Tetraphenylphosphonium Chloride: From Early Synthesis to Emerging Research

Historical Development

Chemists in the mid-20th century took great interest in the synthesis of quaternary phosphonium salts. Tetraphenylphosphonium chloride first appeared on the experimental scene during research into ionic compounds that could act as phase-transfer catalysts and provide unique solubility traits. By the 1960s, scientists uncovered its potential to break solubility boundaries in polar and non-polar systems. This opened new pathways not only for phase-transfer catalysis, but also for understanding ion pair interactions in organic synthesis. Laboratories quickly incorporated tetraphenylphosphonium salts into a growing toolkit that supported organometallic chemistry, analytical detection methods, and the development of more advanced synthons. Over decades of lab work, published studies made it clear that this compound stood out because of its robust ionic character and versatile cationic core, which allowed it to interact with a wide range of anionic partners. Growth in its usage mirrored the broader rise in phosphorous-containing reagents that shaped both academic and industrial chemical engineering from the latter half of the twentieth century through to today.

Product Overview

Tetraphenylphosphonium chloride typically shows up as a white to off-white crystalline powder. Scientists and technicians value its ability to move easily across phase boundaries, which means it can help shuttle ions between solvents that do not mix. This property underpins a variety of its roles, especially in making certain chemical processes run more smoothly and efficiently. Suppliers offer this compound at purity levels that fit strict laboratory requirements, with the material packed in air-tight containers to guard it from moisture and atmospheric carbon dioxide. Both research-grade and industrial quantities can be sourced, reflecting the compound’s solid reputation as a workhorse chemical in both bench and pilot-scale applications. In my own hands, working with tetraphenylphosphonium chloride proved valuable for stubborn extractions involving halides and weakly soluble salts that resisted other efforts.

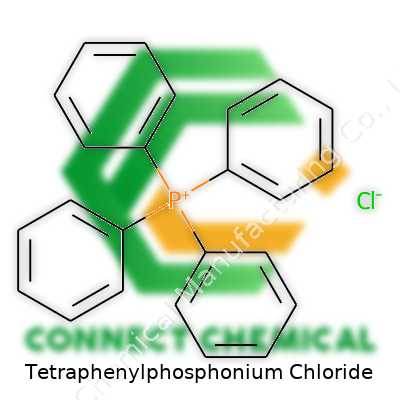

Physical & Chemical Properties

Tetraphenylphosphonium chloride holds the formula C24H20PCl and tips the scale close to 374.84 grams per mole. Its solid crystals melt at roughly 260°C, showing significant thermal stability well above standard laboratory and industrial process temperatures. It dissolves readily in polar organic solvents such as methanol and acetonitrile, yet offers low solubility in water, lending an advantage in some extraction techniques. The compound features a positively charged phosphonium ion flanked by four phenyl groups, each bringing aromatic bulk and lending steric stability. That kind of stable platform helps keep unwanted side reactions to a minimum in complex reaction mixtures. Sensitivity to moisture and air can lead to hydrolysis or slow decomposition, making careful handling and proper storage important to anyone working with it on the bench.

Technical Specifications & Labeling

Bottles of tetraphenylphosphonium chloride should list its CAS number, gross and net weight, date of manufacture, and purity—often quoted at or above 98%. Safety guidance highlights the need for gloves, lab coats, and eye protection; tightly sealed glass or HDPE packaging ensures a long shelf life. Manufacturers run batch tests to certify residual solvents, heavy metals, and related anion content, with certificates of analysis included in every lot. Accurate labeling remains critical, as even small label errors can cause confusion or risk during inventory management and experimental planning. In labs I have managed, small lapses in labeling on similar compounds have led to setbacks that cost more than the price of the chemical itself.

Preparation Method

To produce tetraphenylphosphonium chloride, a straightforward alkylation approach serves the purpose. Chemists often stir triphenylphosphine with chlorobenzene under reflux, then treat the resulting mixture with a suitable oxidant or halide source. The triphenylphosphine soaks up the additional phenyl group and fixes the chloride ion as the counter-anion. Filtration, crystallization, and repeated washing with non-polar solvents purify the product and ensure removal of side products. Scale-up for industrial production demands careful monitoring for by-products and the presence of unreacted starting material. Many colleagues report that improvements in process-control equipment, and a move to greener solvents, now help meet environmental regulations while keeping overall yields high and impurity profiles low.

Chemical Reactions & Modifications

Tetraphenylphosphonium chloride sits at the center of several important reaction classes. In phase-transfer catalysis, it carries anionic reactants across solvent boundaries that would otherwise block progress. The phenyl-rich structure provides unusual stability, allowing the cation to survive harsh reaction conditions, bases, and oxidants. Chemists can exchange the chloride for other halides or anions, tailoring the material to specific processes. The molecule also accepts modification through derivatization of the phenyl rings, opening up new families of custom phosphonium salts. Researchers use its chloride version to precipitate unwanted anions or as a standard in molybdenum blue assays, taking advantage of the compound’s insolubility in water and its tendency to pull certain ions out of solution.

Synonyms & Product Names

Suppliers might list tetraphenylphosphonium chloride as TPPCl, tetraphenylphosphorane chloride, or with the systematic name tetraphenyl-λ5-phosphanium chloride. Labels may include its registry and product code as references for bulk order workflows. Some catalogues list it under trade names that highlight its phase-transfer catalysis capabilities, shortening the chemical name to ease communications among order managers and research chemists. I’ve found regular confusion between names to slow down shipping and spark repetitive “double-check” emails—accuracy matters here.

Safety & Operational Standards

Direct skin or eye contact with tetraphenylphosphonium chloride should be avoided. Standard operating procedures always enforce glove use, eye shields, and fume hood work to manage fine dust and avoid inhalation. The compound scores low for acute toxicity but regular handling can trigger mild respiratory irritation. Spill management plans treat it like a non-volatile irritant, focusing on immediate containment and vacuum-assisted cleanup. In-house audits review storage, labeling, and risk controls routinely; regulatory compliance draws on GHS labeling and chemical risk registers. In research facilities, following well-practiced routines for weighing and transfer keeps accidents rare. I appreciate safety protocols that streamline chemical movement while expecting researchers to double-check compatibility during scale-up experiments, as the stakes can change quickly with volume.

Application Area

Lab teams reach for tetraphenylphosphonium chloride during phase-transfer catalysis, particularly where other ionic compounds fall short. Analytical chemists rely on it as a precipitation agent and counter-ion for less common metals and anions—useful in the isolation of pertechnetate or permanganate salts and in the purification of organometallic complexes. Organic chemists preparing phosphonium ylides draw on its parent structure, and coordination chemists value the space-filling steric shield provided by its aryl groups. Engineers designing ionic membranes see promise in exploiting the large hydrophobic surface, aiming to upgrade performance in electrochemical devices. My own introduction came during a project separating scarce transition metal complexes, where the selectivity of the phosphonium cation tipped the balance for high-purity yields.

Research & Development

Current R&D efforts center on two main areas: alternative synthesis methods to reduce by-product loads, and the creation of functionalized tetraphenylphosphonium derivatives for advanced materials. Teams are exploring greener reaction routes, including new oxidants, flow-chemistry reactors, and solid-state synthesis that slash solvent use and energy consumption. Electrochemical applications, especially in lithium-ion battery research, see this compound tested as an electrolyte additive or conductive salt, with research groups reporting improvements in ion mobility and shelf-life stability. Collaboration across academia and industry, especially in Europe and East Asia, supports grants aimed at probing both the molecular behavior and macro-properties when these salts are blended into novel polymers or supramolecular assemblies.

Toxicity Research

Rodent studies performed by safety assessment teams highlight low acute toxicity for tetraphenylphosphonium chloride compared to more hazardous phosphorous compounds. Chronic exposure still brings questions, particularly regarding long-term respiratory irritation and possible cumulative effects on liver enzymes. Environmental toxicity remains minimal, with quick degradation in natural soil and water environments, but the compound’s bulkier organic structure could bioaccumulate under unusual conditions. Testing on aquatic life and soil bacteria continues to inform chemical safety sheets and local disposal rules. I’ve benefited from clear communication between EHS committees and end-users, as real-world incidents offer valuable lessons on misunderstood hazards or underestimated accumulation in lab drains.

Future Prospects

Further growth for tetraphenylphosphonium chloride looks tied to breakthroughs in green chemistry and sustainable materials. Teams aim to develop recyclable phase-transfer catalysts and support materials by tweaking the core cation-and-anion combinations. Emerging fields like ionic liquid engineering and advanced analytics for next-generation batteries will demand material purity, robust safety data, and reliable supply chains. The push for low-waste manufacturing processes that harness organic salts as both reagents and medium could make this compound even more critical to research labs and specialty production. Feedback loops between academic research, regulatory shifts, and industry adoption will set the pace. For anyone working at the interface between synthesis and application, following the evolving story of tetraphenylphosphonium salts is less about copying yesterday’s methods and more about shaping tomorrow’s discoveries.

Understanding the Role of Tetraphenylphosphonium Chloride

Tetraphenylphosphonium chloride shows up in chemistry labs more often than most folks realize. I remember seeing the big jars of it back in college, always marked with warning labels, tucked into the shelves of the organic chemistry stockroom. People tend to skip over it, but this compound plays a role that’s not nearly as obscure as it looks.

Laboratory Applications

Researchers turn to tetraphenylphosphonium chloride when they need a reliable source of the tetraphenylphosphonium ion. This isn’t an everyday household name, but it’s part of a niche group of compounds known as phase-transfer catalysts. Chemists use these to help molecules from different layers — like water and oil — finally mix and react together. Without catalysts like this one, organic reactions could grind to a halt. I’ve watched colleagues struggle to coax two stubborn reactants into reacting until someone finally adds a dash of tetraphenylphosphonium chloride, and off it goes. That’s why chemists keep it close at hand for those tricky synthesis steps.

These catalysts make certain chemical transformations possible — or at least a lot more efficient. Sometimes, people forget how much time and money a reaction can eat up without help. The speed and yield of making pharmaceuticals or advanced materials can hinge on this compound. It’s not often front and center in headlines, but its role gets woven into drug discovery, new polymer creation, and advanced dyes. Doctors down the road rely on those molecules; patients waiting on custom drugs rely on the labs piecing things together efficiently.

Use in Analytical Chemistry

Tetraphenylphosphonium chloride also works as a useful tool for measuring ions. Imagine trying to spot a single drop of ink in a huge swimming pool — that’s what detecting low concentrations of certain anions can feel like. This compound forms salts with those anions, making them easier to isolate and study. I’ve seen it help confirm the purity of water, test for contamination, or even check batteries for trace byproducts. Scientists and engineers often lean on this technique to verify quality and safety.

Environmental and Technical Impacts

With any chemical that’s fairly specialized, concerns surface about how much waste ends up in the environment. Safe handling matters; plenty of us learn about risk management on the job, not just in textbooks. Improper disposal could harm water systems or even soil microbes. Adherence to safety guidelines and local regulations keeps the compound from causing problems in the broader world. Lab managers stress this point every time they train new folks.

Room for Safer or Greener Alternatives

Demand for cleaner chemistry grows every year. Research groups experiment with bio-based or less hazardous catalysts, sometimes using plant-derived compounds or clever enzymatic methods. If safer alternatives can match the performance of tetraphenylphosphonium chloride, the switch makes sense. Investment in chemistry education helps students and professionals make smart, ethical decisions as they develop new processes. This focus on stewardship benefits not just those inside the lab but everyone downstream.

Final Thoughts

Understanding the contributions and risks around tetraphenylphosphonium chloride keeps the conversation honest. Many of us who work with chemicals every day recognize that the best science doesn’t just chase progress — it considers the impact on people and the planet, too.

Understanding Purity in Practice

Tetraphenylphosphonium chloride usually gets supplied with a stated purity, often around 98%. In my experience, this figure on the bottle is not just for show. It sets the tone for how well your results line up with your expectations, whether you’re running research in a university or scaling up for industry. Sharp experimental work relies on each reagent performing the same way every time. If purity slips, yields crash, reactions stall, or oddball peaks start popping up in an NMR or chromatogram. That’s not just frustration—it’s lost time and missed deadlines.

Why Purity Levels Shape Outcomes

This compound finds its way into a whole spread of chemistry: phase-transfer catalysis, organic synthesis, even analytical labs. The price tag nudges buyers to reach for the 98% or higher grade. Anything lower can saddle a project with invisible sabotage. Imagine isolating a sensitive intermediate, only to discover trace metal ions or unreacted triphenylphosphine tainting your pathway. It doesn’t take much impurity to turn a promising breakthrough into a non-starter.

Anyone running a controlled experiment learns fast that starting material matters. Analytical reports often pinpoint water, phosphine oxide, or stray chloride as culprits. I’ve worked with batches where even a 1% drop below spec meant troubleshooting across an entire week.

How Labs Measure Purity

Reliable suppliers back up their claims with certificates of analysis, titration data, or spectral fingerprints. Infrared spectroscopy highlights lurking side products. Titration for chloride gives a real-world snapshot, while melting point checks flag possible contamination. In conversations with colleagues, we often swap supplier stories. Nobody wants to spend days replicating a known reaction, tracing unexpected outcomes back to a faulty input.

In one organic synthesis project, our team opted for a low-cost sample below the 97% mark. We saw weird byproducts, had to run multiple column purifications, and still lost much of the target product. After investing in a higher-purity lot, everything fell into place: clean separation, reliable yield, data matching known literature.

Quality Control and Safer Outcomes

Sourcing high-purity tetraphenylphosphonium chloride becomes more than a numbers game. It’s about securing safety and reproducibility. Contaminants sometimes carry real risks—unexpected reactivity, health dangers, or environmental messes. Labs with good practices double-check every batch and keep close records. These habits catch problems before they snowball.

There’s a clear path to better purity: demand suppliers provide clear analysis, budget for better-quality reagents, and track results every time you open a new bottle. Education plays a role too. Emerging chemists should learn not just what a purity label says, but what it means for their experiment’s success.

Anyone with a few failed syntheses behind them knows the peace of mind that comes from opening a bottle and seeing crystals as clean as a snowdrift. There’s real satisfaction in knowing you’ve stacked the odds in favor of a clean reaction—by starting with the purest materials you can find.

Understanding the Risks

If you’ve spent any time working in a lab, it’s clear that handling chemicals isn’t a routine chore—it’s a loaded responsibility. Tetraphenylphosphonium chloride lands firmly in that camp. With its white crystalline appearance, it doesn’t look dangerous at a glance. Under the surface, though, this compound brings hazards. Problems start when people get complacent. I’ve watched coworkers store chemicals wherever space allows, and every time, that choice chips away at safety.

Stability and Storage: Going Beyond the Basics

Tetraphenylphosphonium chloride keeps fairly stable under the right conditions. That doesn’t mean it handles neglect with grace. If humidity creeps in or sunlight pours onto a loosely capped bottle, the risk starts multiplying. I still remember a colleague who learned the hard way—water vapor in the storage cabinet led to clumping and tricky clean-up, and everyone had to waste an afternoon on a spill drill. It’s a reality check: store the bottle in a tightly sealed container. Be strict. Genuine air-tight seals matter here, more than people expect.

The Temperature Factor

I once worked in a lab where seasons dictated safety. Heat waves hit, and suddenly chemicals stored near a window suffered; labels peeled, and powders turned lumpy. Tetraphenylphosphonium chloride hates swings in temperature. Keep it cool, and keep it consistent. This usually means placing it in a flammable storage cabinet or a cool, dry, clearly marked drawer. Shelves close to heat sources like radiators or sunlight send the wrong message about safety culture. My habit now? I reach for the thermometer inside the storage unit before adding a new bottle. Consistency wins out over convenience every single time.

Avoiding the Domino Effect

You might have seen pictures of tightly crammed cabinets, bottles pressed against each other like sardines. That’s not just messy—it ups the risk if a spill or reaction happens. Tetraphenylphosphonium chloride shouldn’t share space with acids, bases, or strong oxidizers. The idea isn’t to be paranoid, but to respect chemical compatibility. Once, an intern mixed incompatible substances out of sheer ignorance, causing a minor incident that could have gone much worse. People sometimes overlook training, thinking “it won’t happen here.” That attitude courts disaster.

Clear Labelling and Accountability

It amazes me how often labs overlook good labeling. The number of times I’ve squinted at faded writing is higher than I’d like. Clear, legible labels mean no second-guessing in a rush. Include the full chemical name, date of receipt, and hazard warnings. No room for shortcuts. A friend of mine started color-coding by chemical class, and it cut down on confusion. That sort of discipline pays off fast, especially during audits or emergencies.

Training Makes the Difference

Anyone storing tetraphenylphosphonium chloride, or anything with a tongue-twister name like that, benefits from regular refreshers. I’ve sat through enough safety sessions to know that even veteran staff slip up without reminders. Teams that talk through their procedures regularly dodge more close calls than those who “just know” what to do. My old lab had a simple rule—everyone could quiz each other on storage guidelines anytime. It wasn’t about catching mistakes, but keeping each other sharp.

Practical Steps Overlapping with Science

At the end of the day, storing tetraphenylphosphonium chloride isn’t only about ticking boxes. The most experienced chemists I know see every bottle on the shelf as a test of discipline and mutual respect. Treat it as you’d expect others to handle your lunch: clean, labeled, and kept at the proper temperature—away from things that might spoil it or create unplanned reactions. Maintaining a strict approach makes work safer and gives peace of mind that nobody’s taking shortcuts at your expense.

Everyday Encounters with Chemical Hazards

Anyone who’s spent a bit of time in a chemistry lab has seen more unfamiliar compounds than they can count. Tetraphenylphosphonium chloride tends to blend into those rows of bottles—an unassuming white powder hardly anyone outside of research would recognize. With so many chemicals in circulation, it’s tempting to lump less-famous names into “safe enough” categories, especially if there’s little talk of them outside science circles. Yet, comfort or convenience shouldn’t downplay genuine risk, particularly for workers, students, or technicians sharing spaces with chemicals like this one.

Peeling Away the Complex Name

Tetraphenylphosphonium chloride carries a hefty name for a set of molecules that’s surprisingly useful in chemistry. Researchers use it to shuttle ions around or help drive particular reactions. It doesn’t sound exciting, but this sort of salt sits behind a fair number of projects in molecular biology and materials research. Its appearance—white, crystalline, bland—offers nothing that “feels dangerous.” That alone can set up a false sense of safety among new hands in a lab.

The Toxicity Question

What makes things tricky with tetraphenylphosphonium chloride is that its hazards don’t always shout for attention. Breathing in fine dust, getting it on your skin, or swallowing some by accident can do damage, sometimes with subtle warning signs. Studies say it irritates eyes, skin, and the respiratory system. Some animal tests show harmful effects on organs such as the liver and kidneys. Long-term impacts remain poorly understood. One issue: chemicals that seem mild from limited data sometimes gain a “not particularly hazardous” label, at least until more years of research fill out the picture. History repeatedly teaches that ignoring these gaps sometimes backfires.

Not Just a Lab Story

Hazards like these don’t stop at the lab bench. Cleaners, waste handlers, or maintenance personnel might stumble on this stuff with little warning. Poor labeling and lax safety habits heighten the chance of unnoticed exposure. Outdated safety sheets or worn-out sticky labels have real consequences. Too many times, someone far from the original experiment ends up in harm’s way—unaware of the risks until after accidents occur.

Facts and Real Risks

The European Chemicals Agency classifies tetraphenylphosphonium chloride as “harmful if swallowed.” Inhalation should also be avoided, and prolonged skin contact can cause problems. Material safety data sheets from leading suppliers outline recommendations for gloves, vent hoods, and eye protection—not just formalities but real barriers that protect health. Despite this, accidents crop up when safety culture slips or newer users brush off guidance, feeling overconfident with substances that don’t look intimidating.

Practical Steps for Safer Handling

Clear labeling beats guesswork. Training doesn’t just mean a rushed safety lecture—it pays to walk through emergency routines, spill cleanups, and proper waste handling. Storing chemicals away from food and keeping them in tightly sealed containers keeps accidental contact at bay. Lab managers benefit from regular audits of safety practices. Even researchers who think they “know the drill” need reminders to avoid shortcuts.

Why This Matters Beyond Headlines

People have a habit of underestimating danger from less-famous chemicals. Keeping attention on the real risks of compounds like tetraphenylphosphonium chloride means fewer health scares and workplace injuries. Respect is the best safety gear—earned from experience, from honest communication, and from acknowledging that science doesn’t always have every answer up front. The workplace becomes safer not because rules exist, but because people practice them with full awareness of what’s at stake.

Unpacking the Molecular Weight

Tetraphenylphosphonium Chloride, with a molecular formula of C24H20PCl, clocks in at 372.84 grams per mole. That number isn’t just trivia for a textbook; it drives how chemists approach measurement and mixing in the lab. Weighing chemicals accurately impacts everything from reaction success to product purity. This number, 372.84 g/mol, becomes a cornerstone in experiments using this compound as a phase-transfer catalyst or in analytical chemistry.

Why Molecular Weight isn’t Just a Classroom Question

Making accurate calculations happens everywhere in science. In my own days prepping chemistry labs, measuring out this white crystalline powder felt routine, yet one error meant backtracking on hours, or even days, of work. There’s little forgiveness for mistakes; one decimal out of line leads to the wrong concentration or even a failed reaction. Tetraphenylphosphonium Chloride’s specific weight focuses your math, especially since you don’t want to open a new bottle for every trial—the stuff isn’t cheap.

Everyday Consequences in Applied Chemistry

Lab professionals rely on that molecular weight for stoichiometry: how much of this, how much of that, so the reaction yields what you want. This makes the difference in fields like environmental testing or pharmaceuticals, where consistency and purity keep people safe. Pharmaceutical chemists, for instance, handle trace amounts of complex compounds. Skipping accuracy isn’t just unprofessional — it risks patient outcomes.

Beyond the Numbers: Real-Life Chemistry

In environmental labs, Tetraphenylphosphonium Chloride helps identify anions by acting as a counterion in extraction procedures. Its reliable behavior comes partially from its known molecular weight. That number factors into compliance calculations for organizations trying not to run afoul of EPA or FDA rules. Labs can’t just guess; regulators expect hard numbers and transparency.

The Teachings of Mistakes

Errors in measurement have real consequences. A few years back, I watched a colleague overlook decimal places, which threw off an entire series of results. Thankfully, that mistake happened before any publication or project launch. This experience highlighted a simple truth: accuracy builds trust in every result released. Molecular weight isn’t just for the back of a bottle; it’s in every report and every conversation with regulators or research partners.

Building Reliable Systems

Consistent results stem from nailing down details like molecular weight. Many chemical suppliers provide quality certificates, but double-checking with your own lab scale keeps the process honest. Cross-checking numbers, using well-calibrated balances, and keeping standard reference materials on hand aren’t fancy steps—they’re necessities.

Moving Toward Fewer Errors

Better education around topics like molecular weight can cut down costly waste. Workshops and hands-on training sessions embed the numbers into muscle memory, helping new chemists grasp why accuracy matters outside the textbook. Peer-checked protocols and routine audits stop small errors from snowballing.

Strong Foundations in the Smallest Details

Tetraphenylphosphonium Chloride’s molecular weight shapes nearly every decision when using this substance. Attention to details, from prep bench to report, makes each result trustworthy and every reaction reproducible. To those outside the lab, it may look like small beans, but inside, precision shapes safe and effective science.