Tributylhexylphosphonium Tetrafluoroborate: An Industry Commentary

Historical Development

Phosphonium-based ionic liquids have been around in academic and industrial circles for decades. Tributylhexylphosphonium tetrafluoroborate came out of early work exploring alternatives to traditional volatile organic solvents. As researchers hunted for substances with both low volatility and advanced solvation power, focus shifted toward ionic liquids based on tetrafluoroborate anions. Scientists started recognizing their practical value in the late twentieth century, especially as environmental regulations tightened and conventional chemistries ran into trouble over emissions, safety, and compatibility. The chemical’s commercial story grew alongside the larger narrative of green chemistry, as more firms looked to these salts for solutions in electrochemistry, catalysis, and advanced materials.

Product Overview

Tributylhexylphosphonium tetrafluoroborate belongs to a family of room-temperature ionic liquids where quaternary phosphonium cations play an outsized role in the product’s physical and chemical behaviors. Unlike classic quaternary ammonium salts, the longer alkyl chains and specific steric effects create liquids with remarkable thermal and chemical resilience. Many industries see these liquids as both solvents and process aids—something that isn’t easy to find with most organics. My own experience with large-scale separations brought home the advantage: fewer emissions, less flammability, and broad compatibility with metals and organics.

Physical & Chemical Properties

Looking at the physical profile, tributylhexylphosphonium tetrafluoroborate shows up as a viscous, colorless to pale yellow liquid at room temperature. The long alkyl chains increase hydrophobicity, which can be a game changer when separating organics from water. The compound stands out for its low volatility. It won’t evaporate at ambient conditions, so labs and factories don’t deal with persistent solvent odors. Density typically runs above 1 g/cm³, with moderate to high viscosity. The tetrafluoroborate anion endows the ionic liquid with exceptional electrochemical stability, especially in reduction and oxidation environments. The product remains stable in air and can handle heat in ways normal solvents can’t, tolerating temperatures past 200°C without rapid breakdown. Water solubility stays low, which reduces losses and environmental escapes.

Technical Specifications & Labeling

Suppliers provide tributylhexylphosphonium tetrafluoroborate in sealed drums or high-density polyethylene containers, identifying it clearly by IUPAC name, often as "tributyl(hexyl)phosphonium tetrafluoroborate." Labeling must cite the correct CAS number—often 692650-57-2—plus hazard statements and recommended handling procedures. Purity grades vary, but most applications demand at least 98% to avoid contamination in high-sensitivity processes. Manufacturers present data sheets showing moisture levels, acid content, and impurity profiles, since stray halides or phosphines wreck many applications. Storage guidance keeps the liquid in dry, cool conditions away from incompatible reactants like strong oxidizers.

Preparation Method

Manufacturing typically involves quaternization of trialkylphosphine—like tributylphosphine—with an appropriate alkyl halide such as 1-hexyl bromide. The reaction takes place in an anhydrous solvent. A careful work-up follows to remove the resulting alkyl halide salt and byproducts. For the anion exchange, a metathesis reaction brings in sodium or potassium tetrafluoroborate, which swaps its cation for the phosphonium under controlled stirring. Filtration and washing finish the purification, and vacuum drying drives off solvents without degradation. A well-run plant follows strict standards due to the sensitivity of the tetrafluoroborate anion to moisture and hydrolysis during the process.

Chemical Reactions & Modifications

Experiments with tributylhexylphosphonium tetrafluoroborate open up access to a range of chemical modifications. Functional groups on the alkyl chains can be tweaked, tailoring solubility or polarity for a given reaction. In my own work, introducing aromatic moieties changed extraction selectivity in metal recovery. The tetrafluoroborate anion resists hydrolysis better than PF6-based ionic liquids, which makes it more robust in real-world process environments. As a solvent, it dissolves a variety of transition metal salts, lending a hand to electrosynthesis, homogeneous catalysis, and advanced materials processing. Some newer studies look at swapping the anion for other non-coordinating types to tune performance for specific reaction or separation challenges.

Synonyms & Product Names

In chemical catalogs, this product often appears under names like TBHP-BF4, P66614BF4, or tributyl(hexyl)phosphonium tetrafluoroborate. “Ionic liquid” shorthand sometimes turns up, though that obscures the precise composition. A supplier may list several trade references depending on where it’s registered or certified. Awareness of these synonyms prevents misorders, especially for multinational teams.

Safety & Operational Standards

No discussion on this chemical goes far without touching on safety. Phosphonium ionic liquids offer a safer profile than many VOCs, but users still face real hazards. Direct skin contact and inhalation of mist or vapor can irritate tissues, although incidents are rare under normal handling. I always recommend gloves, goggles, and splash protection in the lab or production line. Tetrafluoroborate can decompose under intense heat, releasing corrosive gases like hydrogen fluoride if exposed to open flame or strong acids. MSDS sheets spell out response steps for spills, fire, and first aid. Industry best practice means local exhaust ventilation, airtight storage, and slow addition in chemical reactions. Having a written standard operating procedure reduces accident risks and supports regulatory compliance.

Application Area

The real-world impact of tributylhexylphosphonium tetrafluoroborate shows up in everything from electrochemistry to extraction to complex catalysis. Electrochemical cells use it as a non-volatile, ion-conducting solvent, letting processes run at higher voltages or with highly reactive species. Separation chemists like the selective extraction of transition metals, rare earths, and organic molecules—the long alkyl chains and the sturdy anion work together to pick out targets from tough matrices. Process industries benefit from its stability in harsh environments, reducing cleanup and waste. Research groups also deploy it in high-purity syntheses for pharmaceutical intermediates and specialty polymers, where cross-contamination or water sensitivity present recurring headaches. Not many solvents manage this blend of resilience, solvating power, and operational safety.

Research & Development

In R&D, teams keep pushing boundaries with this and related phosphonium salts. Work continues to map out phase behavior with water, acids, and mixed solvents. Synthesizing derivatives to tune viscosity, conductivity, and thermal window opens new avenues for battery electrolytes, especially in next-gen lithium or sodium systems where standard electrolytes can catch fire or degrade. Some groups chase new function by embedding metal complexes or nanoparticles in the ionic liquid, building catalytic materials or sensors with properties you can’t achieve in standard solvents. Multinational projects look at scale-up, sourcing greener feedstocks, and developing robust recycling streams to close the loop. Universities fuel open-access journals with data on longer-term degradation, biotransformation, and compatibility with process materials. The pipeline of incremental and disruptive improvement continues to grow in depth and breadth.

Toxicity Research

Over the past decade, toxicologists began digging deeper into the human and environmental impact of phosphonium ionic liquids. The available data suggest a profile somewhat less risky than short-chain imidazolium or pyridinium salts, but caution holds. Acute oral and dermal exposures in rodents show modest effects, but subchronic and chronic testing remains underway. Environmental researchers worry about persistence if these salts get into natural waters because aquatic organisms can experience delayed toxicity depending on concentration and exposure time. Regulatory agencies call for full material flow analyses and lifecycle assessments for large-scale deployments. The relatively bulky, non-biodegradable cation and stable anion put pressure on chemical makers to implement secondary recovery or destruction technologies, preventing buildup in wastewater or accidental release. Each year, the pile of peer-reviewed studies grows taller, helping industry and regulators work out suitable limits and exposure scenarios.

Future Prospects

Looking to the horizon, tributylhexylphosphonium tetrafluoroborate stands to play a bigger role as industries try to swap out hazardous, volatile, or unsustainable solvents. Global firms want process aids that tick all the boxes: high stability, non-flammability, chemical flexibility, and processability in both small and large plants. Advanced materials sectors ask for new ionic liquids able to facilitate precise synthesis at scale or work under the punishing conditions of renewable energy, electronics, and environmental sensing. As society faces tighter controls on emissions and persistent pollutants, the shift toward recoverable, task-specific liquids like these seems sure to grow. The technical community turns its attention to lifecycle impact, closed-loop operations, and continuous improvement—not just in performance, but in risk management and sustainability. Today’s research shapes the bench conditions of tomorrow’s process lines, with tributylhexylphosphonium tetrafluoroborate opening doors for safer, cleaner, and more efficient chemical manufacturing.

What This Substance Means for Industry

Chemical names rarely make the headlines. Yet every so often, one pops up that's quietly shaping the way materials, energy, and manufacturing move forward. Tributylhexylphosphonium tetrafluoroborate doesn't sound glamorous, but a surprising number of engineers and chemists rely on it for cutting-edge work, especially in green chemistry and materials science.

Chemistry's Swiss Army Knife

Picture this: a salt that stays liquid at room temperature, mixing smoothly with a range of solvents and solutes. That gives scientists a chance to escape traditional solvents—many of which come with nagging safety or environmental baggage. This compound belongs to the ionic liquid family, a field that’s grown rapidly because of its flexibility in both industry and research.

A few years back, I watched a group of researchers replace volatile organic solvents with ionic liquids so they could carry out reactions with less ventilation and fewer worries about toxic fumes. Tributylhexylphosphonium tetrafluoroborate stood out for how well it handled electrochemical tasks and dissolved tricky substances.

Making Batteries Better

One of the main uses I’ve noticed comes in battery development, especially for next-generation lithium-ion and flow batteries. The push for longer life and improved stability has chemists hunting for safer, higher-performance electrolytes. This substance stays stable at higher voltages, doesn't break down easily, and shrugs off temperature swings. It creates a safer environment by reducing fire risk and corrosion inside a power cell.

Researchers at several universities have shared strong evidence that these ionic liquids can extend the lifetime of batteries—cutting down on landfill waste and making electric vehicles more practical for everyday use. It's not just about the laboratory bench; anytime an innovation makes devices safer and longer-lasting, people pay attention.

Cleaning Up Chemistry

Anyone who's cleaned up after a solvent spill understands the headaches involved with common substances like acetone or hexane. They evaporate fast, release unhealthy fumes, and stick around in the ecosystem. Replacing those with safer, non-volatile options makes a difference, both in an industrial setting and inside research labs. By using ionic liquids such as this one, companies can aim for processes that generate less waste and stay within tougher safety rules. The chemical industry, long criticized for pollution, sees a way to cut hazardous byproducts and step toward cleaner practices.

Real-World Obstacles

Of course, every solution brings its own set of challenges. The cost to produce these specialized salts can discourage smaller outfits from adoption. Not every process works better using ionic liquids, either. Disposing of or recycling these chemicals takes careful planning so that the environmental benefit doesn’t fade with improper handling. Safety data continues to evolve, so ongoing research on toxicity and breakdown is crucial.

Possible Paths Ahead

Scaling up production could mean lower costs over time, especially as more industries demand greener and safer processes. Investment in recovery and recycling tech matters, since truly green chemistry can’t stop at the first use. Sharing more real-world performance data—outside the boundaries of the laboratory—could also clear a path for broader use.

Chemists bridging the gap between academic work and industrial application have their hands full, but any progress here helps rewrite the larger story of sustainability in manufacturing and energy. Tributylhexylphosphonium tetrafluoroborate might not become a household name, but its fingerprints are showing up in the cleaner batteries, greener labs, and safer industries people count on every day.

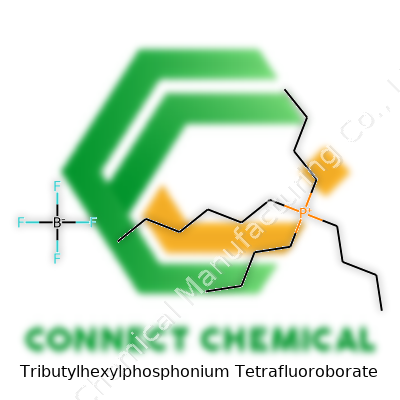

Understanding the Structure

People in chemistry often get curious about the nuts and bolts behind new ionic liquids. Tributylhexylphosphonium tetrafluoroborate has been gaining traction across electrochemistry, green solvents, and even advanced batteries. At its core, its chemical formula is [P(C4H9)3(C6H13)]BF4. Here, the center is a phosphonium cation—the phosphorus atom is bonded to three butyl groups and one hexyl group—matched with the versatile tetrafluoroborate anion.

Why the Formula Holds Significance

Dig into the structure and the reasons for its popularity show up. Designers of ionic liquids focus on tuning cations and anions for specific uses. The bulky side chains (three butyls and one hexyl on phosphorus) do more than just sound exotic—they create a wide liquid temperature range and lower volatility compared to old-school solvents. Tetrafluoroborate, on the other side, offers chemical stability and handles water well, making it handy for applications that can’t tolerate much reactivity or contamination.

Getting Practical With Applications

I’ve seen firsthand how researchers rely on such formulas to explore uses in real-world scenarios. Batteries, for example, need electrolytes that won’t break down easily or catch fire. Tasks like this pushed me to check every molecular detail. Knowing that [P(C4H9)3(C6H13)]BF4 pairs that phosphonium group—engineered to be both large and asymmetric—with a robust BF4 anion, signals strong thermal and chemical durability. That’s what spurred more research at my lab into room-temperature molten salts.

Verification and the Role of Experience

Reaching the right chemical formula takes more than a quick glance. It’s about checking trusted chemical databases, talking with specialists, and studying how these compounds behave under different conditions. I remember needing this compound for catalysis. The suppliers listed [P(C4H9)3(C6H13)]BF4 with an empirical formula of C22H48BF4P. Once I cross-referenced this with major inventories like Sigma-Aldrich and the PubChem database, confidence grew.

Potential Hazards and Responsible Handling

Advanced chemicals also come with baggage: handling requirements, toxicity concerns, environmental impact. Those fluorine atoms in the tetrafluoroborate draw the attention of both chemists and environmental health specialists. It’s essential to weigh not just cool lab results, but the reality of disposal, long-term degradation, and toxicity to aquatic life. Open conversations among researchers, chemical suppliers, and safety officers can help build more responsible practices around using salts like these.

Making Sense of the Future

In my own professional journey, staying curious about the identity of compounds, their properties, and the logic behind their formulas helped me spot both risks and opportunities early. Advanced ionic liquids—backed by clear, verifiable formulas—have already begun shifting the standards in laboratories and industries. Much of the future progress next-gen battery tech or greener solvents will make comes back to solid understanding and respect for details like the formula [P(C4H9)3(C6H13)]BF4.

Understanding the Chemical Up Close

Tributylhexylphosphonium tetrafluoroborate isn’t a substance most folks encounter every day. It sits in the toolkits of chemists and engineers, often showing up in research labs and some specialized industries. The features that make it useful—its stability and ability to dissolve a range of compounds—also raise key points in any talk about safety.

Real Handling Risks

My years in laboratory settings taught me the importance of respecting every liquid or powder, no matter how modern or obscure. Like many ionic liquids, tributylhexylphosphonium tetrafluoroborate brings the reputation of ‘green chemistry,’ but that doesn’t grant a free pass for careless use. It’s tempting to think all ionic liquids are gentle. Truth is, human skin and eyes do not fare well with many of these. Splashes send workers headed for eyewashes. Extended contact risks irritation, sometimes more. A 2021 paper in “Journal of Hazardous Materials” flagged the corrosive and irritant qualities of related phosphonium compounds, confirming what I’ve seen spreading from research safety data sheets.

Inhalation and Toxicity—Don’t Let Curiosity Override Caution

There’s always someone in a group who thinks a whiff of an open bottle can’t do damage. With tributylhexylphosphonium tetrafluoroborate, that curiosity causes real trouble. Although its vapor pressure is usually low, accidental splashes, heating, or spills can send fine droplets or vapors drifting into the air. Data is not complete, but animal studies on phosphonium compounds show acute effects in the lungs and nervous system when inhaled. There’s still a lot to learn. In my experience, investing in proper fume hoods and wearing a fitted mask matters. People sometimes forget that chronic low-level exposure, not just sudden big exposures, shapes health outcomes in the long run.

Environmental Spills and Waste Handling

One major pain point: what happens if this stuff lands outside the lab? Tributyhexylphosphonium tetrafluoroborate, unlike simple salts, can persist in water and soil. Phosphonium salts resist breaking down quickly, so a drain dump or outside spill can leave residues that affect plants and aquatic life. The European Chemicals Agency marked similar compounds for their persistence and potential to cause long-term harm to aquatic animals. At my old workplace, proper disposal made or broke compliance inspections. Chemical waste bins and licensed disposal services kept us out of trouble. Would I ever toss this in the trash or down the drain? Not a chance.

Training and Vigilance Matter More Than Labels

Labels with hazard symbols only go so far—skill and memory make the difference. Every new lab worker I trained dodged mistakes if they watched old hands demonstrate careful handling. Gloves, goggles, and lab coats turn into habits, not afterthoughts. As technology and chemical options advance, safety protocols don’t get simpler, they deserve more attention. The compound might claim ‘low volatility’ or ‘low acute toxicity’, but the best defense always comes down to preparation and respect for what you’re working with.

Seeking Solutions for Safer Practices

Better information and faster updates to safety data sheets help. Accurate hazard information—based on fresh, independent research—means fewer surprises. Moving to enclosed systems cuts down on spills and exposure. Routine safety drills, clearly marked spill kits, and real accountability go a long way. My advice to any lab or plant: act with caution, train hard, and never shortcut protocols, no matter the bottle or the name on the label.

Why Storage Details Matter

Anyone who spends time in a chemistry lab knows that shelf life and safety often boil down to how well chemicals are stored. Tributylhexylphosphonium tetrafluoroborate is no exception. Neglecting proper conditions can lead to unnecessary risks, higher costs, and inconsistent results down the line. In my years working with ionic liquids and specialty reagents, it never fails: shortcuts with storage come back to bite. If you value lab safety and data reliability, there’s no excuse for sloppy storage routines.

Key Storage Conditions

Moisture control takes top priority. This compound, thanks to the phosphonium cation and tetrafluoroborate anion, attracts water from the air, even if the container looks tightly closed. Over time, moisture changes its chemical properties and knocks purity off course. I made this mistake years ago and ended up junking a whole batch that went cloudy and failed every test. A tightly sealed vial inside a desiccator fixes the problem before it starts.

Temperature stability closely follows. Refrigeration buckets usually tempt people, but this one thrives at regular room temperature—avoid hot spots, direct sunlight, and radiators. High temperatures break down ionic liquids faster than most folks realize. Several sources, including the manufacturer’s safety sheets and handfuls of peer-reviewed papers, highlight this. A standard cool, dry storage cabinet away from heat sources does the trick for most people.

Ventilation matters too. Ionic liquids like this one don’t create obvious fumes during normal storage, but the tetrafluoroborate component breaks down into nasty byproducts if it sees too much heat or water. That’s not just a chemistry classroom warning. I once watched a glass jar fizz after months out in a humid storeroom. Outgassing caught everyone off guard and spiked unnecessary alarm. Good air circulation around storage spaces limits such surprises and provides a buffer in case of accidents.

Label accuracy isn’t an afterthought. Permanent marker fades faster than chemicals sometimes, so printed or embossed labels save bigger headaches—especially where regulatory audits step in. I keep duplicate records, both digital and in a hardcopy log, as mixing up ionic liquids with visually similar solvents turns a routine day into a nightmare.

Health and Safety Risks

Most people skip the fine print: tributylhexylphosphonium tetrafluoroborate can cause skin and eye irritation on contact. Accidental splashes partly trace back to poor decanting systems or using old bottles gummed up by moisture. Simple disposable gloves and splash goggles seem like common sense, but too many cut corners and pay the price later. Safety data sheets suggest direct medical attention for splashes—not just for legal compliance, but because exposures are harder to treat than many realize.

Cost and Supply Impacts

Good storage preserves value. I’ve seen supply chain hiccups turn a cheap ionic liquid into a rare commodity overnight. During those times, not wasting a drop becomes personal. Manufacturers ship smaller batches, and fresh lots cost more. Letting one go bad because of lazy storage multiplies that pain. Seemingly minor investments in moisture-absorbing packets and clear storage logs add up to big savings and fewer lost hours.

Better Storage Starts with Consistency

There’s no single magic answer for every lab, but consistency outranks everything else. Regular checks, smart rotation, and honest reporting cut risks. Solid habits, like using desiccators and avoiding heat sources, keep tributylhexylphosphonium tetrafluoroborate reliable. Each bottle lasts longer; each result means more. Paying attention up front makes the difference between smooth research and preventable problems. An organized, safe lab is always worth the extra effort.

What You Need to Know Before Shopping Around

Tributylhexylphosphonium tetrafluoroborate isn’t something you grab from your corner pharmacy. This compound often plays a role in advanced chemistry labs, industrial research, and a stretch of niche applications from electrochemistry to catalysis. If curiosity about buying this chemical strikes, a quick search online fills the screen with supplier catalogs and regulatory warnings. Sorting the trusted from the sketchy isn’t a simple task.

Back when I stepped into the world of specialized chemicals for research, I learned suppliers don’t just hand out compounds with fancy names. They vet clients, check requirements, and ask for details about your project or business. Safety and traceability matter because chemicals like this come with health and environmental risks. If a supplier sells to just anyone, liability and ethical standards fly out the window.

Where Labs and Companies Turn to Buy

Many researchers and companies I’ve spoken with order from established chemical supply outfits. Some common names in the science community include Sigma-Aldrich, TCI America, and Alfa Aesar. Each maintains strict standards for packaging, transport, and documentation. To get a quote, you often create an account tied to an institution or registered business, share your intended use, and provide credentials. A few operations offer limited retail sales, but most focus on institutional and business accounts. This isn’t about gatekeeping; it’s about responsible distribution.

For those outside academia or industry, access can get tricky. Legitimate suppliers rarely deal with individual buyers unless there’s a clear professional reason. Every order triggers compliance checks – checking for export restrictions, local law, and end-use. Multiple countries list tetrafluoroborate salts on regulatory watchlists since mishandling or improper disposal causes real harm. Environmental risks pop up through improper waste management, and health impacts aren’t just ink on paper – skin contact, inhalation, and accidental ingestion carry consequences. A shipment to an address without the training or facilities to handle it safely? Good suppliers don’t risk it.

Don't Cut Corners: Why Proper Sourcing Matters

Folks new to chemical procurement sometimes try online marketplaces, figuring it’s just another product. Several years ago, a friend tried a third-party site for a different reagent, skipping the usual vetting. The material arrived without a proper label or handling instructions. What seemed like a workaround actually made everything harder and riskier. The supplier offered no clarity on storage, transport, or disposal, leaving the buyer exposed. An incident like this can draw fines, academic sanctions, or worse.

Industry experts and regulatory bodies recommend sticking to verified suppliers who provide full safety sheets and transparent shipping processes. Way too many times, careless purchases end up with chemicals sitting in poorly ventilated, insecure spaces. Disaster has an open invitation when materials get stored or disposed of without a plan.

Solutions for Researchers, Businesses, and Hobbyists

If you work with a legitimate organization, ask your purchasing or compliance office for supplier recommendations. Partnerships with approved vendors save time and keep your operation above-board. If you truly need tributylhexylphosphonium tetrafluoroborate for independent research or a startup project, apply for business credentials, arrange proper training, and speak with suppliers about best practices. Regulatory hurdles can seem strict, but they keep people and the environment safe. Cutting corners only breeds trouble.

Knowledge, preparation, and responsible choices build credibility – both for buyers and the supply chain. If you can’t meet the safety requirements for handling specialized chemicals, reconsider whether it’s right to pursue such purchases at all. Every step toward responsible sourcing is one less news story about chemical accidents or environmental damage.