Miscommunication in even a single synthesis step leads to ruined batches. On more than one occasion, clear labeling with the full formula stopped close calls before they grew into hazards.

Supporting Information with Scientific Sources

Looking through Sigma-Aldrich and other chemical suppliers, the formula stays consistent: C7H16N3O2. Tech sheets urge paying attention, because handling organic bases—especially ones that can sneak through gloves—calls for respect. NIOSH cites exposure routes and stresses the usefulness of acetate salts for reducing volatility.

Actionable Solutions for Safer Chemistry

Misunderstanding formulas led to small, avoidable lab disasters where I worked. Simple steps keep things on track. Routinely checking Chemical Abstracts Service (CAS) listings and cross-referencing material safety data pays off. Before starting synthesis, training new hands on what the formula actually means (beyond rote memorization) helps dodge simple mistakes.

Label everything with both name and formula. Digital inventory systems can mark hazards right at the storage shelf. I’ve seen workshops transform after installing one clear database spelling out not only chemical names but also empirical formulas.

For supervisors, bringing the formula into planning meetings with everyone—purchasing, logistics, safety—shapes a culture that prizes precision. This habit respects both health and the bottom line. Tetramethylguanidine acetate sits as one small piece in a huge puzzle, but when formulas get respected at every step, the whole process moves faster and runs safer.

Why Storage Matters for Tetramethylguanidine Acetate

Tetramethylguanidine acetate isn’t your everyday household substance. This chemical comes with its own set of quirks, and proper storage can make all the difference in safety and usability. Anyone who has handled even mildly reactive chemicals in a lab learns quickly: don’t cut corners on storage. In my own research days, one wrong choice with chemical storage meant wasted experiments, ruined samples, and plenty of paperwork.

Moisture and Air: The Silent Enemies

This compound reacts easily to moisture from the air. A humid day might not bother most folks, but a single open lid or loose seal can lead to clumping or, worse, chemical changes that ruin batches. I kept a batch on a bench during a rainy week, thinking, “It’s only overnight.” The result — a sticky mess, data lost, and a tough cleanup. Every reliable lab stores tetramethylguanidine acetate in tightly sealed containers, often under a dry, inert gas like nitrogen or argon when a project really matters.

Temperature Makes a Difference

Leaving chemicals anywhere on a benchtop saves a few seconds until something goes south. Direct sunlight bakes plastic containers. Warm spots push reactions forward in sealed bottles, even without catalysts or extra ingredients. Every bottle in my chemical fridge sits away from the light and is labeled with the date it arrived and the date opened, so nobody plays guessing games about stability. Below room temperature, somewhere cool and stable, keeps this compound reliable. Not freezing, not near radiators — just a calm, cool shelf does best.

Labeling and Segregation

Anyone who’s sorted jars in a cluttered pantry knows proper organization prevents a lot of headaches. The same thing applies here. A clear label cuts down on mistakes. A permanent marker on a frosted glass bottle isn’t old-fashioned, it’s common sense. Keep it separated from acids and materials that can cause accidental reactions, since even fumes from nearby bottles can trigger changes over time. In shared spaces, a color-coded sticker system reduces “who moved my chemical?” moments and helps everyone on the team steer clear of dangerous situations.

Safety Doesn’t Quit at the Shelf

Storing chemicals becomes a community habit in any good lab. Training new folks matters. The best labs I worked in started every term with a walk-through: “Here’s what we store where, and here’s how to report something off.” No one likes filling out incident reports, but they’re learning opportunities as much as they are procedures. At my last job, a small spill triggered a fire alarm since the chemical mixed with something it shouldn’t have — a sharp reminder that storage isn’t busywork, it’s protection for people and the work itself.

Building Safer Habits

Most storage mishaps come down to rushing. Taking thirty seconds to double-check a cap or wipe a spill has saved hours of drama later. I keep desiccant packs handy beside the storage area — swapping them every few weeks, and logging each change alongside inspections. Quality control measures, no matter how small, build habits. Focusing on these details means lower risk and higher confidence in every step that follows, from experiment to final results.

What Kind of Chemical Are We Dealing With?

Tetramethylguanidine acetate doesn’t ring any bells at the grocery store, but you’ll find it in research labs, chemical plants, and sometimes in pharmaceutical production. The name fits that family of industrial compounds scientists use for reactions, especially when precise, controlled chemistry matters. People in these settings trust that their training matters — because exposure, even to small amounts, shakes up more than a lab notebook.

What Health Hazards Can Show Up?

Getting to the facts: Tetramethylguanidine by itself acts as a strong base. That means it burns—fast—if spilled on skin or splashed in eyes. The acetate salt form isn’t much gentler just because it dissolves easier in water. I’ve patched up a colleague’s glove after seeing the label on a reagent bottle, and it reminds me that even common solvents and bases on the workbench can seriously wound.

Toxicological reports show inhaling even low concentrations over time will irritate airways, sometimes causing chronic cough, headache, and nausea. Swallowing a small quantity may trigger abdominal pain, dizziness, or vomiting. Lab accidents with this chemical, thanks to a splash or a spill, mean you’re hoping your eyewash and safety shower keep you out of the ER.

Environmental Impact: Not Just a Personal Issue

Spills don’t just evaporate into thin air. Just because you can’t spot Tetramethylguanidine acetate flowing through a creek doesn’t mean there’s no problem. Water-soluble chemicals wash into storm drains, eventually hitting waterways and local plants or fish. I’ve stood downstream from a chemical facility after a rainstorm, breathing in the smell of things that shouldn’t be there. It’s not always a fast catastrophe, but aquatic toxicity builds up in the food chain, and you won’t read about it until someone tests those waters months later. Responsible labs consider runoff as much as in-house risk.

Safeguarding Health and Reducing Incidents

No matter which side of the scale you stand on—worker, manufacturer, or local resident—overlooking risks isn’t an option. First step is stockroom basics: gloves, goggles, lab coats, and accessible data sheets. I keep a habit of checking chemical storage regularly for leaks, not just for inventory, but for everyone else’s peace of mind. Staff turnover means newcomers might never have seen a bottle of this stuff before. Regular drills and clear signage turn confusion into muscle memory when things go sideways.

Ventilation counts. It’s not enough to open a window and hope for the best. Chemical fume hoods, tested and used right, save more than one headache in a research year. Disposal protocols should be clear — pouring anything down a drain without thinking twice is out of the question. Community right-to-know ordinances prompt facilities to communicate, in plain language, what’s on their shelves and what might reach the fence line if containment fails.

Path Forward: Transparency, Training, and Accountability

What works isn’t treating a hazardous chemical like a secret. Honest communication builds a safer workplace and a safer neighborhood. Public records, safety audits, and even annual open-door days give laypeople a chance to ask about risks — not just the regulators. Firms investing in more robust containment, engineering controls, and regular education send a message: prevention beats reaction, every time.

Sensible respect for hazards like Tetramethylguanidine acetate comes from real information and practice. Relying on luck or hoping someone else reads the fine print won’t do. A firm grasp on real risk keeps more people and places out of harm’s way.

Understanding the Risks

Tetramethylguanidine acetate (TMGA) is a chemical that pops up most often in research, particularly in organic synthesis. Anyone who has opened a container of this stuff knows it carries a strong, ammonia-like smell. That’s not just offensive—it's a sign the fumes can irritate eyes and lungs. Many safety data sheets warn about the risk of skin burns, eye injuries, and even serious respiratory reactions if inhaled in high concentrations. Decades of occupational health data show long-term exposure to amines and similar reagents can damage sensitive tissue.

Personal Experience Working in Labs

Back in the university lab, I watched a grad student struggle after spilling TMGA on his glove. Sweat made the material thin, and not all gloves stop a spill like this. The skin suddenly turned red and raw. That got me in the habit of using two layers of gloves during weighing and transferring. Nitrile or neoprene gloves work better than thin latex or vinyl. It never pays to skimp on good eye protection either. Goggles with splash guards offer much higher confidence than basic glasses, especially if splashing is possible—a lesson many pick up the hard way.

Working with Ventilation

TMGA sends fumes into the air fast. Even a brief exposure in a closed room can leave everyone coughing. It's smart to set up all handling under a certified fume hood, no exceptions. Regular maintenance checks matter here. I once saw a vent fan fail, which led to a lingering, almost unbearable odor that forced a room evacuation. That’s a solid reminder: check airflow before starting work, and keep ductwork clear of obstructions.

Storage Ideas

This compound shouldn’t go anywhere near heat, sparks, or open flames. Organic bases can ignite under the wrong storage conditions. Simple choices make storage safer: use clearly labeled, tightly closed bottles, and place them in dedicated chemical cabinets, away from acids, oxidizers, and direct sunlight. I’ve seen colleagues store small reagents in random drawers out of laziness, only to run into trouble months down the road when a leak reacted with something else. Good practice means returning containers immediately after use and writing the opened date on each bottle for quick reference.

Spill Response and Cleanup

Even small spills deserve respect. Wear thick gloves, goggles, and a fitted mask if airborne dust or fumes crop up. Absorb liquid spills with non-combustible material, such as vermiculite or dry sand. Never reach for paper towels or rags, which can trigger chemical reactions or catch fire. I’ve handled one too many poorly prepared lab benches to trust casual cleanup. After sweeping residues into a labeled hazardous waste bag, wash down the area with plenty of water to remove any trace. If the spill reaches skin or clothing, flush immediately under running water and change out of contaminated gear.

Training and Documentation

Regulation in chemistry labs often draws groans, but every accident pushes rules harder. Training new scientists to respect TMGA and similar reagents shapes safer habits. Staff briefings before experiments and refresher drills on chemical handling build real-world readiness. Keeping a tidy chemical inventory and updating hazard documents helps spot risks early. In my experience, a culture of transparency—where people can admit to mistakes or accidents without fear—leads to better reporting and smarter prevention.

Looking Forward

Chemicals like TMGA do amazing work in the right hands and controlled environments, though the dangers never leave. Proper gear, clear labeling, and respect for protocols keep everyone safe. If something feels risky or smells off, trust your gut and stop to double-check procedures. Over time, those habits sink in and help everyone in the lab or workplace go home healthy at the end of the day.