Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate: A Real-World Look at an Unconventional Ionic Liquid

Historical Development

Chemists have always chased versatility in their quest for better solvents, catalysts, and functional materials. The 20th century opened the door to ionic liquids, salts that somehow stay liquid near room temperature. Finding one that balances stability and customizability without dangerous volatility remained elusive for decades. Tributyl(hexadecyl)phosphonium tetrafluoroborate grew out of a persistent hunt for safer, tunable alternatives to volatile organic compounds. Scientists built on phosphonium frameworks from mid-century organophosphorus chemistry, swapping out shorter side chains for longer alkyl groups. By adding a sixteen-carbon chain (hexadecyl) along with three butyl arms, the final molecule—paired with the reliable tetrafluoroborate anion—landed squarely in the family of ionic liquids able to handle demanding roles in synthesis, separations, and beyond.

Product Overview

This compound’s structure delivers a bulky, asymmetric cation anchored on phosphonium with three butyls and one hexadecyl piece, paired against small but robust BF4- (tetrafluoroborate). Its unique combination of sterics, hydrophobicity, and charge makes it valuable in everything from phase transfer catalysis to green chemistry. Instead of evaporating into the workplace, this salt usually stays put, which helps cut down on exposure risks faced with more traditional solvents or transport agents. Availability has increased significantly over the past two decades as ionic liquid use migrates from academic curiosity to wider industrial reality.

Physical & Chemical Properties

The pale yellow liquid carries a mild odor and refuses to boil away under standard conditions. The long hydrocarbon branch bumps up viscosity, making this fluid thicker than many better-known organic solvents. That extra length also shifts solubility patterns—hydrophobic groups glide past water, keeping the compound mostly in the organic phase. Melting point hovers just below room temperature, so the product can remain liquid without heating. Electrochemical windows reach up to around 4V, reflecting thermal and chemical stability prized by researchers in electrosynthesis. Resistance to hydrolysis and limited vapor pressure foster healthier workplaces and easier recycling.

Technical Specifications & Labeling

Batches rolled out for industrial or lab use usually specify a purity percentile greater than 97%, with phosphorus, boron, carbon, and fluorine content carefully tracked to trace any contamination. Chemists look for a light yellow, oily texture, testing by titration or NMR when quality matters most. Each bottle or drum arrives with hazard statements—mainly skin, eye, and respiratory system irritation warnings—plus a unique CAS registry and batch trace numbers for safety audits. Labels call out incompatibility with strong oxidizers and moisture to avoid accidental decompositions.

Preparation Method

Synthesizing tributyl(hexadecyl)phosphonium tetrafluoroborate starts by reacting tributylphosphine with 1-bromohexadecane, forming a phosphonium bromide intermediate via nucleophilic substitution. This precursor gets swapped (metathesized) against sodium tetrafluoroborate in a two-phase system, which forces the final product into the organic layer and the sodium bromide byproduct into water. Extraction, drying, and vacuum removal of solvents polish up the ionic liquid for use. Each step gets tracked by analysts, who flag phosphorus-based impurities, excess halides, or water as routine hurdles. Since the synthesis relies on careful control of stoichiometry and clean separations, genuine technical expertise—along with high-purity starting materials—matters for good results.

Chemical Reactions & Modifications

Out in practice, tributyl(hexadecyl)phosphonium tetrafluoroborate serves as more than just an inert solvent. The rich electron density around phosphorus helps the liquid shuttle negative ions, acting as a phase transfer catalyst in organic transformations. Researchers sometimes tweak the anion, swapping out BF4- for PF6-, NTf2-, or other variants to dial in physical traits like hydrophobicity or viscosity, depending on the target reaction. The long hydrocarbon arm gives the molecule added flexibility—unusual among other ionic liquids—lending itself to modification for surfactant use or carrying functional groups for specialty extraction. Scientists still experiment with backbone modifications to fine-tune charge distribution, hydrophobic-hydrophilic balance, or ionic conductivity for emerging applications.

Synonyms & Product Names

Digging through catalogues, chemists run across a range of names: Tributylhexadecylphosphonium tetrafluoroborate, (tributyl)(hexadecyl)phosphonium tetrafluoroborate, or simply TBHDPP-BF4. Some suppliers use internal codes or trade names, but the unique structure sets it apart from other phosphonium or ammonium-based salts. Mastering these nuanced differences takes experience in organic synthesis or specialty chemicals, especially since naming conventions often shift with the supplier or field. Catalogs assign CAS numbers to guarantee identity in purchase, quality control, or regulatory paperwork.

Safety & Operational Standards

Handling this compound calls for direct protective measures. It doesn’t explode easily or fume, but the organic chains can cause skin defatting and mild irritation, while tetrafluoroborate contains trace HF risks if decomposed under strong acid. Protective gloves, tight-fitting eye shields, and clean, well-ventilated labs become non-negotiable. Spills—though rare—demand absorbent cleanup and disposal via hazardous waste protocols, not down the drain. Emergency eyewash and first aid nearby serve as backstops for accidents. Regulatory oversight has gotten stricter, urging chemical managers to keep detailed batch logs, SDS access, and thorough training regimens for new staff.

Application Area

This ionic liquid pushes boundaries in separation science, serving as both solvent and carrier for extraction of rare earth metals, pharmaceuticals, and complex organics where ordinary solvents fail. The phosphonium center outshines common ammonium competitors in thermal and chemical stability, allowing for batch runs at elevated temperatures or in the presence of aggressive reactants. Engineers and synthetic chemists favor its use in biphasic catalysis, sometimes extracting difficult organics from water and transferring them to the organic phase, then back again. Battery researchers study the material as a safer electrolyte component, trying to tamp down flammability. Environmental teams inspect it for wastewater remediation and greener reaction media, since lost product typically stays contained instead of lingering in atmosphere or groundwater.

Research & Development

Academic studies have stretched traditional applications, seeking ways to replace more volatile, toxic solvents in transformations like alkylation, oxidation, or polymerizations. Electrochemical groups probe the wide voltage window, pushing ionic liquid technology toward next-generation capacitors and lightweight batteries. New research explores integrating the compound into metal recovery workflows, using the hydrophobic backbone for targeted separation of precious elements—palladium, platinum, rare earths—from electronics or spent catalysts. Synthetic teams tinker with chain length and head group chemistry to get even lower melting points, finer-tuned viscosities, and compatibility with growing green chemistry demands. Collaborative groups from materials science, energy, and catalysis cross traditional boundaries, curious how small tweaks can swing cost, performance, or environmental impact.

Toxicity Research

Long alkyl chains may seem benign at first glance, but researchers keep a close eye on bioaccumulation, toxicity, and persistence. Early toxicity screens on zebra fish embryos, daphnia, and bacteria have turned up low acute hazards, a step up from legacy organophosphorus compounds, though chronic data remains incomplete. The tetrafluoroborate anion did spark some debate given its potential to decompose into fluoride sources under severe conditions, but real-world exposures under typical laboratory or plant scenarios remain rare. Waste management protocols urge incineration or chemical digestion before disposal, to reduce routes of aquatic or soil pathway exposure. Environmental scientists keep updating risk assessments as more data rolls in on metabolites and long-term persistence in industrial settings.

Future Prospects

As the push for sustainable chemistry grows louder, engineers, academic researchers, and green advocates want more from every functional material. Market demand for robust, recyclable ionic liquids aims to phase out less stable, more hazardous organic systems. With its stability, broad operational envelope, and ease of recovery, tributyl(hexadecyl)phosphonium tetrafluoroborate stays in the conversation as a go-to candidate for new extraction, catalysis, and energetic applications. Research funding flows toward lowering production costs, expanding purity grades, and engineering derivatives with still lower environmental footprints. The next decade might see this molecule or close relatives bridge the gap between niche lab work and high-volume, industrial sustainability—especially as supply chains prioritize safety, longevity, and green performance.

Where Chemistry Meets Real-World Benefits

Science pushes into some wild territory, and tributyl(hexadecyl)phosphonium tetrafluoroborate is one of those mouthfuls that quietly drives modern chemistry. If your background includes time in a laboratory or research facility, you’ve run into these types of ionic liquids. They look like regular old salt at a glance, but dissolve in ways that open up all sorts of new opportunities. You might spot them in catalyst applications or as game-changing solvents. Researchers haven’t chased them for nothing; these chemicals deserve attention for the practical impact they deliver.

Chemical Synthesis and Green Chemistry

Laboratories need to find more responsible ways to run reactions and extract products. I’ve spent enough hours at a fume hood to know that tradition leans far too hard on volatile organic compounds. Most of them stink (literally and figuratively) and cause environmental headaches. Tributyl(hexadecyl)phosphonium tetrafluoroborate changes things. It’s an ionic liquid, meaning it keeps its cool and stays liquid at low temperatures without busting into toxic fumes. Chemists use it as a solvent, and the result is a safer workspace and less pressure on waste handling. Not every solvent deserves this much love, but greener reactions help us all breathe easier.

Role as a Phase-Transfer Catalyst

Transfer reactions often stall out if the two chemicals don’t like to mingle. Over the years, I’ve seen creative fixes for this, but phase-transfer catalysis has always stood out. Tributyl(hexadecyl)phosphonium tetrafluoroborate solves the stubborn problem of oil-and-water mixing. Dropping it into a reaction between an organic and inorganic phase lets chemistry happen that would otherwise never get off the ground. Its use as a phase-transfer agent shows up in pharmaceutical labs, helping speed up key steps in making medicines and specialty compounds. As more manufacturers pursue cleaner and faster syntheses, these catalysts steal the spotlight for both performance and reduced waste.

Electrochemistry and Material Science

Anyone who dabbles in batteries or energy storage research will recognize ionic liquids. Conventional electrolytes run hot and put engineers on edge because of their flammability and short lifespan. Tributyl(hexadecyl)phosphonium tetrafluoroborate keeps the current moving while adding more thermal stability and avoiding the risks tied to old-school electrolytes. I’ve seen teams work this compound into advanced batteries and electroplating baths. The aim: safer devices and sharper performance.

Sustainability Challenges and Safer Handling

Every chemical brings two sides. Any complex compound carries unknowns, and it pays to stay cautious. The toxicity data for phosphonium salts can look more reassuring than some older quaternary ammonium salts, but we still treat these with respect in the lab. Sustainability is not just about swapping out solvents; it’s about rigorous monitoring, proper PPE, and controlling release outside the lab. The move toward ionic liquids like tributyl(hexadecyl)phosphonium tetrafluoroborate is less about ticking boxes on a green checklist and more about making deliberate, measured progress. Changing the backbone of industries like pharma, energy storage, or advanced materials won’t come overnight. But looking at these compounds, the momentum feels real and well-earned.

What Lies Behind the Name

Looking at the full name, Tributyl(hexadecyl)phosphonium tetrafluoroborate, it’s easy to get lost in the jargon. Let’s unpack it. This molecule carries a phosphonium core—phosphorus holding court in the middle, joined to three butyl groups and one hexadecyl chain. Then, balanced across from it sits tetrafluoroborate, a well-known anion in chemistry. The chemical formula comes out as C28H62BF4P.

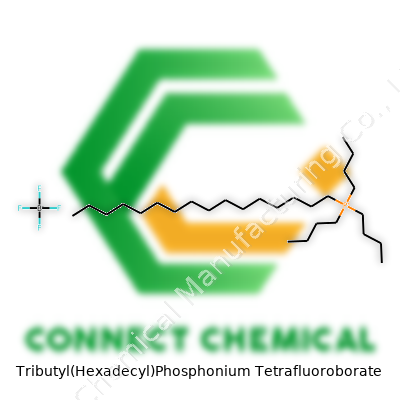

Breaking Down the Structure

To picture this compound, first focus on the cation part. The phosphonium ion features three butyl groups—basically, four-carbon alkyl chains. Hexadecyl is even longer, stretching to sixteen carbons, making it long and waxy. Phosphorus bonds directly with all those chains, creating a positively charged ion. Pair this with the anion, tetrafluoroborate: one boron atom, four fluorines.

Structurally, the central phosphorus atom holds a +1 charge, surrounded almost like a sea urchin by the long tails of the butyl and hexadecyl groups. The BF4– anion balances the charge, sitting nearby thanks to ionic attraction.

Why Structure Shapes Application

Chemicals like this don’t just stay in the lab. Many researchers appreciate phosphonium salts for their roles as ionic liquids. The combination of those bulky, oil-like alkyl groups and the stable tetrafluoroborate creates a liquid at room temperature—or at least something with a very low melting point. I’ve seen similar ionic liquids used in electrochemistry, green chemistry, and even specialty separations. In these niche areas, stability and unique solubility patterns matter. Phosphonium salts like tributyl(hexadecyl)phosphonium tetrafluoroborate don’t easily vaporize, which cuts down on volatile organic compounds. That’s a rarer trait among organic chemicals.

Concerns and Responsible Handling

With any specialty salt, safety keeps coming up. Phosphonium-based salts can irritate the skin and eyes. The large alkyl chains often linger in the environment. I’ve found the suppliers recommend gloves, goggles, solid storage practices, and designated waste containers to keep risks low. Over the years, labs have improved their waste minimization strategies—using less, reusing, or recycling solvents where possible.

Potential and Promise

Solid evidence shows their use as an alternative to traditional organic solvents. Green chemistry circles keep looking for replacements that work under milder conditions or that don’t produce noxious byproducts. The cation’s size and the nature of the anion both impact properties like viscosity and electrochemical window. By tweaking the side chains on phosphonium salts, people keep finding new combinations for specific tasks. Recycling and reuse need more focus—especially since large alkyl groups mean these molecules don’t degrade quickly after disposal.

Moving Forward

Staying curious about why certain molecular designs succeed opens options for safer, more sustainable practices. Tributyl(hexadecyl)phosphonium tetrafluoroborate isn’t just a mouthful—it signals a path toward cleaner chemistry. Using what we know to build more responsible materials matters both in research and in industry settings.

Getting to Know the Chemical

Tributyl(hexadecyl)phosphonium tetrafluoroborate isn’t a household name. You usually find it in research labs or industries working with advanced materials. Its job often links to ionic liquids, catalysis, or electrochemistry. A lot of folks haven’t heard of it unless they’re knee-deep in science. Still, the question lingers: does handling or using it bring serious risks?

Hazard Profile: What Scientists Say

People look to chemicals for their usefulness but can forget they pack risks. Scientific literature and safety data sheets flag tributyl(hexadecyl)phosphonium tetrafluoroborate as potentially hazardous. Skin and eye irritation show up on its hazard label. Swallowing or inhaling the substance can do harm as well. The phosphonium part and the tetrafluoroborate anion don’t belong in food or drink — they aren’t designed for human contact.

Workers exposed to chemicals like this often wear gloves, goggles, and lab coats. It reminds me of past talks with chemists: the stories about rashes, headaches, and the nagging worry something will slip through.

Toxicity Risks Loom Over Use

Long carbon chains in the molecule could allow it to cross barriers in the body. Some ionic liquids damage aquatic organisms or persist in the environment, even though these compounds tend to be more stable than volatile solvents. Tetrafluoroborate, for example, can break down in certain conditions to form boron compounds and fluorides, neither of which you'd want in groundwater or tap water. Safety doesn’t end at the lab bench — waste streams push these risks outward, making disposal a big deal.

Look at the Globally Harmonized System hazard statements. They show this compound fits the category for irritants and shouldn’t touch unprotected skin. No one likes seeing chemical burns or redness that comes from missing a drop on your shirt cuff. Inhalation always raises a flag since our lungs deal poorly with organic powders that aren’t part of normal air.

Why Care About This?

Research jobs often pay lip service to risk, but in practice, safety details get skipped under time pressure. Cutting costs or skipping ventilation means someone might get sick. Even small spills stack up if they aren’t cleaned right away. I watched students ignore posted warnings, thinking “a few milligrams can’t hurt.” Over time, that load grows. More than one friend has developed allergic responses from repeated exposures to similar chemicals.

Practical Steps to Protect People and the Planet

Facility managers and researchers can lead by example. Labs and plants ought to enforce strict glove and eye protection rules — not just stick posters on the wall. Regular safety training helps people remember why they do it. Fume hoods and proper waste bins slow accidents and keep these chemicals out of sinks and rivers.

Companies should share toxicity data and encourage chemists to design safer alternatives. Some universities ask every researcher to document waste disposal and close the loop on what leaves the lab. That helps regulators pinpoint hotspots and reduce risk before something serious happens.

Far too many times, new chemicals come into use before full toxicity studies are public. Sharing data on not just this compound, but a whole family of related chemicals, arms people with information to act carefully and avoid repeating past mistakes. It’s less about eliminating risk altogether — more about using eyes-open judgment and making smarter choices every day.

Why Care About Proper Handling?

Anyone who’s spent time around chemicals knows the damage a careless moment can do. Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate isn’t one of those household substances you can just shove on a garage shelf. It requires genuine attention and respect. Even after years in a chemistry lab, the sharp lesson remains—take shortcuts, and you risk expensive accidents, waste, or even serious health consequences.

Understanding Risks and Hazards

This compound, a type of ionic liquid, offers unique stability and thermal properties, making it useful in specialized processes. Even so, it can pose skin or eye irritation, toxic vapors, or fire risks, especially if handled carelessly or stored next to incompatible chemicals. I learned early in my career—never trust an unopened bottle, always check the safety datasheets, and remember that one wrong mix can turn a clean benchtop into a blazing mess.

Smart Storage Practices Keep People and Product Safe

The difference between a safe workspace and a hazardous one often boils down to storage. This isn’t just about following some dusty rulebook—these are habits you build to protect yourself and your colleagues. Keep Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate in tightly sealed, clearly labeled containers. A dry, well-ventilated cabinet will make a world of difference. Damp storage environments can degrade quality or, worse, turn it into something unpredictable.

Years back, a friend of mine thought a simple plastic bin would keep similar compounds out of harm’s way. Two months later, the lid had warped, vapor had escaped, and replacing ruined stock cost thousands. Hard lessons like that teach the value of robust, chemical-resistant containers. Glass or high-quality plastics designed for chemical use have never let me down.

Temperature Control: More Than Just Good Practice

Leaving sensitive chemicals out on a bench after a long day can almost feel harmless, but slow degradation or unexpected reactions become real threats over time. Store this compound at stable room temperatures, away from direct heat or sunlight. This isn’t paranoia—it’s about preserving potency and reliability. I’ve watched samples lose their clarity and purpose after a hot summer weekend.

Minimize Exposure, Maximize Safety

Even seasoned chemists forget their goggles on busy days, but it only takes one splash to remember forever. Always gear up with gloves, eye protection, and a lab coat before handling. Spills can be tough to clean, and residue on hands can move where it shouldn’t. I keep a strict handwashing routine and check for leaks or drips every time I finish up.

Spill kits and emergency eyewash stations don't collect dust for long in active labs. Training everyone on their use builds more than compliance—it sharpens a team's ability to respond quickly if something goes wrong. Watching new staff learn these routines reminds me that building habits saves real lives.

The Importance of Disposal and Documentation

Finished with a batch or cleaning equipment? Don’t just toss anything down the drain. This kind of compound isn’t meant for ordinary waste streams. Partnering with certified hazardous waste services ensures used product and containers don’t end up contaminating soil or water—something my old university emphasized intensely. Detailed logs of purchases, usage, and disposal help trace every gram, which becomes essential if regulators or auditors come knocking.

Building Better Lab Culture

Too often, people assume safety depends on regulatory frameworks or someone else’s checklist. In real experience, inner discipline and a watchful, learning culture prove far more important. Storing and handling Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate isn’t just about avoiding trouble today—it’s about setting up everyone, from interns to researchers, for long-term health, safety, and scientific success.

Getting to Know the Compound

Plenty of folks in chemistry circles might see a name like Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate and think, “That’s a mouthful.” But behind the name, this compound serves a pretty specific set of jobs, especially in the world of ionic liquids and electrochemistry. The best way to get a handle on it is by taking a look at the way it behaves physically—each property tells a story about what it can do and where it fits in modern research or industry.

Physical Properties Carrying Real-World Weight

The melting point sits right around 60–70°C, which means you won’t see it turning to liquid on a summer day, but a standard lab hotplate handles it just fine. That kind of range provides flexibility for experimental setups that call for control over solid and liquid phases. From experience, consistency matters—a wide swing in melting points from batch to batch complicates scale-up or repeat trials, so having a reliable range gives researchers confidence.

Its appearance falls in the waxy, almost greasy solid category. There’s nothing brittle about it—a block in your hand won’t crumble. This texture makes handling safer and less prone to accidental spills than a fine powder, where you have to worry about dusting or flying particles. The tactile experience always matters in a real lab.

Density sits above water, at roughly 1.1 to 1.2 g/cm3. Most folks won’t care about that until it’s time to separate or mix it with other compounds. Anyone who has tried to layer fluids while running a liquid-liquid extraction knows a difference of just 0.1 in density can make cleanup noticeably easier or trickier.

Viscosity sets ionic liquids apart. Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate lands in the high viscosity camp—almost syrupy compared to water. I’ve worked with more than a few ionic liquids that act like motor oil, and it’s tempting to think “thicker means better.” That’s not always the case. When solutions are slow to mix or don’t wet surfaces well, measurements get patchy and heat doesn’t distribute evenly. In catalysis experiments or electrochemistry, the way this substance flows shapes performance in the real world.

Stability and Solubility—Why They Matter

Thermal stability marks another check in its favor, letting it survive temperatures that would break down other salts. That means less worry about decomposition during processing or under electrical load. It usually holds up even at 200°C—a sweet spot for applications from advanced batteries to green solvents.

Moisture sensitivity creates workarounds, though. It won’t explode on contact with air, but toss it in water or use it in a damp room, and the compound absorbs moisture, clumps up, eventually breaking down over time. My own work with phosphonium salts taught me that airtight storage makes life easier—skipping this step wastes money and product.

As for solubility, you see clear limits. It won’t dissolve in water but mixes well with many organic solvents, particularly ones like acetonitrile, dimethylformamide, or alcohols. In the lab, that means you can blend it into a wide variety of systems, especially those using non-aqueous media—sometimes that’s the difference between an experiment that works and one that never gets off the ground.

Leaning on Facts and Pushing for Good Practice

Many studies, including peer-reviewed reports, show consistent values for these physical benchmarks, which improves trust for anyone hoping to use the compound in batteries, catalysis, or material science. Scientists and engineers do best when data stays rock solid—no one wants expensive surprises.

For handling, dry-box storage and tight seals keep things simple and productive. If evaporation or moisture creep in, prepare for inconsistent results and ruined batches. Investing in standard protocols and honest reporting pays off, a lesson that stings early but saves money and time down the line.

Getting hands-on with compounds like Tributyl(Hexadecyl)Phosphonium Tetrafluoroborate always circles back to these details. It’s the physical properties that set the stage for success or failure, not just the numbers on a spec sheet.