Tributylethylphosphonium Trifluoromethylsulfonate: Deep Dive Commentary

Historical Development

Exploring the history behind tributylethylphosphonium trifluoromethylsulfonate brings up the era of ionic liquids’ emergence, shaped by the practical needs of chemists seeking efficient, modern alternatives to volatile organic compounds. In the late 20th century, researchers turned to quaternary phosphonium salts, recognizing their robust thermal and chemical stability. This specific compound started to draw attention as part of the wider family of ionic liquids, which seemed to answer tough challenges concerning solvent loss, safety, and environmental control. Over time, incremental progress on catalyst design and new synthesis approaches led to scalable routes, anchoring its credibility in academic and industrial labs worldwide.

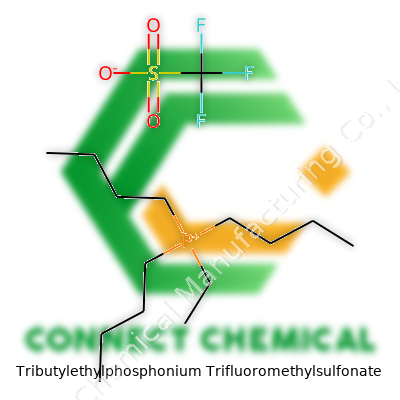

Product Overview

Tributylethylphosphonium trifluoromethylsulfonate stands as an ionic liquid formed by the union of a bulky phosphonium cation and a triflate anion. Each bottle or drum carries a clear, oily liquid that resists easy vaporization. The structure combines a propeller-like set of butyl groups with an ethyl tail, attached to phosphorus. Marrying this cation with the stable and non-nucleophilic trifluoromethylsulfonate ensures a low-melting, non-volatile fluid, which makes it useful for high-end tasks where controllers want minimal contamination. Some suppliers package it under various trade names, but the compound delivers the same core characteristics regardless of label, cutting across supplier lines.

Physical and Chemical Properties

The density of this phosphonium salt tends to float near 1.2 grams per cubic centimeter, although actual values can shift based on purity and ambient temperature. Color shows up as colorless to pale yellow if stored properly. Odor, if any, carries that faint, sweet, organic scent typical for phosphonium salts. Lab thermometers often record a decomposition point well past 200°C, with melting points ranging from 30°C to 60°C depending on the manufacturing process and sample handling. Insolubility in hydrocarbons but full mixability with polar organic solvents round out the main notes, pointing to its role in systems needing separation or targeted solvation. Chemical profiles show it resists hydrolysis in moderate conditions, but moisture over time can degrade performance.

Technical Specifications and Labeling

Manufacturers list purity figures above 98%, and successful analyses of contaminants include moisture, halide reduction, and low residual phosphorus oxyacids. Some suppliers follow rigorous batch testing, publishing spectral data from ^1H and ^31P NMR, plus infrared verification. Labels follow strict hazard communication standards, typically reflecting its low volatility but flagging its classification as an irritant. Packaging arrives in airtight glass or high-density polyethylene, and every batch comes with a certificate of analysis. Regulatory compliance ties to GHS labeling and, in some regions, REACH or TSCA pre-registration. Bulk packs for scale-up operations must resist permeation and light exposure, a lesson learned from older bag-in-box models that led to slow degradation and loss of product integrity.

Preparation Method

The tried-and-true route starts with tributylethylphosphonium bromide, prepared by gently bubbling ethyl bromide through tributylphosphine. This intermediate undergoes ion exchange in aqueous solution, meeting sodium trifluoromethylsulfonate. Many researchers prefer direct metathesis, stirring both salts in water or acetonitrile until the denser phosphonium product separates. The lower layer then sees repeated water washes and a drying sequence using magnesium sulfate, followed by vacuum distillation or rotary evaporation. Each cycle aims for the clean, halide-free ester that defines high-end batches. Early failures with impure ionic liquids taught the importance of phase separation patience and the discipline of slow temperature ramps during drying.

Chemical Reactions and Modifications

Though the bulkier phosphonium restricts nucleophilic attacks right at phosphorus, clever syntheses have targeted the terminal ethyl group, sometimes attaching bioactive moieties for molecular probes. The triflate anion opens up options as a mildly coordinating base in organic transformations; use in transition metal catalysis picks up speed thanks to minimal catalyst poisoning. Some teams repurpose it to fine-tune the polarity of solvent systems, combining it with other task-specific ionic liquids for custom separations, especially when dealing with chiral drug intermediates. Stability against oxidation proves valuable in electrochemistry, particularly in low-voltage applications where rapid breakdown of less robust salts derails experiments. Teams trying to graft phosphonium groups onto silica or polymer supports keep returning to this compound’s well-balanced properties.

Synonyms and Product Names

Tributylethylphosphonium trifluoromethylsulfonate sometimes appears as TBEP OTf or [P4442][OTf] in academic articles, echoing IUPAC naming conventions but offering easier shorthand in long reaction recipes. Other known monikers include tributylethylphosphonium triflate and sometimes simply TBEP triflate. Each supplier might coin a proprietary name for catalog purposes, but chemical listings on global trading platforms point straight to CAS identifiers and the unmistakable phosphonium and triflate descriptors.

Safety and Operational Standards

Direct handling requires gloves and splash-proof eyewear, less due to acute toxicity and more because ionic liquids react unpredictably with trace water or skin oil. Skin contact can leave slight irritation, and eyes demand real care—rinsing and medical review in case of direct exposure. No cloud of vapor escapes under open air, but residues can still accumulate on surfaces or tools, so wiping and regular decontamination becomes the norm. Storage in tightly sealed containers at room temperature, away from sunlight and humid air, stretches shelf life past two years. Standard operating protocols include ventilation, chemical waste collection compliant with regional rules, and avoidance of open flames since impurities sometimes ignite under certain circumstances.

Application Area

Ionic liquid fans keep tributylethylphosphonium trifluoromethylsulfonate close for catalyst recycling, often in transition-metal-catalyzed cross-couplings where product purity matters. Electrochemical researchers harness its wide liquid window for energy storage and supercapacitor technology, betting on its low volatility and high conductivity. Synthetic chemists use it as a phase-transfer agent, with measurable boosts in reaction yields where more traditional quaternaries fall short. In polymer science, adding this salt fine-tunes flexibility and thermal resistance, shaping engineering plastics for aerospace, automotive, and electronics. Environmental labs have tested its performance for extracting persistent organic pollutants from soil and water matrices, motivated by the push for greener remediation tools.

Research and Development

Work in labs stretches across academic conferences and patent filings, much of it relating to tailored combinations with other ionic liquids or the search for new applications where competitive salts degrade or foul. Teams study its behavior in two-phase catalytic reactors, seeking ways to lower costs of catalyst separation and reuse. In battery and supercapacitor circles, the push for higher energy density draws continued focus on these robust ionic liquids, typically turning to advanced spectroscopies and real-world cycling trials for answers. Engineers in plastics and advanced composites look for blends resisting heat and mechanical shock, often running long-term exposure testing to spot microstructural creep or decomposition. Feedback loops with safety and environmental scientists drive outreach on best disposal routes and spill-response methods, ensuring continued support for responsible research expansion.

Toxicity Research

Long-term health impact studies play catch-up with industrial adoption. Animal-model experiments show limited acute toxicity but incomplete data on chronic exposure pathways, especially for inhalation or ingestion. Research on biodegradability points to moderate environmental persistence, raising questions about the compound’s behavior in wastewater. Some labs have recorded minor irritation on repeat contact, pushing for more rigorous workplace exposure limits, material safety data sheets, and employee training programs. Community health advocates call for annual re-evaluation as new data emerge, with regulatory agencies requesting environmental monitoring in regions with concentrated ionic liquids manufacturing.

Future Prospects

Chemists keep searching for greener, safer alternatives, but until a clear winner emerges, tributylethylphosphonium trifluoromethylsulfonate continues backing critical sectors where purity, non-volatility, and reproducibility matter. The next generation of research projects explores recycling methods, direct links to renewable energy applications, and hybrid systems combining phosphonium ionic liquids with bio-based cations for root-to-leaf lifecycle improvement. Progress on real-time sensing, in-situ catalyst regeneration, and safer handling protocols expand its role outside labs and into manufacturing suites, supply chains, and even disaster-response toolkits. Funding keeps rising for projects blending engineering, toxicology, and environmental safety, signaling a phase of development guided as much by ethics as by raw chemistry.

Opening the Door to Ionic Liquids

People often ask why certain chemicals get so much attention in research and manufacturing. Tributylethylphosphonium trifluoromethylsulfonate rarely shows up in headlines, yet this mouthful of a compound remains quietly central wherever cutting-edge ionic liquid research happens.

Folks in chemical development talk about ionic liquids as the future of green chemistry. Traditional solvents—think old-school paint thinners or petroleum-based cleaners—create headaches ranging from harsh fumes to stubborn residue pollution. Ionic liquids rewrite that story. Thanks to their stability and low volatility, projects in electronics or pharmaceuticals lean on these new mixtures to ditch harsh chemicals that dominated labs for decades. Tributylethylphosphonium trifluoromethylsulfonate doesn’t just fill space on a shelf—it helps build a safer, cleaner workbench.

Changing Electrochemistry and Energy Storage

Back in my student days, battery research labs always smelled like sulfuric acid and melting plastic. Car batteries and small electronics both relied on dangerous liquids that heated up and leaked if pressed too hard. Researchers now push for safer electrolyte mixes, and ionic liquids like this one find their way into prototypes.

This compound draws attention for its ability to carry ions without catching fire or evaporating. Better conductivity means smarter, longer-lasting batteries. Electric vehicles need every edge to run farther on a single charge. As carmakers chase those improvements, materials like tributylethylphosphonium trifluoromethylsulfonate become bigger players—even if nobody outside the lab remembers their names.

Improving Industrial Reactions and Synthesis

I remember supervisors at chemical plants growing frustrated over solvent loss and tough waste rules. Manufacturing specialty chemicals or pharmaceuticals often involves reactive conditions that typical solvents just can’t survive. Ionic liquids resist breakdown. They don’t join in with every side reaction.

This resilience simplifies recovery and reuse. Less waste goes out the door. Researchers who synthesize high-value drugs or custom polymers find that tributylethylphosphonium trifluoromethylsulfonate offers a viable platform for reactions that demand both efficiency and better yields. Fewer steps and purer products help drive down costs.

Reducing Air Pollution and Worker Risk

I’ve seen firsthand the toll traditional solvents take on workers. Headaches, sore throats, and worse crop up in poorly ventilated spaces. That’s not just discomfort—it disrupts livelihoods and drives up health insurance for employers.

By switching to low-volatility ionic liquids, companies give staff access to safer working conditions. Tributylethylphosphonium trifluoromethylsulfonate doesn’t vaporize like older chemicals. That means less air pollution, easier compliance with environmental rules, and more attractive workplaces for skilled technicians.

Room for Better Standards and Oversight

Despite all the promise, oversight sometimes lags behind. Not every ionic liquid has a clean record or clear health profile. Regulatory agencies and lab managers need stronger frameworks for evaluating exposure and safe use. Stronger investment in research—and not just for profits—can help fill those safety gaps.

Industry partners should also support long-term health tracking. Nobody wants history to repeat older mistakes made with solvents once thought totally benign. Progress means keeping both workplace safety and environmental impact at the center of future breakthroughs.

Tributylethylphosphonium trifluoromethylsulfonate’s value grows as a result—not just as another tool, but as a symbol of greener, safer ways to power modern chemistry.

The Numbers Behind the Name

Chemistry names have a reputation for tripping people up, but learning what a label really stands for makes all the difference. Tributylethylphosphonium trifluoromethylsulfonate may sound like something dreamed up for a sci-fi villain, yet behind the name lives the sort of straightforward detail that matters to chemists and anyone working with advanced materials.

Start with its chemical formula. Tributylethylphosphonium trifluoromethylsulfonate combines two distinct parts: a big, hydrophobic phosphonium cation and a trifluoromethylsulfonate (or triflate) anion. The formula looks like this:

C16H37P(C2H5)+ + CF3SO3–

Writing it another way, the full molecular formula comes out as:C20H44F3O3PS

Molecular Weight and Why Precision Prints Value

For pharmacists, engineers, and researchers, precision is a daily companion. The molecular weight tells you about the quantity of substance—you can’t set up reactions or analyze by mass spectrometry without knowing it. So here is what the numbers add up to:

Molecular weight: 452.60 g/mol

Relying on accurate formulas and weights avoids mistakes in the lab. I learned this lesson in a university course, after making a few miscalculations during a synthesis—one decimal point off and suddenly you’re wondering why your results don’t match the literature. In the world of ionic liquids, where this compound appears, precision gets even more critical. These aren’t household substances, but they keep finding their way into processes that matter for batteries, extractions, and even pharmaceuticals.

Relevance in Modern Chemistry

The details above have real consequences. Tributylethylphosphonium trifluoromethylsulfonate belongs to the ionic liquid family, a group of salts that stay liquid near room temperature. Ionic liquids have proven useful as solvents that don’t evaporate easily, tools in green chemistry, and even materials in the electronics sector. Their heavy, asymmetric ions mean they don't form strong crystalline lattices, so you pour them out like thick oil.

This compound rounds out the toolbox for labs looking to avoid volatile organic solvents, cut down on waste, or improve material stability. Safe handling depends on the precise understanding of molecular structure—both for safety data sheets and real-life risk management. This is where facts, not just friendly descriptions, support both the health of workers and the outcome of research.

Building Better Practices

Stronger protocols, detailed documentation, and clear sharing of information help everyone in the chain, from students to seasoned chemists. I remember my first time handling an ionic liquid—double checking the label, cross-referencing the CAS number, tracking down that formula and weight. Making knowledge accessible, without layers of jargon or missing info, saves time and resources.

A good starting point to improve outcomes lies in clear chemical naming, robust database indexing, and training that shows why those little numbers next to molecules matter. When chemists trust the information they work with, errors drop, waste shrinks, and discoveries speed up. That’s the kind of impact these formula details can carry, far beyond the classroom or storeroom.

A Chemical That Deserves Respect

Working in a lab often means meeting all sorts of chemicals, and some of them come with complicated names like tributylethylphosphonium trifluoromethylsulfonate. Many folks pause at the table, take stock of the familiar hazard diamond on the bottle, and maybe feel a little worried about the long label. The dangers aren't always right in your face, so it’s easy to get too casual about safety. Every bottle holds its own set of risks, and this one stands out because it mixes organic phosphorus with a strong sulfonate, which means you can't just toss it in a cupboard and forget about it.

Storage Isn't Just About Space

Most problems with specialty chemicals begin with storage. I’ve seen plenty of labs try to cram all their reagents into a single closet or make-shift shelf, only to face leaks or ruined stock later. Tributylethylphosphonium trifluoromethylsulfonate needs a stable, cool spot without sunlight beating down. Sunlight and warmth often set off reactions, and the results aren’t always predictable. Neat labeling—laminated, not marker-writing on tape—helps everyone know what they’re handling. The container always needs a tight seal, and it can’t sit next to acids or oxidizers. Too many old accidents started with careless shelf neighbors. Store it in its original packaging or anything chemically compatible, and avoid metal shelves if there's a chance of corrosion. I remember a cabinet whose thin steel racks started to rust unnoticed, releasing a slow trickle of fumes that made everyone uneasy for days.

Handling Echoes Kitchen Sense—But with Gloves

Pulling the stopper out of a bottle like this without ventilation or gloves turns a regular lab day into a trip to the safety shower. This isn't simple caution—phosphonium salts pose risks to skin and lungs, and the sulfonate part only adds trouble. I always use chemical-resistant gloves that come up toward the wrist, safety glasses, and, in most setups, a lab coat with a closed collar. Spills still happen. One time, a researcher dropped a pipette, splashing reagent on their arm. Immediate rinsing and a quick safety report probably kept it from becoming a bigger deal. It’s worth checking the compatibility of gloves and aprons regularly, since manufacturers update the recommendations based on new studies. When I need to make up a diluted solution, I do everything under a fume hood. Relying on open benchtops only courts disaster if things get messy.

Disposal and Cleanup—No Shortcuts

Working with these compounds doesn’t stop at use. Scraps and surplus linger around. Pouring leftovers down the drain can cause damage far beyond the building. Collect waste in the correct container, away from acids and bases—the local environmental guidelines aren’t there for show. Even the paper towels and pipette tips that touched the substance should go in hazardous waste. Regular audits keep people from getting lazy, and asking questions saves lives. I remember an intern who asked the right question about waste compatibility, catching a near mistake that could have led to a fire.

Building a Safety Habit

Practicing safety around hazardous chemicals comes down to routine—a personal checklist as natural as tying your shoes. Learning from small near-misses can prevent something large and dangerous. Training everyone in the room, posting updated guidelines, and making it easy to find emergency contact numbers can make every lab a safer place. People working with chemicals carry responsibility for themselves and those around them. It’s not about paranoia. It’s about respect—one sharp mind and ten minutes of attention at a time.

Straight Talk on Chemical Stability

Tributylethylphosphonium trifluoromethylsulfonate isn’t something you’ll find on most lab shelves, but anyone working with ionic liquids or advanced solvents has probably run across compounds in this chemical family. Handling these molecules comes with a few rules, and it pays to know exactly what kind of character you’re inviting into the lab. From years of working with similar salts, I’ve learned that not all ostensible stability is the same—inorganic salts may look tough, but organic cations often play by their own rules.

Assessing the Risks

Most phosphonium salts stay stable under regular storage conditions. Tributylethylphosphonium cations have size on their side; those long alkyl chains tend to dodge water a bit better than smaller, fussier cousins. Pair that with trifluoromethylsulfonate anions, which don’t like to coordinate or react much, and on paper, you get a salt that shrugs at air and room temperature.

Still, a chemical doesn’t live on paper. In practice, moisture always finds its way in. Even a well-sealed bottle gets opened and closed a hundred times, letting in just enough air to slowly introduce hydrolysis. Many chemists ignore the little bits of foggy data that show up after six months—minute decomposition, acid formation, discoloration. Ask any grad student who’s had to troubleshoot a finicky synthetic protocol: the old bottle and the new bottle never seem to work the same way.

The Real World of Ionic Salts

One important factor lies in how phosphonium cations eventually react with tough nucleophiles under the right conditions. Phosphonium salts with long chains may resist attack, but strong bases (or heat above 120°C) can cleave side-arms and generate phosphine oxide or quaternary breakdown products. The triflate anion carries some stability, but always adds a hint of volatility—trifluoromethanesulfonic acid is powerful stuff, and even tiny amounts can cause serious complications if the salt picks up moisture and hydrolyzes.

Literature reports reinforce these worries, showing that phosphonium triflate salts survive months at ambient settings but lose their edge with prolonged exposure. Even in closed vials, regular use and handling often introduce tiny amounts of water or contaminants. If used in applications sensitive to impurities—say, catalysis, or ionic-liquid synthesis—a trace of acid or decomposition can derail results in ways that frustrate both graduate students and seasoned researchers.

Practical Solutions for Safer Handling

I’ve found that strict storage is key. Keep the compound in a dry, tightly closed container, away from sunlight and direct heat sources. Use a glovebox if available, or substitute with a decent desiccator. Silica gel packs in storage boxes make a subtle but real difference. Buy in small quantities; fresher material means fewer headaches. If the bottle starts to clump or smells off, it’s time to replace.

Documentation makes a difference. Mark the date of opening, and keep notes on any changes in texture, color, or yield. Some chemists even run periodic NMR checks on their salts, just to ensure nothing funky happens behind the scenes. Using high-purity solvents and scrupulously cleaned glassware drops the chances of accidental contamination, especially since small errors have a way of snowballing with delicate organophosphorus salts.

Thinking Forward

Safer and smarter chemistry doesn’t ask for superheroes—just solid habits and willingness to trust experience. Tributylethylphosphonium trifluoromethylsulfonate can deliver reliable results, but only if handled with respect for the way it interacts with its surroundings. Small steps, like good labeling and climate-aware storage, keep sensitive chemicals in their happy place and prevent unexpected setbacks down the line. Lab benches across the world would run a bit smoother if everyone remembered that, even though these salts look sturdy, they need a little care to stay reliable.

Why Safety Around Chemical Compounds Matters

Every time I step into a laboratory or plant, basic safety routines kick in before the work even starts. Proper handling of chemical compounds like Tributylethylphosphonium Trifluoromethylsulfonate isn’t just about keeping the workplace tidy or following rules—it’s about protecting your own well-being and the health of others.

This compound, often used in research or specialized industrial applications, raises more than a few eyebrows on a safety data sheet. Workers and researchers need to pay attention—not because someone is being overly cautious, but because even exposure at levels not high enough to cause an accident can have surprises down the line.

What Makes This Compound Worth a Closer Look

Tributylethylphosphonium Trifluoromethylsulfonate looks harmless on paper. No vibrant color, no strong odor. But the lack of warning signs you can see or smell is exactly what makes it tricky. You let your guard down, and the next minute, you might feel irritation on your skin or a strange burning in your eyes.

Phosphonium salts as a class have been around for a while, used to speed up reactions or serve as specialized ionic liquids. I’ve found that smaller spills go unnoticed because people think “clear and colorless means less risk.” It’s an easy trap to fall into. The trifluoromethylsulfonate part isn’t much friendlier. Fluorinated substances can linger in the body or the environment, and some of them are notorious for their persistence and bioaccumulation.

Hazards You Can’t Ignore

Skin irritation is one of the biggest things I notice if my gloves have even the tiniest nick. Redness, itching, sometimes a rash that stays way longer than you’d expect. If the compound turns into a fine mist or if vapors rise up during mixing, your eyes or lungs might get the brunt of it. There’s no glory in skipping that face shield or forgetting to check that your fume hood is actually turned on.

Accidental swallowing—pretty rare, but still on the risk list—gets treated as a medical emergency. Toxicological studies, though limited, point toward acute symptoms like headaches, dizziness, gastrointestinal upset, and even nerve issues if exposure is high or keeps happening over time. There’s a real concern about what long-term, low-level exposure means, especially with compounds that have phosphorus and fluorinated groups.

Good Habits Lower the Stakes

I treat every new chemical the same way until the facts prove otherwise. Protective nitrile gloves fit tight, goggles leave no room for error, and lab coats never come off until every surface gets cleaned. Ventilation matters more than ever: local exhaust, closed systems, and careful storage in cool, dry conditions.

Labeling containers solves half the problem, especially in crowded workspaces where mistakes with look-alike bottles happen fast. Training makes a bigger difference than people admit—walking new staff through what PPE actually protects against and what doesn’t. I keep emergency eyewash and showers close, not tucked away in a storage closet.

Looking Forward: Real Solutions Start With Responsibility

Substitution always crosses my mind. Lab managers often ask if a safer alternative or a different process works. Sometimes you can’t switch, but at least you can minimize volumes, close the loop on waste, and run regular health checks for workers.

Ignoring small exposures or skipping daily reviews feels easy, especially during a busy week. But for chemicals like Tributylethylphosphonium Trifluoromethylsulfonate, small steps add up to a safer work environment. The science is clear—good habits and responsible choices beat wishful thinking every time.