Tetrapropyl Ammonium Tetrafluoroborate: A Deep Dive

Historical Development

Stories about modern industry often start with a handful of discoveries in laboratory flasks. Tetrapropyl ammonium tetrafluoroborate comes from that world, born out of curiosity and the need for performance materials in organic synthesis. Chemists back in the late twentieth century searched for salt compounds that worked well as electrolytes and catalysts, especially as organic electronics started grabbing headlines. Simple alkylammonium salts gave way to more elaborate ones, and research teams realized that swapping out the alkyl chain or the anion changed the way these compounds behaved. The unique structure of this compound, marrying a tetrafluoroborate anion with a tetrapropyl ammonium cation, was no accident; it came from systematic studies looking to balance chemical stability, solubility, and reactivity. The path from early reports to today’s applications showcases how persistent experimentation shapes industrial chemistry.

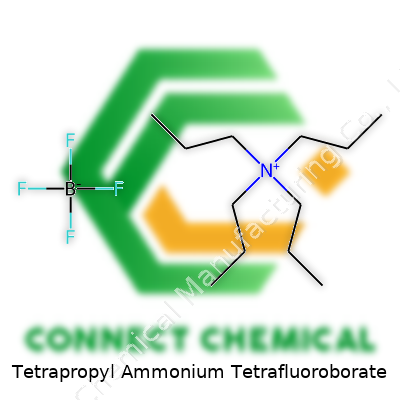

Product Overview

Tetrapropyl ammonium tetrafluoroborate shows up as a white crystalline solid—ordinary on the surface, but with a reputation for reliability once you dig into its chemistry. Laboratories and manufacturers count on it for its ionic nature, and people handling synthesis or electrochemistry know it can be trusted not to break down or cause trouble in the middle of a reaction. Where some salts draw moisture or struggle to dissolve, this compound brings both stability and flexibility to the bench. Anyone who has spent time around analytical chemistry has probably used or handled it—perhaps without taking a second look. That’s part of what makes it interesting; its uses often hide in plain sight, tucked into protocols and parts of high-value materials.

Physical & Chemical Properties

This salt looks like many other lab solids, but now and then a closer look reveals a few excellent features. Its melting point lands high enough that you don’t worry about storage, and the compound stands up to air and humidity. Chemically, it stays in line: non-oxidizing, stable across a wide range of solvents, and able to dissolve at the levels needed for ionic liquids or electrolyte mixes. The tetrafluoroborate anion resists hydrolysis, meaning the salt keeps its integrity where others might break down and turn into acids or other byproducts. Such features matter more than most people think, especially when working with sensitive reactions or expensive substrates. The cation–tetrapropyl ammonium—brings solubility in organic solvents, so researchers lean toward this compound instead of the tacky, less soluble salts of years past.

Technical Specifications & Labeling

On a technical sheet, buyers expect some basic metrics—purity (usually above 99%), moisture content, particle size, and recommended storage conditions. People outside of chemical manufacturing might not recognize the coded meanings in batch labels, but these numbers pack a punch in QC labs, where analysts check for even trace impurities. Each bag or bottle needs clear hazard markings, including the UN numbers, proper hazard pictograms, and a breakup of chemical constituents. Storage at room temperature, in sealed packaging, keeps performance predictable. In production facilities, labeling has shifted over time, now including QR codes or trackable manufacturing data, locked into cloud databases so purchasers can check supply chain integrity. These little changes may seem trivial, but they protect both users and consumers down the line.

Preparation Method

In practice, making tetrapropyl ammonium tetrafluoroborate starts with tetrapropyl ammonium bromide or chloride, salts that are easier to handle and source. Labs add sodium tetrafluoroborate in an aqueous medium and let the ions swap partners—a pretty standard metathesis reaction. The insoluble sodium halide gets filtered out, and crystallization pulls the target product from the solution. More advanced sites refine the solid through repeated washing and dissolutions, stripping away even trace halide or sodium contamination. Chemical engineering has improved yields and purity over the years, with careful tweaks to temperature, solvent choice, and crystallization timing. That attention to detail reflects the professional pride most chemists take in their work, understanding that every step has a ripple effect downstream, especially in pharmaceuticals or electronics.

Chemical Reactions & Modifications

Once in the lab, this compound offers more than just a source of tetrafluoroborate ions. It works as an electrolyte in organic electrochemical cells, letting electrons flow smoothly and reproducibly. Chemists sometimes tweak the alkyl groups, swapping propyl for butyl or ethyl, tuning solubility and viscosity for a desired application. Its chemical inertness gives it a seat at the table in oxidative processes; it won’t throw off byproducts that gum up expensive reactions. In my own experience, using this salt in electrosynthesis or phase-transfer catalysis led to faster, more reliable reaction rates. That came as a relief after slogging through inconsistent outcomes with less stable salts. People have also played with cationic substitutions, searching for tailor-made salts in ionic liquids—a field that keeps turning up new possibilities for greener chemical processing.

Synonyms & Product Names

Around the world, this chemical travels under a handful of names: Tetrapropylammonium tetrafluoroborate, N,N,N-Tripropylpropan-1-aminium tetrafluoroborate, and its standardized CAS number. Producers each have their own codes and catalog designators, making cross-referencing an exercise in patience for newcomers. These aliases matter—mixing up a compound at the order desk can turn into an expensive mistake. Some suppliers mark it with grade specifications, such as “electrochemical grade” or “analytical grade,” and that unlocked a few doors for lab managers who watch budgets closely. Learning the vocabulary around these products means fewer headaches, especially for those just entering fieldwork or bench research.

Safety & Operational Standards

Handling the salt means sticking to the best habits in chemical safety. The material won’t explode or catch fire if you glance away, but dust can irritate eyes and lungs. I habitually rely on goggles, gloves, and dust masks; it only takes one stray sneeze during weighing to realize why those rules exist. MSDS sheets require clear communication of hazards, including the need for ventilation and strict hygiene. Since the salt travels globally, producers comply with REACH, OSHA, and other international standards, testing toxicity, and documenting protocols in exhaustive detail. Chemistry labs spend a lot of time on spill response drills, waste disposal, and storage audits—a discipline built from hard lessons in the past. Safety isn’t just paperwork; it’s a living mindset everyone builds with each new batch or delivery.

Application Area

Industry, academia, and specialty manufacturers all turn to this compound. Electrochemistry labs rely on it for supporting electrolytes in organic solvents, giving steady current flow in synthetic and analytical setups. Battery researchers use it in prototype cells, especially where lithium salts raise cost or toxicity concerns. The pharmaceutical industry turns to it for phase-transfer catalysts, and its resistance to hydrolysis makes it a practical component in moisture-sensitive syntheses. In organic synthesis, this salt flat-out enables approaches that simpler salts would stall. A few years back, I saw a colleague breathe a sigh of relief after switching to this compound in an electrooxidation protocol. Not only did the yields go up; the mess of side products dropped off, saving days of purification and solvent use. The story repeats itself across dozens of labs—those who find the right salt hold a real edge.

Research & Development

Development teams and university groups keep testing boundaries for what these salts can offer. Technological change rarely moves in straight lines, but recent work has turned up more stable electrolyte blends for organic flow batteries, biodegradable ionic liquids, and even environmentally responsive sensors using these cations and anions. Researchers chase performance benefits—higher conductivity, lower viscosity, or wider electrochemical windows—but they also dig into sustainability. High-throughput screens now let scientists scan for derivatives that shed old downsides like toxicity or handling hazards. In my own reading and conversations, the focus keeps returning to lifecycle impact and cost-of-ownership. Consumers may not see that research, but it drives improvements in product reliability and environmental stewardship.

Toxicity Research

Toxicology teams take nothing for granted, even with chemicals that have long track records for reliability. In animal studies and cell-based assays, this salt shows relatively low acute toxicity compared to other tetrafluoroborate salts. Chronic exposure or mishandling can still bring risks—a reminder that even trusted tools need respect. Regulatory agencies in the EU and North America push for ever-tighter documentation, and third-party labs test breakdown products to check for environmental persistence. The story isn’t just about personal exposure; it’s also about what happens downstream, after disposal or accidental release. I once spent a month working with a regulatory team preparing paperwork for product safety reviews. The main lesson I learned: risk isn’t something you “check off a list,” but rather something you manage with constant vigilance and a willingness to change protocols as new data appears. Industry grows safer when data replaces guesswork.

Future Prospects

Next-generation research keeps rolling forward, and this compound—stable, versatile, and increasingly affordable—still has big shoes to fill. Expanding use in battery and sensor sectors keeps demand rising. As the world pushes for decarbonization and greener industrial processes, chemists look for electrolyte salts that don’t trade performance for environmental health. There is a growing interest in hybrid systems where traditional salts and new organic frameworks merge to bring better conductivity and recyclability. Sectors such as pharmaceuticals and advanced electronics show that even a small improvement in background electrolyte chemistry can unlock new syntheses or speed up commercialization by months or years. During recent conference seasons, panelists argued over the next Ionic Liquid revolution, but this compound remains a benchmark—proof that deep work in chemistry yields materials that seem almost ordinary until you need them most.

Why This Compound Pops Up in Labs

If you hang around people working on advanced batteries or in electrochemical research, tetrapropyl ammonium tetrafluoroborate pops up more often than you’d think. While the name sounds intimidating, it acts as a supporting electrolyte—essentially a sort of traffic cop that helps ions flow smoothly during various electrochemical reactions. I’ve seen it used to keep experiments running consistently, especially in non-aqueous solvents where water-based salts just fizzle out.

The Science Connecting Batteries and Chemistry

In non-aqueous electrochemical cells, finding a salt that dissolves easily and doesn’t muck up the reaction is a tough job. Tetrapropyl ammonium tetrafluoroborate does this job better than most. You just need a salt whose ions don’t jump into the chemical reaction themselves but provide solid conductivity. That’s a tall order for many common salts, but this one manages it without creating weird byproducts.

I remember helping a colleague run a set of experiments with organic semiconductors. We switched from traditional perchlorate salts to this tetrafluoroborate option because perchlorates had a nasty habit of exploding once things heated up. The new salt didn’t just stay out of the way, it let us push the limits in voltage and temperature, making our test runs safer and more reliable.

Tested and Trusted in Research

Electrochemists have used tetrapropyl ammonium tetrafluoroborate for years because it provides stable ion conductivity without decomposing, even at higher voltages. If you’re trying to test a new battery design or dig into the basic science of electrode reactions, you need to keep the experiment as clean as possible. This compound helps there by not breaking down or making messy side products that cloud up the results.

Outside the lab, this salt plays a quiet role in helping researchers understand how charge transfer and energy storage work. Without a reliable supporting electrolyte, insights into battery life, energy efficiency, and new material properties get a lot murkier. Current advances in battery technology—needed for everything from your phone to electric cars—lean on careful, reproducible experiments. Choosing a compound like tetrapropyl ammonium tetrafluoroborate helps keep that foundation stable.

Real Safety Considerations

Like many chemicals used in the lab, it’s not something to handle without care. Exposure over time can hit the lungs and skin, which means gloves and proper air handling matter. Our lab kept it locked in a ventilated cabinet, and we double-checked safety data sheets before every experiment. Accidental spills call for serious cleanup, because this salt isn’t exactly friendly to water systems and can linger long after you think it’s gone.

Building a Better Future with the Right Chemicals

Researchers and engineers keep looking for better, greener alternatives, but for now, tetrapropyl ammonium tetrafluoroborate remains a go-to for high-precision battery and electrochemical research. Its reliability keeps experiments on track and lets us chase the next big step in energy storage without getting bogged down by side reactions or safety scares.

The real challenge lies in finding compounds just as effective but with a smaller environmental footprint. That’s where chemists, policymakers, and industry leaders need to pull together—applying their experience, sharing their data, and making sure the solutions go beyond the bench and into the world at large.

Tetrapropyl Ammonium Tetrafluoroborate: More Than a Mouthful

Reading the name, "Tetrapropyl ammonium tetrafluoroborate" feels like one of those spells from a Harry Potter book, but this compound pulls real weight in the world of chemistry. Its formula, C12H28N BF4, might look like just a cluster of letters and numbers—but understanding what goes into this formula gives you an edge in so many modern laboratory settings.

The Formula Breakdown

This salt comes from a tetrapropylammonium cation (N doped with four propyl chains, giving you C12H28N) paired with a tetrafluoroborate anion (BF4). In the lab, once you see those long propyl chains, you expect a bulky, organic-friendly ion that gets along well in organic solvents. The BF4- part is a non-coordinating anion, which means it won’t easily stick to metal ions—this comes in handy for reactions where you want to "free up" a metal center or avoid unwanted side chemistry.

Experience From the Bench

My time in electrochemistry research taught me how certain formulas do more than just describe a substance—they shape how experiments run. You learn fast that picking the wrong salt clogs up reactions or scrambles your data. Tetrapropyl ammonium tetrafluoroborate rises above the noise because in many non-aqueous setups, it dissolves well and doesn’t interact with the molecules you actually care about. You can focus on the electrons moving, not which impurity might be sneaking in from your electrolyte.

If you've tried using simple salts like sodium chloride in an organic solvent, disappointment sets in quickly—little to no conductivity, precipitation, or just cloudy messes in your flask. Bring in a salt like tetrapropyl ammonium tetrafluoroborate and the solution runs clear, and the reactions run true to theory.

Why The Formula Carries Weight

People sometimes underestimate the compound’s formula, but this structure impacts everything from conductivity to thermal stability. The size of the tetrapropyl group helps the salt spread out in organic phases, and that alone supports research in advanced batteries or organic electronic devices. Non-coordinating behavior of tetrafluoroborate helps researchers push reactions further, allowing them to make more complex molecules without side effects.

Science rewards those who pick their materials carefully. For example, researchers working in catalysis or spectroscopy can trust this compound to keep ionic strength high, avoid interactions with sensitive components, and remain soluble at the concentrations needed for accurate measurement. The compound lets researchers keep focus on innovation, not troubleshooting.

Room For Improvement and Safety Steps

While this salt works wonders, there’s always the push for greener, safer alternatives. Tetrafluoroborate, though useful, can release fluoride under certain conditions, and labs must factor in waste disposal and personal safety. Researchers have started to explore other "spectator" ions with less environmental impact, but they often lack the stability or solubility offered here.

Handling tetrapropyl ammonium compounds means clear labeling, proper ventilation, and respect for material safety data sheets. Outcomes improve for everyone when accidents drop and waste finds its way into the correct waste stream, not the local water supply.

Solution-Oriented Mindset

Strong science grows from picking reagents for purpose, not just habit. New researchers, take time to look for safer, biodegradable ions that still match the performance of these stalwarts—industry and academia both need solutions that keep the environment and workers safe while pushing knowledge forward. C12H28N BF4 may rule the lab now, but tomorrow’s chemistry depends on smarter, safer choices.

What Stands Out About Tetrapropyl Ammonium Tetrafluoroborate

Tetrapropyl ammonium tetrafluoroborate, often found in chemistry labs and specialized battery applications, comes with a reputation for both utility and risk. This salt shows up most often as a white crystalline powder, dissolving pretty well in water or organic solvents. Chemists and engineers find its ionic conductivity useful for developing batteries and fuel cells. That said, routine lab use brings safety questions to the table.

What Science Says About Toxicity

Like a lot of ammonium-based chemicals, tetrapropyl ammonium tetrafluoroborate can cause problems if handled carelessly. Studies show that ammonium compounds have an irritating effect on eyes and skin. Breathing in the dust leads to coughing or sore throats, and sometimes animals used in research show reversible changes in liver and kidney function after significant exposure. People who work with these chemicals often know to expect such symptoms and come prepared with personal protective equipment — gloves, goggles, and masks — to cut down exposure.

There isn’t a mountain of long-term toxicity data publicly available about this chemical in humans. Still, the tetrafluoroborate ion in itself can break down, and sometimes this produces tiny amounts of boron and fluorine-containing byproducts. Fluoride exposure, even at low levels, has links with bone and dental problems long-term. Regulatory agencies mark many tetrafluoroborate salts as substances that deserve caution but stop short of labeling them as acutely toxic in typical lab settings.

Recognizing the Risks

People who come across tetrapropyl ammonium tetrafluoroborate in industry might not appreciate, at first, that such a bland-seeming powder needs strict handling. Spills on skin feel uncomfortable and need immediate washing. Chemicals drifting through the air irritate lungs — it doesn’t take a lot for sensitive folks to cough or feel a mild burning in their noses. If a spill happens in the lab, a quick mop-up with gloves and a fume hood running keeps the situation from turning serious.

Most trouble comes from not respecting enough the simple guidelines: respect glove barrier breaks, clean up after yourself, avoid stirring up dust, and keep chemicals labeled. Many accidents in my years working with similar substances occurred because someone forgot to double-check which bottle they snatched off the shelf, or tried to pour something back into the original container. Safety habits matter more than the complexity of the chemical name.

Pathways to Safer Practice

Preparation and training pay off. Staff working with ammonium salts or tetrafluoroborate compounds need clear instructions, good protective gear, and access to fresh air. Good ventilation cuts down risk. Eye wash stations and safety showers help in emergencies; their absence turns a minor incident into a bigger medical issue.

I found over the years that consistent reminders keep everyone safer. Labeling, regular safety briefings, and encouraging even experienced workers not to take shortcuts stops many accidents before they start. Most workplaces, forced by regulations or good experience, keep safety data sheets ready. These spell out first aid steps, storage methods, and disposal rules to control the risks from day one.

Aim for Informed Use, Not Fear

No chemical replaces common sense or sound protocols. Tetrapropyl ammonium tetrafluoroborate earns respect by responding to precaution, not panic. Researchers, students, and workers who treat it with care help keep labs and workplaces safe places for learning and discovery.

The Real Stakes Behind Product Purity

Buyers want answers that cut through jargon. Purity isn't a checklist item. It decides how safe a product feels, whether it's headed for a lab or a food factory. I remember working with small cosmetics brands who lost weeks of work to uncertainty about ingredient grades. Everyone on those teams expected vendors to share straight facts—percentages, certifications, types of contamination tested. Instead, they caught vague answers and had to chase down safety data themselves. Too many suppliers gloss over what “pure” actually means for each batch.

Why Grades Set Expectations

Any product—be it a chemical, supplement, or food ingredient—shows up with a grade attached: pharmaceutical, food, or technical. A food-grade ingredient matches strict safety standards, tested for everything from heavy metals to toxins. Pharmaceutical grade? That level means even tighter controls and oversight, all documented for public agencies. I once handled paperwork for a nutrition startup requesting pharmaceutical-grade vitamin C. Lab reports had to show readings of 99.9% purity, with controlling agencies triple-checking the figures. Less clarity opens the door for guesswork, risky shortcuts, and maybe even legal headaches.

Real World Costs of Vague Purity Claims

Many businesses pay extra for top-level purity, believing it will tick every box for quality assurance. Still, the label “high purity” rarely tells the full story. In 2023, a wave of small supplement companies in the US got dinged by regulators after batches fell below promised purity levels—by even 0.1%. The fallout? Recalls and a wipeout of customer trust. Never mind the money lost. What’s missing in these cases is simple: documentation that spells out purity levels and states what contaminants—if any—are present or absent.

Cutting Out Uncertainty: How It Should Work

Being open about purity and grade isn’t just a best practice. It’s a basic promise. Top suppliers give buyers a certificate of analysis for every batch. This document shows exact figures for purity, the methods used for testing, residual solvent levels, and limits for toxins. Good labs run spectrometry or chromatography tests that spot impurities down to fractions of a percent. In my time consulting for electronics firms, these certificates acted like trust anchors—no one placed a bulk order without reading through them in detail, line by line. End users began to ask for them even when ordering small quantities.

Solutions for Smarter Sourcing

Clear answers to purity and grade questions only come from real, tracked data. Third-party testing shuts down doubt and catches suppliers who want to cut corners. Manufacturers both big and small now turn to recognized agencies for monthly random audits. With blockchain tools and digital records, customers today get access to batch histories at the click of a button. Such steps strip away the guesswork for consumers and regulators alike. If a vendor can’t back up their claims with specific test numbers and credentials, that’s a red flag buyers can’t afford to ignore.

Knowing the Risks

Anyone who’s worked with chemicals has felt that little flicker of caution when unsealing a new container. Tetrapropyl ammonium tetrafluoroborate might not set off alarm bells at first glance, but this compound demands respect. It doesn’t grab headlines, but it quietly powers research and specialty applications, especially in electrochemistry. You start to understand its value when you see it helping shape electrolytes for batteries and supporting the work behind the gadgets we use daily.

It weighs in as a stable salt, yet that shouldn't lull anyone into carelessness. The dangers often crop up with the careless touch: spills, inhaled dust, contact with skin, and what nobody wants—fire or a toxic release. I’ve seen up-close how a forgotten spill can corrode equipment and ruin more than just the day’s work.

The Simple Steps Matter Most

Proper storage sets you up for safety. This compound belongs in a cool, dry spot—locked and away from acids or sources of moisture. Humidity doesn’t just make the labels peel; it can trigger reactions that spoil the material and introduce hazards. Moisture in the storage room? You’re already heading down a risky path. Flammable storage isn’t the place for it; a corrosion-proof cabinet serves better.

Avoid plastic bags or weak containers that might tear or puncture. Every chemist I’ve worked alongside trusts high quality, sealed glass or non-reactive plastic containers. Tight-fitting lids aren’t a luxury—they’re the difference between safe storage and a headache after accidental exposure. Don't stash it on a high shelf either. Accessibility matters, for your convenience and in emergencies.

Don’t Curb Corners—Personal Protection Counts

Handling always calls for basic protection. I’m talking about gloves—nitrile or latex, with no holes or tears—plus eye protection. The stuff looks like a harmless powder, but it can irritate the eyes and skin. I’ve seen a veteran researcher blink away discomfort for a week after accidentally brushing powder into an eye. A lab coat and splash-proof goggles aren’t optional. If the air might get dusty from making solutions, use a fume hood. An open bench exposes your coworkers as much as yourself.

Don’t eat, drink, or touch your face when working with chemicals like this, no matter how basic your lab procedures feel. It sounds like schoolyard advice, but one slip and lunch can turn into a call to the poison helpline. Always wash hands afterward. Change gloves if there's a splash. Keeping cleanup supplies handy lets you react fast. All it takes is one moment of laziness to contaminate a workspace.

Planning for Mistakes and Emergencies

Spills and accidents happen. Anyone who pretends otherwise hasn't spent enough time at the bench. Solid protocols, clear labeling, and a written handling plan set good labs apart from dangerous ones. Spill kits work best when checked often and replaced as needed. Everyone should know where eyewash stations and showers sit. Nobody thinks they’ll need them—until they do.

Waste deserves attention. Don’t pour this salt down the drain. Use marked waste containers, and follow disposal policies that treat chemical waste with the same care as radioactive or biohazard material. Local regulations shape disposal, but complacency causes real harm. With increasingly strict environmental controls, labs stay compliant—or risk costly penalties and real harm to health and the environment.

The Road to Safer Work

Regular training pays off more than fancy new equipment. Short safety refreshers, quick drills, and honest talk about accidents keep staff alert. Creating a culture where questions get answered without judgment does more for safety than any sign on the wall. Safer storage and handling protect you, your teammates, and the work itself. It takes extra effort, but in the end, that’s what keeps the entire operation running smoothly—and everyone heading home healthy after the work is done.