Looking Deeper into Tributyldecylphosphonium Bromide

Historical Development

Chemistry sees new materials appear all the time, but Tributyldecylphosphonium bromide came into the spotlight as part of a wave of ionic liquids research in the late twentieth century. Back then, scientists started searching for safer, more customizable chemicals for industrial and laboratory use. Phosphonium salts, often overlooked, began attracting attention. Compared to their nitrogen-based cousins, these showed stability, less flammability, and a bit more versatility in how they interacted with organic solvents. Researchers started tweaking alkyl chain lengths on the phosphonium group, hitting on the tributyldecyl combination for a perfect balance between hydrophobic properties and solubility. This made Tributyldecylphosphonium bromide interesting for catalysis and as a solvent. I’ve learned from picking apart old papers and conference notes that much of its value comes from a willingness to re-examine boring old phosphorus chemistry using modern tools.

Product Overview

This compound does not turn heads in appearance—white to off-white crystalline powder, sometimes a waxy solid. But dig beneath the surface and its ionic liquid roots show up: it can dissolve a wide range of organic compounds, and brings unusual thermal properties uncommon in traditional solvents. Chemical manufacturers offer it with careful purity guarantees, knowing even slight contamination can ruin its catalytic talent. In my years in the lab, finding a phosphonium salt with this blend of chemical reactivity and handling ease never fails to make process work flow more smoothly. The molecule’s structure centers on a bulky phosphonium cation paired with a bromide ion, which helps when designing selective extraction methods or phase separation schemes.

Physical & Chemical Properties

Tributyldecylphosphonium bromide stands out for both its stability and its behavior under heat. Its melting point hovers around 50-60°C, depending on crystal form and moisture content. The compound resists oxidation better than many organic ammonium salts and handles moderate heating without decomposition. Solubility spans polar to nonpolar solvents—alcohols, ketones, chloroform, sometimes even water—making it handy for researchers who switch reaction media frequently. The electrical conductivity isn’t high enough to qualify as a true ionic liquid, but it shows low volatility and little tendency to evaporate even in warm, open setups. In practice, this means fewer headaches managing vapors or inhalation risks. The compound’s high molecular weight and large alkyl groups produce a chunky, sometimes greasy feeling solid, with negligible odor and a reassuring lack of dust.

Technical Specifications & Labeling

Suppliers mark Tributyldecylphosphonium bromide with clear technical details. Purity grades stretch from 95% up to 99.9%, with residual moisture and halide contaminant levels measured in the low ppm range. The product label includes batch number, lot code, shelf life, recommended storage conditions (cool, dry place; tightly sealed bottle), and typical hazard pictograms associated with mild toxicity and possible skin or eye irritation. From handling dozens of these containers, I appreciate labels that skip jargon and present essential data—empirical formula, molecular weight, CAS number—up front, along with contact information for questions. In research settings, traceability on the label is as crucial as the safety warnings.

Preparation Method

Laboratories prepare Tributyldecylphosphonium bromide by quaternizing tributylphosphine with 1-bromodecane. The process takes place in an inert, dry atmosphere—usually under nitrogen or argon—to avoid water getting into the reaction and ruining the product. Mixes run at moderate heat, typically between 50-70°C, in solvents like acetonitrile or toluene. After reaction, the crude salt crystallizes as the solution cools, and filtration gives a pale solid. Recrystallization from ethanol or acetone purifies the product, cutting out oily impurities. This straightforward route fosters robust batch-to-batch results in both academic and industrial labs. Scale-up demands patience, since excess brominated alkane can linger if agitation is weak or reactant purity is low. Years spent teaching chemistry students have shown me that even modest changes in reaction time or temperature alter the solid’s physical form and handling properties.

Chemical Reactions & Modifications

This compound performs as both a phase transfer catalyst and a solvent modifier. It can shuttle anions and cations across boundaries that typically slow down organic reactions. Tributyldecylphosphonium bromide dissolves moderately strong nucleophiles and bases, allowing stubborn reactions—alkylations, oxidations, halogen exchanges—to proceed smoothly. Chemists modify its structure by tweaking alkyl chains or swapping the bromide for other halides and pseudohalides. Simple metathesis with silver salts, for example, converts it to the chloride or nitrate salt, each variant tailored for a slightly different application. Its chemical backbone stays intact in neutral or mildly basic conditions, but strong acids or reductants eventually break the P–C bond, releasing tributylphosphine. I’ve seen creative teams use this robust skeleton as a building block for task-specific ionic liquids, plugging in new groups to make phase separation or extraction work in petroleum labs or rare earth recycling plants.

Synonyms & Product Names

On chemical catalogs and research databases, this substance hides behind several names: Tributyl(decyl)phosphonium bromide, TBPDecBr, tributyl-n-decylphosphonium bromide, or sometimes abbreviated as C10-Pph-Br. Regulatory lists often shorten or rearrange the descriptors, but the core remains a phosphorus atom bonded to three butyl and one decyl group, paired with a bromide anion. Product packaging highlights “phosphonium salt” as a warning that this is not a run-of-the-mill ammonium compound. From my experience working across international sites, consistency in naming saves headaches, especially when importing into jurisdictions with narrow customs codes or strict hazardous material rules.

Safety & Operational Standards

Handling this compound demands practical care and good housekeeping. Skin or eye contact can bring irritation, so gloves and splash-proof glasses top the recommended PPE list. Even though volatility runs low, spills on benches can linger as oily patches, best managed with absorbent pads and alcohol-based cleaners. Researchers use fume hoods for weighing and transferring, since grinding or scraping can produce fine dust that poses inhalation hazards. The compound carries moderate aquatic toxicity and regulations often flag it for careful disposal—never down the sink, always into sealed waste containers marked as halogenated organics. From my years as a lab safety officer, regular risk assessments make a big difference, and written protocols help prevent slipups in scale-up or waste handling areas. Fire risks are modest, but the compound decomposes to release toxic fumes above 250°C, so thermal hazards need monitoring in larger operations.

Application Area

This salt finds a surprising range of real-world uses. Chemical manufacturers use it as a phase transfer catalyst in organic synthesis, where moving charged species across nonpolar solvents helps speed up cumbersome reactions. It enhances efficiency in making fine chemicals, pharmaceuticals, and agrochemicals, reducing the amount of excess reagents needed. The compound’s capacity to dissolve both hydrophobic and hydrophilic reagents makes it valuable for solvent extraction and separation of rare metals, especially in recycling schemes for electronic waste. In recent years, engineers in battery research have tested it as a component in ionic liquid electrolytes, chasing longer lifespans and safer battery chemistries. My own work involved deploying it as a solvent modifier that improved selectivity in chromatographic separations, where separating complex natural mixtures kept us onsite late into the night.

Research & Development

Academic curiosity and industry needs keep driving new applications for Tributyldecylphosphonium bromide. University teams explore greener chemistry, using this compound to replace harsher, volatile organic solvents in extractions and organic transformations. Multinational corporations have experimented with custom derivatives in drug manufacture and as antistatic and antifouling additives in coatings. Many research labs investigate its properties under high pressure, in supercritical fluid extraction, or combined with nanomaterials to create novel ion-conducting films. Recent papers detail its role in the capture and recycling of heavy metals from wastewater—a crucial step as climate policy shifts toward closed-loop processes. Personally, I’ve seen small changes in chain length or counter-ion selection yield entirely new possibilities, making this compound a launching pad for new classes of ionic materials.

Toxicity Research

Toxicologists invest time understanding how these phosphonium salts interact with the environment and living tissues. Short-term exposures cause mild skin and eye irritation, while repeated inhalation or ingestion (thankfully rare due to strong odor and low volatility) leads to more significant symptoms—nausea, dizziness, or abdominal pains. Environmental studies flag this salt and similar ones as moderate aquatic toxins, with lethal concentrations to fish and algae around low mg/L. Biodegradation runs slow, especially in cold water or oxygen-limited environments, so waste management teams stress minimizing releases. Long-term animal studies remain few, creating some uncertainty over chronic effects; as industry ramps up ionic liquid use, these knowledge gaps need closure. Conversations with environmental consultants reinforce the importance of full risk assessments before using such compounds in open processes or large-scale manufacturing.

Future Prospects

Looking forward, Tributyldecylphosphonium bromide finds itself part of larger movements in green chemistry and sustainable manufacturing. Demand rises as more companies chase alternatives to flammable, toxic solvents in everything from synthetic chemistry to resource extraction. The drive for efficient, less polluting batteries rewards compounds with thermal stability and tunable properties. As governments tighten regulation over hazardous waste and emissions, manufacturers and labs face pressure to show not just short-term safety but the long-term environmental impact of their materials. Research pushes for newer, biodegradable phosphonium salts, but the reliability of Tributyldecylphosphonium bromide keeps it in play for years to come. Progress in recycling, new reaction pathways, and precision medicine promise new roles for this modest but versatile compound, provided diligent research and transparent safety standards stay at the forefront.

Tributyldecylphosphonium bromide shows up in a handful of chemical processes that rarely get much attention outside laboratories or specialty industries. Chemists and engineers count on this compound for its role as a phase transfer catalyst, a material that boosts certain reactions where two substances wouldn’t naturally mix. More simply, it's like a translator in a room where no one speaks the same language, helping everyone get on the same page fast.

How Tributyldecylphosphonium Bromide Supports Chemical Synthesis

In recent years, people have seen growth in the use of phase transfer catalysts. Tributyldecylphosphonium bromide lands at the center of several organic reactions, such as alkylations and oxidations. These processes take place in industries focusing on specialty chemicals, plastics, and even some pharmaceutical intermediates. Scientists often prefer this chemical because it holds up under tough reaction conditions better than traditional ammonium-based catalysts.

Science journals document tributyldecylphosphonium bromide’s ability to speed up slow reactions between water-soluble and oil-soluble compounds. This saves both energy and resources, leading to reduced production costs and lower waste. Although it sounds technical, this means companies using it have a smaller environmental footprint—an important step when people push for greener manufacturing.

Potential Concerns and Real-World Considerations

Any time industry leans on a specialty chemical, folks ask about the risks. Research notes that phosphonium salts are not as widely studied for toxicity as some other industrial chemicals, but they deserve scrutiny. Toxicological testing suggests tributyldecylphosphonium bromide lacks high acute toxicity for humans at the usual levels found in workplaces, yet some signs point to irritation after prolonged contact or inhalation. Handling it with gloves and masks remains a common-sense safety move.

Waste from processes involving this compound needs proper management. Phosphonium salts can escape into wastewater during rinsing or cleaning steps. Treatment systems, like activated carbon or advanced oxidation, help keep these compounds out of rivers and municipal water. Responsible firms follow guidelines set by agencies such as the EPA to limit exposure and contamination.

Shaping a Safer, More Efficient Future

The chemical industry often wrestles with balancing performance and safety. Whenever I toured specialty labs, chemists described the pressure to deliver results and stay ahead of regulations. Tributyldecylphosphonium bromide answers that challenge in some settings, but the industry should keep looking for alternatives with even lower environmental risk or hazard profiles. Universities and private firms carry out experiments using "greener" catalysts that break down faster in the environment or show less tendency to accumulate in living tissue.

Governments and environmental agencies need to keep investing in good science and strong oversight. Regular monitoring of workplace exposure and emissions, public access to safety information, and investment in better wastewater treatment all steer this industry toward safer practices. Putting a priority on worker health and community wellbeing drives everyone forward, from manufacturers down to the local water treatment plant crew. Transparent communication and public engagement keep companies accountable and encourage continued innovation that meets both performance needs and sustainability goals.

Why Safety Measures Matter

Handling chemicals like Tributyldecylphosphonium Bromide can rattle the nerves a bit, especially for folks new to the lab. This compound doesn’t show mercy if mishandled; it targets the skin, eyes, and the respiratory system. That stinging feeling from just a bit of it near your eyes or on your skin lasts longer than a paper cut. For anyone weighing the risk versus the hassle, think about the long hours spent recovering from a preventable splash. Several cases of chemical burns and hospital trips stick in my mind from my early days — things no one wants to go through because of shortcuts or carelessness.

Understanding the Hazards

Exposure comes easy — a tiny spill gets onto your hands, or vapor sneaks past poor ventilation. Besides irritating the skin and eyes, inhaling it can bring on headaches, coughing, or even make it tough to breathe. Some phosphonium compounds cause more harm with repeated or high exposure, including potential impacts on organ function. Real stories pop up where long-term care became necessary because gloves, goggles, or a simple fume hood weren’t treated as essential gear.

Stepping Up Personal Protection

Goggles aren’t optional here. Splash risk is real every single time. Chemical-resistant gloves stand out as a first line of defense. Latex just doesn’t cut it — nitrile or neoprene offers more peace of mind. For lab coats, anything that buttons up and covers the arms beats short sleeves or lightweight scrubs. Closed shoes shield feet from the drops that bounce onto the ground and run under cuffs. For operations that stir up dust or release vapor, using a properly fitted face mask or respirator with a P2 or higher filter makes a difference. Years in the lab have taught me that skipping even one of these layers invites trouble.

Keeping the Work Area Safe

Clean benches, working sinks, and clear labeling transform a cluttered work area into a safer one. I’ve seen more mishaps from unmarked bottles than from nearly any other mistake — quick labeling prevents others from grabbing the wrong container. Adequate ventilation corners vapors and pulls them away from breathing zones. Working in a fume hood might slow you down, but it protects your lungs. After handling Tributyldecylphosphonium Bromide, I make it a point to wash my hands even before pulling off my gloves; that habit limits what gets onto doorknobs or my coffee mug.

Dealing with Spills and Waste

Spills panic people, but training and prep turn a mess into a manageable job. Absorbent materials, dedicated disposal bags, and neutralizers should always be close at hand. Once, a spill across a bench got out of control and took three people to tidy up what would’ve taken five minutes had there been a spill kit nearby. Always treat rags or absorbents as contaminated waste — seal it up, don’t toss it with regular garbage. Disposal should follow local hazardous waste regulations. You know things have gone wrong when the trash starts smelling like the lab.

Planning for Emergencies

Know where the eyewash station and safety shower stand. A drill might feel like a time-waster, but that minute saved remembering which way to turn puts out the fire before it spreads. Emergency numbers posted on the wall cut confusion when every second counts. Nobody wants to rifle through a drawer for instructions with chemicals on their skin.

Pushing for a Safer Culture

Encourage coworkers to speak up if someone skips steps. Praise consistent use of PPE and good habits. Top-down commitment helps, but individual responsibility builds real, lasting safety. Over time, these habits pay off — fewer injuries, stronger trust, and peace of mind at work and home. Safety wins are worth the small daily effort, every time.

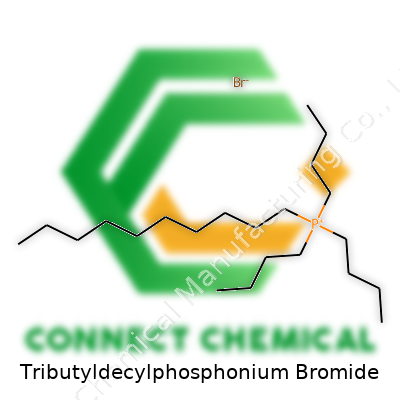

Looking at the Chemistry

Tributyldecylphosphonium bromide draws attention in chemical circles with its formula: C25H56BrP. People working with this compound notice it stands apart because of its special structure combining a phosphonium center with one decyl and three butyl groups, all matched up with a bromide ion. Weighing it out, its exact molecular weight comes to around 487.59 grams per mole. For anyone who double-checks their data, reliable sources like PubChem and Sigma-Aldrich support these figures. Leaning on credible resources helps keep labs safe and consistent, which proves critical in any real-world application.

Why Formula and Weight Actually Matter

Some folks might glaze over when they see numbers and letters, but knowing the chemical formula and weight isn't just nice for a quiz — it’s essential in the lab and in industry. When preparing mixtures or solutions, accuracy depends on weighing out the right amount. Mess that up, and the outcome heads off the rails. I’ve seen students wrestle with reactions that go nowhere, all because of a tiny error in the calculation. Getting these details right builds the foundation for any protocol, whether it’s being used in catalysis, ionic liquids, or as a reagent in organic synthesis.

Experience Talks: Practical Use and Troubleshooting

Anyone handling tributyldecylphosphonium bromide faces certain challenges, especially with storage and disposal. Moisture and contamination mess with purity, which ends up frustrating more than a few lab techs. I’ve worked in setups where using old or improperly stored compounds torpedoed whole batches, wasting valuable time and resources.

Packing away the product tightly and labeling it with the date and supplier gives everyone a clear view of what’s in the bottle. If the material sits on a shelf, regular purity checks and spot tests make sure it still performs as expected. Documenting every batch used gives the entire team traceability, which pays off when troubleshooting a bad result. This level of diligence is more than bureaucracy — it’s a matter of safety and good science.

Addressing Environmental and Health Concerns

Handling organophosphorus compounds like this means staying aware of potential hazards. Exposure risks depend on ventilation, personal protective equipment, and staff training. Eye and skin contact pose obvious dangers, so gloves and goggles stay non-negotiable. I once saw someone scoop out a powder without gloves, figuring a quick wash would handle any risk. That small shortcut led to skin irritation and a quick lesson on why protocols reflect real concerns, not just legal paperwork.

For waste, proper neutralization and collection go a long way in protecting both workers and waterways. Institutions set protocols for a reason. From personal experience, mixing different chemical wastes for convenience caused a scare and an emergency call, highlighting the necessity of treating each substance with the attention it demands.

Encouraging Smarter, Safer Chemistry

Quality work with tributyldecylphosphonium bromide means paying attention to the details — formula, weight, handling, and disposal. Laboratories thrive on careful research, respect for chemicals, and a willingness to learn from mistakes. Sharing practical advice and facts not only prevents error but also fosters a safer, more collaborative environment. The stakes may seem small, but the impact of good chemical stewardship affects everyone who steps into the lab or receives the products it produces.

A Chemical Worth Handling with Care

Tributyldecylphosphonium bromide isn’t something many folks encounter day-to-day, but researchers and folks working in labs know it’s no toy. I’ve spent enough hours in labs to see firsthand what a difference careful storage of specialty chemicals can make. Let’s talk about why this salt deserves caution, and how to keep it—and everyone around it—safer.

Understanding the Risks

This compound shows up as a white to off-white powder. It feels harmless if you go by looks, but it’s not just dust you can brush off your pants. Most sources cite risks like skin and eye irritation, and it doesn’t take reckless handling to bring on a problem. Accidental contact, or a dust cloud flaring up as you pour, can hit fast. Some phosphonium salts will break down if heat or moisture gets to them, sometimes releasing compounds you’d rather not inhale.

Practical Conditions for Storage

A dry, cool spot makes all the difference. Most labs set up chemical cabinets for this exact reason. I’ve got a memory of a summer afternoon, sun streaming through a supply closet window, making a nearby shelf searing hot. That sort of situation always spells trouble for sensitive chemicals. Find a storage area out of direct sunlight. A temperature range just a notch below room temperature works best. Avoid places susceptible to temperature swings or humidity spikes, such as next to sinks or vents.

Good airflow in the storage area slashes the risk of accumulation if any fumes escape. This isn’t just for comfort—plenty of us have learned the hard way that a whiff of the wrong thing can end a working day. Ventilated cabinets help brake that risk.

Why Labels and Segregation Matter

Every lab should adopt a strict approach to separation. Strong oxidizers can spell disaster if stored together with organic phosphonium salts. I once spotted a shelf where acids and bases kept bumping elbows—not safe with any substance, and not wise here either. Tributyldecylphosphonium bromide belongs in a clearly marked container, away from acutely reactive stuff.

Resealable, tight containers are a must. Even a little exposure to moisture can start changes you don’t want. I’m a fan of plastic screw-top jars, or the glass ones with a gasket, and I always check the seal before putting anything away. Double-checking labels avoids that pit-in-your-stomach moment when a faded handwritten tag leaves you guessing the contents.

Personal Protection with Every Handling

Don gloves. Safety goggles. In a shared workspace, lab coats stop powder from getting on your everyday clothes. After handling, scrub your hands whether you noticed a spill or not. This isn’t just vague advice—I’ve come home before with an itch that didn’t show up until later, just from rushing and skipping the sink.

Real Solutions: Reassess and Train

Make storage checks routine. Even if you think everything’s in order, supplies shift and seals loosen day after day. Walking through your storage area each week can catch leaks early. Keep up the habit, make it a team effort, and don’t leave the next shift guessing. It pays off many times over. Clear, written procedures posted at the storage site help everyone remember what matters, even if the chemical isn’t an everyday tool.

Looking Ahead

No magic fix beats diligence and real attention. Taking chemical storage lightly pushes luck no one really has. A little care, week in and week out, keeps people and projects safe.

Why this Chemical Raises Red Flags

Working in research labs, I’ve watched countless compounds come and go—each with its own safety profile. Some chemicals raise eyebrows right away, not because of their use, but due to questions about their long-term effects. Tributyldecylphosphonium bromide, used as an industrial catalyst and in specialty formulation, fits this profile. It’s not a household name, yet its chemical structure and uses demand a closer look from anyone who cares about public and occupational health.

Where the Hazards Start

Phosphonium salts like this one don’t just vanish after use. People who mix, transfer, or dispose of them experience the risks firsthand. Skin and eye irritation often rank among the common short-term problems. A small spill on the hand might lead to redness or even an itchy rash. Inhaling dust or fumes can mean headaches, coughing, or even more severe respiratory symptoms over time. These are basic, immediate reactions, but the trouble might not stop there.

Animal studies and related phosphonium compounds suggest possible risks beyond irritation. Certain phosphonium chemicals have shown toxicity in liver and kidney tissue. Repeated exposure to similar compounds led to signs of organ stress and behavioral changes in laboratory settings. Data on tributyldecylphosphonium bromide remain limited, but its close chemical cousins give reasons to worry. Those handling this material in factories need to know what they could face with months or years of contact.

The Environmental Factor

Many worry about personal protection, yet pollution brings another layer of danger. Phosphonium compounds can linger in water and soil. Tributyldecylphosphonium bromide doesn’t break down quickly in the environment, increasing the chance it can reach groundwater or build up in living organisms. If workers wash tools in local systems or tanks leak during storage, nearby communities could get exposed without knowing it. Such situations contribute to bioaccumulation—when small amounts in the environment build up in fish, then work their way into human diets.

Watching news about chemical spills makes these hazards less abstract. I’ve helped advise cleanup crews before, and the gap in public information about “minor” industrial chemicals can leave communities vulnerable. Testing for these specific compounds takes sophisticated equipment and isn’t routine in most regions.

Patching the Safety Gaps

For those facing regular exposure, engineering controls—proper ventilation, sealed systems, and effective personal protective equipment—can lower risks drastically. Routine monitoring for signs of toxic effects in workers’ blood or urine helps catch problems before they become permanent. Employers should train teams not only in emergency response but in safe handling before accidents ever happen.

Regulators play a role too. Clear labeling and hazard communication let everybody from transport drivers to custodians know what they’re dealing with. Stronger reporting for spills and releases gives public health officials a chance to respond quickly. Mandating safer alternatives, where available, steers industries away from chemicals linked to health and environmental harm.

Looking Forward

Even though tributyldecylphosphonium bromide isn’t in every workplace, its risks illustrate the value of up-to-date chemical data, careful handling, and honest conversation about workplace health. Everyone deserves access to these protections, especially the workers at the heart of chemical production. Watching out for the invisible dangers makes a safer future for everyone.