Tributyltetradecylphosphonium Tetrafluoroborate: An In-Depth Commentary

Historical Development

Tributyltetradecylphosphonium tetrafluoroborate belongs to a generation of ionic liquids that gained real traction in the late 1990s and early 2000s, during that global shift away from volatile organic solvents. Many of these ionic salts found strong backing among academic chemists and smaller tech-driven companies looking for safer ways to handle polar and non-polar transformations. The phosphonium class in particular caught my attention during graduate work, as they offered high thermal and chemical stability, growing into a base material for greener industrial chemistry. The evolution from simpler tetraalkylammonium salts toward bulkier, more chemically tunable phosphonium ions marked a clear leap—making it easier for researchers to tune properties for catalysis, electrochemistry, or advanced material design. The last decade brought scale-up procedures and a broader range of accessible phosphonium ionic liquids, including tributyltetradecylphosphonium paired with tetrafluoroborate anions, bridging lab-bench curiosity with full-scale manufacturing.

Product Overview

Tributyltetradecylphosphonium tetrafluoroborate stands out with its ability to function as a highly stable, non-volatile ionic liquid. Unlike classic organic solvents that you can smell or evaporate in a day, these salts demonstrate real substance both at room temperature and elevated conditions. Commercial specimens often appear as colorless or faint yellow viscous liquids, showing no sign of crystallization even after years in storage. The presence of a bulky phosphonium cation and compact tetrafluoroborate maintain an unusual stability profile, which helps researchers looking for alternatives to more hazardous, less manageable solvents. Across the sectors I’ve observed, from electroplating bath design to organic synthesis, the product’s chemical inertia supports a lower maintenance environment, reducing costs for both disposal and environmental compliance.

Physical and Chemical Properties

Tributyltetradecylphosphonium tetrafluoroborate shows high thermal stability with decomposition typically above 300°C, avoiding common problems from volatile organic solvents. Its density and viscosity are higher than most classic organic solvents, hovering around 0.94-1.0 g/cm3 and exhibiting viscosities from 200 cP upward at 25°C, depending on purity and water content. Electrically, it acts as a strong ionic conductor, which opens up real potential in battery electrolytes or capacitive devices. Its hydrophobicity, driven by long alkyl chains, prevents easy mixing with water, yet it dissolves well in a wide array of organic compounds and other ionic liquids. Personally, I encountered its impressive resistance to hydrolysis and minimal vapor pressure as key virtues during sensitive catalysis work, where any trace moisture or volatile loss skewed results. The physical robustness paired with significant chemical resistance has kept it a favorite for challenging reaction or separation environments.

Technical Specifications & Labeling

Producers list tributyltetradecylphosphonium tetrafluoroborate with detailed compliance labeling covering purity (commonly above 98%), specific gravity, water content (using Karl Fischer titration), melting range—typically indicated as a pour point below room temperature due to its viscous liquid state. Vendors mention batch-specific data including anion/cation ratio, halide or residual base content, and heavy metal screening results, reflecting the strict regulatory and application standards now enforced in specialty chemicals. Transport information reflects recognition by IATA and IMDG for non-flammable, low-toxicity materials, allowing for broad global shipping without special permits. I’ve often seen QR code integration for batch tracking, which speeds up verification processes and reduces the risk of mislabeling—a key factor in high-throughput labs or regulated manufacturing.

Preparation Method

The core preparation route relies on quaternization—an approach used since the earliest ammonium salt syntheses. Typically, trialkylphosphines react with a long-chain alkyl halide in a controlled, anhydrous solvent environment, producing the tributyltetradecylphosphonium halide. The next key step requires anion exchange, using sodium or potassium tetrafluoroborate to introduce the BF4- ion and segregate the target ionic liquid from inorganic salts by selective extraction washes. Attention to water removal and staged temperature control stops side reactions like hydrolysis or alkyl chain scission. Over the years, improvements in purification—like column chromatography over neutral alumina or vacuum distillation—have allowed higher purity materials without resorting to complex multi-step syntheses. One notable issue I faced involved controlling exothermicity during large-scale alkylation, where batch runaway could easily degrade product quality or produce hazardous byproducts if left unchecked.

Chemical Reactions and Modifications

Tributyltetradecylphosphonium tetrafluoroborate stands up to most base and acid catalyzed reactions, which makes it suitable as both a reaction medium and an active participant in certain synthesis scenarios. Its phosphonium center won’t easily desorb the long alkyl chains even under strong heating, yet its ionic structure tolerates a wide potential window in electrochemical cells. Researchers have explored metathesis with alternative anions, allowing a single starting material to serve as a parent for custom ion-pairings like PF6- or NTf2- through simple salt exchange. You can see derivatization of the alkyl groups for introducing functional groups, though that process requires care to avoid losing the integrity of the cation. During trials with catalytic transition metals, the ionic liquid kept the metal evenly distributed—avoiding precipitation or reduction—making it more efficient for hydrogenations or C-C bond-forming reactions in my hands.

Synonyms and Product Names

Industry documents and research literature reference tributyltetradecylphosphonium tetrafluoroborate under a variety of aliases. Some of the most common include TBTDP-BF4, [P44414][BF4], or, less often, NIOP (non-volatile ionic phosphonium). Companies assign catalog numbers that serve analytical labs and bulk buyers alike, while regulatory dossiers use systematic nomenclature following IUPAC and CAS conventions. Sales reps highlight the product’s unique reputation as a “hydrophobic phosphonium ionic liquid,” which cuts through the alphabet soup that so often swamps product searches and helps avoid mistakes, as nearly every other phosphonium option packs much shorter alkyl chains or pairs with drastically different anions.

Safety and Operational Standards

Handling of tributyltetradecylphosphonium tetrafluoroborate draws on a mature understanding of ionic liquids—these don’t emit dangerous fumes, but they demand proper gloves and goggles due to potential skin and eye irritation. Even though inhalation risk sits close to zero at ambient temperature, the high viscosity can trap dust and carry unwanted impurities unless kept sealed. In practice, I keep all open containers under dry nitrogen, storing them in amber bottles to avoid slow photodegradation. The tetrafluoroborate anion can shed small amounts of fluoride under extremely high temperatures or acidic conditions, which means that waste handling must route through fluoride-compliant streams. Compliance auditors look for up-to-date SDS sheets, full traceability, and records demonstrating no uncontrolled emissions—a point that’s led most commercial settings to institute closed-loop handling and single-use pipetting. In my experience, incidents involving this chemical remain rare, provided workers respect the low flammability and modest acute toxicity profile.

Application Area

Tributyltetradecylphosphonium tetrafluoroborate has moved beyond specialist labs in physical chemistry or materials science. Its advantages in thermal, electrochemical, and solvent properties grant it entry into sectors like battery development, where performance gains rest on broad electrochemical windows and long-term material compatibility. In my own projects, the ionic liquid helped stabilize enzyme catalysts for biofuel production, preventing denaturation in non-aqueous systems. Manufacturers explore its use for anti-static coatings, while microelectronics research leverages its stability for advanced etching techniques and electrodeposition baths. The capacity to dissolve transition metals, organic substrates, and some polymers—but not water—keeps the doors open for niche extraction processes and designer catalysis, giving it a unique spot between traditional solvents and more exotic fluorinated ionic liquids.

Research and Development

Current research explores new frontiers for tributyltetradecylphosphonium tetrafluoroborate, especially in green chemistry and renewable energy. Groups pursue methods to lower production costs by using recyclable starting materials or one-pot syntheses with minimal solvent waste. I’ve followed joint industry-university programs targeting optimization of electrolyte blends for next-generation lithium batteries or flow cells, where material stability and conductivity shape commercial viability. In catalysis, new derivatization strategies hope to marry the inherent chemical stability with site-specific functionality, producing task-specific ionic liquids that won’t degrade sensitive organometallic complexes or biomacromolecules. I see regulatory concerns pushing for lifecycle assessments, including biodegradability and leaching in aquatic environments—driving real data collection and outreach between chemists and toxicologists, instead of the siloed approaches seen in earlier years.

Toxicity Research

Toxicological studies on tributyltetradecylphosphonium tetrafluoroborate paint a measured, cautious picture. Acute toxicity remains low, especially compared to legacy alkyl phosphates or alkyl amines. Standard LD50 values in rodents show minimal risk at practical lab or industrial exposure levels. I take special note of longer-term aquatic toxicity findings, which reveal some bioaccumulation potential due to the chemical’s hydrophobic long-chain nature. Breakdown in soil or wastewater proves slow, though far less persistent than heavily fluorinated compounds. Regulatory authorities press for thorough wastewater treatment prior to environmental release, which echoes my experience in facilities forced to ramp up UV or oxidative treatment steps for ionic liquid disposal. Chronic toxicity in humans has not emerged as a major concern, with the biggest worries centering on possible eye or skin irritation from repeated unprotected handling.

Future Prospects

Tributyltetradecylphosphonium tetrafluoroborate sits ready for broader adoption as industry pivots toward safer, non-volatile chemical technologies. Cost remains a sticking point—I see breakthroughs on the horizon with improved synthetic efficiency and recycling methods. Its high stability and unique solvation potential will support the next generation of sustainable catalysis, energy storage, and advanced separation technology. Research keeps pushing into bio-compatible modifications, aiming for products that leave less environmental residue. From all I’ve tracked, real growth depends on scaling up production while meeting stricter safety and environmental criteria. Collaborative efforts between chemists, engineers, and toxicologists—plus clear communication with end-users—will shape whether this ionic liquid becomes a foundational tool, or stays limited to specialist niches.

Applications in the Real World

Chemicals with long, complicated names often wind up on boring lists, never making headlines. Tributyltetradecylphosphonium tetrafluoroborate falls into that group for most people, but in places where chemistry shapes industrial progress, this one plays a big role. Companies use it as an ionic liquid, a type of salt that stays liquid at room temperature. This ability pulls it onto the radar for those looking at cleaner, more effective ways to get reactions going or separate substances.

Researchers and engineers like it for electrochemistry. Batteries and energy storage need salts that don’t break down, catch fire easily, or mix too well with water. This one brings stability and increases conductivity. Keeping devices safe and running longer matters. For anyone who’s felt a phone battery heat up or run out too soon, making improvements in this area goes straight to daily life. Scientists experiment with different ionic liquids in hopes of finding one that will push clean car batteries or green grid storage further.

Some chemical industries lean on this material for separating out components—think oil refining or fine chemicals production. Traditional solvents in factories often create lots of waste or prove tough to recycle. Here, this phosphonium compound sets a different tone. It doesn’t evaporate much, so workers don’t send clouds of solvents into the air. That means better health and safety records for plant crews as well as less risk for folks living nearby. Chemical recovery gets easier, which matters as regulations grow stricter and companies hunt for ways to keep costs down while marking green checkboxes.

Real-World Impact and Environmental Benefits

Using less toxic, more stable chemicals helps people breathe cleaner air, especially around dense urban areas or places where chemical plants cluster. The U.S. Environmental Protection Agency and groups in Europe keep raising the bar on what plants can release. When a manufacturer swaps in this ionic liquid for something more volatile or flammable, spills and workplace accidents drop. Insurance rates can fall, and companies dodge fines from regulatory slip-ups. Folks like me who have worked in industrial settings know the stress that comes from handling harsh chemicals. Knowing cleaner substitutes exist brings a bit of peace of mind.

Another spot where this chemical steps in is catalysis. Here, it helps speed up chemical reactions while staying steady. Old-style catalysts sometimes wind up as hazardous waste—getting rid of them means special handling and costly disposal. A reusable ionic liquid cuts both waste and expenses.

What Could Boost Its Adoption?

Setting up large-scale systems with new chemicals isn’t simple. People want to know costs won’t balloon, and supply chains stay reliable. Companies making batteries or running chemical plants must see a clear return. Research groups can work to bring production costs down, while collaborations with industry leaders will smooth the path from lab to warehouse floor.

Training workers on safer substances pays off too. Job safety goes up as hazardous exposures drop, but folks on the ground need honest information and equipment suited to new materials. Sharing best practices from early adopters makes a difference.

With good research, transparent practices, and cooperation between industry and regulators, chemicals like tributyltetradecylphosphonium tetrafluoroborate hold more promise than their awkward names suggest.

Knowing What You're Dealing With

Anyone who finds themselves working with specialty chemicals like Tributyltetradecylphosphonium Tetrafluoroborate knows that skipping over safety requirements can invite a mess you really don’t want to clean up. This compound, popular in advanced manufacturing and electrochemical labs, wears several hats—from ionic liquid research to niche catalysis. The complex name hints at a mixture prone to both usefulness and risk. From direct experience, you can’t cut corners with special salts like this one. Getting too casual has a price, whether it’s damaged inventory or a serious health scare.

Exposure Risks Demand Respect

Personal protective equipment isn’t just for the lab coat photo shoot. For something like this phosphonium salt, skin contact or inhalation could produce irritation. Eye splashes can bring on everything from redness to more long-term issues. Gloves made of nitrile provide reliable protection. Regular lab goggles shield your eyes from the odd splash. Ventilated environments (fume hoods included) earn their place, especially during weighing, pouring, or any open transfer. Even veterans in the field keep their gloves and glasses on—old habits save more skin than they waste.

Why Temperature and Moisture Matter

Keeping this salt dry isn’t just best practice. Moist environments might let it absorb water, clump, or, in some cases, react in ways that degrade its quality. Store it in tightly sealed, chemical-resistant containers. Anyone who’s ever found a “cake” of what should have been fine powder knows that humidity sneaks in quickly, especially if the storage area isn’t up to code. Silica gel packs inside storage cabinets work as insurance. Too much warmth spells faster decomposition; room temperature stays safest. Sunny or hot spaces in the lab or warehouse create weird side-reactions, and no one enjoys tracking down the source of a foul smell or failed reaction.

Fire and Chemical Compatibility

Though not known for violent flammability, this compound comes from a family that doesn’t always play well with oxidizing agents. Storage away from sources like nitric or perchloric acid avoids mixing hazards. Forget about open flames or potential sparks. If fire does start, standard dry chemical extinguishers or CO2 models cover your bases better than foam or water, which can react or spread the mess.

Labeling, Inventory, and Responsible Waste

Clear, updated labeling keeps accidents at bay and satisfies auditors checking compliance. Include the exact chemical name and hazard pictograms—no shorthand or outdated stickers. Empty bottles, wipes, and residual waste carry risk. Collect waste separately and schedule proper disposal through certified chemical waste services. Flushing them down the drain, or tossing them in standard trash, just redistributes the risk elsewhere.

A Culture of Accountability

In every chemical workspace, nobody masters it alone. Training, posted procedures, and regular safety reviews help keep people and materials intact. Taking shortcuts with storage or handling means betting against your own luck. The more you care for these details, the fewer stories you end up telling about “that time something went wrong.” Safety and respect for chemicals like Tributyltetradecylphosphonium Tetrafluoroborate aren’t just about compliance—they make sure you show up for work the next day, healthy and ready for the next experiment.

The Chemical Behind the Name

Tributyltetradecylphosphonium tetrafluoroborate doesn't exactly roll off the tongue. It belongs to a family of chemicals known as ionic liquids. Industry often turns to ionic liquids for tasks like catalysis or as solvents in specialized processes. Over the past decade, I’ve worked alongside professionals in chemical engineering and process safety, so any newish compound popping up usually triggers an internal alarm bell—especially when folks ask about hazards.

What the Evidence Shows

No one wants an unexpected hazard at work or in the natural world. The honest truth: public data for tributyltetradecylphosphonium tetrafluoroborate remains thin compared to classics like benzene or lead. MSDS sheets from chemical suppliers help get a feel for the basics. Tributyltetradecylphosphonium compounds don’t have major red flags like being a known cancer agent or acute toxin on the level of cyanide. Still, several properties make them worth a cautious eye.

This chemical comes together from a phosphonium cation and a tetrafluoroborate anion. Some ionic liquids, especially those involving tetrafluoroborate, can release corrosive boron trifluoride gas if you heat them or mix them with strong acids. Strong alkyl phosphonium ions often present skin and eye irritation risks, so contact without gloves usually isn’t wise. Breathing in fine droplets creates risks too. Researchers have reported that some similar phosphonium-based liquids can disrupt cell membranes, meaning accidental splashes in the lab can become more than just a passing sting.

Environmental Stake

One worry with ionic liquids—especially modern ones—is their long-term persistence. Many don’t break down easily in water or soil. Researchers testing other phosphonium-based ionic liquids have seen aquatic toxicity in some species when concentrations build up. Since this particular compound doesn’t break down in the blink of an eye, spills in water or drains start a chain of worry, especially for people living near industrial facilities.

Industry and Lab Practices

In the labs where I’ve handled ionic liquids, especially those with tetrafluoroborate, a decent fume hood always formed part of the routine. Companies typically keep closed handling systems and strong spill management procedures for these liquids. Experience says lab workers who avoid consistent glove use can end up with rashes or irritation even with short exposure. Simple steps like proper containers, labeling, and storage away from acids or bases lower the odds of unexpected reactions or emissions.

Room for Smarter Regulation

Regulatory standards for newer ionic liquids have lagged behind. Major agencies, including the EPA, have flagged the need for better testing of long-lived industrial chemicals. Chemical companies and university labs often end up as the first responders, plugging in protocols before the government catches up. The solution lies in deeper third-party studies, mandatory hazard communication, and regular review of environmental spread. Transparency in supply chains supports community safety. History with chemicals like PFAS and PCBs proved that giving chemicals a "safe until proven otherwise" pass costs lives and dollars down the line.

Awareness and Caution

Anyone working around this compound—engineers, lab workers, environmental consultants—needs to treat tributyltetradecylphosphonium tetrafluoroborate with the same care as other untested modern industrial chemicals. That means personal protective equipment, good ventilation, and a commitment to cleaning up properly after spills. Until researchers supply more robust toxicity and fate data, keeping this chemical on the "better safe than sorry" list makes sense both for people and the environment.

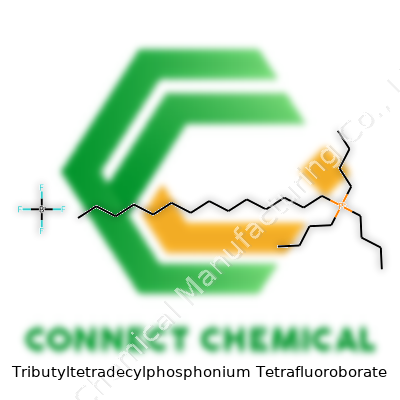

Getting to Know the Structure

Tributyltetradecylphosphonium tetrafluoroborate isn’t the sort of compound most folks run across every day. It stands out among ionic liquids and specialty chemicals. The name itself is quite a mouthful, but it tells a story about the shape and make-up of the molecule. The chemical formula reads as C26H58BF4P. Each part means something specific—three butyl groups and a tetradecyl group attached to a phosphonium center, paired up with a tetrafluoroborate anion (BF4-). This creates a bulky, uneven cation that changes the way it acts and feels in real-world uses.

The structure looks complex at first. Picture a phosphorus atom sitting in the center, tied to three butyl chains—each a simple, four-carbon run with hydrogen branches—along with one longer, fourteen-carbon tetradecyl chain. The phosphorus holds a positive charge once all these pieces link up. On the other side, the tetrafluoroborate (BF4-) balances things out, offering a stable, compact anion with a boron core surrounded by four fluorine atoms. This combination—big, flexible cation and small, sturdy anion—gives the compound a set of properties impossible to find in simpler salts.

Why This Structure Matters

In my years of keeping an eye on chemical trends, I’ve noticed that the arrangement of atoms often decides both safety and usefulness. The long carbon arms dangling from phosphorus in tributyltetradecylphosphonium shrink down its melting point and change its solubility. These big hydrocarbon tails also push the molecule to dissolve in places where water would never work—think oily or plastic-like environments. Because of this, chemists have tapped these ionic liquids for tough jobs: electrochemistry, green solvents, and even certain batteries. Researchers at industrial labs focus on the impact of the long tetradecyl chain, exploring how it spreads out other molecules and stops them from sticking too tightly to each other. This trait keeps the whole solution from turning into a solid block or getting out of hand under high heat.

Phosphonium-based ionic liquids like this one have also pulled interest for their stability. Unlike ammonium cousins, these compounds tend to resist breaking down, even after hours at strong temperatures or under tough test conditions. That’s a trick that owes a lot to the phosphorus core and the protective effect of the carbon chains. Tetrafluoroborate, while not perfect, adds its own bonus by making the ionic liquid a poor conductor of unwanted side effects like corrosion. It gives these materials a helping hand in electronics work, where any bit of unwanted reaction can spell disaster for the circuit.

Spotlighting the Risks and Solutions

Not everything about this compound leans positive. People working in chemical labs can confirm the need for careful handling with ionic liquids. Some, including those with tetrafluoroborate, can form small amounts of toxic by-products if broken down improperly. Reporting in peer-reviewed sources points out that hydrolyzing the BF4- anion risks producing toxic hydrogen fluoride, which brings on a new set of hazards. Facilities must watch for leaks, store these compounds secure, and use proper exhaust systems. Gloves and goggles remain the bare minimum in personal protection. That responsibility extends to disposal as well—special waste containers and protocols prevent accidental mixing and risks to the water supply.

The field rarely stands still. Chemists keep looking for alternatives and tweaks to the anion side of things, swapping out BF4- with safer, yet stable options such as bis(trifluoromethanesulfonyl)imide (NTf2-) in some applications. As more industries step up to stricter safety and environmental rules, the pressure grows for companies to test and retest both the raw product and every way it might break down along the chain. Getting that right makes it easier for new technologies to grow without leaving hazards behind for the next generation.

The Reality Behind a Chemistry Bench

In every lab I’ve stepped into, the whisper of “handle with care” rings out louder when complex organophosphonium salts enter the discussion. Tributyltetradecylphosphonium Tetrafluoroborate isn’t a household name, yet its role in research and industry brings real risks to those who interact with it. Many compounds like this one put more than just glassware in danger. Fingers, eyes, and lungs get exposed. The stories from emergency room visits and near-misses have left an impression. Staying safe isn’t just about following a protocol on paper; it comes down to smart habits, the right gear, and an unspoken agreement that no shortcut ever saved a life.

The Facts About Handling This Compound

This salt brings with it several hazards: skin and eye irritation, respiratory tract issues, and in some cases, adverse effects if inhaled or accidentally swallowed. Even if the word “tetrafluoroborate” doesn’t strike fear, it’s good to know that fluorinated species can release toxic gases if mishandled. The CDC and NIOSH have outlined general steps for chemical safety, but seeing the residue on a glove or the vapor cloud in cold air tells you all you need to know: complacency doesn’t help anyone.

Real-Life Precautions that Make a Difference

In practice, setting up a chemical work area means removing distractions. Phones don’t belong on the lab bench. Every bottle, pipette, and waste container goes in its proper place before work begins. Gloves—nitrile offers strong protection with most ionic liquids like this—cover up to the sleeve, and a pair of goggles stays on for every minute at the hood. Lab coats shouldn’t just hang for show. I’ve seen sleeves soaked by a quick spill, and washing up with soap and running water right after handling the chemical made the difference between red, raw skin and a normal day.

It might sound obvious, but working inside a chemical fume hood protects lungs from stray vapors. Sliding the sash down low keeps a barrier between you and the unexpected. Never taste or sniff anything; after one lesson early in my career—an irritated nose and a lot of embarrassment—I never forgot that rule again. Safety data sheets may seem tedious, but they hold important emergency plans. Knowing where the eyewash and emergency shower stand is part of the mindset that keeps a team safe.

Reducing Harm at Every Step

Label every container as if your worst enemy will be handling it after you. No abbreviations, no shortcuts. It pays off when someone faces an emergency and needs to know what was in that flask. Clean up immediately. No one likes to revisit last week’s spill or wonder if that residue on the bench is harmful. Disposal brings another step of caution: only approved chemical waste containers, well-sealed and away from drains or sinks.

Changing the Culture and Looking After Each Other

In places I’ve worked, mistakes happened least when everyone called out risks, shared stories, and settled for nothing short of best practice. Training sessions had real value when people shared examples, not just slides. If supervisors create an open environment, younger researchers ask more questions, and the group learns together. Companies who invest in higher-grade ventilation, regular safety checks, and easy-access first-aid kits cut down on injury rates.

Safety is personal. The choices you make protect not just your own hands, but the community you work alongside. No shortcut or hurried task is worth a trip to the emergency room or a chemical burn that lingers for months. Handling compounds like Tributyltetradecylphosphonium Tetrafluoroborate means bringing skill, habit, and a team mentality to every day in the lab.