Tetramethylguanidine Lactate: Impact, Risks, and the Road Ahead

Historical Development

Looking back, Tetramethylguanidine Lactate did not spring up from nowhere. Chemistry labs in the late 20th century brought forward several organic base salts, trying to improve catalysis and solvent properties in emerging syntheses. Stories from older chemists mention how scientists realized some organoguanidine salts could outdo traditional amines when coaxing sluggish reactions along. Lactate as a counterion entered the picture after researchers started noticing environmental and regulatory demands ballooning around less sustainable acid partners. The search for cleaner by-products, safer handling, and less corrosive alternatives made lactate pairings a reasonable choice. In my experience, veteran chemical engineers have watched the profile of substances like Tetramethylguanidine Lactate shift as the industry chases faster, cleaner, smarter chemistry.

Product Overview

Tetramethylguanidine Lactate stands out as a salt formed by pairing tetramethylguanidine, a robust base, with lactic acid, a well-known organic acid. This combination results in a crystalline or sometimes syrupy solid, depending on water content and preparation. Unlike the more finicky or hazardous guanidinium salts, its lactate version favors easier handling. Folks working on organic synthesis, pharmaceuticals, or material science have found the compound valuable because it blends substantial basicity with lower volatility and friendlier environmental disposal profiles over sometimes dirtier alternatives like strong inorganic bases or halide bases. Anyone using this in a lab setting values its balance between strength and gentleness.

Physical & Chemical Properties

Those who’ve uncapped a vial of Tetramethylguanidine Lactate often describe a faint, slightly sweet odor. Its physical appearance ranges from clear, hygroscopic crystals through to pale, sticky lumps if not stored carefully. The melting point hovers around 90–110°C, variable with water pickup, and solubility in water runs high — reflected by its use in polar, aqueous environments. Chemical folk appreciate the low volatility but note the basic pH leans toward the corrosive. Once in solution, its basicity offers a punch similar to many amine-based bases. Thanks to this, it’s earned a spot in reactions where pH control carries critical consequences, such as peptide bond formation or selective deprotonations.

Technical Specifications & Labeling

Labeling usually calls for content about purity — most commercial Tetramethylguanidine Lactate lands above 98%. Clear, accurate details about water content, storage temperature limits, and shelf-life help users track stability. Batch records from reputable sources include details on drying, crystallization steps, or residual solvent analysis. Labels must flag corrosive potential and the proper use of PPE. I have spent hours in chemical storerooms matching CAS numbers to product names; for this base salt, those numbers help dodge confusion with similar guanidium or lactate products. Consistency in labeling saves lives and money, especially during spot-checks or audits.

Preparation Method

To make Tetramethylguanidine Lactate, lab techs usually react tetramethylguanidine free base directly with lactic acid, often in a controlled solvent like ethanol or methanol. The process demands temperature control to avoid runaway exothermic spikes. After neutralization, the product precipitates as a salt, and drying removes excess solvent and water. It pays to use careful recrystallization to get a product free of colored by-products or foreign ions. In cases where batch scale increases, controlling moisture and pH during synthesis becomes more challenging, sometimes causing caking or incomplete salt formation. Workers in manufacturing must dial in these parameters to deliver clean, reproducible product.

Chemical Reactions & Modifications

In practical chemistry, Tetramethylguanidine Lactate often shows up as a base catalyst, especially in organic transformations where water-tolerant basicity rules. It pushes condensation reactions faster, drives acylations, and helps in rearrangements such as those used in pharmaceutical building blocks. Enzyme engineers sometimes experiment with this salt as an alternative buffer or pH adjuster in biocatalysis. Chemical tinkerers have worked out various modifications: swapping the lactic acid for other hydroxy acids or altering the substituents on the guanidine framework brings fresh possibilities, often in the hunt for more fine-tuned reactivity or selectivity. These modifications can dial up solubility, thermal stability, or even biological compatibility.

Synonyms & Product Names

Chemical catalogs and suppliers scatter a handful of names around this molecule: N,N,N',N'-Tetramethylguanidine Lactate, TMG lactate, and sometimes guanidine, tetramethyl-, lactate (1:1) keep popping up in references. Regional catalogs occasionally flip the order, but the structure remains clear if the user checks the CAS registry number. A history of inconsistent naming caused hiccups for older procurement systems, yet standardized regulatory databases now keep widespread confusion at bay. For researchers or purchasing teams, tracking synonym lists ensures the right substance ends up in the right bottle, avoiding misfires in formulation or regulatory filings.

Safety & Operational Standards

Safe use of Tetramethylguanidine Lactate draws from both the basic property of the guanidine group and the low-to-moderate toxicity of lactic acid derivatives. Staff who handle chemical drums wear full gloves, goggles, and lab coats, paying attention to ventilation and spill management. Spills on skin or eyes can sting or burn; prompt washing remains the best defense. MSDS documents stress good labeling, proper containment, and emergency eyewash stations nearby. Disposal typically requires neutralization — not every drain can handle basic, nitrogen-rich residues safely. Auditors and safety trainers preach risk assessment and regular chemical hygiene reviews, since even familiar chemicals can cause harm if corners get cut or procedures slip.

Application Area

Many labs reach for Tetramethylguanidine Lactate for its role as a non-volatile, strong base in organic synthesis. Pharmaceutical chemists find value here, especially in steps where product purity gets hammered by less gentle reagents. Biotech teams appreciate the narrower environmental profile compared to harsher amines or hydroxides. In polymer science, some industrial settings take advantage of its ability to drive ring-opening polymerizations with careful pH control. Biodiesel researchers eye it for transesterification as a specialty catalyst. Its footstep can also be found in fine chemicals, coatings, and even analytical chemistry as a pH titrant. No matter the field, users stay mindful of the benefits and the slight risk elevation compared to weaker bases.

Research & Development

Research teams routinely experiment with new guanidine salts, aiming for even greener production, lower humidity sensitivity, or greater selectivity. Laboratories devote plenty of resources testing blends and derivatives in enzyme chemistries or pharmaceutical synthesis. Open literature and patents both testify to a continuing interest in tweaking the lactate counterion — sometimes adding extra hydroxyls or substituting chirality for a new edge in selectivity. Companies invest in scalability studies, automation for safer handling, and real-time QC for purity or contaminant control. Cooperating with regulatory agencies, scientists look for data on environmental breakdown, possible impacts on wastewater, and life-cycle analysis to satisfy demands from eco-conscious clients.

Toxicity Research

Toxicological data on Tetramethylguanidine Lactate has expanded alongside public concerns over lab chemical exposures. Acute studies spotlight some irritation—skin and eye contact cause inflammation, with long-term exposure in rats revealing mild to moderate organ stress. The guanidine backbone, while less hazardous than many alkali salts, attracts scrutiny for potential reproductive or genetic impacts with high exposures. Regulators in the US and EU keep pushing for tighter long-term studies, especially for chemicals migrating toward pharma or food-adjacent applications. Toxicity data from in vitro cell lines and in vivo animal studies feed into stricter workplace exposure guidelines. Smart lab managers stay ahead by investing in better ventilation, PPE protocols, and spill response training, connecting the dots between workplace safety and reporting obligations.

Future Prospects

Looking onward, Tetramethylguanidine Lactate faces both challenge and opportunity. Demand in catalysis and fine chemical routes keeps climbing, especially as industries chase efficiency with less waste. Green chemistry pushes for production improvements, possibly shifting to renewable starting materials for both parts of the molecule. As AI-driven design disrupts organic synthesis, researchers expect more demand for bases and salts that marry strength with environmental and regulatory friendliness. Emergent applications in biodegradable polymers, new analytical tools, and pharmaceutical building blocks suggest the molecule’s best days still lie ahead. To keep up, chemical manufacturers and R&D crews will keep hunting for safer, more scalable production, tighter toxicology data, and nimbler supply chains that meet evolving customer needs and legal requirements — staying grounded in both scientific rigor and the lived experience of working safely with every batch that comes through the door.

Where Tetramethylguanidine Lactate Fits In

Tetramethylguanidine lactate shows up surprisingly often in labs, especially in organic synthesis and industrial chemistry. Scientists and manufacturers value it because of one main thing: it acts as a strong organic base. Anyone who has ever tried pushing through a stubborn reaction knows the struggle. Imagine trying to speed things along, but the conditions never seem just right. Tetramethylguanidine lactate solves that problem. It brings the push modern chemistry demands, and it does so with more control compared to harder, harsher inorganic bases.

What Makes It Useful

People working on fine chemicals often look for selectivity—aiming for particular bonds and leaving everything else untouched. Tetramethylguanidine lactate supplies this kind of focus. The molecule's lactate partner means lower toxicity and improved solubility in water or polar solvents, a practical edge when you want to avoid volatile sources. Chemists reach for this compound because it gets reactions going without bringing along a mess of unwanted byproducts.

Beyond the beakers, tetramethylguanidine lactate gets called up during manufacturing steps that create specialty materials and resins. The electronics industry sees frequent use of strong bases to build up polymers and tweak the properties of coatings. The pharmaceutical sector also makes room for this compound in synthesizing drug candidates, chasing reactions that traditional bases sometimes botch.

Why Safety and Training Matter

Not all strong bases are born equal. Tetramethylguanidine itself pulls a reputation for being caustic, but pairing it with lactate takes some edge off and boosts handling safety. Anyone who has ever spilled unbuffered base on their glove knows just how quick things can go wrong. The lactate form brings relief for lab techs because it means dealing with less harsh fumes and easier disposal protocols. This characteristic shifts the compound into a friendlier zone for small labs and teaching environments, where maximizing safety lets work proceed without fear taking over.

Quality and Purity Calls

Research and manufacturing demand trust in every bottle. Reliable supply chains, clear labeling, and airtight quality checks go hand-in-hand with modern chemical work. Tetramethylguanidine lactate needs proper handling and storage to prevent contamination. Proper controls catch impurities, as even tiny traces impact downstream product quality—in pharmaceuticals and electronics, that margin leaves no room for error. This is where companies with a reputation for clean production and thorough testing shine. Their chemistry enables others to run safe and consistent operations.

Paths Toward Smarter Use

Environmental standards continue rising. Wastewater full of residue draws more attention these days. Choosing safer bases like tetramethylguanidine lactate helps departments reduce hazardous waste, and simplifies cleanup steps. Sustainability directors push for greener chemistry. Substituting traditional bases with alternatives like this compound counts as progress.

Across disciplines, better training pays off. New users need to know what they're dealing with, and that means ongoing education. Suppliers who go beyond shipping drums out the door—by sharing updated guides and supporting responsible handling—make all the difference.

Looking Forward

Tetramethylguanidine lactate might not draw headlines, yet its impact ripples out through many sectors. Every controlled reaction, every advance in pharmaceuticals or specialty coatings, leans on choices like this. In my own experience, adopting safer, cleaner reagents often brings faster progress and fewer headaches. Each time industry moves toward compounds that balance performance with safety, the work gets better for everyone—from bench chemist to end user. Reliable access to compounds like tetramethylguanidine lactate lets science grow steadily, one step at a time.

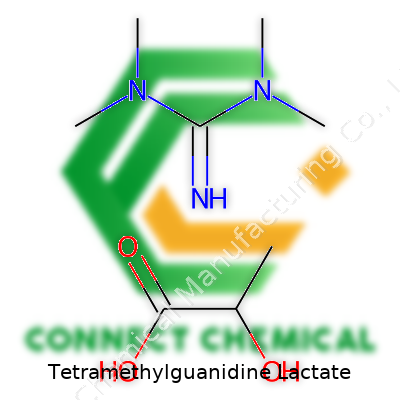

Understanding the Formula

The formula of tetramethylguanidine lactate is C5H13N3·C3H6O3. This combines tetramethylguanidine (C5H13N3) and lactic acid (C3H6O3). Mixing these two in a 1:1 molar ratio will give the salt, with tetramethylguanidine acting as a base and lactic acid as the acid.

Why This Chemical Stands Out

Tetramethylguanidine—often shortened as TMG—packs a punch as a strong, non-nucleophilic base. Add lactic acid into the mix, and you get a salt that opens up some interesting possibilities, from advanced chemical synthesis to green chemistry. Working with chemicals like this brings up all sorts of questions around safety, application, and environmental impact. So what does this combo really offer?

In most lab settings, chemists use TMG as a base because it doesn’t get involved in side reactions easily. By pairing it with lactic acid, a common, biodegradable acid produced during fermentation, you’re looking at a compound that keeps up the tradition of blending operational effectiveness with some degree of environmental respect.

Where Knowledge and Safety Intersect

Anyone who’s mixed strong bases and organic acids knows this isn’t just about balancing pH. There’s heat, there’s reactivity, and more importantly, there’s the human side—people mixing, handling, and required to stay safe. As someone who has spent time in both research and teaching labs, those safety data sheets don’t just collect dust. Understanding the formula means you can anticipate risks, check compatibility with glassware, and avoid mixing up hazardous byproducts.

Labs have rules about PPE for a reason. A spill with something like TMG will burn, and adding the lactic acid doesn’t erase the danger. Thinking chemically and thinking ahead can keep people on the right side of safe.

Moving Beyond the Bottle: Practical Uses

Chemists turn to tetramethylguanidine lactate for a few key reasons. Its strong basicity in a convenient, measured form has caught the eye of researchers in organic synthesis. It’s showing up in catalysis, peptide chemistry, and sometimes in developing greener reaction routes, especially as the field keeps searching for alternatives with fewer heavy metals or toxic side products.

One thing that stands out in academic circles: the shift towards chemicals that break down more easily in the environment. The lactate part goes a long way here, as lactic acid is a familiar face in both industrial bioprocesses and even the food industry. The use of such a derivative means the industry can lean toward processes with less persistent waste. This can help cut down on disposal problems and reduce the chances of long-lived pollution from obscure reaction byproducts.

Room for Improvement and Solutions

Like a lot of “middle ground” chemicals, this one isn’t perfect. Supply chain transparency has room to grow. Not all producers stick to the same purity levels, so buyers should demand clear certificates of analysis and track batch histories. Anyone using this salt at scale could look for suppliers using bio-based lactic acid, or find partners who prioritize greener synthesis routes for the guanidine component as well.

Green chemistry isn’t just a buzzword. Knowing the formula helps chemists make smarter judgments about what to stock and use. More importantly, it shapes safer practices for everyone along the way—from the people at the bench to communities downstream from manufacturing facilities.

Understanding Tetramethylguanidine Lactate

Tetramethylguanidine lactate can turn up in lab settings and specialty manufacturing circles. I remember working in a facility where the word “tetramethylguanidine” alone made experienced chemists careful. This compound forms through a reaction involving tetramethylguanidine and lactic acid, which binds together strong basic properties with organic acid features.

Health and Handling Risks

Handling tetramethylguanidine or its salts always calls for respect. Straight tetramethylguanidine is classed as corrosive and brings significant risk: it can burn skin, damage eyes, and irritate airways with just a small splash or a whiff. Now, the lactate salt offers some changes in chemistry, but the core hazards do not simply disappear. The molecule still packs enough punch to harm tissue if it gets direct contact.

Hazard assessment databases, such as PubChem and entries from the European Chemicals Agency, show tetramethylguanidine derivatives remain on official watchlists for toxicity. Labs treat them with gloves, goggles, and fume hoods. I have watched old-timers catch mistakes in fresh trainees’ glove selection or storage protocol, recalling stories about chemical burns that took months to heal and lab accidents that could have turned tragic without quick emergency rinses.

If It Gets Into the Environment

Every chemical spill or rinse-down adds up. If tetramethylguanidine lactate enters drains, worries about how it breaks down and whether it poisons aquatic life pop up. Strong bases like these alter pH fast, and sudden shifts mess with delicate freshwater habitats. Some research flags persistent toxicity risk, especially for smaller invertebrates. Accidental flushes or leaks should always set off alarms for containment and proper clean-up.

Inside a plant, good containment lines and spill trays offer front-line defense. Disposal routines collect related waste in locked drums and send it to specialized incinerators, rather than main sewage. Recycling or reusing solvents where possible helps cut the risk.

Protecting Workers and Communities

Lab managers and safety officers I’ve worked with insist on basic rules for anything involving tetramethylguanidine lactate. Training comes before anyone can transfer, mix, or pour. Emergency shower and eye-wash stations stay open and tested weekly. Safety data sheets post in eye-level spots near benches. Everyone respects the need for quick actions if an accident happens.

Air monitoring systems help spot vapor build-ups early. Close inspection of ventilation makes sure emissions from fume hoods get filtered before exiting. Glove choice is never left to habit: nitrile or butyl gloves hold up much better against amines than simple latex. No one eats or drinks in these rooms, ever.

I have seen some companies go further, offering take-home safety guides for workers, and hosting info sessions for neighbors about nearby chemical stocks. It helps keep trust if people know which compounds are on-site and how spills would get handled. Early honest talks beat rumors after a siren goes off.

Looking Ahead: Reducing Hazards

Switching to less harmful alternatives drives many research projects now. For any place still using tetramethylguanidine or its salts, attention stays on keeping stocks tight, reviewing safety plans often, and backing up people with good gear and knowledge. Advances in green chemistry might soon shrink the use of risky substances in favor of milder ones.

Until that happens, the best insurance remains respect for these chemical building blocks—strong knowledge, sharp procedures, and the commitment to speak up at the smallest red flag.

Why Storage Matters More Than You Think

Tetramethylguanidine Lactate runs a role in research labs and certain manufacturing settings, especially for folks troubleshooting in organic synthesis or dealing with specialty solvents. Getting complacent about chemical storage usually stirs up bigger problems later. Poor storage habits lead to product degradation or, worse, health and safety hazards. Both mistakes take up time, gobble up budgets, and sometimes put lives at risk. I’ve seen overlooked labels and shortcuts in university labs translate to ruined experiments or frantic safety calls. A little respect for proper storage cuts those risks out of the picture.

Spotting Common Risks

People don’t always realize how sensitive Tetramethylguanidine Lactate can be. Its basicity alone is enough to demand extra care. If it sits near acids, the mix produces unwanted reactions. Some might shrug off a spill or poorly sealed container, yet even low exposure to air starts to degrade quality over time. I’ve had folks swap stories of chemicals left out on benches, discovered weeks later looking nothing like the original compound and completely useless for their work. Losses pile up quickly with this sort of oversight.

Temperature and Container Count for a Lot

From my time in industrial labs, lessons around temperature never fade. Chemicals like this don’t fare well as temperatures spike or dip. A consistent, cool spot—away from direct heat, radiators, or sunlight—slows down decomposition. A fridge used for chemicals cuts down on surprises and keeps contents stable. Glass containers with tight seals do the heavy lifting in warding off moisture and air, so there’s no point gambling with plastic bags or improvised lids.

Label Every Step

Sharp labeling isn’t just obsessive behavior; it heads off confusion and misuse. Shortcuts taken with labels almost always lead to future regrets. Every bottle in my workspace carries the full name, concentration, and date received. I make sure hazard labels tell the next person exactly what they’re picking up. Faded or missing handwriting on labels lands more people in trouble than almost anything else I’ve seen over two decades in labs.

Keep Incompatible Compounds Out of the Picture

Bumping Tetramethylguanidine Lactate up next to strong oxidizers or common laboratory acids only sets the stage for disaster. Even shelving chemicals with loose lids nearby can cause vapor transfer and contamination. I’ve seen racks collapse and send bottles tumbling, so secure shelving, especially for bulk storage, is worth the investment. Organized layouts, with every family of chemical kept well apart, take minutes to set up and save labs from a days-long clean-up or even a shut-down after a preventable mishap.

Personal Protection Always Pays Off

It’s easy to forget gloves or ignore goggles during a rushed day, but handling this substance calls for the full line-up—nitrile gloves, splash-proof goggles, and sometimes a lab coat. I’ve gotten minor skin irritation from brief contact in the past, and I’ve seen far worse happen to colleagues who skipped the basic precautions. Even routine bottle transfers or small transfers inside the fume hood deserve that level of attention.

Simple Steps With Real Impact

Storage habits build trust—not just with safety auditors, but with everyone working in the same space. These measures reflect attention and respect for both the science and the people behind it. Storage sounds simple. Done right, it keeps your work running, reputations intact, and accidents out of the news.

A Matter of Care, Not Just Compliance

Handling chemicals with punch, like Tetramethylguanidine Lactate, never feels routine to anyone who has cracked a bottle of it open. I’ve worked with organic bases a fair bit, and even after years, I don’t let old habits or pressure to rush take over. This is the stuff that demands attention, not only out of respect for the rules but because one slip can mean everything from a bad reaction on your skin to bigger trouble in the air.

Straightforward Precautions Save Headaches

Goggles and gloves get the first nod. Nitrile gloves keep splashes from touching your hands, since even a mild corrosive can cause burns or lingering irritation. Face splash risk isn’t just a chemistry textbook scenario—I’ve seen a misjudged pipette or spill splatter higher than you’d think, which makes tight-fitting goggles critical. Don’t grab whatever gloves are around; latex breaks down with strong organic bases. Go with nitrile or neoprene for this job.

Airflow matters more than people sometimes realize. Fume hoods aren’t just there to pass safety inspections, they actually pull vapors away, and you feel the difference right away. If you ever get a whiff of a sharp, amine-like smell, that’s a sign the hood isn’t pulling well or the sash is too high. Those fumes, inhaled over time, can torch your throat and nose and make your day a lot worse. I always flick on the hood fan and check the air current with a tissue or strip of paper before starting.

Don’t Let a Small Spill Become a Big Deal

It’s easy to act like a minor spill is just part of the job, but ignoring a little puddle or droplet leads to more exposure than most realize. Spilled Tetramethylguanidine Lactate calls for sand or vermiculite, not paper towels, since you want something that absorbs and contains chemical reactions. I’ve watched new lab members rush unprotected into a cleanup, but grabbing gloves and even protective sleeves stops the stuff from working its way onto your forearms or jacket. Clean the bench with lots of water after you’ve scooped up the solid.

Respect the Label and Don’t Chase Shortcuts

Original containers matter because it helps you avoid mix-ups. I’ve been in labs where a reused bottle led to a harsh surprise; labels scratched off in a hurry spells disaster later on. Keep MSDS sheets or some kind of quick reference nearby to double-check what you’re dealing with. Relying on memory or improvising storage usually backfires. I keep a binder by the hood, and it’s saved me more than once, especially with new, unfamiliar chemicals.

What About Safe Disposal?

Pouring extra Tetramethylguanidine Lactate down a drain doesn’t just mess with the local water—it’s usually against the rules for a reason. Local waste regulations almost always spell out specific disposal containers, and skipping this step can stick you with fines or a nasty clean-up. I make it a point to segregate organic bases from acids and solvents, since mixing can bring unwanted chemical reactions, plenty of heat, or even fires.

The Human Factor

Even if gear and rules are solid, training keeps people safe. One-on-one mentoring and real walkthroughs work better than handouts. I still remember lessons from my first lab supervisor, who drilled into me that safety isn’t just about personal risk—it’s about the people around you, too. If someone nearby ignores a step or misses a label, you’ve got to speak up. That habit builds a culture where mistakes are caught early, and everyone gets home in one piece.