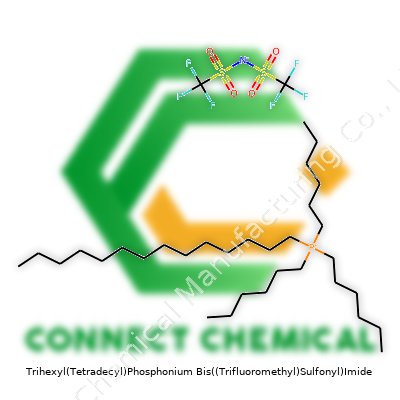

Trihexyl(Tetradecyl)Phosphonium Bis((Trifluoromethyl)Sulfonyl)Imide: More Than Just a Chemical Compound

The Road Here: A Look at Historical Development

Phosphonium-based ionic liquids didn’t pop up out of thin air. Back in the late 20th century, researchers started realizing how the classic chlorinated solvents and volatile organic compounds were hammering both workers and the environment. In this scramble for safer and smarter chemistry, novel ionic liquids started making their way from obscure academic journals into real-world labs. Trihexyl(tetradecyl)phosphonium bis((trifluoromethyl)sulfonyl)imide (often shorthanded as P66614-TFSI) took shape from deep explorations into ionic mobility, temperature stability, and hydrophobicity. The structure owes much to phosphonium innovations out of the UK and Germany. These chemists kept pushing the envelope, figuring out that long-chain phosphonium cations paired with TFSI anions yield a compound without the mess and health risks traditionally associated with volatile organics or heavy metal-based solvents. The journey from niche research to pilot plant runs reflected a larger trend: industries demanded custom-designed molecules that didn’t just get the job done, but did so with fewer headaches and liabilities.

Product Overview: What We’re Dealing With

P66614-TFSI looks pretty unremarkable in a jar—clear or light yellow, almost oily. Yet, this ionic liquid packs features that matter. It doesn’t evaporate easily, keeps its cool under heat, and refuses to catch fire without serious provocation. The long alkyl chains attached to the phosphorus center give it a waxy feel, while the TFSI anion keeps the liquid flowing and stable—even when things heat up. Practical workers notice its almost complete lack of vapor pressure, meaning you’re not breathing it in like volatile solvents. It stands out with an ability to dissolve metals, organic molecules, and even some gasses—a rare trick that opens doors for creative applications in both benchtop chemistry and big industry.

Physical and Chemical Properties That Stand Out

No need for sugarcoating—the big lies of industrial chemistry have always been about volatility, corrosivity, and environmental impact. Here’s where P66614-TFSI breaks traditional molds. The melting point stays far below what most ionic salts manage—sometimes even remaining liquid below freezing. Its thermal stability stretches past 300°C in airless conditions. Water barely touches it. Thanks to its ionic nature, electric conductivity stays moderate, while viscosity tends toward the higher end, often described as “greasy.” You rarely see such wide electrochemical windows, letting engineers use it in high-voltage devices. Chemically, the molecule shrugs off most acids, bases, and oxidants you’ll find on a daily basis. Fragile? Not a chance.

Technical Specifications & Product Labeling

From an experience standpoint, technical data sheets don’t help unless they’re honest. Industrial grades of this material usually declare a purity above 97%, with moisture content measured in parts per million. Labels will state its phosphonium core, C6 and C14 alkyl chains, and the presence of TFSI as the counter-ion. Safety data sheets spell out hazard classes, recommended personal equipment, and first-aid instructions. Color and odor often get noted, but what most people care about in the field is clear guidance on storage—most advice boils down to keeping everything dry, well-sealed, and outside the reach of incompatible chemicals. Barcodes and batch numbers shouldn’t get ignored, since traceability matters if there’s a recall or safety concern down the line.

Preparation Method: A Chemist’s Perspective

Making P66614-TFSI isn’t like baking bread. The synthetic route starts with making the trihexyl(tetradecyl)phosphonium bromide or chloride. This usually happens in a one-pot alkylation, with phosphorus trihalide reacting with long-chain alkyl bromides. Next comes metathesis—a fancy word for swapping partners. Mixing the phosphonium salt with lithium TFSI (sometimes sodium or silver TFSI for higher purity) in a water-organic solvent mix triggers the exchange, with the new ionic liquid separating out. Many labs use filtration and washing to strip out residual salts, followed by drying it all under vacuum. Scale-up means watching for heat, stubborn emulsions, and keeping atmospheric moisture away, as the product loves to pull in stray water from the air. Anyone who’s worked on these syntheses will tell you: patience and attention beat fancy glassware every time.

How This Compound Behaves: Chemical Reactions and Modifications

The backbone of P66614-TFSI doesn’t just sit around. Those long alkyl chains can stand up to weak acids and bases, but break down if attacked with halogens or strong oxidizers. The TFSI anion rarely reacts, but in aggressive environments—think high-temperature metalwork or bright sunlight—it can fragment and kick off fluoride or sulfur-based byproducts. Modifications of the cation push performance in specific directions. Swapping out a few carbons, or adding functional groups like ethers or esters, tweaks solubility, conductivity, and viscosity, sometimes in ways you don’t expect until you test them directly. Anyone who’s modified these molecules in an R&D space learns quickly: subtle structural changes bring surprising results in performance and stability.

Synonyms and Names That Matter

Science loves its jargon. On the factory floor, you might hear this compound go by “Phosphonium IL 66614-TFSI,” “P14,666-TFSI,” or just “phosphonium TFSI.” The IUPAC crowds refer to it as trihexyl(tetradecyl)phosphonium bis(trifluoromethanesulfonyl)imide. Watch out for minor shifts in chain lengths and anion names—they make a difference, both in regulatory filings and when sourcing from international suppliers. Common shorthand helps, but exact names matter if you want the right product every time.

Safety and How to Run Things

Here’s where mistakes hurt. P66614-TFSI may offer lower volatility and toxicity than chlorinated solvents or dialkyl phthalates, but it’s not water. Splashes burn eyes and skin, so gloves and face shields aren’t optional. Spills feel slippery—just ask anyone who’s mopped one up—and create a real risk of falls. Server rooms and labs value its low flammability, yet any synthetic organic chemist knows not to store ionic liquids near oxidizers or open flames. Waste management needs careful oversight. Disposal departments require compliance with local rules—ionic liquids often rank as “special waste,” which means extra paperwork and licensed haulers. There’s also a strong push for clear labeling and ongoing staff training, since complacency grows fast when things look “safer.”

Where You’ll See P66614-TFSI Used

All this fancy talk doesn’t mean much without real applications. P66614-TFSI finds a home in electrochemistry labs working on advanced batteries and capacitors, since its thermal stability and wide electrochemical window trump what classic electrolytes can handle. Industrial extractors leverage it to pull rare earth metals from ore, beating out the old toxic solvent systems. Engineers at biorefineries use it to separate lignin from cellulose without fouling the plant’s plumbing. In the energy sector, fuel cell designers employ it as a functional additive, adding much-needed stability. Even solar panel developers give it serious attention as a charge carrier. Personal observation in R&D settings confirms it saves time on cleanup and cuts down on safety incidents compared to volatile solvents—though it can’t solve every problem, especially price and long-term reliability.

What’s Driving The Research, Where It’s Going

Nobody in the lab wants to waste time on a dead-end molecule, so developments focus on three burning topics: achieving better environmental profile, cutting costs, and pushing performance for next-gen tech. Current studies try to swap out the fluorinated TFSI anion for greener, more biodegradable options—think of phosphates, sulfonates, or even custom-made bio-derived partners. Active researchers look at scaling up production from kilos to tons, since that’s where costs can drop and real-world adoption spikes. A lot of green chemistry programs put P66614-TFSI and cousins under the microscope, trying to check for subtle breakdown products, especially fluorinated byproducts, that might dodge current environmental testing.

Questions About Toxicity

People deserve to know what they’re breathing, touching, and eventually dumping back into the ecosystem. Standard animal models and cell cultures show low acute toxicity compared to legacy solvents. This doesn’t mean you can dump it down the sink or soak your hands in it. Chronic studies, especially those pushing dose and duration, still lack long-term clarity. Some concern exists over the bioaccumulation potential of the TFSI anion in aquatic systems, especially since current municipal treatment plants have trouble breaking down highly fluorinated organics. Europe’s REACH and the EPA lean on conservative side, sometimes flagging these materials until more is known. Open conversations between companies, regulators, and health researchers drive the field towards more transparent test reporting and careful monitoring.

What Does the Future Hold?

It’s not enough to just make a new chemical and call it “safer.” Businesses want better performance, simpler handling, and less paperwork, while regulators ask for greener footprints and solid data. The next big jump comes from chemistry leaders who partner with supply chains, turning benchtop miracles into tools that solve actual manufacturing and energy challenges. Watch for smarter, eco-friendlier anions that help slash both toxicity and costs, scaling up from grams to metric tons without cutting corners on quality. More automation, better data tracking, and sharper focus on recyclability will shape how companies and labs use P66614-TFSI. Facing these challenges means learning from both wins and painful mistakes, then doubling down on what actually delivers value for people, profits, and the planet.

What Stands Out About This Ionic Liquid

Trihexyl(tetradecyl)phosphonium bis((trifluoromethyl)sulfonyl)imide, usually called [P6,6,6,14][NTf2], doesn’t roll off the tongue, but researchers across the globe see it as a staple in their toolbox today. This ionic liquid draws interest mostly because of its unique ability to stay in a liquid state across a huge temperature range. I remember learning about this category of chemicals in grad school and thinking how wild it is to have something look and pour like ordinary oil, but work as a nearly universal solvent.

Electrochemistry Gets a Real Boost

Lithium-ion batteries and supercapacitors have taken over the conversation about energy storage. The choice of electrolyte often holds back how far we can push devices. [P6,6,6,14][NTf2] resists breaking down at high voltages and temperatures, which helps protect phones, cars, and even solar panels from runaway reactions or early failure. Tesla and other EV makers pay special attention to electrolytes with just these properties. Long battery life and charging speed lean heavily on chemical stability, and this is one liquid that delivers.

Chemical Processing Steps Forward

As more companies try to clean up production, they look for alternatives to harsh, volatile solvents. Regular folks might not often think about solvent vapor winding its way into the air in small-scale labs and gigantic plants alike. I’ve stood in spaces where onions burn your eyes just because someone spilled a regular solvent. [P6,6,6,14][NTf2] nearly stops this kind of trouble because it hardly evaporates. Companies use it to capture toxic gases, strip metals from ores, and help reactions run smoothly without unnecessary risks to the people around or the planet.

Catalysis and Green Chemistry

Catalysts work better or worse depending on their chemical neighborhood. This ionic liquid makes it possible for catalysts to work at lower temperatures, which saves money and lowers carbon emissions in big industrial operations. Some chemical processes that used to need high-pressure equipment or dangerous solvents now run with fewer hazards because of [P6,6,6,14][NTf2]. I’ve met industrial chemists who credit these kinds of ionic liquids for slashing work accidents involving fires and chemical burns.

Cleaning Up Wastewater

Heavy metals and other toxic contaminants in water stick to this ionic liquid in a way that water alone can’t pull off. Instead of using old, inefficient ways like activated carbon or sand filters, some modern water treatment plants pump water through solutions containing this ionic liquid to grab lead, mercury, or chromium. In regions wrestling with legacy pollution or rapid growth, these new treatments make cleaner drinking water a real possibility.

Challenges and Looking Ahead

[P6,6,6,14][NTf2] doesn’t promise a fix for everything. Disposal, lingering toxicity, and high price sometimes keep it on the sidelines for large-volume work. Still, the jump in safety, performance, and efficiency means the chemical industry keeps testing it in more roles, from new batteries to eco-friendly ways of mining metals for smartphones and wind turbines. Continued research from teams in the U.S., Europe, and Asia aims to shrink the environmental footprint even further, and someday bring costs down to where even small outfits can take advantage of what this intriguing liquid can do.

Getting Beyond the Basics

People often ask for the chemical structure and formula of a compound expecting a short, neat answer. The truth runs deeper. Each chemical structure tells a unique story, showing the arrangement of atoms and the relationships locking them together. These details affect how a compound reacts, lasts, and even how it interacts with the human body or environment. Take glucose, for example. Most high school chemistry students can repeat C6H12O6 on cue. Flip its structure in the wrong way, though, and you don’t just lose a snack—you risk missing a life-saving diagnosis for diabetes. Structural differences translate, in the real world, to health outcomes, chemical safety, and product performance.

Personal Experience With Chemical Accuracy

During my undergraduate years, my organic chemistry class hit a road bump over lactic acid. Our professor posted two structures on the board—almost identical. Yet, our noses disagreed. The right-handed (D-lactic acid) showed up in sour milk, while the left-handed (L-lactic acid) cropped up in muscles after a long run. This discovery left a permanent mark: As small as these differences seem on paper, life depends on them. Labs, food makers, and drug manufacturers can’t afford to ignore a single atom’s position.

Why Structure Tells More Than Formula

The simple formula lays out how many atoms of carbon, hydrogen, oxygen, and so forth are present. The structure sketches a three-dimensional map. Look at acetaminophen (Tylenol’s main ingredient). The formula—C8H9NO2—tells you the types and counts of atoms. Only the structure explains why it knocks out headaches but doesn’t help you fall asleep. Chemical bonds and atom placement turn this information into real action in our bodies.

Real-World Stakes—Errors in Structure

Pharmacists, chemists, and industry leaders have learned through hard experience that guessing at a structure or copying a formula carelessly is a recipe for disaster. Thalidomide’s history taught us that one “side” of a structure can be therapeutic, while the mirror image can cause birth defects. The wrong structure isn’t just a paperwork error; it can ruin lives.

Driving Change With Better Tools and Practices

To avoid dangerous mistakes, chemists today rely on advanced tools like nuclear magnetic resonance (NMR) and X-ray crystallography. These methods strip away the guesswork and let scientists see molecules as they exist. Databases like PubChem give fast access to peer-reviewed structures, helping pharmacists cross-check what’s safe and effective. In industry, strict documentation and routine audits offer another layer of protection.

Building Trust Through Accurate Reporting

People outside the lab don’t always realize how easily a clerical slip—or an assumption based on a textbook name—can spiral into a full-blown crisis. Verifying chemical structures protects not just businesses, but everyone—patients, consumers, communities. When teaching, I make a point of walking students through common mistakes and their unintended consequences. Chemical literacy doesn’t just stop at the table of elements; it stretches into medicine cabinets, supermarket aisles, and local rivers. Getting the structure and formula right isn’t a technicality. It’s a matter of safety, trust, and, sometimes, life itself.

Recognizing What You're Dealing With

Most folks might imagine ionic liquids as mysterious hi-tech substances, but in labs and industry, they often turn up in green chemistry, batteries, and catalysis because of their non-volatile character. Just because they don't give off obvious fumes like old-school solvents doesn’t make them harmless. Many have low toxicity on paper, but real life can toss surprises. Some can irritate skin or eyes, and others can mess with the environment. Knowing the specific type – say, imidazolium-based or pyrrolidinium-based – helps narrow down the likely hazards.

Why Respecting Safety Protocols Matters

Personal experience tells me a label’s “low toxicity” tag should never build a sense of invincibility. Take the time to put on nitrile gloves and safety goggles every single time before opening a bottle. I’ve watched colleagues reach for flammable solvents without a care, only to trigger a spill when they least expected. Even though many ionic liquids don’t catch fire easily, some do break down under heat and release nasty decomposition products, including hydrofluoric acid and other corrosive gases if the structure has halogens.

Ventilation and Storage Decisions

A quality fume hood keeps the work space clear of invisible vapors. I’ve seen students try quick setups on open benches, assuming liquids lacking scent carry little risk. Humidity, temperature, and air movement change stability fast, so a dry, closed container stored away from direct sunlight serves well. Avoid storing ionic liquids alongside strong acids, oxidizers, or reducing agents. Compatibility issues have triggered avoidable reactions and shelf-life problems in more than one university storeroom.

Attention to Disposal Is Not Optional

Labs and factories must take ionic liquid waste seriously. Most municipal wastewater systems cannot handle them safely. Sending these substances down the drain risks long-term aquatic toxicity and contamination. I’ve sat through enough environmental seminars to know that a moment’s convenience can lead to regulatory headaches for years. Hazardous waste bins marked for “organics” remain the only reliable route. Proper paperwork with exact contents helps avoid confusion later.

Dealing With Spills and Exposure

When something spills, don’t hesitate. Contain the liquid with a spill pad or vermiculite, then collect and dispose following hazardous waste procedures. Keep a wash station or eyewash nearby, just in case. Any skin or eye contact means immediate, thorough rinsing. Medical evaluation comes next if there’s any sign of irritation. Always tell the supervisor or safety officer – honest communication prevents injury patterns down the road.

Ongoing Training Makes a Difference

Even seasoned professionals slip into routine. Regular training on chemical handling and up-to-date safety data sheet (SDS) reviews help catch blind spots. I remember a workshop where we simulated glove failures and learned proper emergency responses. Having written protocols and easy-to-find labels on every container can save time and confusion. Refreshers make everyone in a shared lab or plant less likely to cut corners.

Smart Use Supports Trust in New Materials

Ionic liquids sound futuristic and show lots of promise in reducing flammable solvents and making cleaner processes. That promise depends on who handles them and how. Treat these new tools with the care borrowed from the toughest old chemicals. Good habits and clear respect for risk keep researchers, workers, and the community safer without slowing down innovation.

Respecting Chemical Properties and Real Hazards

This compound carries a long name, and behind it, some real responsibilities. Trihexyl(tetradecyl)phosphonium bis((trifluoromethyl)sulfonyl)imide is an ionic liquid often used in the lab for its thermal stability and ability to dissolve a range of materials. It’s not the type of thing you’ll find next to household goods, and that’s for good reason: it brings high performance but demands organized, careful handling.

I’ve worked with all sorts of chemicals, from benign buffers to aggressive acids, and there’s a basic rule that applies across the board: never cut corners with unfamiliar compounds. Phosphonium salts can pose specific risks. This particular one doesn’t catch fire as easily as volatile solvents, but you can't ignore the potential health effects from skin contact or inhalation. A spill on a bench might not make a sound, but over months, exposure can tangle with long-term health. Every safety datasheet I’ve seen for phosphonium ionic liquids puts skin and respiratory warnings front and center. Take these messages seriously and use gloves, lab coats, goggles, and—if there’s any chance of mist or aerosol—a chemical fume hood.

The Right Home: Container, Label, and Location

Keep this liquid in a sturdy, airtight glass or select plastic container that keeps moisture out. Not every container works with aggressive chemicals; I’ve seen cheap lids crack or leak, especially with repeated use. Large labs and chemical suppliers provide products in high-density polyethylene or amber glass for good reason, since some plastics near their limit with solvents like this.

Labels spare everyone hidden risks—no guesses, no mystery fluids. Mark the date, compound name, and any warnings. I always throw a bold hazard sign on high-risk chemicals, since things get hectic in busy workspaces. After all, a tired lab mate could grab the wrong bottle late at night.

Finding the Right Spot

Heat breaks down even robust ionic liquids over time. Store at room temperature, out of direct sunlight, and far from radiators, furnaces, or hot shelves. Sunlight and strong UV can also trigger slow decomposition. Put it away from acids, bases, oxidizers, or anything that could cause a fire or toxic fumes in a spill. No one sets out to make a mess, but storage next to aggressive reactants multiplies the risk when they do happen.

Accountability: Routine Checks and Procedures

Locks and inventory logs sound excessive unless you’ve experienced a surprise audit. A routine check on chemical stocks has saved me more than once—once, I caught a leaking lid before a slow drip turned into a sticky hazard under a cabinet. List this compound on your log with amount, date opened, and who last used it. Small steps like this take minutes but prevent the big problems that cost labs thousands and endanger people.

Chemical Safety Culture Isn’t Extra; It’s Essential

Every chemical has quirks, but I’ve never regretted building habits around safe storage. You might spend extra time up front, but the cost of an accident or a lost supply runs higher. Trihexyl(tetradecyl)phosphonium bis((trifluoromethyl)sulfonyl)imide belongs behind solid doors, trusted labels, and like all specialty chemicals, in an atmosphere of respect. Find a safe, protected place, keep a sharp eye on containers, and you’ll keep yourself, your team, and your results out of unnecessary trouble.

Understanding the Physical Qualities

Everyday life depends a lot on the physical makeup of products—whether someone’s pouring salt on fries or mixing cement at a construction site. Appearance may give the first clues: Is it a fine powder, crystal, or sticky goo? This connects with how the product behaves during storage and real use. For example, a fine white powder often signals easy mixing, but can also mean dust lingering in the air, which anyone working in a bakery or workshop knows isn’t fun to breathe in.

Density makes a difference, too. Lighter powders float up and spread fast, while heavier ones settle quick. I’ve worked with both, and the wrong guess messes up measurements. Those numbers, like bulk density or moisture pick-up, let workers predict how a product flows or stores. If it clumps in the bag, folks might waste money or ruin a batch—think flour in humid weather. Granule size can sneak in problems during manufacturing. If particles range too widely, you see frustrating jams and uneven mixing.

Physical stability means a lot. Some powders cake together over time; others drift apart if shaken. You learn fast—after enough messes on production lines—that storage needs a dry, steady spot. For this reason, producers rely on solid data from humidity and temperature tests, which guide warehouses and packaging choices.

Going Beyond Looks: The Chemical Side

Chemical properties steer how a product reacts, blends, and even how safe it feels. Working behind-the-scenes in food science, I’ve watched folks scramble when a supposedly harmless additive unexpectedly fizzed up, because nobody checked reactivity. Products break down, catch fire, or form gases if stored wrong. pH is a good example. Acidic or basic powders change taste or corrode equipment. Neutral pH brings peace of mind in kitchens and labs.

Solubility matters. Some materials dissolve instantly in water or oil, others don’t budge. Picture instant coffee versus chunky spices: speed and completeness shift taste and texture. Flammability touches safety. Powders like flour or sugar—usually seen as harmless—can explode in the air under the right conditions. Over years, that led to new rules in bakeries and grain silos, like installing better ventilation or spill controls.

Chemical compatibility also gets important during blending. Two products looking almost the same can behave differently. Mix the wrong ones and watch a reaction heat up or gel out of control. Experience tells you—never trust looks alone, always check the label and safety sheets.

Supporting Safe and Smart Use

Testing before wide use prevents surprises. Reliable suppliers share certificates showing test results for appearance, particle profile, and chemical make-up. Responsible users still run quick checks on new shipments. A faint smell can signal breakdown, off-color hints at impurity.

Regulatory bodies, especially in food and pharma, press companies for proof before hitting shelves. Both regular folks and professionals rely on accurate property data to avoid health risks, equipment failures, or ruined products. Hazards aren’t always obvious, so clear reports build trust and keep operations running.

The main lesson: don’t cut corners on understanding what’s in the bag. For anyone responsible for quality or safety, getting a handle on these details isn’t just paperwork—it’s smart, practical, and sometimes lifesaving.