Tributylhexylphosphonium Chloride: A Thorough Look

Historical Development

Chemists started exploring organophosphonium compounds many decades ago, chasing down new ionic liquids and versatile reagents for industrial chemistry. Tributylhexylphosphonium chloride stands out from the crowd because its structure branches out in a way that gives it unique physical and chemical behavior. In the early days, most phosphonium salts in the lab stuck to simple symmetrical alkyl chains and shyly avoided bulky, asymmetric versions. Eventually, tolerances in synthesis improved. Researchers found that swapping out groups like methyl for hexyl and blending in tributyl opened doors for ionic liquids with low melting points, stable thermal windows, and useful solubility. As green chemistry picked up steam, these salts became valuable for their low volatility and minimal flammability. Production jumped from the benches of academic labs to pilot-scale facilities, where manufacturers paid close attention to quality, regulatory shifts, and user safety.

Product Overview

Tributylhexylphosphonium chloride presents as a viscous, clear to pale yellow liquid. It carries a distinctive chemical odor, but nothing overpowering. Unlike the old school ammonium-based salts, this one resists absorbing water from air, thanks to its sturdy organic backbone. It often comes in high-purity grades meant for research, development, or industrial use, and suppliers check for low moisture, minimal halide impurities, and color index. The salt finds its packaging in airtight, compatible containers, shielding it from exposure or contamination until opened in a controlled space.

Physical & Chemical Properties

This compound checks in with a melting point leaning below room temperature, a sign that it qualifies among ionic liquids. Its boiling point soars, so users rarely see evaporation except at extreme temperatures. The chloride anion anchors the compound, lending it a certain hydrophilicity, though its use in nonaqueous or mixed systems remains favored. The density sits higher than water, as with many salts, and viscosity can give users some pause, especially when handled in large amounts. Solubility swings wide—from organic solvents like acetone to a tolerant behavior in some alcohols. Chemically, the phosphonium cation shrugs off most mild bases and resist hydrolysis, but strong nucleophiles or oxidants eventually break the structure down. Its thermal stability runs higher than many organic liquid salts but not infinite, so heating calls for care.

Technical Specifications & Labeling

Quality checks for tributylhexylphosphonium chloride look for content purity, water content, trace metals, and residual solvents. Labels read with caution warnings, chemical identity (including molecular formula and CAS number), net weight, batch number, and hazard pictograms following GHS norms. Any transport comes with MSDS documentation spelling out first aid, reactivity, storage, and disposal, arming end-users with what they need before unscrewing the cap. Suppliers stick to sealed HDPE bottles or steel drums with inert liners, and warehouses assign storage in cool, dry spaces, well-separated from strong acids and bases.

Preparation Method

The synthetic route combines tributylphosphine with bromohexane or chlorohexane in aprotic solvents, often under reflux. The reaction proceeds as nucleophilic displacement, trading out halide for phosphine attachment and releasing sodium or potassium chloride as a byproduct if an alkali halide provides the counterion. Purification typically involves repeated crystallization or extraction, with vacuum drying to reduce traces of water. The final chloride form comes by ion exchange if starting materials leave a different halide, tightening product control. Each stage comes with checks for complete conversion, halide balance, and organophosphorus purity before the drum leaves the line.

Chemical Reactions & Modifications

The compound acts as a phase transfer catalyst, carrying otherwise stubborn anions from one solvent layer into another. It often partners up with nucleophilic reactions, offering a helping hand as bulky cation. With proper design, chemists swap out the chloride for other more exotic anions, using metathesis with silver salts to create new ionic liquids with tailored properties. Thermal or photochemical conditions might rearrange the cation, but ordinary handling standards keep things unchanged. This compound rarely decomposes unless driven hard by high temperatures, chlorinating agents, or strong oxidizers—the phosphorus handles gentle conditions, but every salt has its limit.

Synonyms & Product Names

Users may come across this compound listed as tributyl(n-hexyl)phosphonium chloride or by its precise chemical name, but catalog numbers and trade names take center stage in commerce. The CAS registry number remains consistent across suppliers, helping users avoid confusion in procurement or regulatory filings. Some catalogs use shorthand like TBHP-Cl, streamlining digital searches for stocking or cross-referencing.

Safety & Operational Standards

Working with tributylhexylphosphonium chloride means gloves and goggles stay on. The liquid irritates eyes and skin, and ingestion or inhalation draws stories of burning or coughing. Employers train folks to handle spills with absorbent pads, keep incompatible chemicals miles apart, and manage cleanup with both fume hoods and chemical waste bins. Air-tight transfers and limited headspace in storage drums reduce vapor risk. Emergency showers, eyewash stations, and fire extinguishers back up safe handling. Any transfer to the environment, including accidental drains, gets stopped at the source and reported following state and national guidelines. Chemical safety travels hand-in-hand with responsible operator training, not just paperwork or online modules.

Application Area

Most chemists reach for tributylhexylphosphonium chloride in phase transfer catalysis, ionic liquid formulations, or electrolyte development for batteries and capacitors. Its combination of low volatility and thermal stability nudges it into organic synthesis, especially for reactions needing mild conditions but tough transfer of anionic participants. Its role as a solvent stretches into electroplating, where stability and electrical conductivity spell advantage over water or simple organic media. In research, it steps into analytical methods, acting as an extraction enhancer or solubility engineer. Developers in the battery sector experiment with this salt as an anti-leak, nonflammable alternative to classic carbonate electrolytes. Green chemistry researchers keep a close eye on its mild environmental impact, compared to longer-chain, less biodegradable analogues.

Research & Development

The pace of innovation with this class of phosphonium salts never lets up. Newer synthesis methods trim away waste, amp up yield, or swap in renewable starting materials. Scientists unravel how tweaking the alkyl side groups shapes viscosity, conductivity, and solvation. Cooperative projects with battery firms, membrane developers, or pharmaceutical teams often try to lighten the toxicity load or cut the price per kilo. Labs keep pushing at the boundaries, checking stability under mechanical shear, prolonged heat, or repeated charge-discharge cycles for next-gen energy storage. The academic push also touches on environmental fate, enzymatic breakdown, and recyclability, aiming to keep long-chain organophosphorus salts from slipping out of regulators’ good books.

Toxicity Research

Animal studies and cellular assays provide much of what’s known about tributylhexylphosphonium chloride’s effects. Acute exposures in rodents highlight moderate toxicity, with symptoms matching what most cationic surfactants deliver: skin redness, eye inflammation, stomach aches if swallowed. Chronic studies run less abundant, but no class-wide consensus declares this salt especially threatening unless released in large, uncontrolled quantities. Cell culture work notes possible disruption at elevated concentrations to membrane integrity and metabolism. Environmental fate profiles trace a slow breakdown in soil, though the short-chain versions degrade faster. Wastewater streams carrying organophosphonium salts demand treatment by oxidation, incineration, or secure landfill, since aquatic life records significant sensitivity to high saline organic residues. Each data point spurs improvements in containment and motivates greener alternatives.

Future Prospects

Tributylhexylphosphonium chloride’s story keeps evolving. As sectors like energy storage, catalysis, and pharmaceuticals stretch out for high-performance solvents with manageable footprint, demand climbs. Researchers hunt for even greater selectivity in extractions, hoping to fine-tune molecular interactions for both bulk and fine chemicals. Market signals hint at rising pressure for products that deliver on low toxicity and rapid biodegradation—driving advances in synthesis or total structural redesign. Automation, tighter analytics, and better predictive modeling give a leg up to anyone chasing optimization, whether it’s for reaction rate or eco-label compliance. For all its current merits, tributylhexylphosphonium chloride typifies a broader movement in specialty chemicals: real value comes through balancing utility, safety, cost, and responsibility, not just ticking off a chemical property sheet.

Understanding Tributylhexylphosphonium Chloride’s Role

Tributylhexylphosphonium chloride doesn’t stand out on store shelves. Instead, its impact lies behind the scenes in the world of advanced chemistry and clean technology. Folks working in specialty labs know it as a phosphonium-based ionic liquid. That essentially means it’s a salt that acts like a liquid at room temperature. Chemists have seen this molecule step up in places where traditional chemicals struggle.

The push for safer, greener industrial practices means fewer companies want to rely on harsh solvents. This is where tributylhexylphosphonium chloride proves to be valuable.

Helping the Chemical Industry Shift Gears

Plenty of research backs up phosphonium ionic liquids as tough, stable and non-volatile—traits many old-school solvents can’t boast. In my own experience cleaning up after chemical experiments, I’ve noticed just how stubborn old solvents can be. Not only have I handled residue that required special ventilation, but I’ve also worried about exposure and lingering fumes. Swapping those out with robust and low-volatility liquids makes the lab feel safer and cleaner.

Researchers around the world point to tributylhexylphosphonium chloride as an effective medium for advanced chemical processes, including catalysis and organic synthesis. Chemical engineers often rely on it to speed up tricky reactions, particularly where water-based or traditional organic solvents fall short. Reports from leading journals show that this phosphonium compound fosters unique reactivity, which helps create new molecules or split apart old ones.

Smoothing Out Separation Processes

This compound offers another benefit: improved separation of materials. Commercial separations often eat up energy, especially in areas like recycling plastics, purifying gases, or refining pharmaceuticals. Tributylhexylphosphonium chloride’s molecular structure allows it to dissolve a diverse mix of substances. This helps isolate target compounds with less waste and fewer steps.

As someone who has followed green chemistry trends for more than a decade, it’s clear that ionic liquids are helping companies cut both costs and environmental risks. A 2021 review from the Royal Society of Chemistry highlighted the role of phosphonium ionic liquids in sustainable processes, including carbon capture—a field that demands reliable, high-capacity solvents.

Enabling Cleaner Biotech and Energy Innovations

Scientists working in biotechnology have turned to this compound for enzyme stabilization. Many industrial enzymes break down or denature in common solvents, but phosphonium ionic liquids like tributylhexylphosphonium chloride offer a gentler environment. Their use supports everything from biofuel production to pharmaceutical manufacturing by keeping sensitive components active longer.

I’ve seen these developments reach pilot-scale biorefinery projects, where every chemical partner must perform and protect the rest. The cleaner the process, the less time spent troubleshooting contamination or unstable reactions. The compound’s growing track record in these advanced fields shows just how much modern manufacturing values reliability and sustainability.

Facing Up to Safety and Supply Concerns

No chemical comes without considerations. As tributylhexylphosphonium chloride grows in demand, so does the need for thorough safety data and transparent sourcing. Governments and industrial safety councils push companies to publish data on toxicity, persistence, and best handling practices. Any labs or manufacturers looking to expand use of phosphonium compounds should invest in proper training and personal protective equipment, ensuring that benefits don’t put workers or the environment at risk.

Innovating With Responsibility

The move toward greener chemistry isn’t just about swapping out ingredients. Companies and regulators should prioritize lifecycle analysis for every new ionic liquid, including tributylhexylphosphonium chloride. There’s a lot of excitement here, but innovation carries responsibility. Continued public reports, safety assessments, and cross-disciplinary research will keep the pace positive—so chemists, engineers, and the public see the benefits at every step.

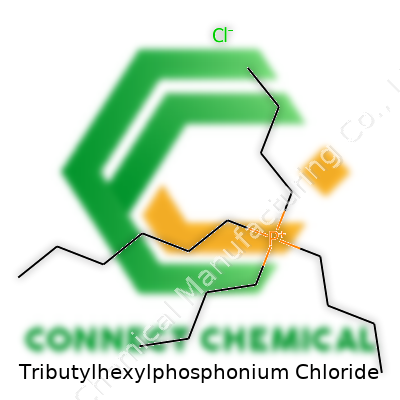

Diving into the Chemistry

Tributylhexylphosphonium chloride doesn’t show up in daily vocabulary, but in labs it often takes a meaningful role. Its chemical formula, C24H54PCl, reflects its building blocks: it contains a phosphonium center with three butyl groups and one hexyl group, plus a chloride anion. To those familiar with organophosphorus chemistry, this structure unfolds as a pattern with both hydrophobic and hydrophilic properties, making it interesting for tasks that require moving molecules between water and organic solvents.

Why the Structure Matters

This compound doesn’t just sit on a shelf. Its molecular makeup shapes its behavior in unique ways. Phosphonium salts like this stand apart from other quaternary salts. Their bulky side chains—a trio of butyls and one longer hexyl—create a unique interaction with other chemicals, giving researchers a handy tool for separating and isolating substances. People working with ionic liquids pay close attention to these properties. As someone who’s spent afternoons in a college organic chemistry lab, I remember the surprise that came from seeing certain phosphonium salts dissolve where nothing else would work. Experiments that struggled with simple ammonium salts sometimes lit up with new promise using tributylhexylphosphonium chloride.

Applications and Impact

Fields like green chemistry hunt for alternatives that minimize waste and environmental harm. Ionic liquids built around phosphonium salts offer lower vapor pressures and better thermal stability than many classic solvents. I’ve met chemical engineers who lean into these properties for battery electrolytes and even for extracting rare earth metals—an urgent topic given the pace of modern technology. Facts show that these salts can improve selectivity and reduce the mess left behind after extraction, helping both the industry and the environment.

In the classroom, tributyhexylphosphonium chloride sparks curiosity because of its structure and its ability to act where more common salts fall short. Some researchers leverage its big nonpolar tail to persuade greasy organic molecules into aqueous solutions. Others choose it for its ability to stabilize reactive intermediates, which makes troubleshooting less intimidating. During a postgrad summer, I worked with a team looking for solvents that could handle impure feedstocks. We found that phosphonium salts handled surprises better—fewer emergency extractions and cleaner end products.

Challenges and Solutions

Despite their appeal, phosphonium salts require careful handling. As with many chemicals sporting long alkyl chains, biodegradability and toxicity matter a great deal. Regulations keep tightening as more evidence appears in scientific journals. Teams who use tributylhexylphosphonium chloride face pressure to recycle and monitor every drop to avoid environmental harm. I’ve met lab managers who opted for closed-loop systems, tracking solvents from purchase to waste, to reduce impact. At the same time, chemists keep hunting for structural tweaks that keep these compounds useful but less persistent in the environment.

Tributylhexylphosphonium chloride, with its formula C24H54PCl, ends up reminding us that what happens at the molecular level drives bigger changes—sometimes for the better. Balancing those changes means staying curious, following the research, and never taking a formula’s utility for granted.

The Realities Behind This Chemical

Tributylhexylphosphonium chloride sounds like one of those long chemical names you hear tossed around in a lab, but this compound hides in plainer sight than many folks realize. It plays a role as an ionic liquid, popping up in industrial processes ranging from solvent extractions to specialized chemical reactions. People often assume that industrial-sounding chemicals spell big trouble, but the truth has more nuance and demands a closer look.

What Health and Environmental Data Say

I never trust hearsay when it comes to health and chemical exposure—decades working on environmental projects taught me to trace things to reputable sources. Scientific research on this compound isn’t as abundant as for legacy toxins like lead or mercury, yet we know a few solid facts. According to peer-reviewed studies, phosphonium salts like this one do raise red flags over toxicity for aquatic life, especially at higher concentrations. One report published in Chemosphere found that certain phosphonium ionic liquids caused developmental delays and organism death in some aquatic species.

As for direct contact with humans, there isn’t a mountain of clinical evidence on widespread exposure or long-term health effects. That doesn’t mean the coast is clear. The general rule with industrial chemicals still applies: irritation may occur if it touches the skin, gets in the eyes, or is inhaled as dust. Some toxicity prediction models—like those run by the EPA—suggest potential for bioaccumulation, which means small exposures might build up if use isn’t managed. Manufacturers generally classify it as not acutely toxic, but label guidance usually recommends gloves, goggles, and handling in ventilated spaces.

Why This Matters for Industry and Community

Feeling invincible around any laboratory or workplace chemical courts disaster. A friend once brushed off a chemical spill as “minor.” Days later, they faced a rash that needed medical treatment. Safety data sheets and risk assessments exist for a reason, and tributylhexylphosphonium chloride’s MSDS underscores that point. If spills reach waterways, the risks to fish and invertebrates climb, threatening local biodiversity. For factory workers or researchers, the stakes sit at a personal level—proper storage and cleanup keep both workplaces and homes safe.

Solutions and Smart Handling

The world doesn’t move away from chemical innovation easily, so the real test revolves around risk reduction. The first step is following recommended personal protective equipment every time the chemical comes out. Simple gloves and safety goggles protect against accidental splashes to the skin or eyes. Containers need good labeling and storage off the beaten path. Large-scale users benefit from clear spill response protocols. In labs I’ve consulted, keeping a spill kit at arm’s reach saved more headaches than fancy engineering controls.

There’s another angle: responsible disposal. Dumping down the drain or tossing with regular garbage isn’t an option. Licensed waste handlers take the burden off the average worker or community member, helping restrict environmental contamination. Regulatory agencies like the EPA or local environmental protection offices offer specific guidelines for ionic liquids, and it pays—literally in fines and health—to heed them. If the workplace feels uncertain, peer-reviewed journals and materials safety experts provide up-to-date facts. This approach puts science and common sense to work, which beats relying on rumors any day.

Watching Out for Chemical Stability

Folks working in labs or industrial setups tend to give chemicals like Tributylhexylphosphonium Chloride some extra care. I remember my first experience with specialty chemicals—one misjudged exposure to humidity proved how these compounds react quickly to a little carelessness. Tributylhexylphosphonium Chloride tells the same story. Its chemical stability starts to slip if people leave containers open, allow moisture to get in, or ignore temperature suggestions. Keeping containers tightly sealed really does the trick. Unwanted reactions or slow breakdown aren't just hard on your pocket—they can put safety at risk for everyone working nearby.

Temperature and Moisture Control

Temperature control sits high on the priority list for this compound. Room temperature sounds safe, but too much heat or freezing cycles make the material degrade or clump up. In manufacturing settings, you’ll find clear warnings on labels and supply room doors: keep it cool, keep it dry. Moisture triggers all kinds of headaches—it can mess with consistency or start a slow reaction you didn’t see coming. Anybody who’s cleaned a sticky, half-solidified drum can tell you the simple step of using desiccants or regular checks for container seals saves a world of trouble.

Shielding from Light, Air, and Incompatible Materials

Direct sunlight can spoil certain phosphonium compounds. I’ve stored sensitive chemicals in dark cabinets or tinted storage bottles—basic steps, but they really help prolong shelf life. Leaving a tub out on a cart might not seem like a big deal, until you come back days later to find the color or odor has changed. Air exposure can also be an issue, sometimes sparking slow degradation or alterations you wouldn’t catch unless you’re running quality checks.

Compatibility remains a big deal. Tributylhexylphosphonium Chloride stays stable only if it keeps a safe distance from strong oxidizing agents and acids. Workers learn quickly not to keep those troublemakers on the same shelf. Once, after a poorly organized shipment arrived at the plant, we found packaging stained and vents blocked by fumes—nobody forgot that lesson. Clearly labeled, segregated storage areas turn what could be a disaster into routine.

Worker Safety: Simple Steps Prevent Big Problems

Personal safety routines pay off over the long run. Everyday gear—gloves, safety glasses, and lab coats—create a basic barrier. Spills do happen, and skin contact with phosphonium salts gets messy fast. Training new colleagues means showing—not just telling—the quickest way to handle leaks and the right neutralizing agents for cleanup. Keeping accessible Material Safety Data Sheets helps avoid confusion during stressful moments.

Solutions for Real-Life Handling

Out in the field, success comes from a few clear habits—routine checks on containers, careful labeling, and using small transfer vessels. Automated dispensing systems limit exposure and accidental spills. Regularly reviewing storage policies with all kinds of teams, not just chemists or lab workers, keeps everyone alert. I’ve seen how preventative maintenance and basic record-keeping spare businesses from expensive waste, lost time, or tougher regulatory questions down the line.

Storing and handling Tributylhexylphosphonium Chloride doesn’t call for rocket science. Just a bit of respect for the compound and steady routines make all the difference between a safe workspace and an expensive issue.

Challenges with Specialty Chemicals

Looking for a compound like tributylhexylphosphonium chloride brings up a couple of hurdles you don’t find in regular shopping. For most people, sourcing chemical products isn’t about walking into a store or clicking “add to cart.” It demands research, a bit of courage, and plenty of caution. I’ve come across labs that spent weeks just verifying suppliers before even considering an order.

Most buyers head toward established chemical distributors. Sigma-Aldrich, TCI, and Alfa Aesar come up often in scientific circles. These companies maintain global supply chains and provide thorough documentation – the safety data sheet and certificate of analysis matter just as much as the product itself. Experience taught me that when regulatory authorities ask, you want that paperwork ready.

Supplier Options and Costs

Lab managers and procurement teams gravitate toward vendors that display regulatory compliance and responsive customer service. Tributylhexylphosphonium chloride isn’t something backyard suppliers keep on hand. International vendors like Sigma-Aldrich feature this product but often require a business account. Prices fluctuate sharply, sometimes over $300 for a 25-gram sample, depending on purity and demand.

Chinese companies, such as Alibaba-listed suppliers, present another option for industrial-scale buyers. Low prices attract attention, but quality checks become crucial. Verifying ISO certification and batch reproducibility helps spot reliable sources. Based on interactions I’ve seen, language barriers and long lead times can turn even a routine order into a logistical puzzle. For new buyers, stick with companies offering transparent English support and solid export histories.

Packaging: From Grams to Drums

Blockbuster chemicals like sodium chloride come in every size, but tributylhexylphosphonium chloride stays niche. Retailers frequently ship in small glass or HDPE bottles for research use, usually 1 gram, 5 grams, or 25 grams. Industrial buyers, especially those in electronics or catalysis, prefer sealed drums or jerry cans – think 1 kilogram, 5 kilograms, sometimes 25 kilograms. Handling and containment requirements drive this: nobody wants a phosphonium salt leak in their storeroom.

Shipping is never “set and forget.” Companies pack this chemical in air-tight bottles, often double-sealed, and sometimes with moisture-absorbing packets. Dangerous goods classification requires hazmat-trained couriers. More than once, I’ve seen delays at customs when paperwork didn’t match the packaging information. For a safe and legitimate shipment, work with suppliers who show expertise in chemical logistics. Clear communication about your intended use helps avoid headaches.

Why Source Matters

Reputation plays a big role in the chemical sector. Universities and regulated industries won’t risk a black-market vendor. Tracking product origin not only reduces legal risk — it helps avoid contamination. My own experience with unregulated sources came with product inconsistencies, shipment damage, and non-existent technical support.

Smart Solutions for Buyers

For those new to buying specialty chemicals, building relationships with reputable distributors pays off. Ask about references and audit histories before sharing purchase orders. Request lot-specific documentation every time. Where large-volume pricing tempts, consider doing a split order with other labs—you save on bulk costs but avoid storing excessive stock. Finally, always involve a chemical safety officer or someone with hazmat certification during receipt and storage.

In this business, diligence outperforms shortcuts. Safeguarding people and results means tracing every bottle back to a trusted source, using proper packaging, and working with suppliers who care about compliance as much as you do.