Triisobutylmethylphosphonium Tosylate: A Candid Look Through History and Modern Use

Historical Development

Chemists started turning toward phosphonium salts in the mid-1900s, right when industry and research labs were hungry for alternatives to older phase transfer catalysts. Phosphonium chemistry found its feet faster once people got wise to the impact of bulky substituents, and researchers started tinkering with trialkyl, tetraalkyl, and aryl variations. Triisobutylmethylphosphonium tosylate rose up as one of the heavy hitters around the late 1990s, especially in the field of ionic liquids—a trend driven by the search for greener solvents and more efficient reaction platforms. After some early skepticism, recognition grew in both academia and industry circles, mostly for its ability to shrug off hydrolysis and flaunt a low melting point.

Product Overview

Triisobutylmethylphosphonium tosylate comes across as a highly functional ionic liquid. The phosphonium center teams up with methyl and isobutyl groups, pairing with a tosylate anion to produce a salt suited for solvent extraction, catalysis, and electrochemical devices. Packing these bulky isobutyl groups onto the phosphorus not only lowers the melting point but beefs up resistance to decomposition as well. Product labels usually spotlight attributes like high purity (upwards of 99%), thermal stability, and low water content, giving chemists a solid sense of what they can depend on when they bring a bottle to the bench.

Physical & Chemical Properties

Crystals of this compound can present as off-white or pale yellow, and you’ll notice an almost greasy consistency at room temperature—typical of many room temperature ionic liquids. Its melting point usually falls below 60°C, making it easy to handle as a liquid or solid. Density and solubility information points up its dual nature: it mixes well with polar organic solvents like acetonitrile and alcohols, but shrugs off most nonpolar hydrocarbons. Chemical resistance makes it a tough contender for phase separation and reaction media where traditional solvents break down too fast, especially in basic conditions or with strong nucleophiles.

Technical Specifications & Labeling

Bottles carry identification numbers and batch data, since regulatory guidelines now demand traceability for specialty chemicals. You’ll see details on moisture content, as water sensitivity matters in many target reactions. Containers earn special markings around incompatibilities—no mixing with strong oxidizers, acids, or strong alkali, and strict storage in opaque, airtight vessels set apart from direct sunlight. Specs sheets delivered by manufacturers mark a minimum purity not just as marketing, but for compliance and to allow for fair comparisons across suppliers. For some countries, GHS-compliant pictograms and clear hazard statements stand out front and center on both drums and vial labels.

Preparation Method

A straightforward route to triisobutylmethylphosphonium tosylate often starts from triisobutylphosphine and methylating agents, forming the phosphonium backbone. The methylated intermediate then reacts with p-toluenesulfonic acid, often in a two-phase or solvent-driven system. You can tweak solvent systems—sometimes using dichloromethane or acetonitrile—to favor efficient migration of methyl groups, then finish with purification under reduced pressure or by recrystallization. By optimizing temperature and order of addition, a well-designed process reduces side reactions and limits the presence of unwanted phosphorus-based byproducts.

Chemical Reactions & Modifications

Triisobutylmethylphosphonium tosylate steps in as both a partner and a catalyst across organic syntheses. In nucleophilic substitution or alkylation protocols, it can shuttle anions or even act as a template in phase transfer catalysis. Its sheer bulk and lipophilicity let it stabilize some transition states, broadening reaction windows. For labs chasing better selectivity or higher yields, it forms a solid alternative to more toxic quaternary ammonium salts. On the modification front, chemists sometimes swap out the tosylate for other anions—turning to F-, Cl-, or BF4-—to tune solubility, viscosity, and reactivity for specialized electrochemical set-ups or synthetic challenges. That flexibility doesn’t just stay in research labs, either; specialty chemical makers pivot product lines in response to demand for custom ionic liquids, tailoring performance toward everything from enzyme catalysis to membrane technology.

Synonyms & Product Names

Chemists referring to this compound might use shorthand like TIBMPT or triisobutyl(methyl)phosphonium tosylate, but other catalogues call it with slight twists—triisobutylmethylphosphonium p-toluenesulfonate, for example. Catalog numbers differ across platforms like Sigma-Aldrich or TCI, which means anyone buying for a lab or production facility needs to double check documentation before ordering. Less common aliases include triisobutylmethylphosphonium-4-methylbenzenesulfonate, a mouthful but worth knowing in case older papers mention it.

Safety & Operational Standards

Handling requirements for this phosphonium salt fall into the rigorous end of standard laboratory practice. Direct skin or eye contact results in irritation, and inhalation shouldn’t be allowed. Labs prepping or manipulating more than small-scale amounts must rely on local exhaust ventilation, nitrile gloves tested for permeation, and chemical splash goggles. Spills call for immediate absorption with inert material, followed by solid waste disposal under hazardous chemical guidelines—no dumping down the drain. Emergency showers and eyewash stations stay within easy reach, something every lab tech should insist upon. In my own experience, backing up engineering controls with solid chemical hygiene keeps accidents rare, especially when bringing new personnel up to speed. As an ionic liquid, these salts resist flammability, but thermal decomposition brings its own risks—releasing noxious phosphorus oxides or sulfonic acid fumes.

Application Area

Industry sees triisobutylmethylphosphonium tosylate as a power player in extraction, recycling, and catalysis. Rare-earth and precious metal extraction benefit from the salt’s selective solvation and ion-exchange abilities, giving recovery operations an edge where water-based approaches struggle. In pharma and fine chemical synthesis, the salt acts as a robust phase transfer catalyst, opening up reaction channels that remain blocked by conventional solvents. Electrochemical devices, including capacitors and some batteries, lean on ionic liquids for low volatility and better ionic conductivity. During my stint setting up a heterogeneous catalysis line, I watched phosphonium salts help stabilize sensitive intermediates, letting us operate without constant supervision or endless nitrogen purges.

Research & Development

Research teams keep pushing to stretch the possibilities with more stable, less toxic, and tunable ionic liquids, and triisobutylmethylphosphonium tosylate fits that strategy. Current studies tackle its role in enzymatic reactions, seeking mild, homogenous platforms to raise yields in green chemistry. Material science labs dig into its electrochemical window and dielectric constants, targeting fuel cell membranes and high-voltage applications. Drug discovery efforts watch for biocompatibility and solubilization performance in pharmaceutical protocols. Graduate students and experienced chemists both see the value in mastering a phosphonium salt that serves as a benchmark for innovation in the broader ionic liquid ecosystem.

Toxicity Research

Like most phosphonium ionic liquids, this compound draws scrutiny for any long-term toxicity. Acute toxicity tests point toward moderate effects, though considerably below traditional quaternary ammonium salts. Aquatic life reacts more strongly, which raises red flags for environmental chemists. European regulators lean into quarterly reviews, feeding data into REACH dossiers to make sure the rules keep pace with new knowledge. Research on metabolic breakdown and bioaccumulation continues. From first-hand work with these chemicals, it’s clear no one can take a shortcut on disposal or risk assessment—good partnerships between chemical suppliers and users help reinforce real environmental responsibility.

Future Prospects

The future for triisobutylmethylphosphonium tosylate hinges on the march toward green chemistry and smarter process engineering. Startups and industry giants both test new blends tailored for battery technology, waste treatment, and enzymatic conversions. Computational chemists draw up predictions for new derivatives, trying to crack performance ceilings in everything from carbon capture to custom catalysis. As regulations tighten, companies double down on worker training and equipment upgrades to meet higher safety standards—a direct payoff in operational reliability and public trust. Time and experience keep showing that, for those ready to put in the diligence, this class of ionic liquids keeps opening new doors.

Digging Into Triisobutylmethylphosphonium Tosylate

Triisobutylmethylphosphonium tosylate doesn’t trip off the tongue, but this salt matters for folks who spend their days deep in research labs and on the production floors of the chemical industry. It sits at a crossroads where old-fashioned solvents fall short and greener, more innovative chemistry steps in. I’ve worked shoulder-to-shoulder with chemists slogging through the muck of trial and error with all kinds of ionic liquids; this one stands out for its versatility and reliability.

The Role in Green Chemistry

Plenty of solvents in use today give headaches, literally and figuratively. They vaporize, plug up air with unwanted fumes, and make both the workspace and planet a little rougher around the edges. Triisobutylmethylphosphonium tosylate helps fix this. As an ionic liquid, it barely evaporates, so it doesn’t stink up a room or float away into the atmosphere. Colleagues at university labs have highlighted its low volatility as a big deal for anyone pushed by tightening safety rules. Using this salt, a chemist reduces exposure risks and drags environmental footprints down.

Opening Doors in Catalysis

What grabbed my interest is how easily this compound unlocks new options in catalysis. A friend of mine in pharmaceuticals once described the hurdle of getting traditional catalysts to behave themselves in tricky reactions. Triisobutylmethylphosphonium tosylate changes the game: it can dissolve polar and non-polar materials, which lets chemists coax stubborn reactions forward. It creates a space where selectivity and speed thrive. Reactions that used to sputter along start making the desired product with fewer leftovers. That level of control saves companies real money and keeps chemical waste in check.

Polymer Science and Advanced Materials

This salt carves out a spot in polymerization, another scientific grind where minor improvements count for a lot. I knew a startup that tried switching away from classic organic solvents for making specialty plastics. They found this compound gives polymers greater uniformity and flexibility. By fine-tuning reaction conditions, folks can create materials with tailored toughness or stretchiness—traits that push new uses in the auto or medical fields. Better polymers can mean lighter car parts or improved medical devices, which brings benefits outside just the lab.

Bumps in the Road

Bringing any new material into everyday production takes effort, and cost matters to everyone from small companies to big corporations. Triisobutylmethylphosphonium tosylate commands a higher price than old-school solvents. Labs with tighter budgets feel this more. Some experts argue that as demand climbs and manufacturing matures, prices will drop. If buyers see concrete safety and waste handling benefits, they’ll justify the up-front expense.

Pushing Toward Practical Solutions

The wider adoption of safer ionic liquids demands collaboration. Firms benefit from swapping experiences—what works, what doesn’t—so others avoid dead ends and wasted funds. Universities can offer resources to explore deeper. Regulators who once blocked new chemicals now open the door for those with proven safety records and lower emissions. More data means more trust and faster moves from bench top to full-scale plant.

My experience says momentum grows where teams bridge the gap between science and the people affected by new technologies. Triisobutylmethylphosphonium tosylate works as one link in the bigger chain toward cleaner, safer chemistry. With more hands and open minds, it could help rewrite what green manufacturing looks like in practice.

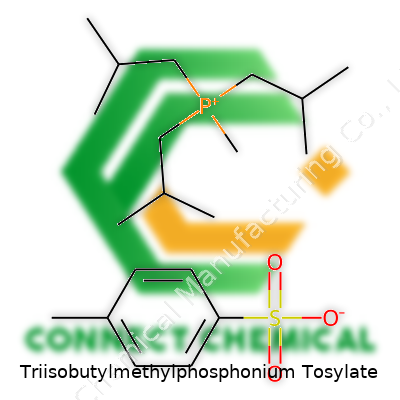

Getting a Grip on Its Structure

Triisobutylmethylphosphonium tosylate isn’t a name that rolls off the tongue, but the chemistry under that name is plenty interesting. At the core sits a phosphonium cation, carrying a methyl group along with three isobutyl arms. The tosylate anion, with its aromatic ring and sulfonate group, brings a different flavor—literally influencing how the compound handles solvents, surfaces, and reactions.

Solid or Liquid? Physical State, Color, and Texture Matter

If the substance lands on your bench, expect it to show up as a crystal or sometimes as a viscous liquid, depending on how dry it is. White to off-white describes the solid form, thanks to its organic origins and lack of transition metals. Its relatively high density feels familiar to those who work with ionic liquids. Sometimes it has a faint odor, usually from the tosylate’s aromatic ring or any trace impurities left after synthesis.

Melting Point and Thermal Stability

Triisobutylmethylphosphonium tosylate boasts a melting point typically in the range of 80 to 120°C. This midpoint between common organic solids and classic inorganic salts comes from phosphonium salts’ big, bulky structure. The compound’s heat resistance lets it work in settings where lower-melting ionic liquids wouldn’t last. Decomposition usually starts above 200°C, breaking down into smaller organic fragments and releasing gases. This means careful attention to temperature helps avoid releasing anything you didn’t bargain for.

Solubility and Handling in the Lab

Most phosphonium ionic liquids love polar solvents. Triisobutylmethylphosphonium tosylate dissolves easily in water and alcohol but doesn’t play well with pure hydrocarbons. The polar tosylate anion helps the salt mix into water-based solutions, but the chunky, hydrophobic isobutyl groups slow things down a bit—don’t expect instant dissolution. As someone who’s handled these salts, it’s easy to underestimate how quickly a little moisture in the air can clump up your crystals.

Chemical Behavior and Stability

What stands out with this compound lies in its chemical stability. Most salts with big, organic cations resist breakdown. This trait makes them attractive for applications like green chemistry—helping reactions along without polluting the mix with unwanted fragments. The aromatic sulfonate anion doesn’t react easily, so the salt keeps its form even when basic or acidic solutions enter the mix.

Reactivity and Uses

This salt finds its place in the field of ionic liquids, supporting reactions where high temperatures or unusual solvent conditions discourage traditional salts. The hydrophobic arms on the cation give it unique solvent properties—sometimes separating out organic or metal-rich phases during synthesis. Electrochemists value the chemical window, often reaching up to 4 volts or more without causing decomposition, which brings advances in batteries and advanced materials.

Safety and Environmental Notes

Most users don’t worry much about acute toxicity, though handling with gloves and goggles stays standard. That said, the breakdown products can irritate eyes or skin and may need careful waste management. The stability and low volatility keep workplace air cleaner than volatile organic solvents do, supporting safer working conditions. As research pushes for greener labs and more sustainable processes, salts like this step forward.

Looking Beyond the Label

Triisobutylmethylphosphonium Tosylate sounds complicated, and the reality matches the name. Anyone who’s dealt with modern lab work or chemical processing knows storage and handling aren’t only about following a manufacturer’s checklist. Experience in the lab taught me that assumptions lead to hazards, especially with exotic salts like this one. Too many accidents start with a simple “It should be fine on that shelf.” One heated summer, improper storage of a different ionic liquid led to container swelling and a nasty mess before noon. So the lessons carry forward.

Respect the Physical Properties

This salt shows up as a white powder, not a drama queen, but don’t let the looks fool you. It absorbs water from the air. Think of it like the rice in your salt shaker, just much less forgiving. Any contact with moisture can mean clumping or degradation. Keeping it sealed in an airtight container matters. Most of us have worked with someone who just loosely caps the bottle—don't be that person. Get into the habit of checking desiccators, using them regularly, and refreshing the desiccant packets. Lab experience makes you appreciate the value of a well-maintained dry box.

Heat: Friend or Foe?

Even if the datasheet says this compound holds up at room temperature, don’t rely on a storage room that blasts past 30°C in July. Stability drops as temperature rises, and repeated cycles of heat and cool can turn powders into sticky masses or mess with purity. Air-conditioned, stable, controlled environments win every time. I’ve seen more than one expensive bottle spoil because someone left it near equipment that ran warm all day. That simple act of choosing a shaded, cool shelf can save a lot of money and rework.

Hands, Eyes, and Skin Come First

Like most phosphonium compounds, Triisobutylmethylphosphonium Tosylate won’t bite immediately, but splashes or dust on your hands or face can sneak up. Gloves matter—nitrile works well for most jobs here. Wash your hands after use, no exceptions. Never trust a clean-looking bottle. Safety glasses stay on because powders drift, especially when measuring in a busy lab or production floor. That quick dash without goggles invites trouble. Skin irritation and accidental eye exposure feel far more personal when you’re the one running to the eyewash station. If anyone’s ever spilled a powder in the hood, you remember how long it lingers in the air. Good ventilation and working in a fume hood keep the air much safer.

Don’t Rely on Memory

Unlabeled containers, forgotten in a drawer, make things dangerous. Date every bottle, record every transfer in a log, and keep a clear inventory. Larger scale storage asks for clear hazard signs and spill kits nearby. Even small spills want immediate cleaning with disposable towels and a keen eye for residue. No one likes tracking white streaks across the lab floor. Disposal regulations for this salt vary, but always involve a designated chemical waste stream—never down the drain or into the trash.

Bringing It Home: Practice Over Policy

Regular staff briefings, spot checks, and trust but verify—those make a difference. People remember stories of mishaps more than safety posters, so share real lessons from real experiences. Every incident, big or small, sharpens the system for the next day. Storage and handling aren’t a chore—they’re self-preservation in slow motion.

Looking Beyond the Chemical Name

Triisobutylmethylphosphonium tosylate won’t ring a bell for most folks outside science circles. It pops up in chemistry labs for synthesis, often used for its specific ionic properties. Just saying the name makes the chemical sound intimidating. Still, everyday safety depends not on syllables but on real risks.

Digging Up Data and Facts

Questions about toxicity and hazards lead most people to search for clear answers. Reliable sources like the European Chemicals Agency (ECHA) and peer-reviewed studies shape those answers best. ECHA classifies triisobutylmethylphosphonium tosylate as irritating to eyes and skin. It hasn’t popped up with evidence of cancer-causing, mutagenic, or reproductive hazards. Despite this, not all gaps in knowledge mean a substance is harmless—many ionic liquids lack decades of widespread use or comprehensive testing.

Studies have found that phosphonium-based ionic liquids can stick around in the environment and show variable toxicity for aquatic life. For example, research by the American Chemical Society points at low to moderate toxicity for some aquatic organisms. That sends a clear message: improper disposal can carry consequences beyond the laboratory.

The Human Touch: Everyday Lab Work

I’ve worked with chemicals that seemed blameless on paper till someone spilled a flask and ended up with skin rash despite gloves. Material Safety Data Sheets (MSDS) recommend using protective gear with substances like triisobutylmethylphosphonium tosylate. Anyone handling it should keep goggles and gloves handy and work with decent ventilation.

One tricky thing about many newer chemicals involves a simple reality: science hasn’t had enough time to watch for delayed effects on health. Solvents and additives that once appeared mild later turned up in toxicology journals. Until more robust, long-term testing comes in, treating triisobutylmethylphosphonium tosylate with healthy respect makes sense.

Reducing Risks and Waste

Sometimes companies focus on cost savings and efficiency, skipping past the nitty-gritty of disposal guidelines. My experience tells me the real world rarely matches the neat lab protocols found in binders. Safe disposal often gets ignored, especially in places where regulatory oversight lags behind. Pouring chemicals down the drain, especially those with unclear toxicity, can add up to long-term problems in municipal water or natural streams.

Strong protocols for handling and discarding chemicals keep labs safe and neighborhoods healthier. Easy access to up-to-date safety training and making MSDS sheets a standard part of equipment, not clutter on a shelf, help in practice. Community right-to-know laws have pushed companies to communicate what’s in use—not just what looks safe this year, but what may matter decades from now.

Room for Improvement

Everyone involved in research, manufacturing, or waste handling can do better by pushing for more transparent, independent studies on substances like triisobutylmethylphosphonium tosylate. Regulators, too, can tighten up data collection, so emerging chemicals aren’t mystery ingredients in the environment. Open dialogue between scientists and the public builds trust and often brings out creative solutions to cut down risks.

Why It Matters

The lesson of the last century has shown all sorts of chemicals can surprise us—sometimes for the better, other times in ways we wish they hadn’t. It’s always smarter to err on the side of caution, especially with a substance whose long-term story remains unfinished.

Shedding Light on Structure and Identification

Triisobutylmethylphosphonium tosylate presents itself on the chemical stage as a notable ionic liquid. Its molecular formula comes together as C16H39P.C7H8O3S. This formula tells a precise story—one part is a positively charged triisobutylmethylphosphonium ion, the other a tosylate anion. The unique identifier for this compound in chemical registries, known as the CAS number, is 551345-41-8.

Why the Details Matter

Anyone who's worked hands-on in a chemistry lab knows a string of numbers and letters does more than fill a space in a database. The molecular formula reveals exactly what’s in the bottle—no guessing if you’re handling this ionic liquid or a close cousin. Even small molecular differences can bring about big changes in stability, reactivity, or toxicity. In academic and industrial circles, errors in identification can snowball into wasted time, money, and sometimes dangerous outcomes. I’ve seen researchers waste weeks tracking contamination down to a simple mix-up over a publisher’s typo.

CAS numbers matter just as much. Think of them as a global phone number for chemicals—universally recognized, with no risk of confusion if you communicate across languages, companies, or continents. As new compounds keep flooding the landscape, getting the right compound every time makes routine ordering, regulatory filings, SDS document searches, and even scholarly literature reviews a lot less nerve-wracking.

Roles and Risks in Real-World Chemistry

Ionic liquids like triisobutylmethylphosphonium tosylate turn up far more often now in green chemistry, battery research, and separations. Their low vapor pressure, thermal stability, and tunability sound good on paper and translate to practical value in labs. For a while, my own work with catalysis focused on solvent selection. Messing up the specific cation-anion combo turned promising reactions into messy failures. Fine details—like swapping one phosphonium alkyl group—tipped the balance between success and stinky, failed runs.

Accurate identification feeds into equipment compatibility, safety measures, and the end goals of research. Some ionic liquids corrode common plastics; others react with stainless steel. Every part of their molecular makeup affects not just utility but handling. Lab safety officers scrutinize formulas and CAS numbers, aiming to match every bottle with the right protocols.

Thinking Ahead: Solutions for Safer and Smarter Chemistry

Many issues around chemical misidentification come down to rushed communication or outdated supply databases. Digital inventory management cuts most risks—scanning barcodes linked to CAS numbers prevents old habits like scribbling ambiguous abbreviations on flasks. Chemical vendors have started sharing certificate documentation with every shipment, confirming both formula and registry number.

Learning the value of clearly-jotted records—full names, molecular formulas, and CAS numbers—pays dividends. For those mentoring undergraduate or new lab techs, setting the expectation that every bottle’s label matches its paperwork builds good habits that matter much more as the stakes rise.

In the world of chemistry, details are far more than trivia. The right formula and CAS number—C16H39P.C7H8O3S and 551345-41-8—act as anchors. They keep researchers focused, safe, and equipped to turn today’s experiments into tomorrow’s solutions.